Adapter plate for mortise broaching of disc parts and disc part machining device

A technology of disk parts and transfer disks, which is applied in the field of mechanical processing equipment, can solve the problem that broaching fixtures cannot be connected with different indexing disks, and achieve the effects of reducing the number of fixtures, reducing production costs, and improving interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

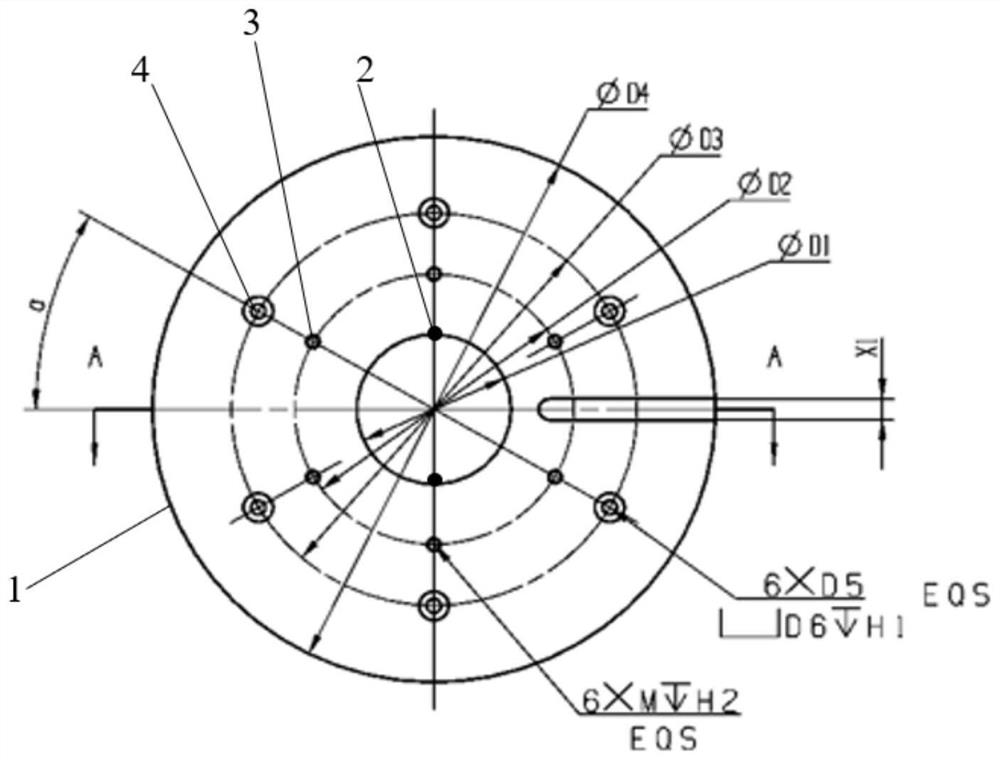

[0036] like figure 1 As shown in the figure, an adapter plate for tongue and groove broaching of disk parts includes an adapter plate body 1, the adapter plate body 1 is circular, and the adapter plate body 1 is sequentially opened along the diameter of the center of the circle to the outer circumference line. There are a first through hole 2, a second through hole 3 and a third through hole 4; the first through hole 2 is used to cooperate with the bottom hole of the external broaching fixture; the second through hole 3 is used to fix the broaching fixture; The third through hole 4 is used for connecting with an externally connected indexing plate.

