Clamping and rotating device for thin-wall workpiece

A technology for rotary devices and thin-walled workpieces, applied to broaching devices, accessories of broaching devices, manufacturing tools, etc., can solve problems affecting indexing accuracy and helical interpolation accuracy, large total mass of reciprocating parts, and complex tool systems Overall rigidity and other issues to achieve the effect of ensuring clamping efficiency, compact structure, and small inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

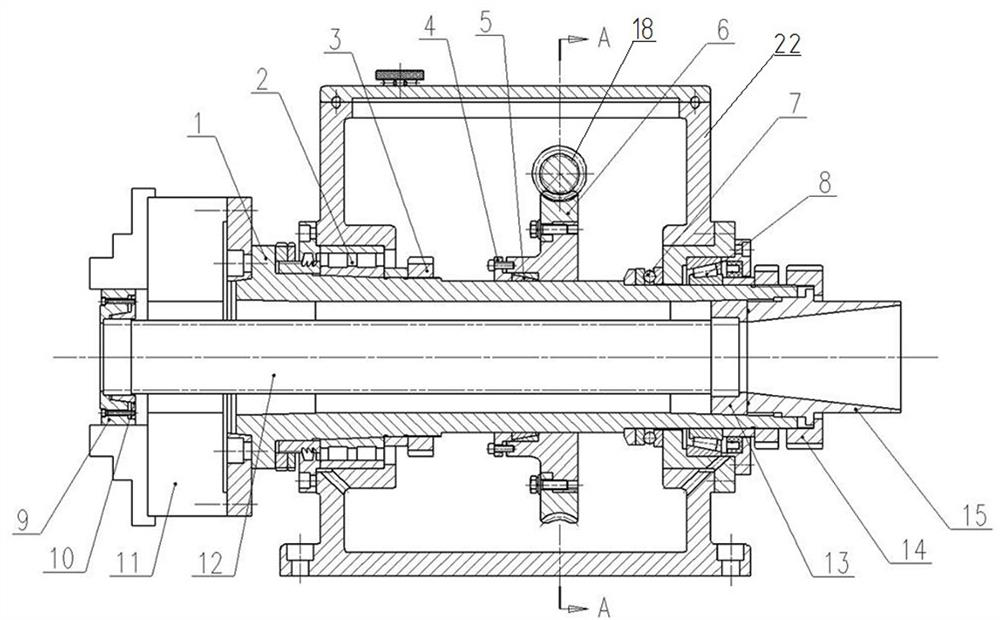

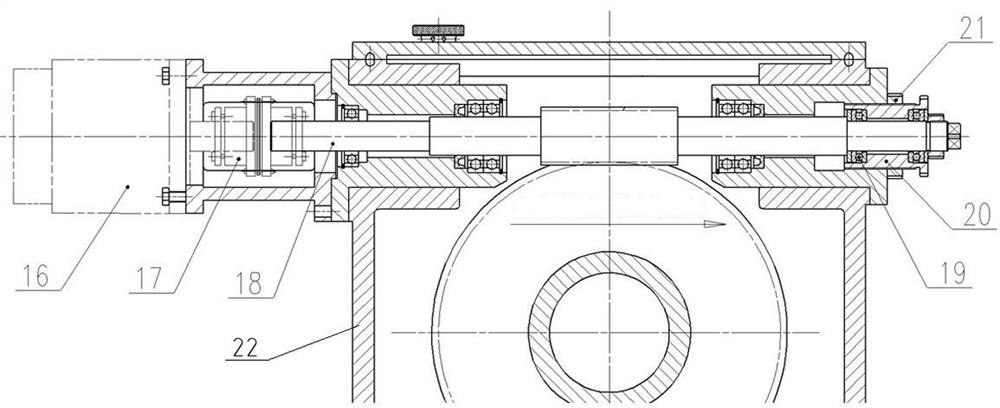

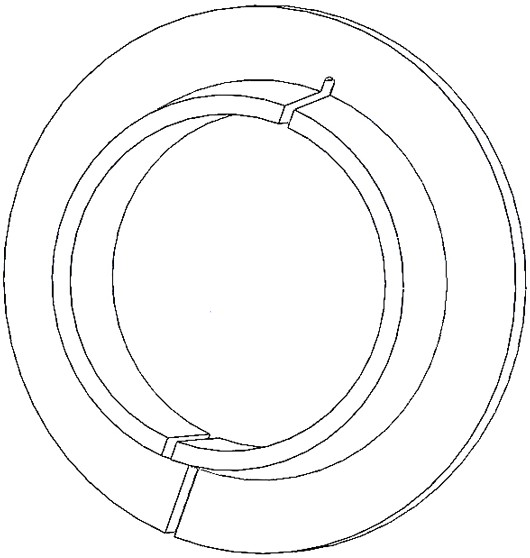

[0028] A clamping and rotating device for thin-walled workpieces, comprising a main shaft 1 provided with an axial center through hole, a transmission box 22, a double-lead worm mechanism and a chuck 11. The double-lead worm mechanism is arranged in the transmission box 22 , and the chuck 11 is installed on the front end surface of the main shaft 1 . The main shaft 1 is installed horizontally on the transmission box 22. The main shaft 1 is clamped by a double-lead worm mechanism and driven to rotate. The workpiece 12 is installed in the main shaft 1. Clamp and rear end are clamped in the central through hole of the main shaft 1. The double-lead worm mechanism includes a worm gear 6 , a double-lead worm 18 meshing with the worm gear 6 and a servo motor 16 .

[0029] The front end of the main shaft 1 is provided with a front bearing 2 and a lock nut I3 to cooperate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com