Loading and unloading control method for broaching machine

A control method and cutting technology, which are applied to accessories of broaching machine, broaching machine, manufacturing tools, etc., can solve the problems of danger to adults, high labor intensity of operators, lifting of workpieces, etc. The effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The orientation words "up", "down" and "top" used in the embodiment of the present invention refer to the orientation of the broaching machine in normal use. "Front" refers to the direction in which the broaching machine faces the operator.

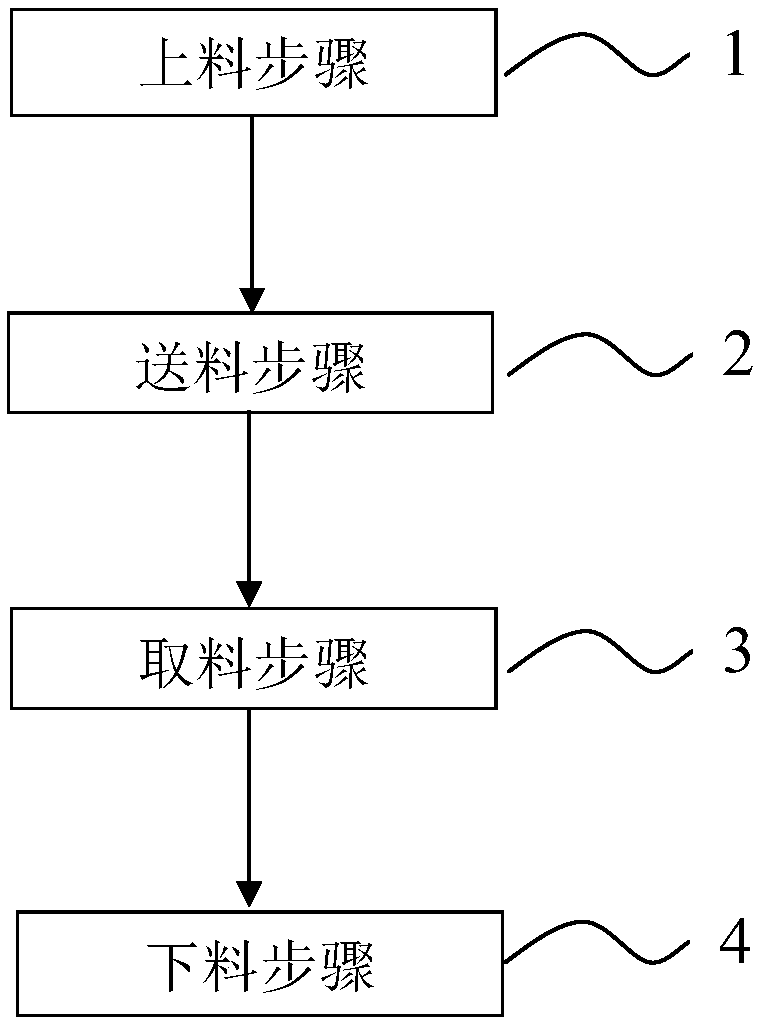

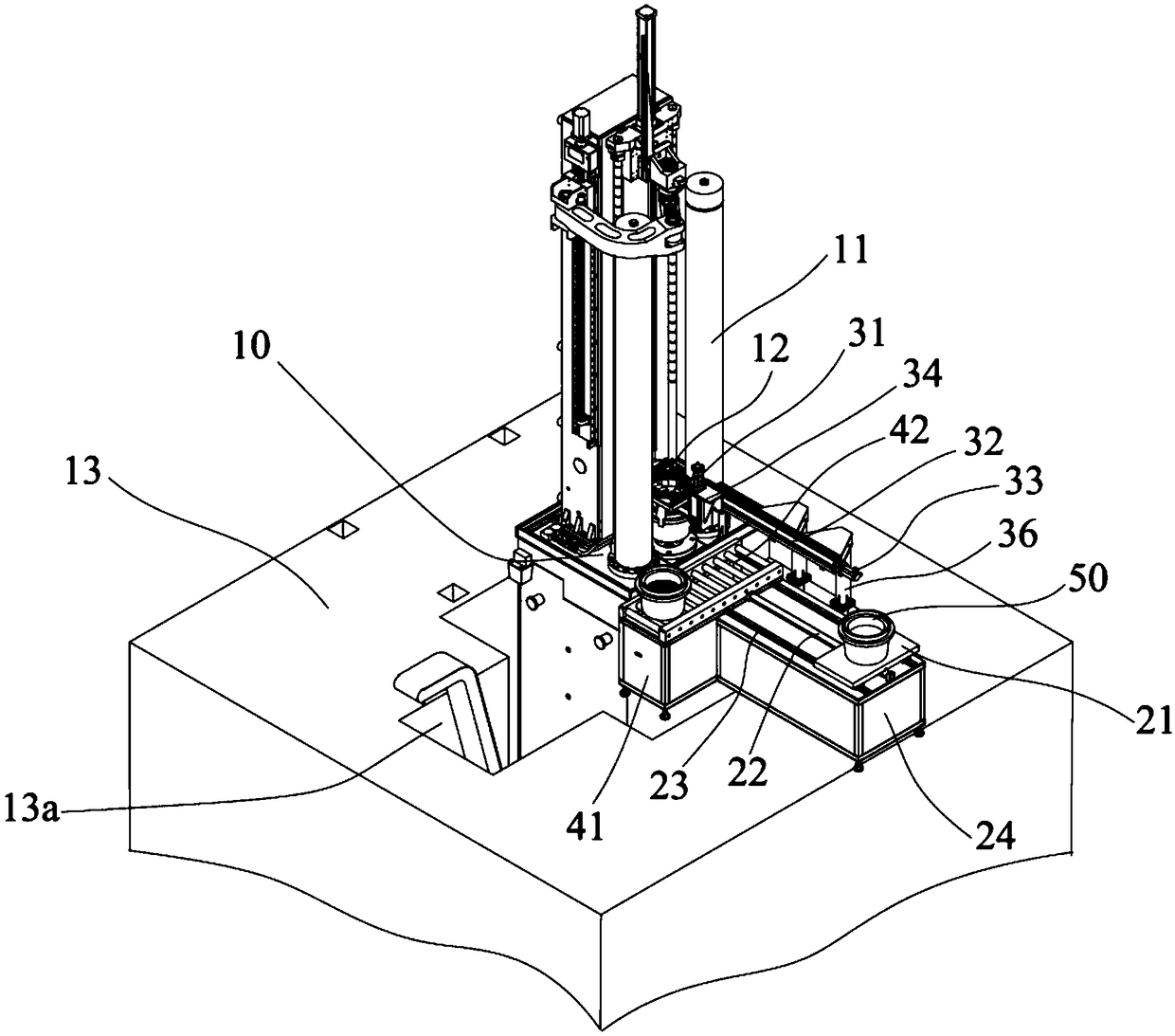

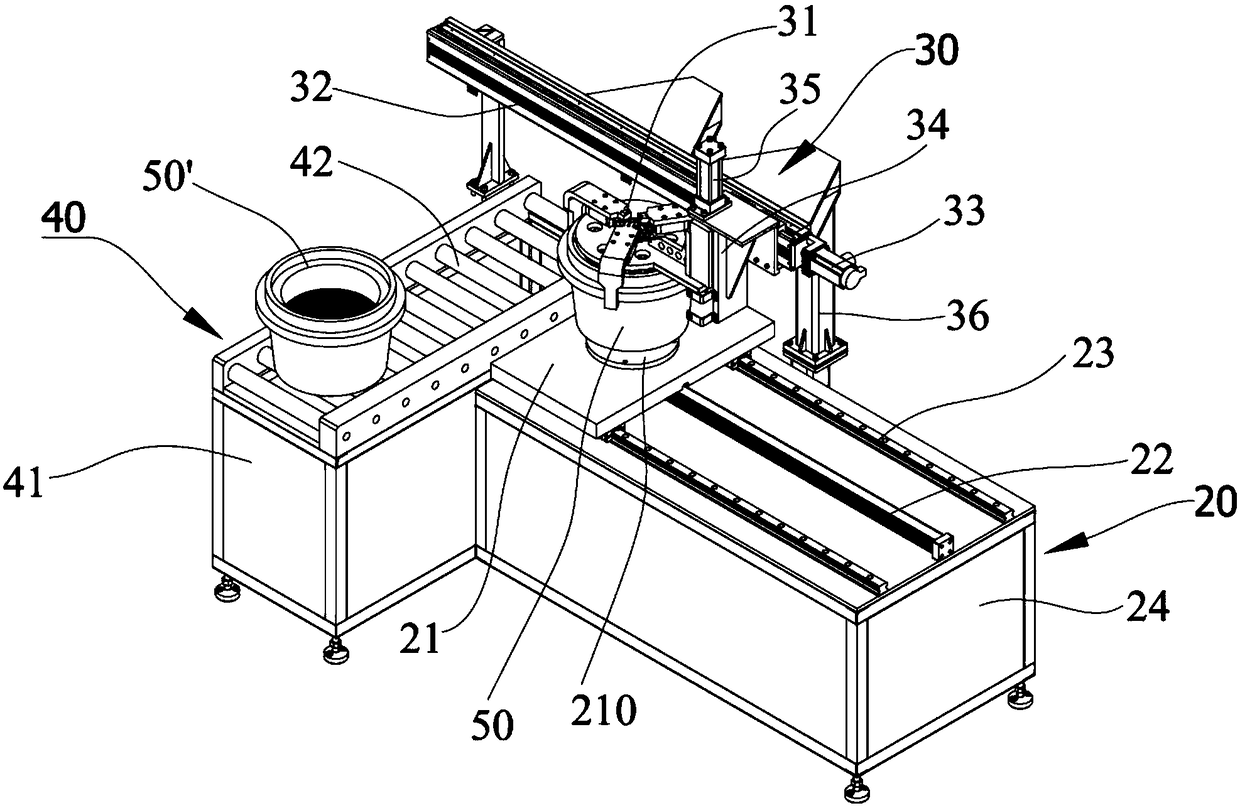

[0028] see figure 1 , is a schematic flow chart of the method for controlling loading and unloading of the broaching machine according to the embodiment of the present invention, referring to Figure 2-Figure 3 , for applying the broaching machine and the loading and unloading device of the loading and unloading control method of the embodiment of the present invention, the broaching machine includes a workbench 10, a broach (not shown), a main oil cylinder 11 and a loading and unloading device, and the workpiece 50 to be processed is placed on the workbench The machining position of 10 is broached by a broach. The loading and unloading device includes a loading mechanism 20, a claw mechanism 30 and a blanking mechanism 40. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com