Embodiment 2

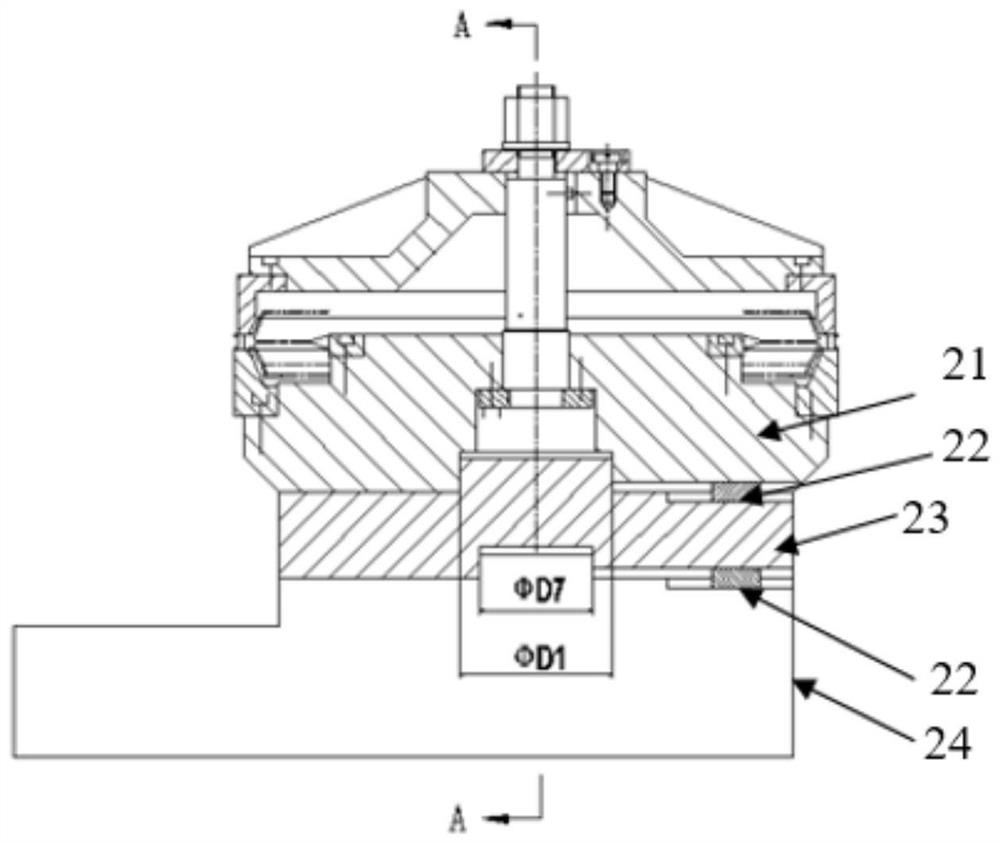

[0038] The utility model relates to an adapter disk for tongue and groove broaching of disk parts, which is a connecting device used for broaching machine fixtures and indexing disks.

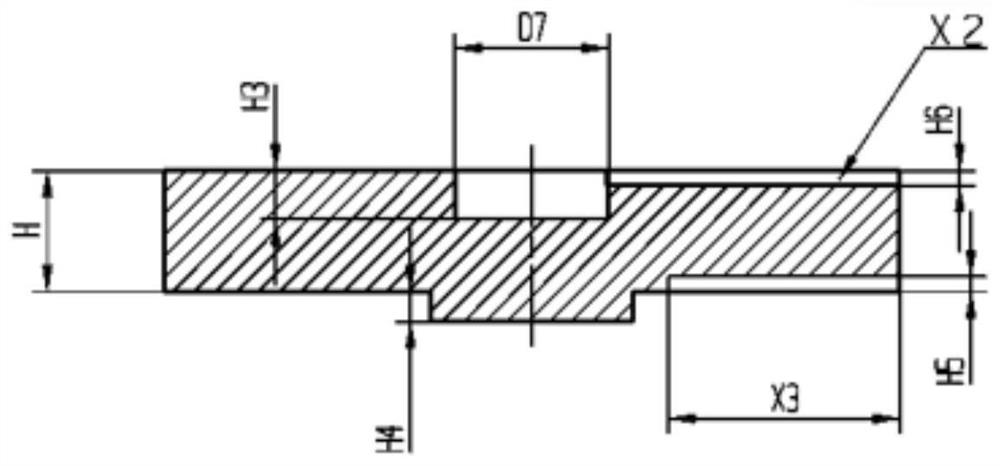

[0039] The adapter plate is used in conjunction with the broaching fixture and the broaching indexing plate, and its shape is as follows: figure 1 and figure 2 As shown, its diameter D1 matches the gap between the bottom hole of the broaching machine fixture, and D1 can be designed according to the general selection of the bottom hole of the broaching machine fixture; the threaded hole with a pitch circle of D2 and the keyway X1 are used to fix the broaching machine fixture, and the pitch circle D2 can be selected according to the broaching machine fixture. The design of the pitch circle of the fixture connection hole; through the inner holes of a set of countersunk holes D5 and D7 (D7 is a blind hole) with a pitch circle of D3 and the keyway X2, the adapter plate is connected to the indexing ...

Embodiment 3

[0041] An adapter plate for tongue and groove broaching of disc parts,

[0042] The bottom hole of the fixture of the third-stage turbine broaching machine is Ф133.37, the pitch circle of the countersunk hole is Ф241, and the keyway width is 19.01;

[0043] The diameter of the central mandrel of the original indexing plate used for broaching of this part is Ф133.37, the pitch circle D2 of the connecting threaded hole is Ф241, and the width of the keyway is 19.01;

[0044] The diameter of the central mandrel of the new indexing plate used for broaching of this part is Ф101.6, the pitch circle D3 of the connecting threaded hole is Ф350, and the width of the keyway is 20.64;

[0045] According to the above dimensions, the relevant dimensions of the adapter plate to be used are Ф133.37 for D1, Ф241 for D2, 19.01 for X1, Ф350 for D3, Ф101.6 for D7, and 20.64 for X2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com