Device for converting two types of spindle tapered bores of machine tool

A technology of conversion device and taper hole, which is used in accessories, positioning device, broaching machine, etc. of broaching machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

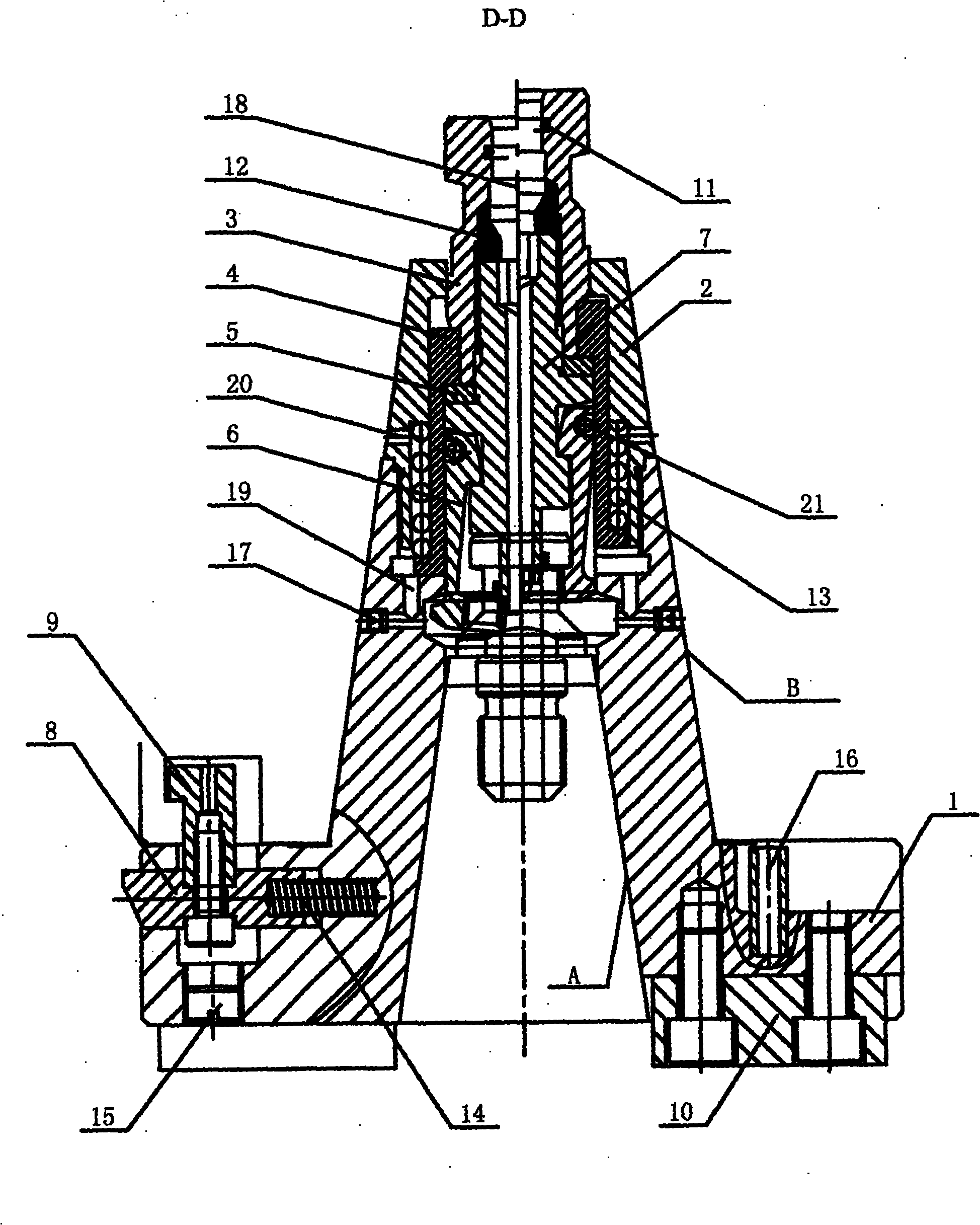

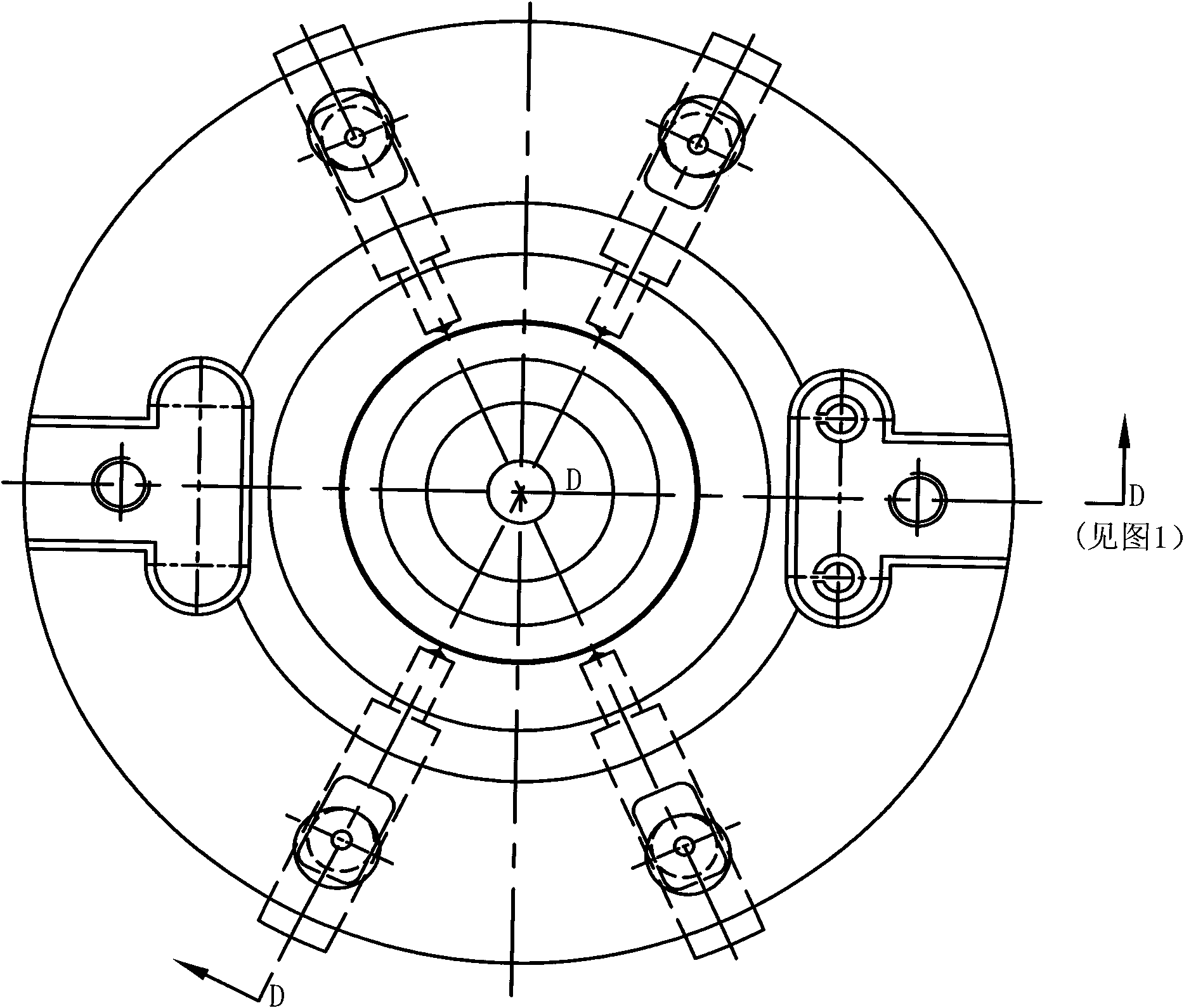

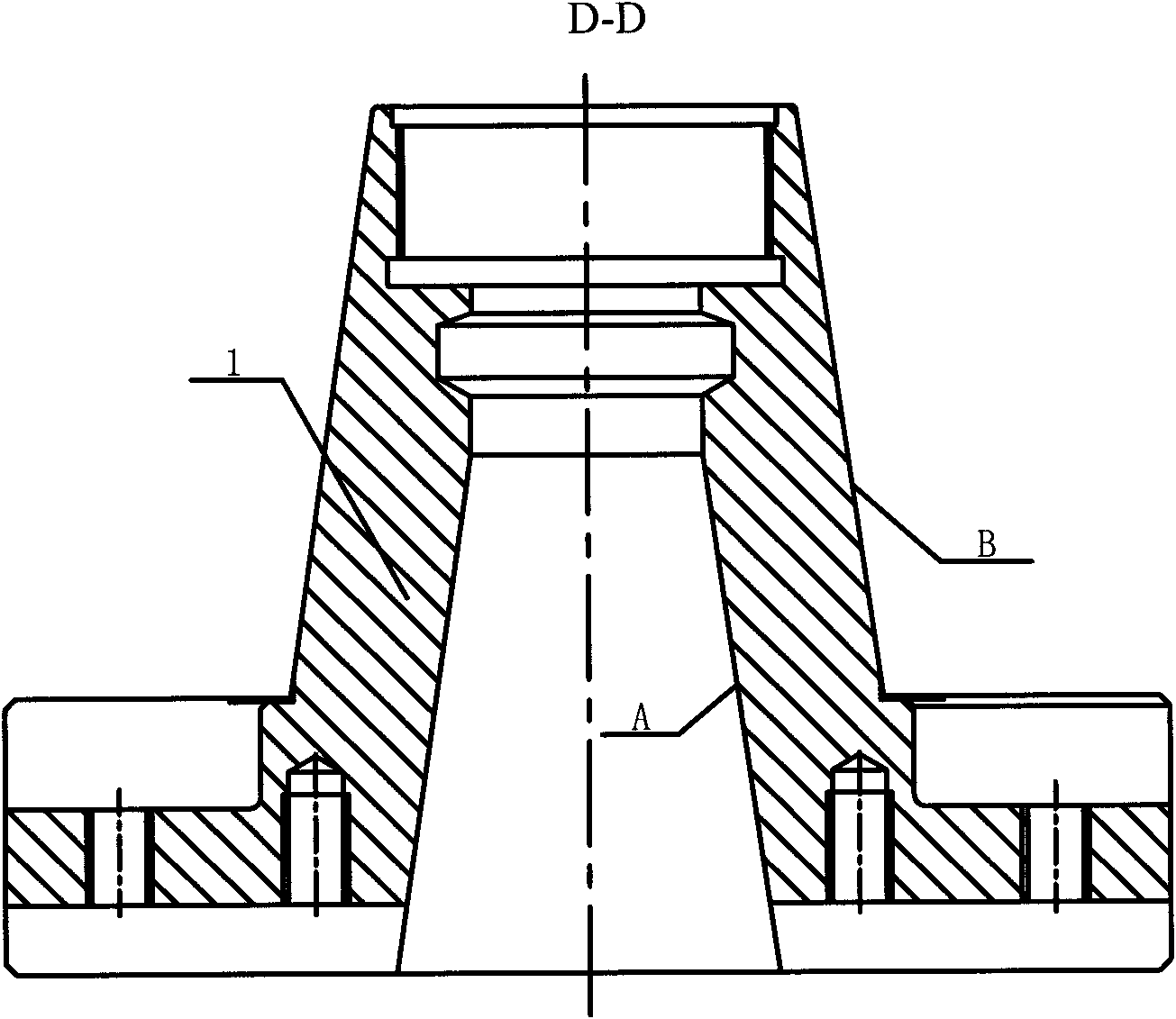

[0022] The conversion device for two types of spindle taper holes of the machine tool, figure 1 Shown is the conversion device for converting the taper hole of the spindle from ISO60 to ISO50, and the conversion device is generally referred to as the head below.

[0023] figure 1 For the combined state of this conversion device: put the spring 21 in the outer diameter arc groove of the four claws 6, which are radially symmetrical, and the angle between the small inner hole and the large inner hole at the upper end is placed first in the middle of the jaw mandrel 7. Between the large outer diameter boss and the second largest outer diameter boss; the seal ring 11 is placed on the inner wall of the upper hole with the outer flange of the pull stud 3, the seal ring 12 is placed under the inner cooling hole 18, and the adjustment sleeve 5 is placed on the clip On the first large outer diameter boss in the middle of the claw mandrel 7, the inner hole of the sliding sleeve 4 is red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com