Broaching force detection device and detection method thereof

A detection device and detector technology, applied in the field of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

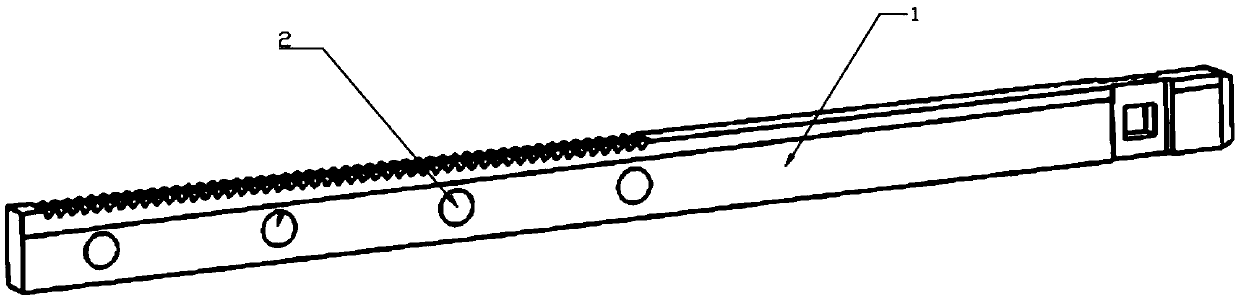

[0031] Such as figure 1 , 2 , 3 and 4, a broaching force detection device includes a broach body 1, a sealing cover 2 and a detector. The broach body 1 adopts a keyway type broach. The blade body side of the broach body 1 is provided with four placement through slots. The four placement through slots are arranged at equal intervals in sequence along the length direction of the knife body. Detectors are arranged in the four placement through slots.

