Tandem compound type solid state fermentation device

A solid-state fermentation and combined technology, which is applied in feed, food science, application, etc., can solve the problems of poor scalability, high cost, and inability to change, etc., and achieve good scalability, guaranteed fermentation quality, and easy automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

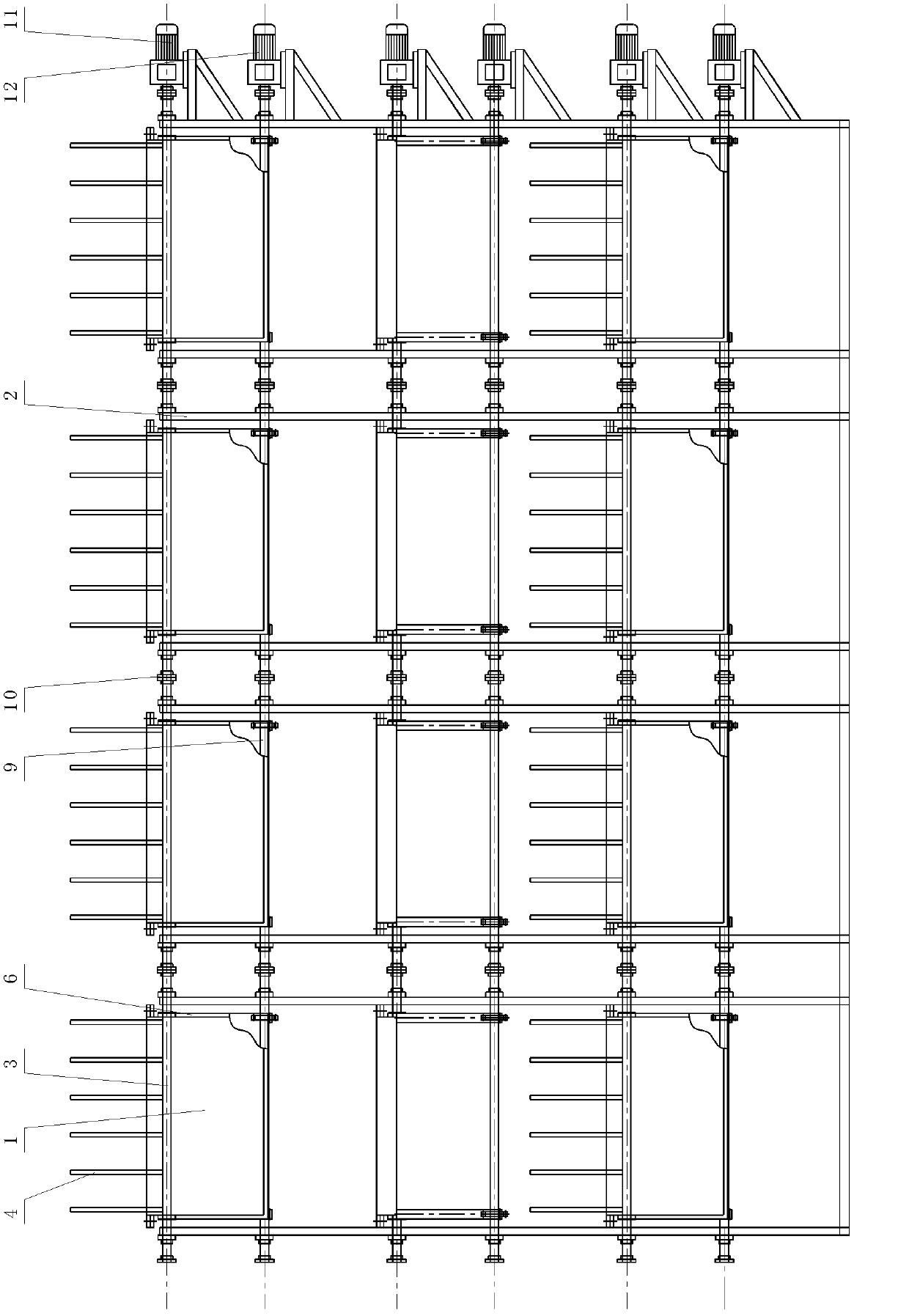

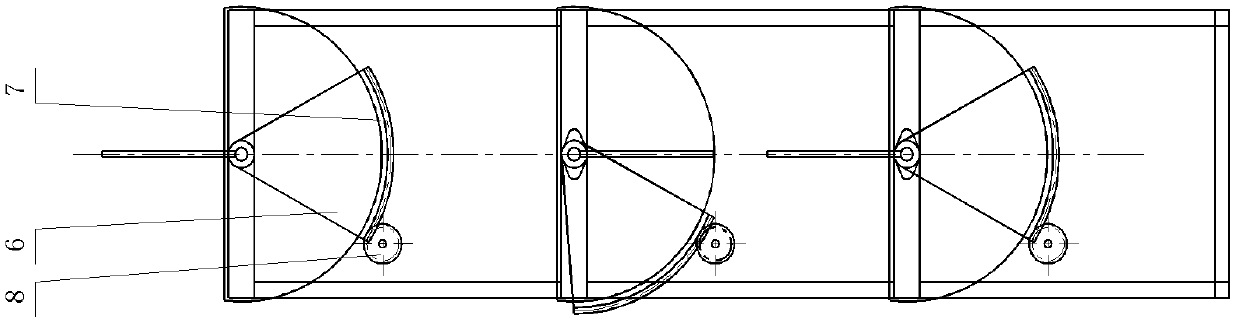

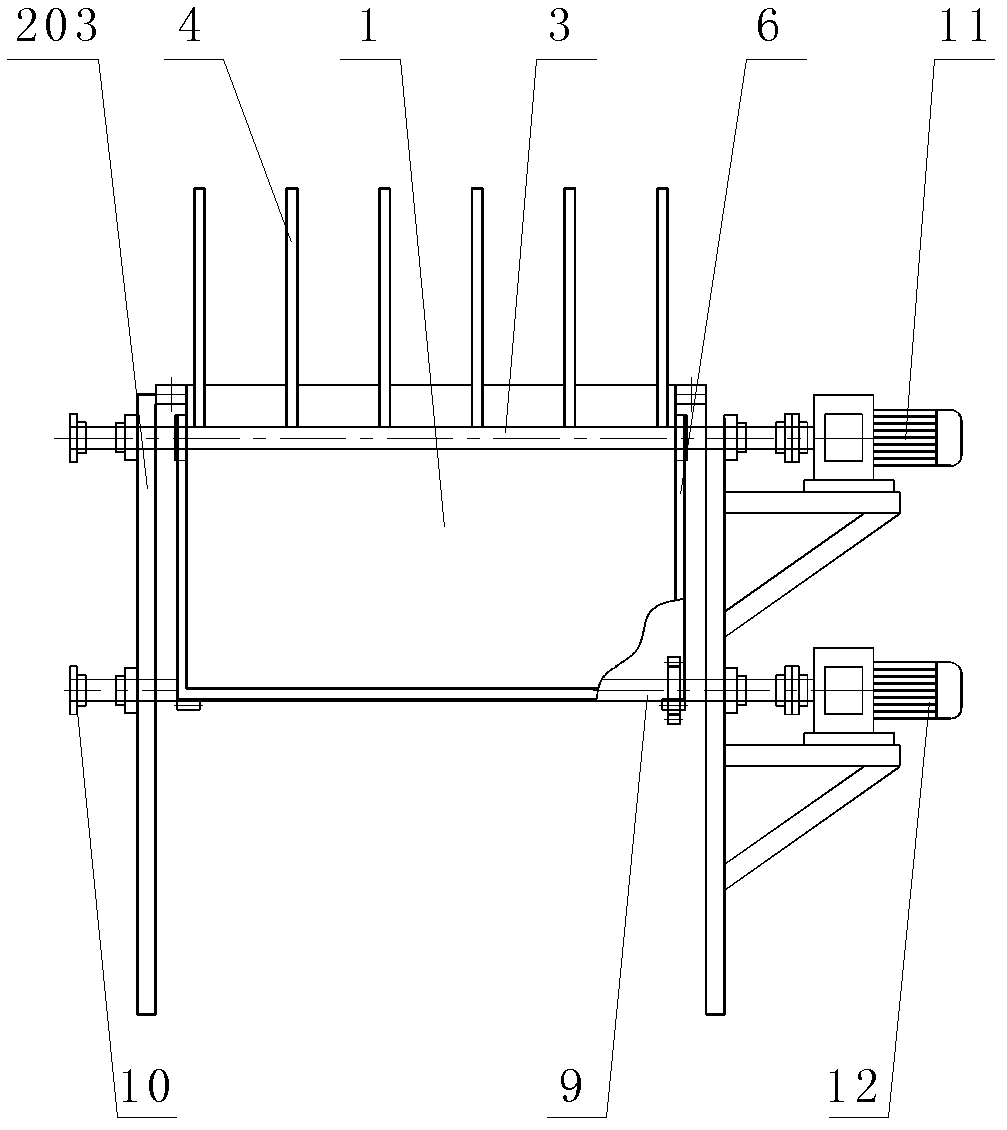

[0032] Figure 1~4 Among them, multiple rows of devices are arranged in parallel, and each device is arranged in a vertical and horizontal rectangular support 2, and the fermentation units are arranged in a matrix of 3 layers*4 columns. The support 2 includes a horizontal rectangular support base 201 resting on the ground, and the support base Positioning holes 202 are provided on the upper surface, and the four corners of a plurality of containers 1 of each row of fermentation units are fixed on four vertical positioning rods 203 , and the lower ends of the positioning rods 203 are screwed into the positioning holes 202 .

[0033] The semicircular fermentation container 1 of the fermentation unit is fixed on the support 2, the opening of the container 1 is upward, the axis is parallel to the length direction of the support 2, and a stirring shaft 3 is arranged along the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com