Machining apparatus for long tube lengths and related methods

a technology of machining apparatus and long tube, which is applied in the direction of broaching machine, broaching accessories, manufacturing tools, etc., can solve the problems of inability to accurately cut the work piece, limited current broaching tools, and limited in the length of work piece they can broach,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In one aspect, embodiments disclosed herein relate to a machining apparatus for long tube lengths and related methods of operation. The machining apparatus is capable of controlling radial and lateral forces (i.e., reaction forces) generated during the machining operation, which allows the machining apparatus to maintain a high level of precision when machining longer tube lengths. Because of the controllability of the reaction forces, any length of tube may be machined using a machining apparatus in accordance with embodiments disclosed herein to machine any type of unique profile on an inner wall of a tube.

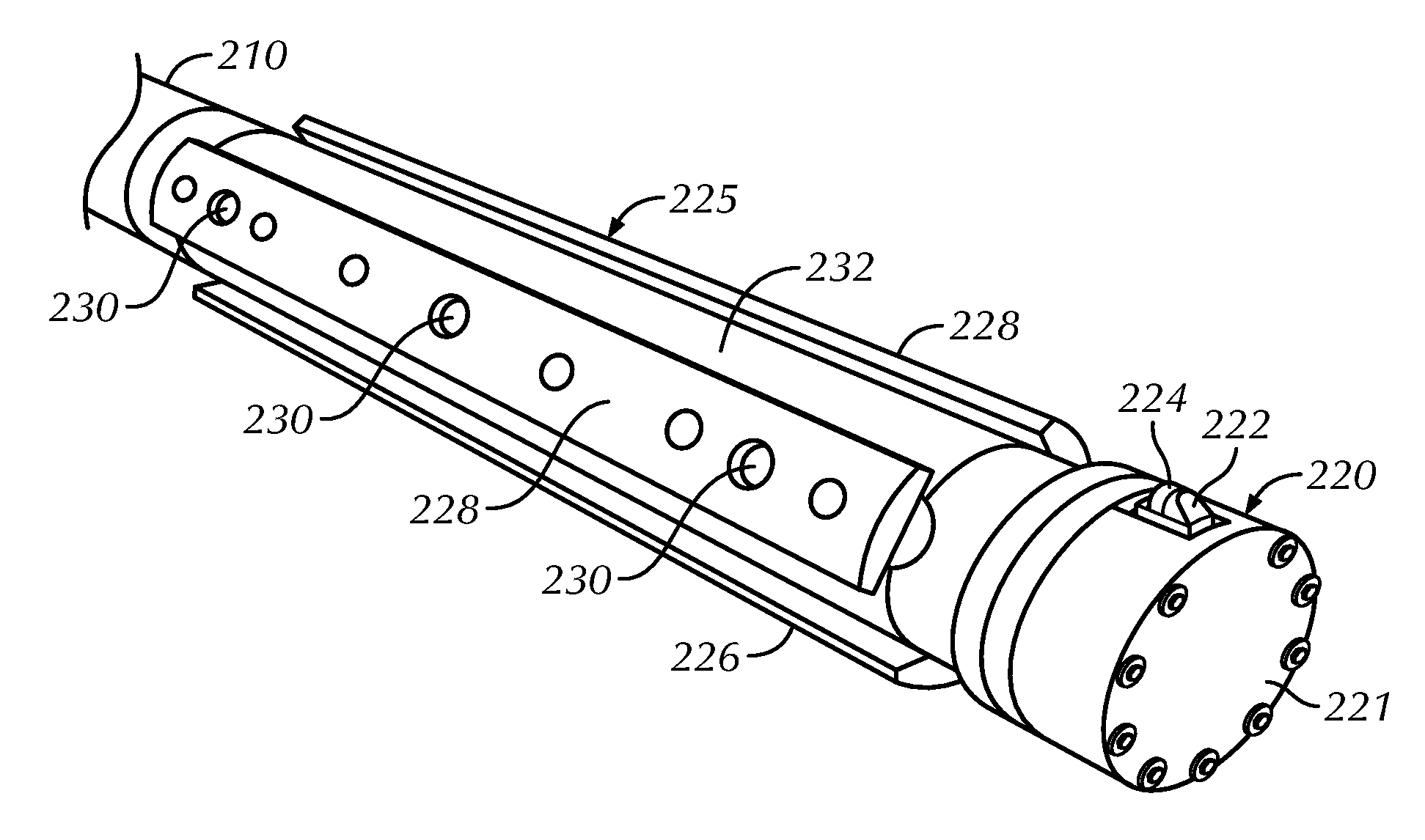

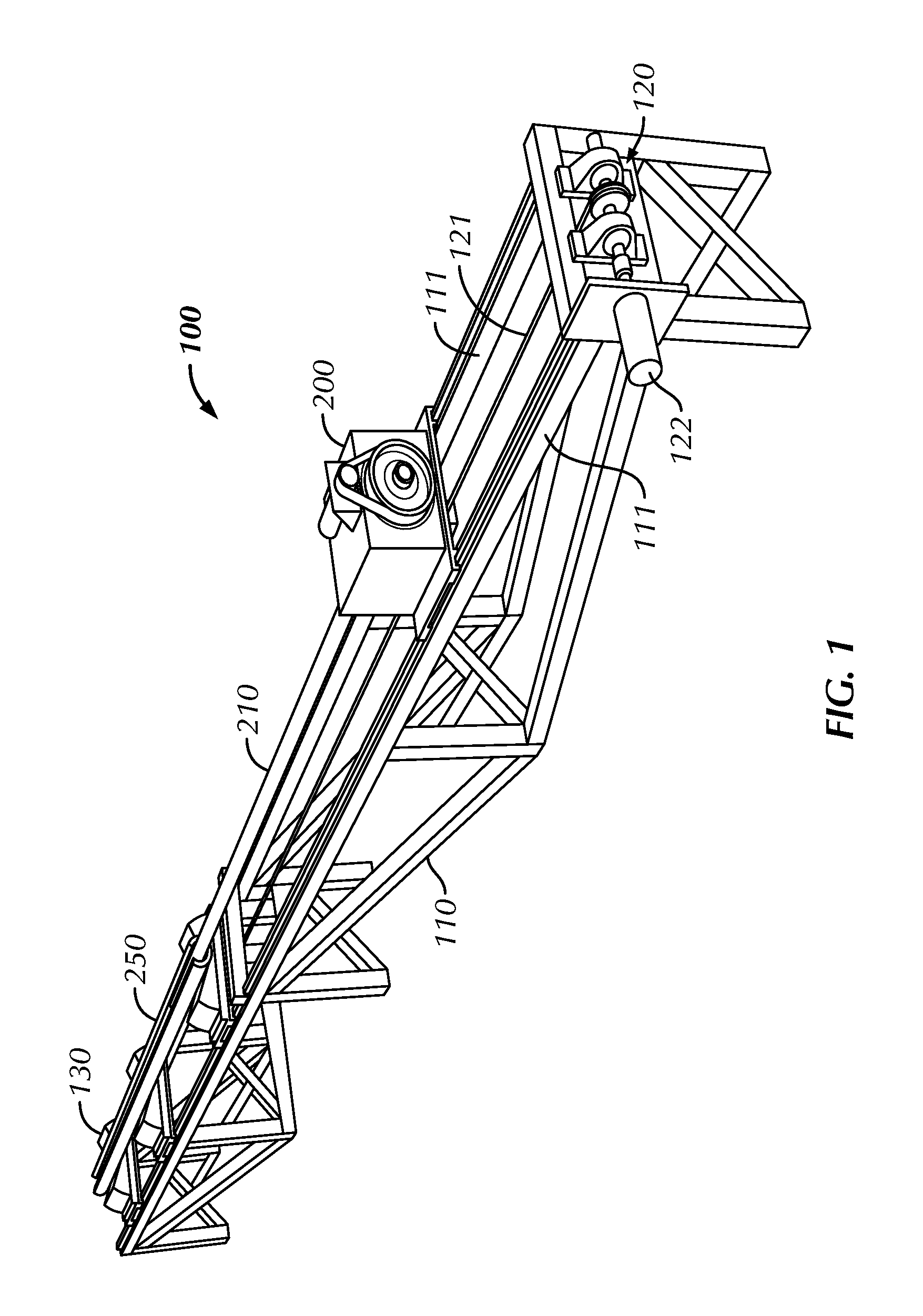

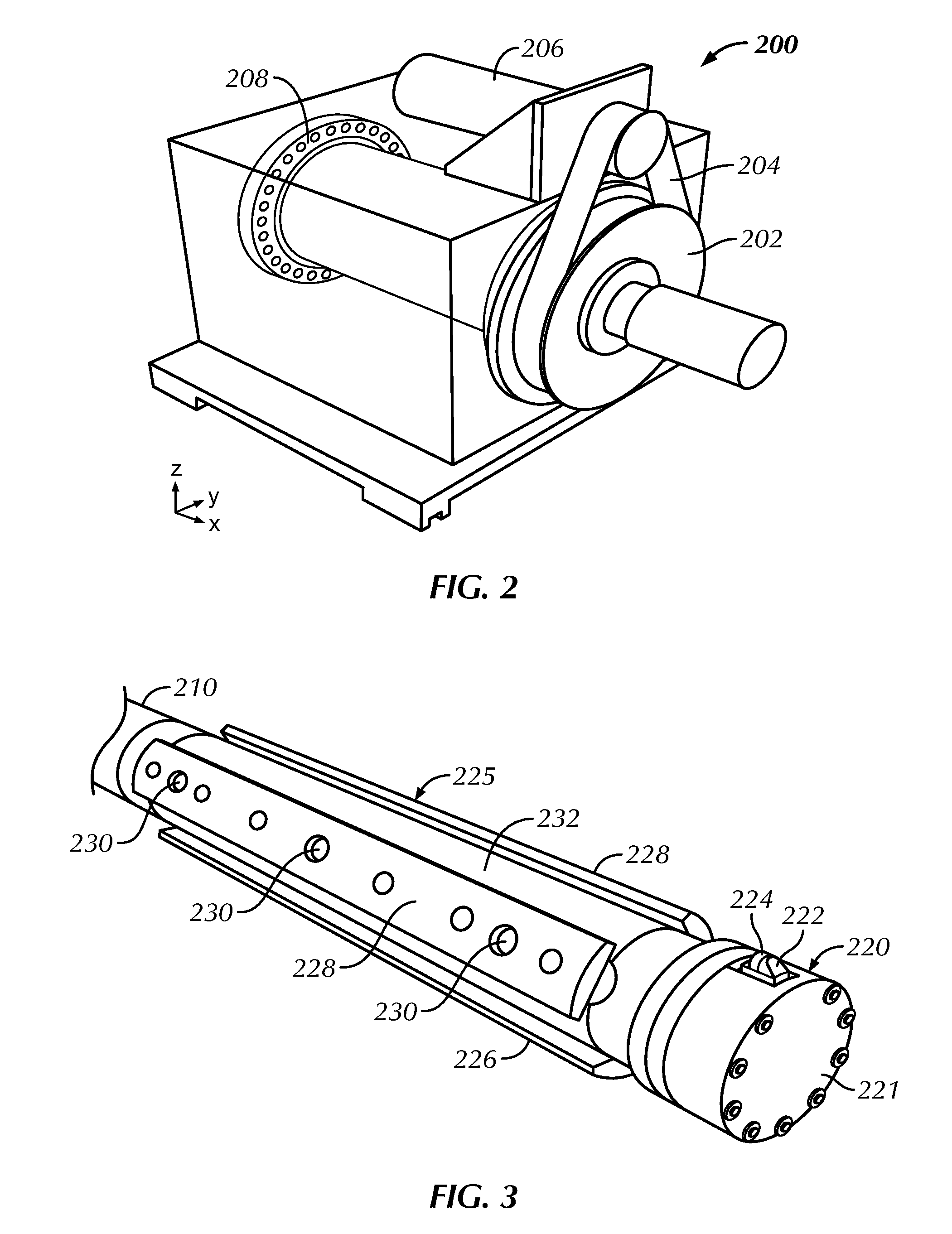

[0022]Referring now to FIG. 1, a perspective view of a machining apparatus 100 in accordance with embodiments of the present disclosure is shown. The machining apparatus 100 includes a frame structure 110 on which components of the machining apparatus 100 are mounted. The frame structure 110 may be constructed as a weldment, the size of which may vary depending on the leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com