Spiral pull-up type broaching machine

A screw and bed technology, applied in the direction of broaching machine, broaching machine device, accessories of broaching machine, etc., can solve the problems of low production efficiency, slow broaching speed, large size of the main slide, etc., to improve work efficiency, The effect of reducing manufacturing cost and ensuring broaching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with specific embodiments in conjunction with the drawings:

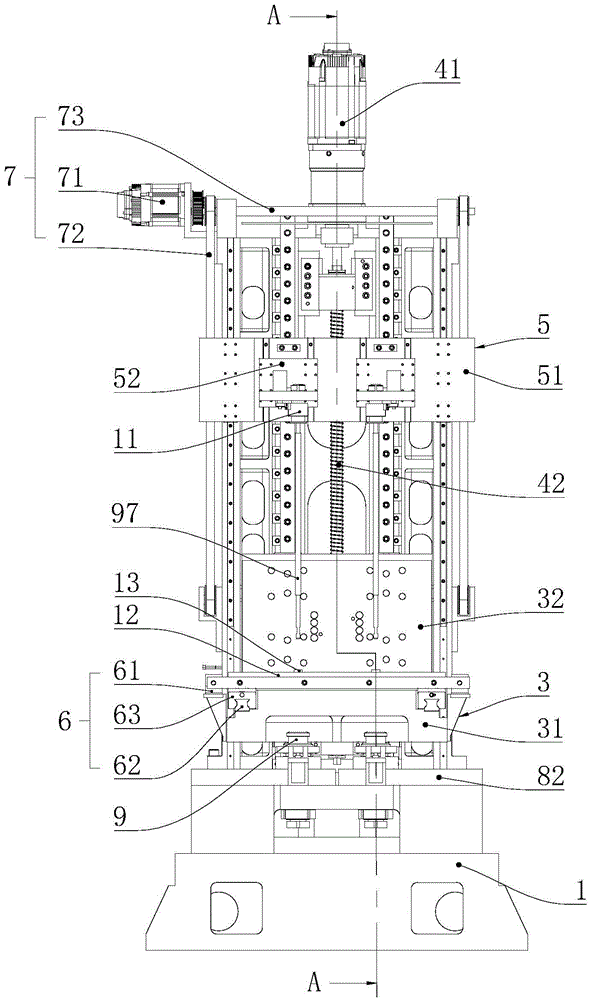

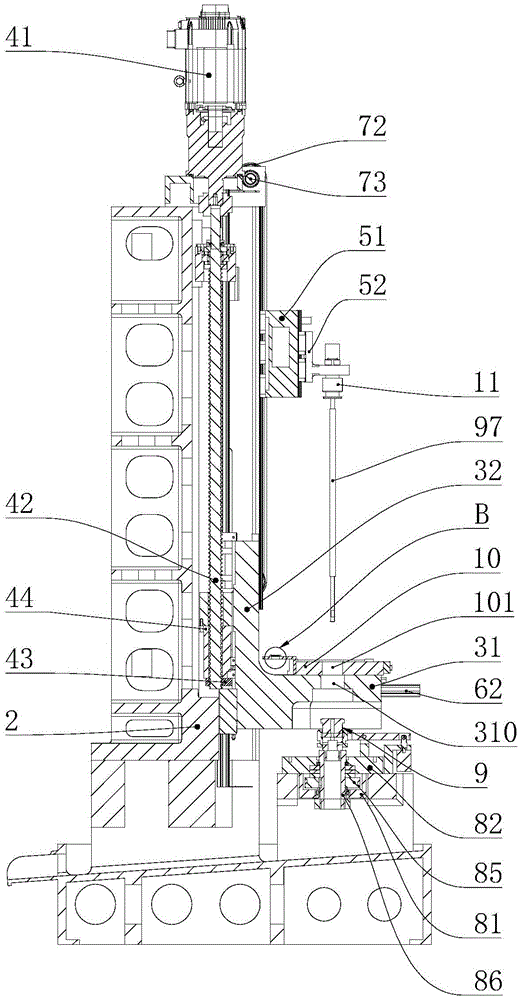

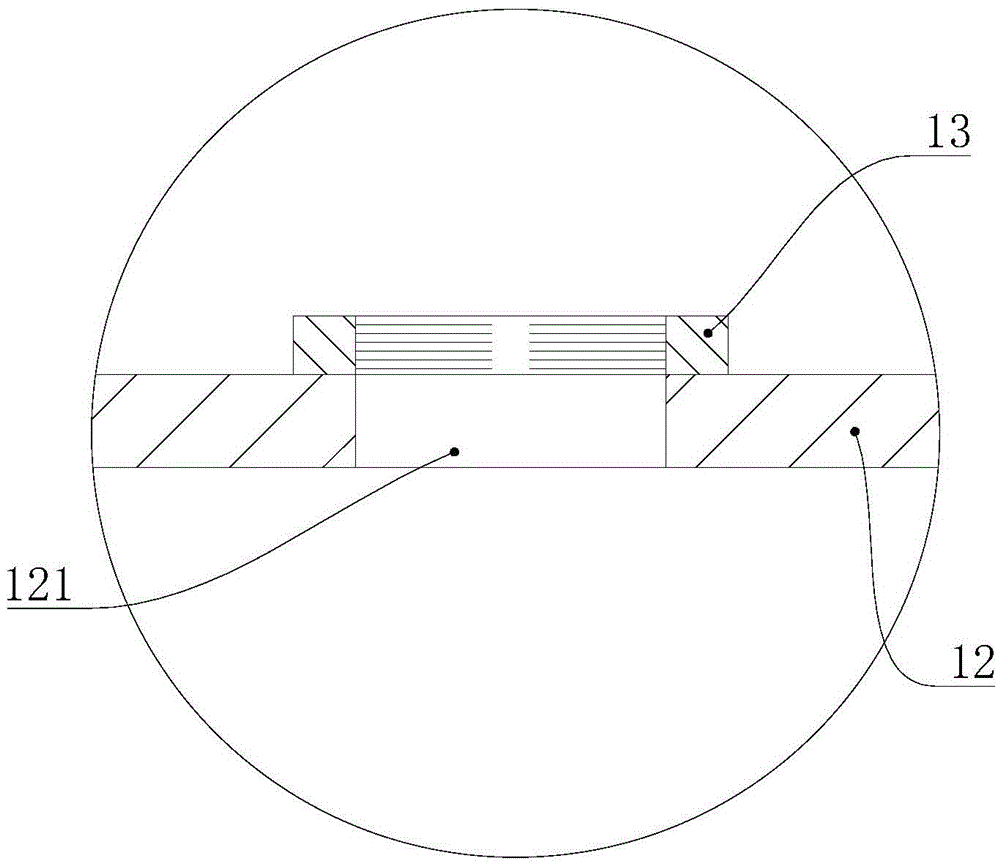

[0026] See Figure 1 to Figure 8 As shown, a spiral pull-up broaching machine includes a base 1, a bed 2 vertically fixed on the base 1, and a slide 3 fixed on the bed 2 and moving up and down along the bed 2, which drives the slide The driving mechanism 4 for the up and down movement of the plate 3, and the worktable 10 arranged on the sliding plate 3 and moving up and down with the sliding plate 3, the knife carrying mechanism 5 and the broach 97 located above the working table 10, the worktable The base 1 below 10 is provided with a lower chuck body 9 for fixing the bottom of the broach 97 and a power mechanism 8 for driving the lower chuck body 9 to rotate. The slide plate 3 is provided with a driving table 10 along the bed 2 The drive assembly 6 reciprocates back and forth. The inner wall of the workbench 10 is provided with a brush mounting plate 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com