Detecting device for multi-workpiece broaching production line

A detection device and production line technology, applied to broaching device accessories, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the area occupied by the equipment production line, cumbersome production process, and long workpiece detection time. Achieve the effects of improving broaching efficiency, shortening detection time, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

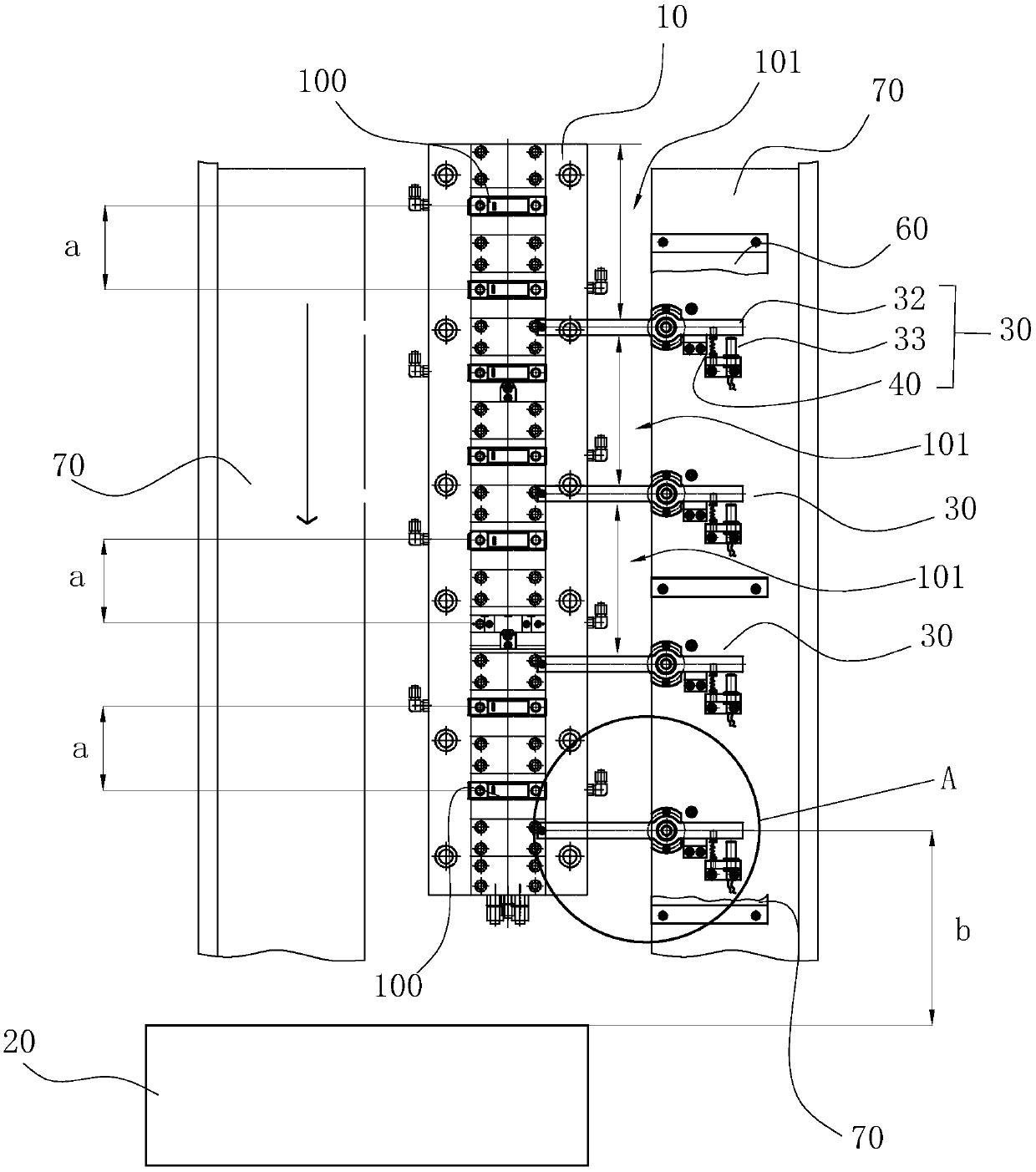

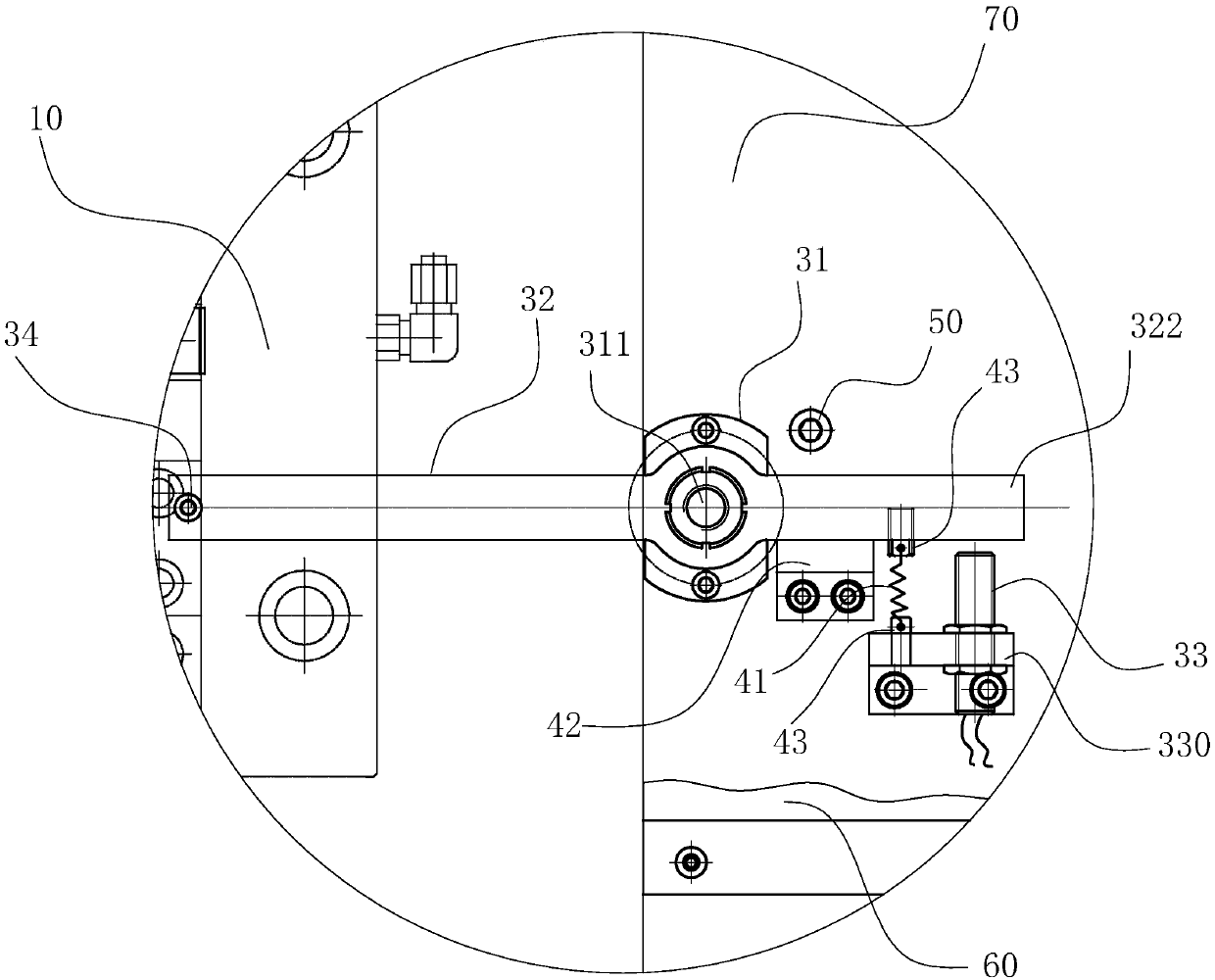

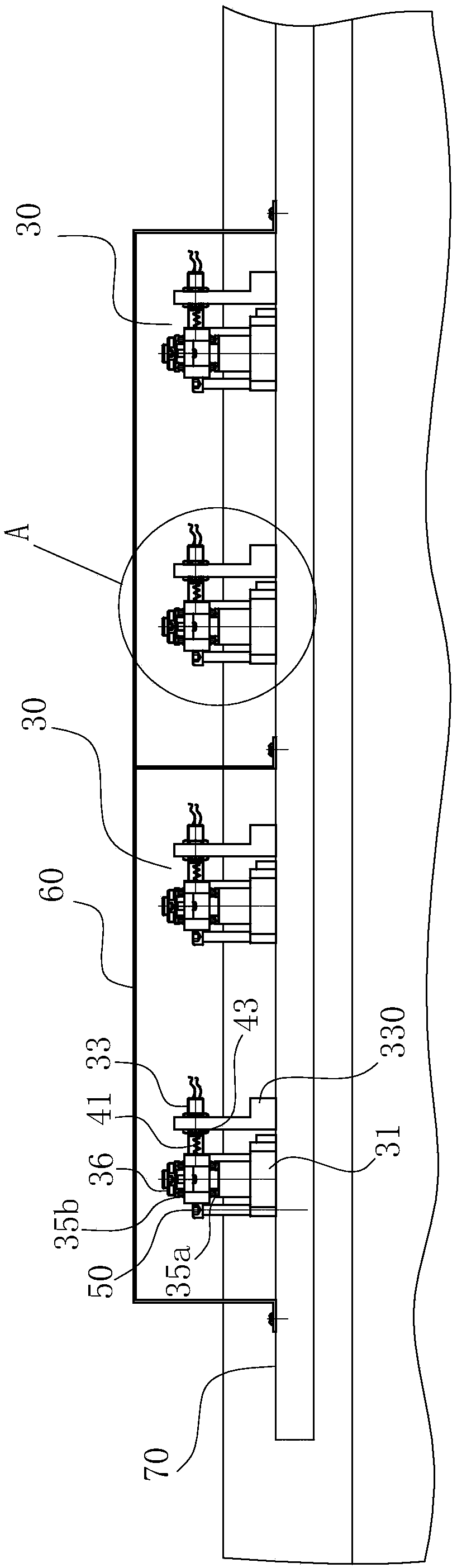

[0024] see Figure 1-Figure 7 , a detection device for a multi-workpiece broaching production line, which can be conveniently applied to a broaching machine tool in which the broach is fixed and the workpiece moves, and each workpiece 100 to be broached is detected. The fixture 11 for clamping the workpiece 100 is fixed on the mobile worktable 10 of the machine tool. The mobile worktable 10 can move linearly under the drive of the drive mechanism, and the processing unit 21 provided with the broach is located on the mobile worktable 10. In the front, a plurality of workpieces 100 of the movable worktable 10 move relative to the broach, and the processing of the plurality of workpieces 100 is completed by broaching once. 70, when the workpieces 100 on the mobile worktable 10 pass the inspection, they can enter the processing unit 21 ahead for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com