Operating method for coal gasification combined cycle power plant

一种运转方法、发电设备的技术,应用在机械设备、燃烧设备、燃烧方法等方向,能够解决损伤燃料喷嘴、燃气涡轮运转故障、缩短燃烧器寿命等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

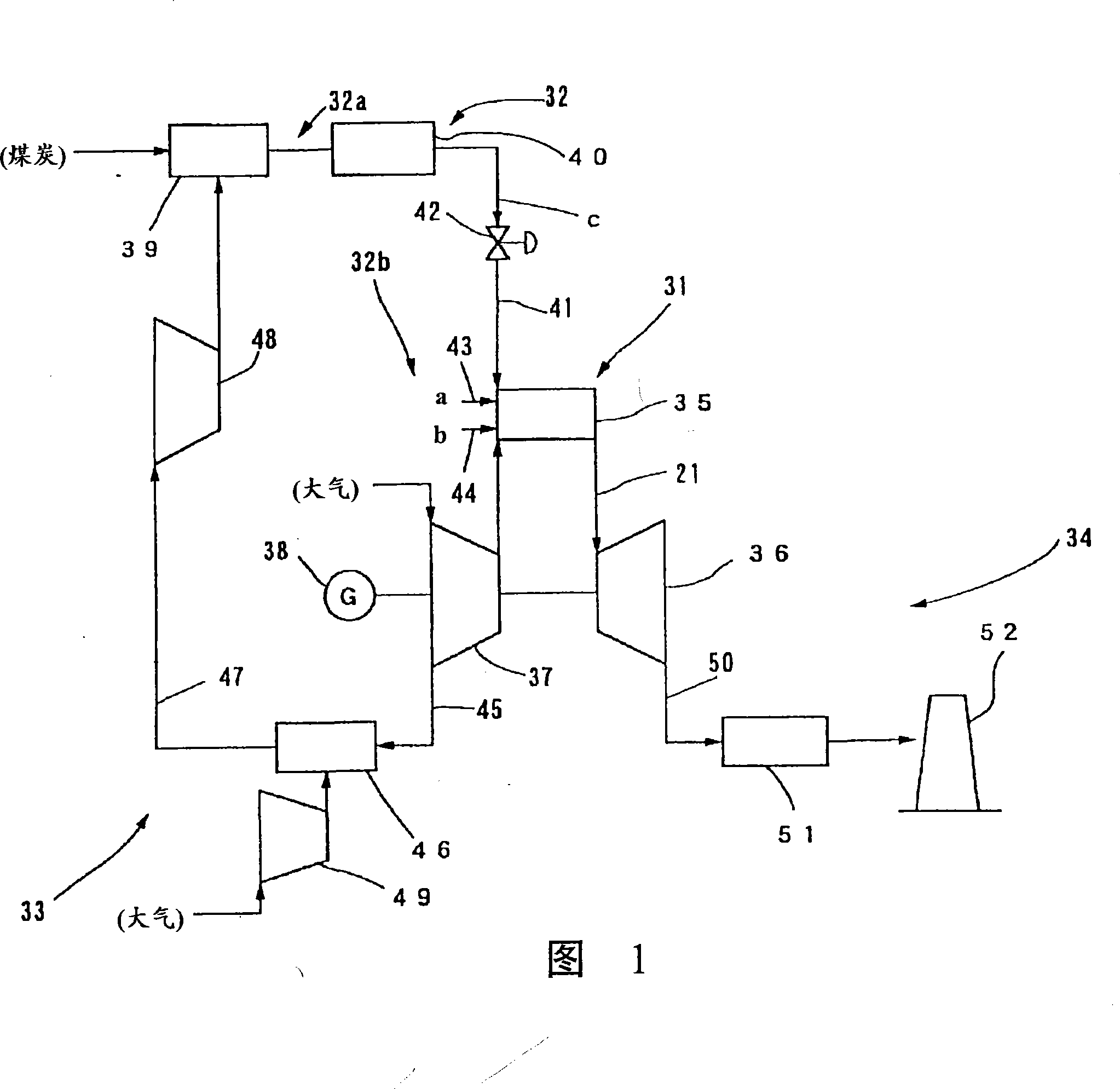

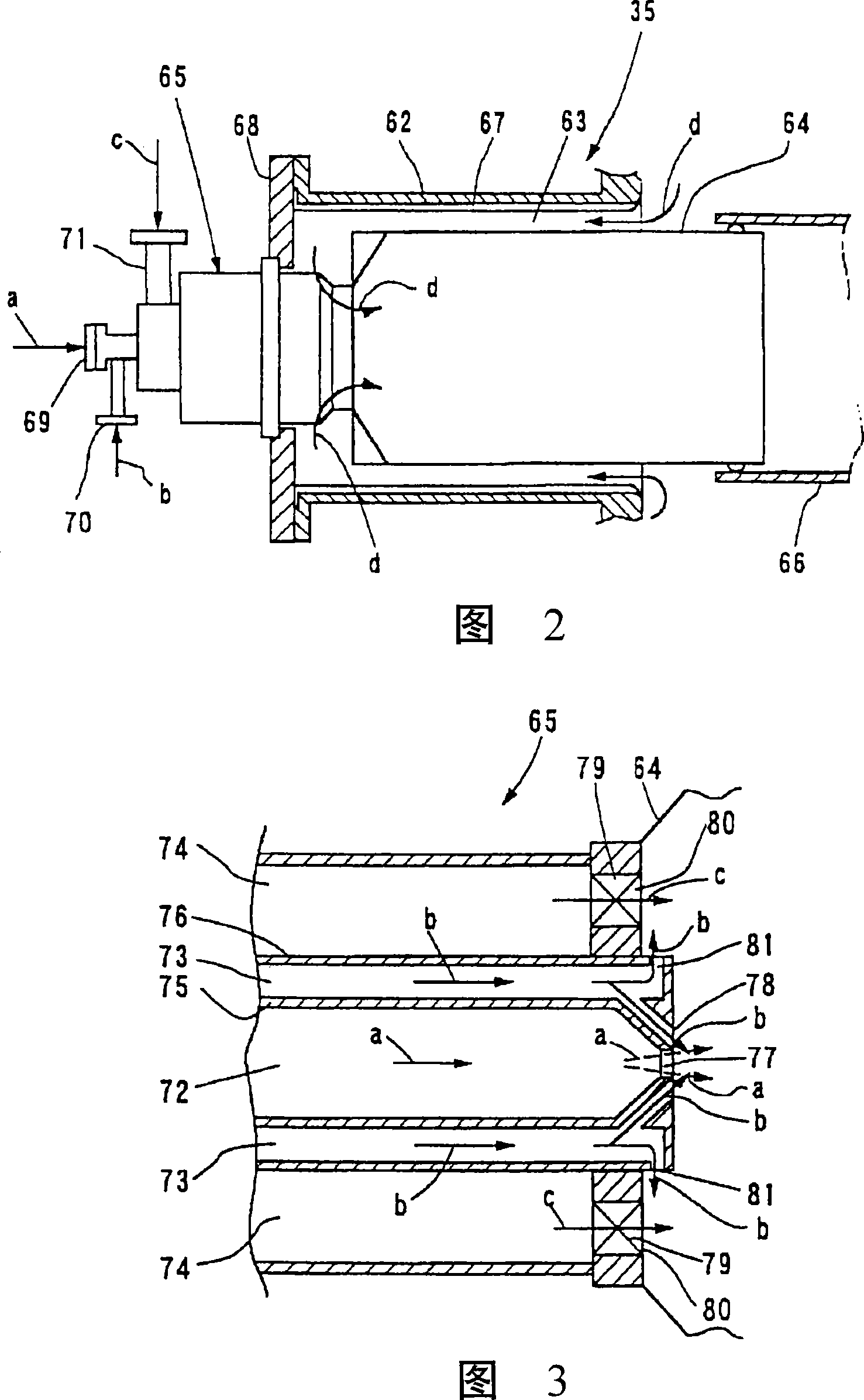

[0038] The first embodiment ( Figure 1 ~ Figure 3 )

[0039] figure 1 It is a systematic diagram showing the overall structure of the combined coal gasification power generation facility of the embodiment of the present invention.

[0040] like figure 1 As shown, the combined coal gasification power generation equipment of this embodiment generally includes: a gas turbine system 31; a fuel supply system 32; an air supply system 33; an exhaust system 34 and so on.

[0041] The gas turbine system 31 has: a burner 35 capable of selectively combusting coal gasification fuel c and liquid fuel a; a gas turbine 36 driven by combustion gas generated by the burner 35; coaxially arranged with the gas turbine 36 Gas turbine compressor 37 and generator 38.

[0042] The fuel supply system 32 is composed of two systems of a coal gasification fuel supply system 32a and a liquid fuel supply system 32b. The coal gasification fuel supply system 32a has a gasification furnace 39 for gasi...

no. 2 Embodiment

[0058] The second embodiment ( Figure 4 )

[0059] Figure 4 It is an enlarged cross-sectional view showing the fuel nozzle 65 portion of the burner 35 in the coal gasification fuel combined power generation facility of this embodiment.

[0060] This example Figure 4 As shown, on the fuel nozzle 65 that sprays fuel to the burner 35, a liquid fuel flow path 72, an air flow path 73 for atomization, and a coal gasification fuel flow path 74 are arranged in a state of being adjacent to each other. The flow path wall 76 near the outlet of the air flow path 73 for atomization is provided with a spray hole 82 for blowing atomization air into the fuel flow path for coal gasification. The spray holes 82 for the atomization air are formed in a plurality along the circumferential direction of the fuel nozzle 65, and are opened near the discharge ports 80 of the coal gasification fuel flow path 74, for example, continuously spray particles to the inner surface of the swirler 79. The...

