Burr removal device for mortise outlet

A technology for clearing device and tenon and groove, which is applied to the accessories of broaching machine, broaching machine, metal processing equipment, etc. It can solve the problem of burrs at the outlet of tenon and groove, affecting the processing quality and service life of disc parts, and the stress at the outlet of tenon and groove Concentrated area and other problems, to improve the service life, reduce the effect of hardening burr and lattice deformation layer depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

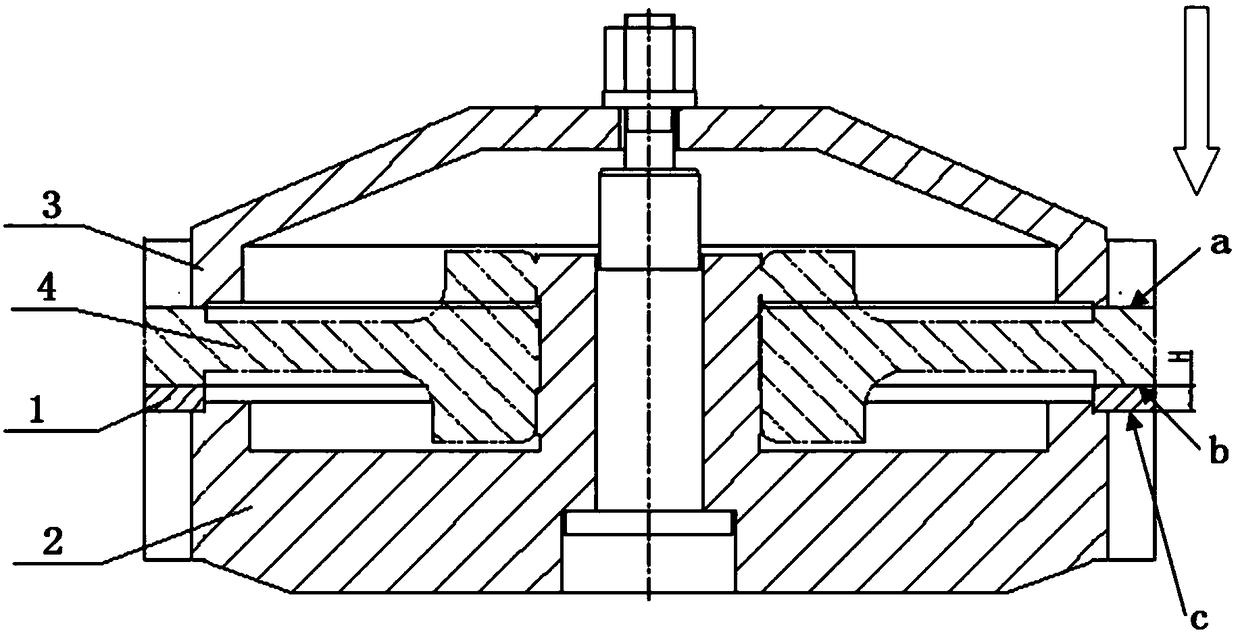

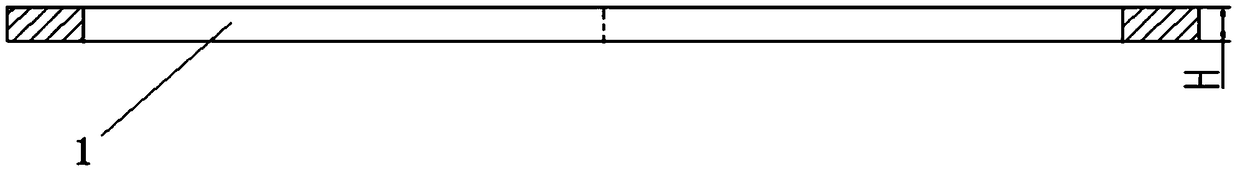

[0037] The chip breaking ring 1 is a ring-shaped part, its inner hole φ535mm is in clearance fit with the intermediate step shaft of the positioning ring 2 in the broaching fixture, one end face fits with the end face of the disc, and the other end face fits with the end face of the positioning ring, The outer circle φ608mm of the chip breaking ring 1 is consistent with the outer circle of the turbine disk, and its height H is selected as 12mm.

[0038] figure 1 Among them, a is the part broach inlet, b is the original broach outlet, and c is the broach outlet of the present invention.

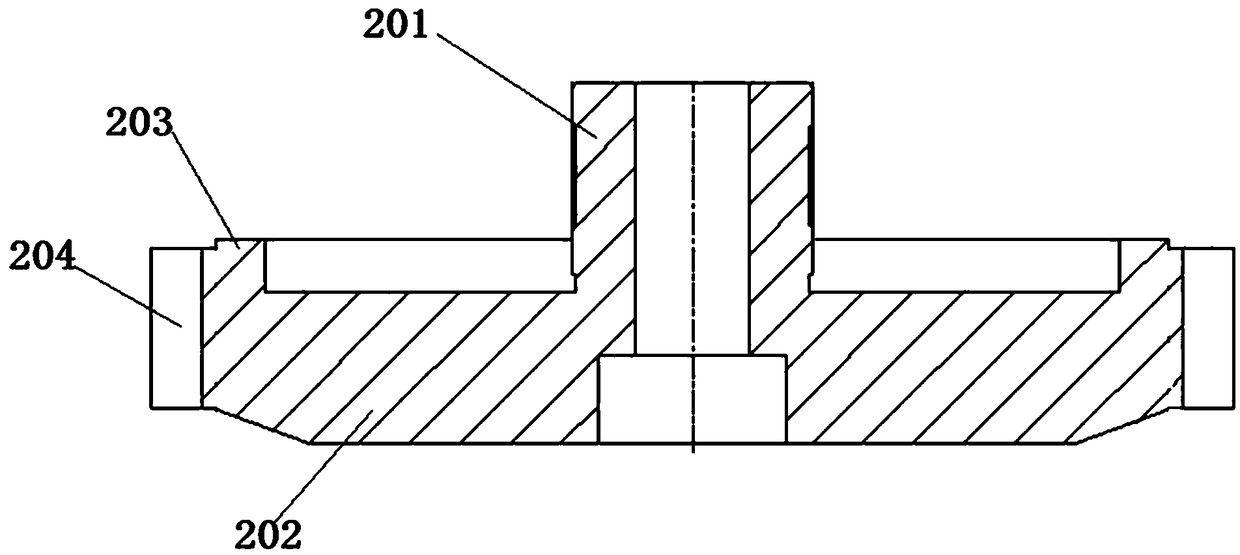

[0039] In the positioning ring 2, the outer circle of the small end shaft of 135.38mm is matched with the inner hole of the part as the radial positioning of the disc parts; the outer circle of the big end is 608mm consistent with the outer circle of the disc; the end face of the chip breaking ring 1 Fitting, the middle step shaft 535mm fits with the inner hole of the chip breaking ring 1; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com