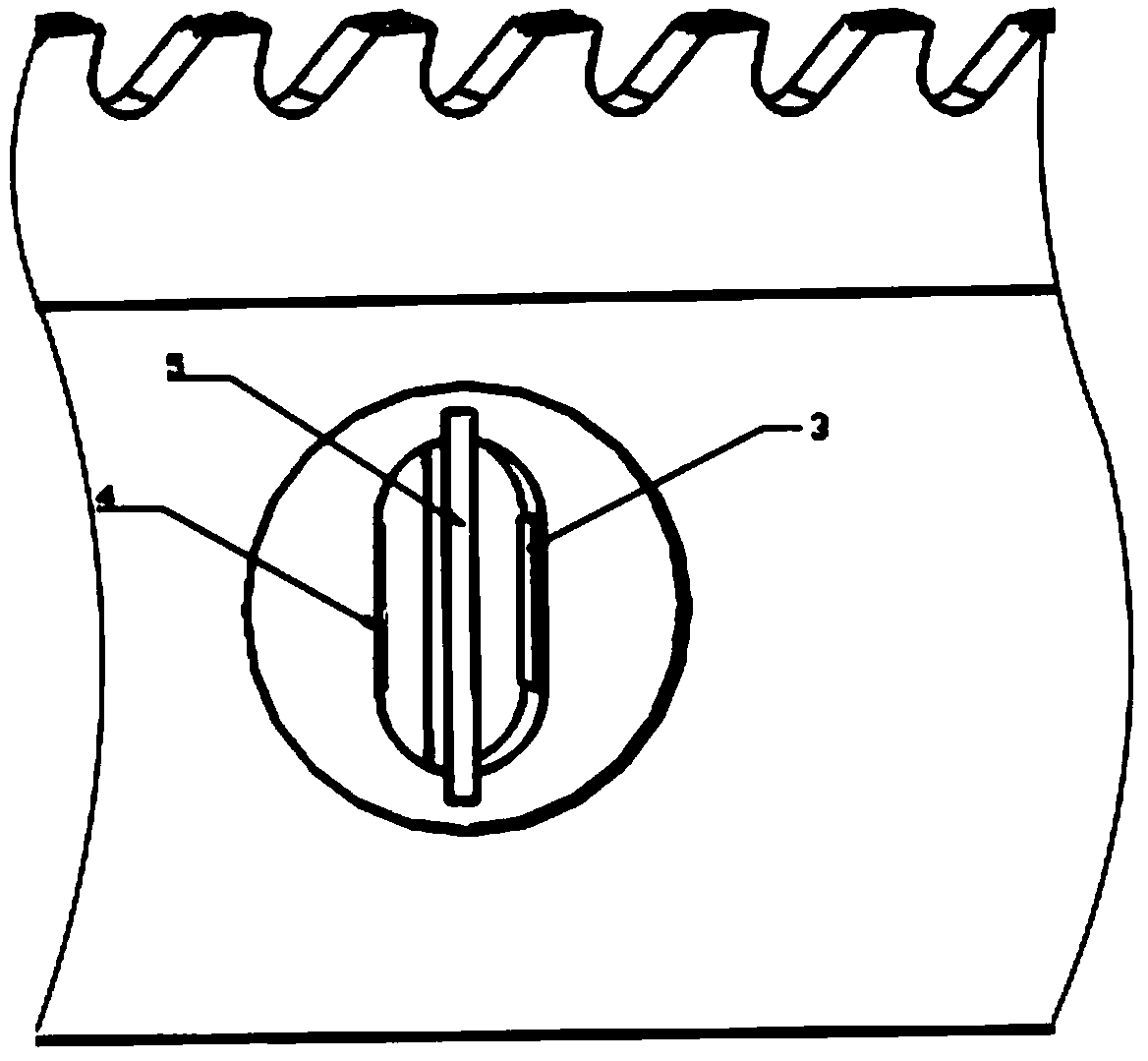

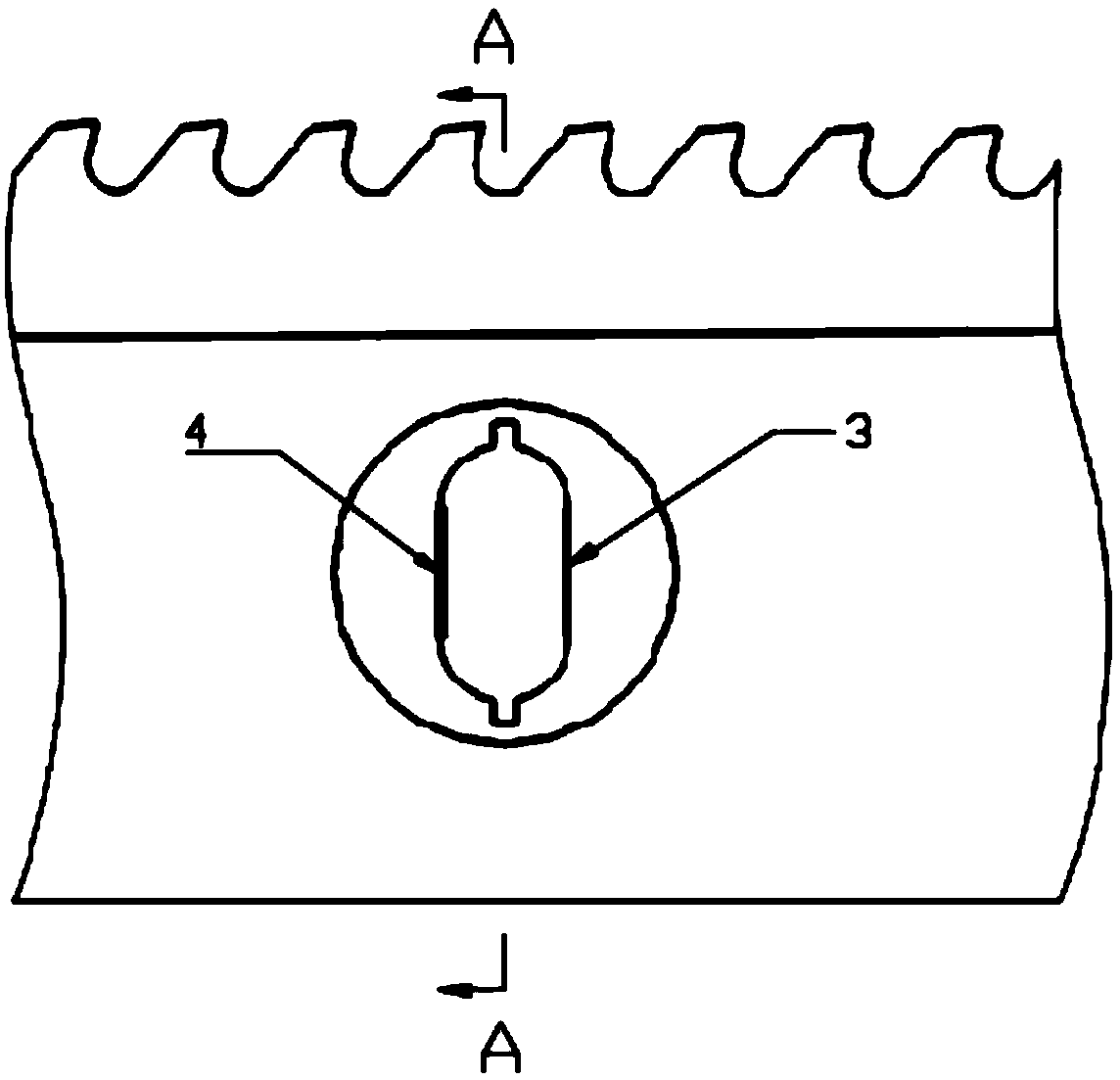

[0032] The detector includes a strain sensor 3 , a piezoelectric sheet 4 and a circuit substrate 5 . The strain sensor 3 and the piezoelectric sheet 4 are arranged on both sides of the installation through groove respectively, and the distance between the piezoelectric sheets in the four installation through grooves and the strain sensor is equal. The joints between the placement through slots, the strain sensor 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com