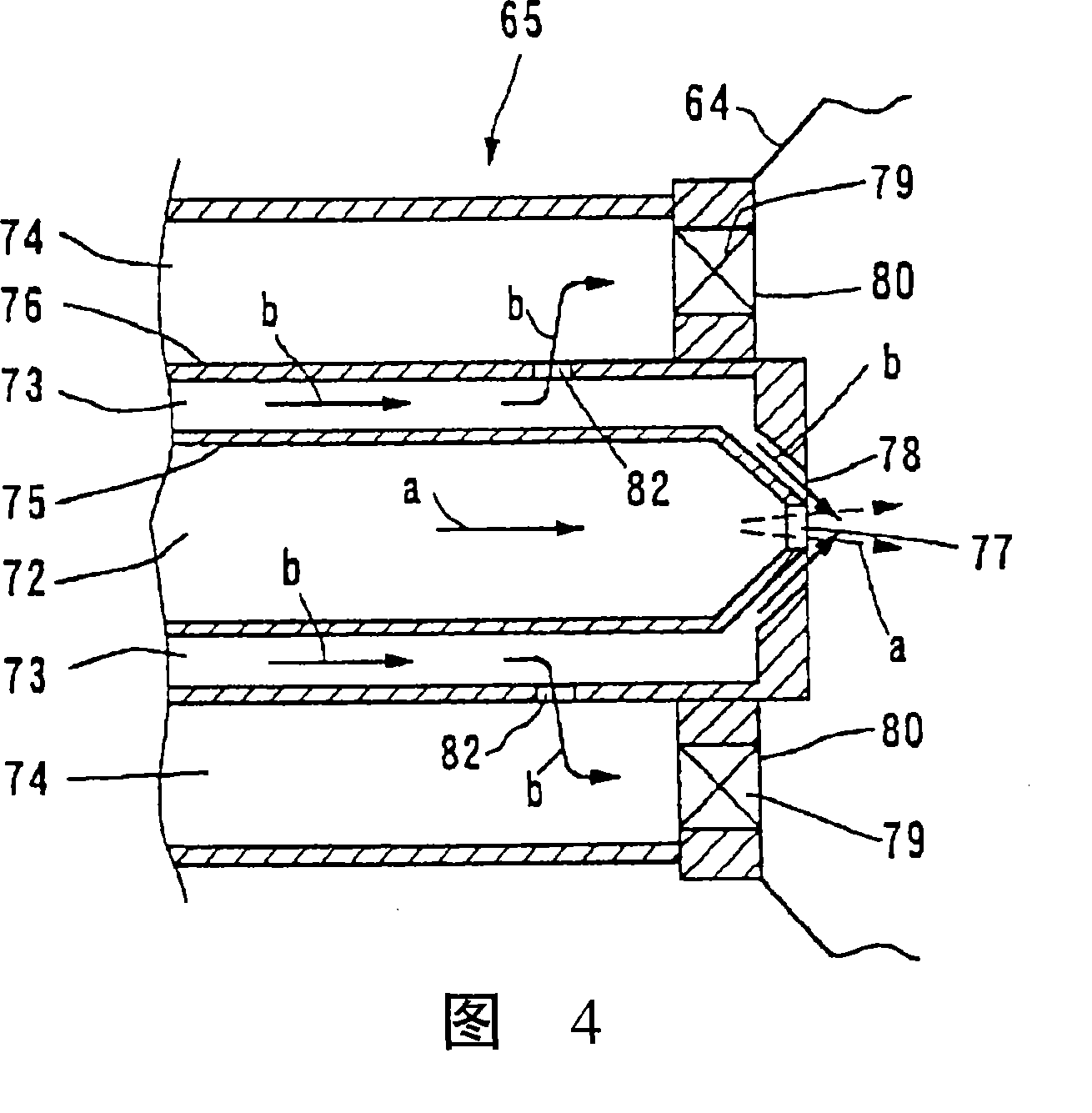

no. 3 Embodiment

[0064] The third embodiment ( Figure 5 )

[0065] Figure 5 It is an enlarged cross-sectional view showing the combustion nozzle 65 of the burner 35 in the combined coal gasification power generation facility of this embodiment.

[0066] This example Figure 5 As shown, in will come from the gas turbine compressor 37 (refer to figure 1) is blown into the outlet portion of the combustion air passage 63 in the burner sleeve 64, and a combustion air ejection portion 83 for ejecting combustion air to the outlet portion of the coal gasification fuel flow passage 74 is provided. . The combustion air ejection portion 83 includes: for example, a hole 84 pierced on the end wall 64a of the burner sleeve 64 on the combustion nozzle 65 side; The guide member 85 protruding from the inner surface continuously injects the combustion air d to the outside of the swirler 79 of the coal gasification fuel injection port 80 , and an air film can be formed on the coal gasification fuel injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com