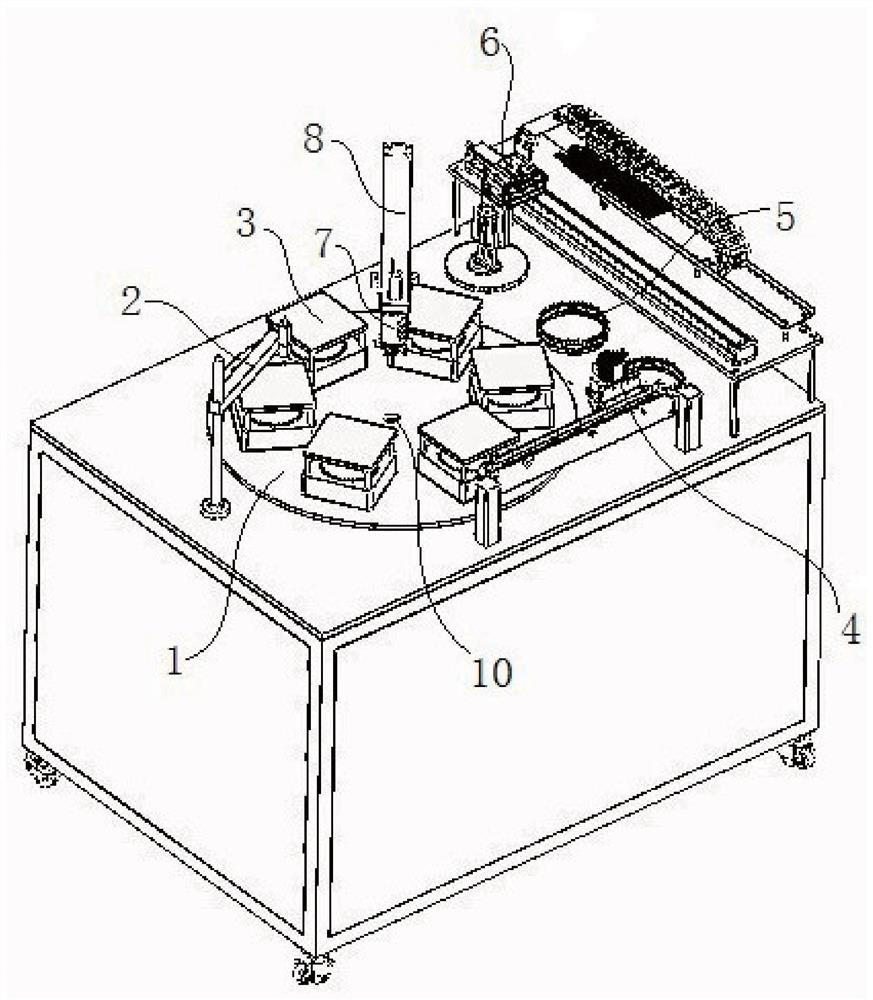

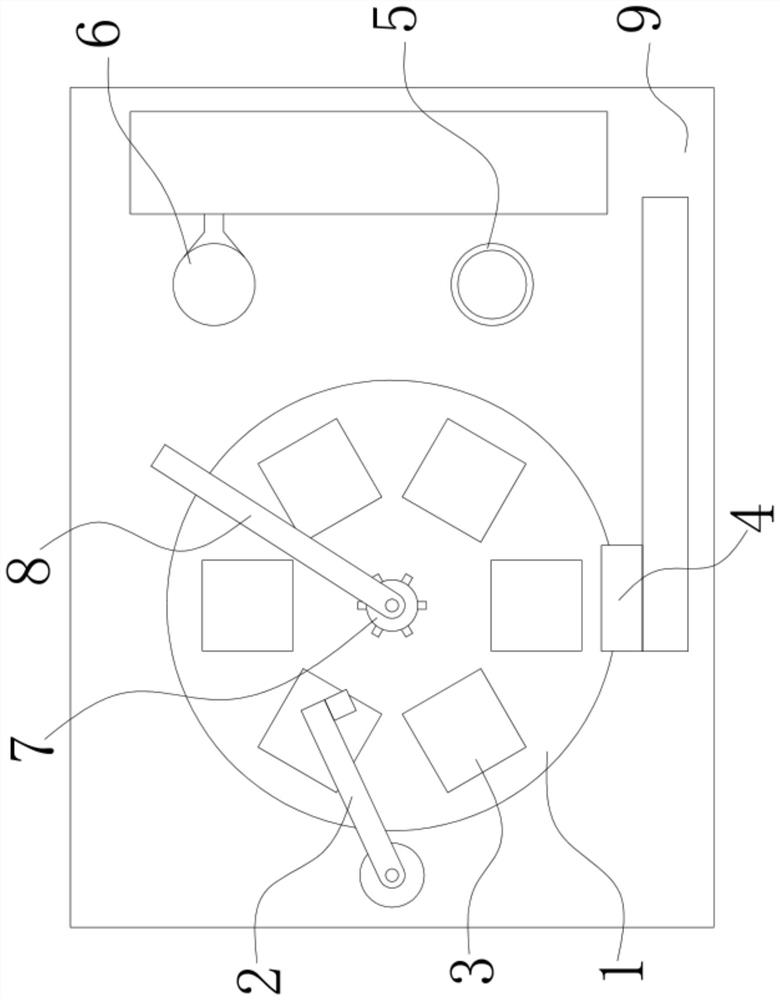

Rotating disc type mold overturning mechanism

A mold-turning mechanism and turntable technology, which is applied to conveyor objects, transportation and packaging, coating, etc., can solve the problems of large equipment renovation costs and increased travel, and achieve reduced equipment costs, fast and reliable action, and movement saving. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0028] In order to achieve the purpose of the present invention, a turntable type mold turning mechanism includes: a turntable station, including a turntable 1 arranged horizontally, and several stations 3 are arranged in an annular array on the upper surface of the turntable 1; a mold taking ring mechanism 6 is arranged horizontally On one side of the turntable 1, the mold taking ring mechanism 6 has at least a linear reciprocating translation degree of freedom along its own length; The length direction of the mold-taking mechanism 4 and the length direction of the mold-taking ring mechanism 6 are perpendicular to each other, and the motion track of the mold-taking ring mechanism 6 intersects with the motion track of the mold-taking mechanism 4; Directly above, the self-axis of the driven pipe 7 is vertically arranged, and the driven pipe 7 has a degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com