Broach cleaning device

A technology for cleaning devices and broaching machines, which is applied to broaching tools, accessories of broaching machine devices, broaching machines, etc., which can solve the problems of reduced ability to remove chips and incomplete removal of chips, and achieve effective chip removal and improved cleaning functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

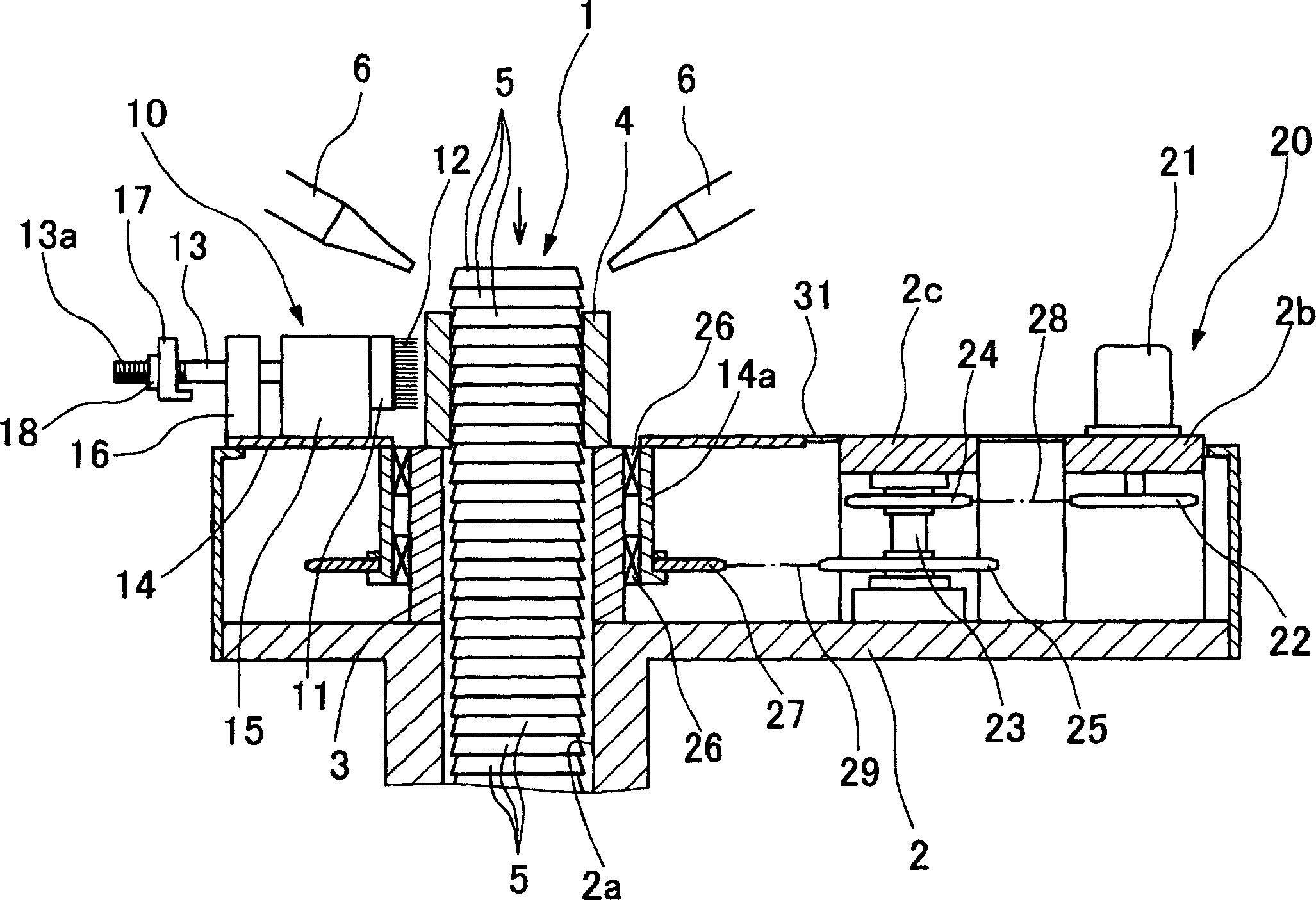

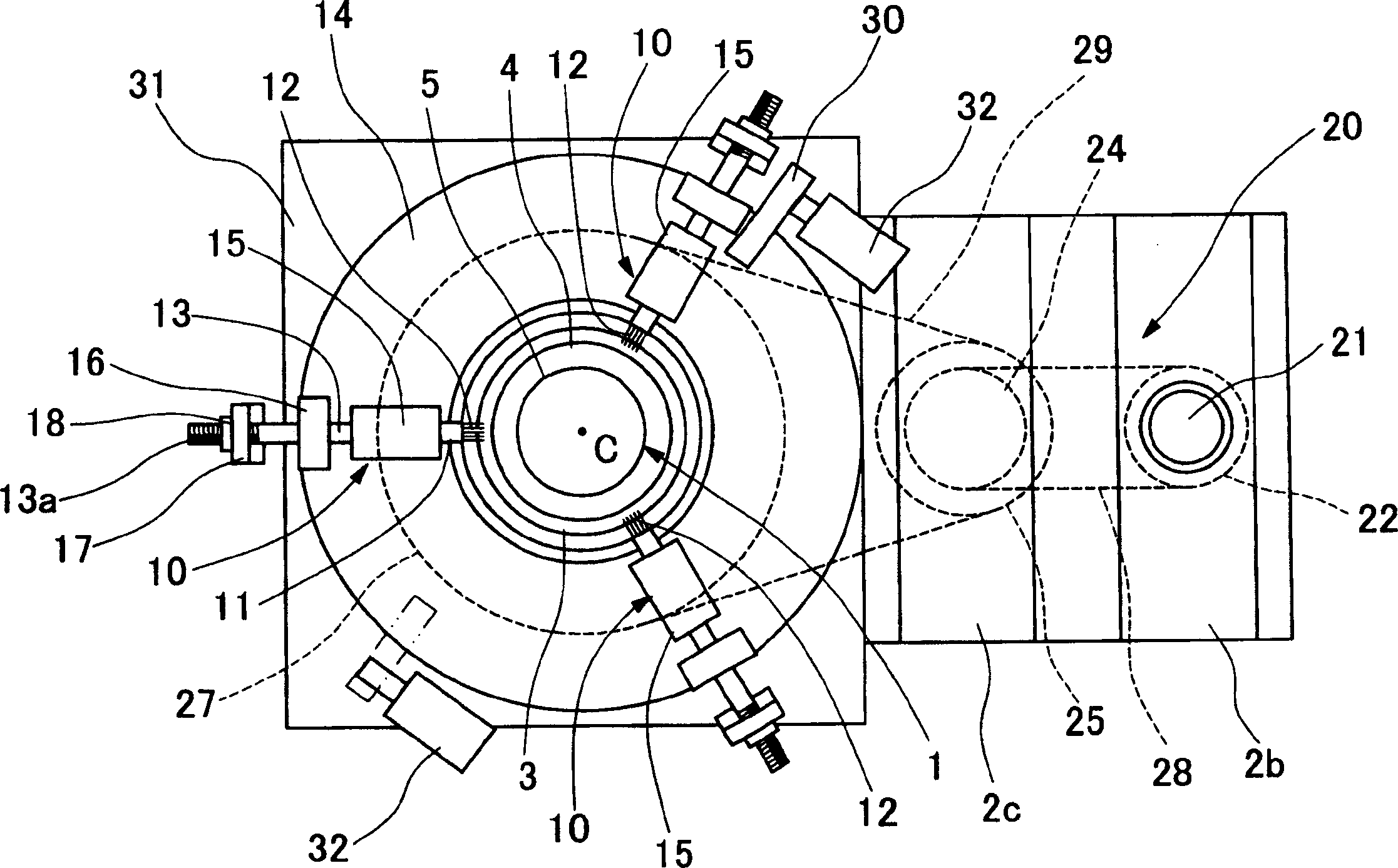

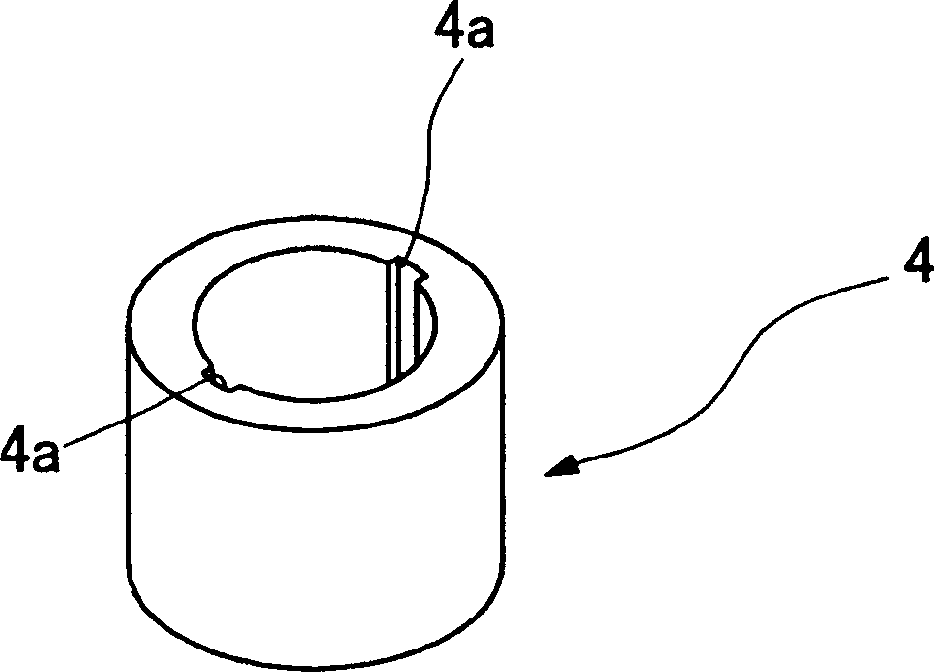

[0019] Embodiments of the present invention are described below with reference to the accompanying drawings. At first, figure 1 as well as figure 2 Indicates the structure of important parts of the broaching machine. In the figure, 1 is a broach, 2 is a support plate, and 3 is a mounting seat, for example image 3 The configuration shown is a portion of the broaching machine for forming a groove 4 a facing the axial direction on the inner surface of a cylindrically shaped workpiece 4 .

[0020] The drawing of the broach 1 is omitted, but its structure has upper and lower clamping parts, and a blade part 5 is provided between the two clamping parts, and is arranged so as to pass through the penetration hole 2a formed in the supporting table 2. . Such as Figure 4 As shown, the cutting edge portion 5 has annular cutting edges 5a facing the axial direction of the broach 1 and arranged at predetermined intervals, and a groove for machining the groove 4a of the workpiece 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com