Man-machine interaction system of programmable transformer iron core lamination robot workstation

A transformer core and human-computer interaction technology, applied in the direction of inductance/transformer/magnet manufacturing, general control system, control/regulation system, etc., can solve the problems of high labor intensity and difficulty in ensuring the consistency of laminations, and achieve enhanced flexibility and adaptability, reduced latency, effects of multiple logic variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

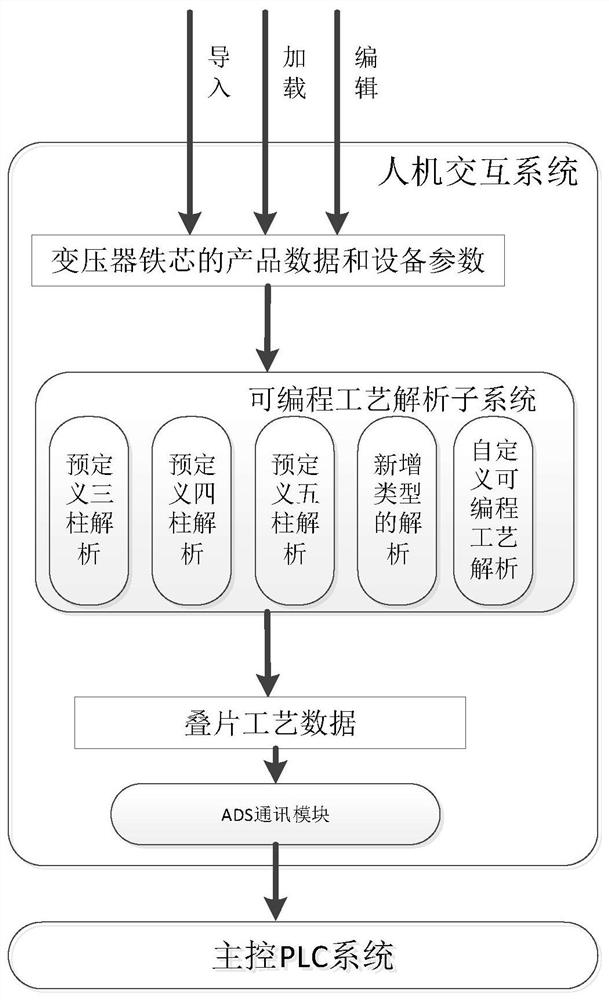

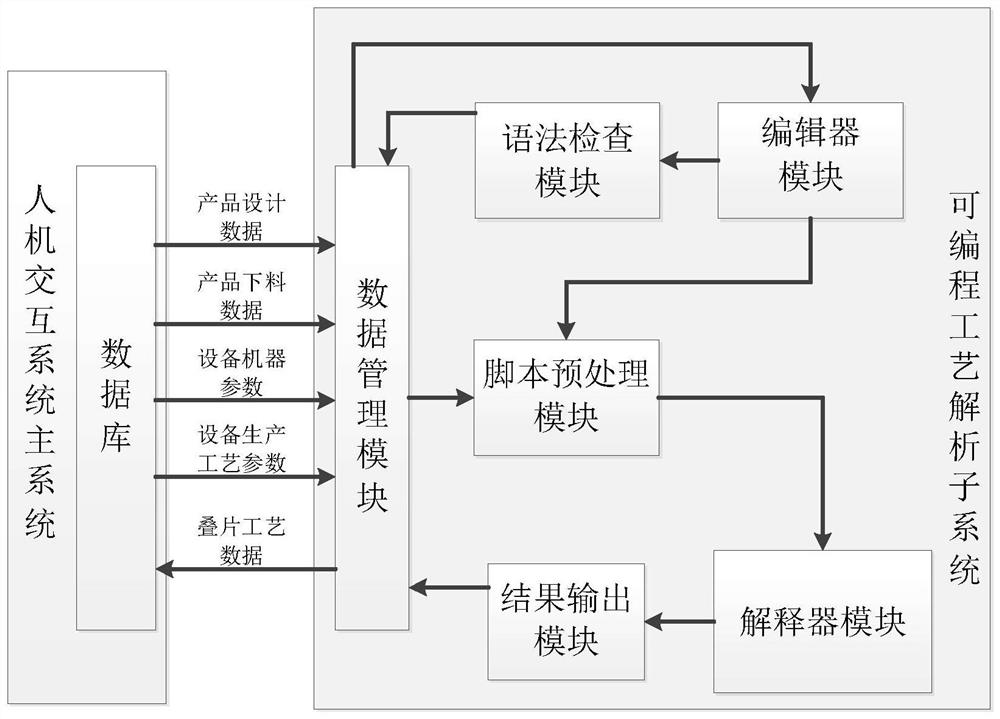

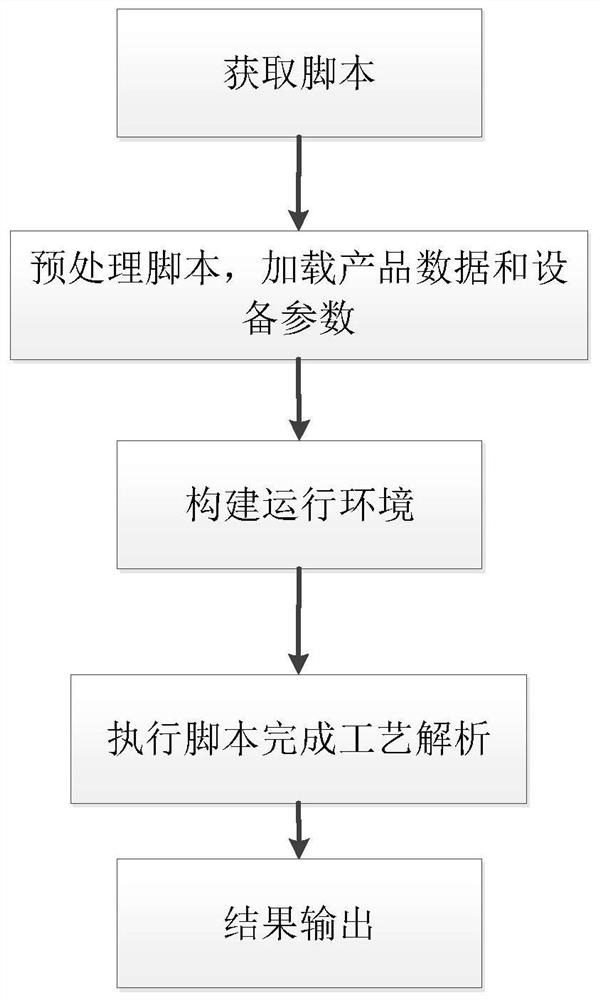

[0023] Such as figure 1 As shown, this embodiment provides a configurable transformer core lamination robot workstation human-computer interaction system, the system includes a human-computer interaction main system and a programmable process analysis subsystem; Languages such as C++ / C# are implemented, called the main system. The programmable process analysis subsystem is implemented through a scripting language such as Python and integrated into the main system. Such as figure 1 As shown, the main system of the human-computer interaction system receives the product data and equipment parameters of the transformer core through file import, database loading or interface editing; the programmable process analysis subsystem calls the product data and equipment parameters of the transformer core, Execute the corresponding script according to the product model in the product data to obtain the executable lamination process data of the equipment; the human-computer interaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com