Wax mold automatic cleaning production line

An automatic cleaning and production line technology, applied in casting and molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of the cleanliness of the wax mold surface, the influence of the pulp quality, the re-contamination of the wax mold, and the high labor intensity. or cleaning effect, improve cleaning efficiency and cleaning effect, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

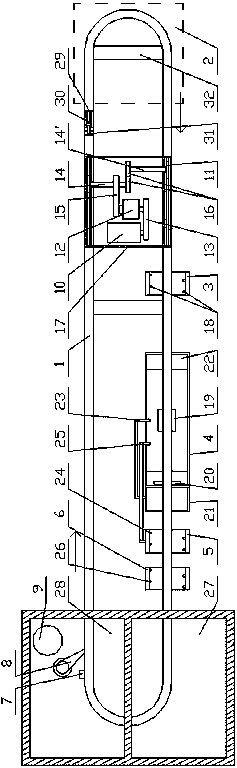

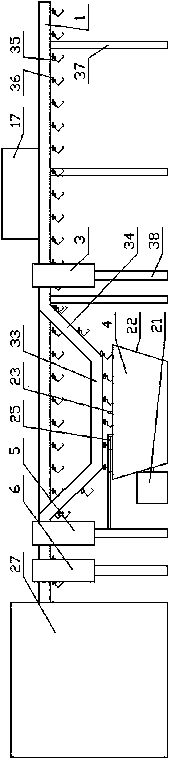

[0059] combine Figure 1~Figure 2 It can be seen that the present invention includes a circular track 1, a conveyor chain is arranged in the circular track 1, the conveyor chain moves along the circular track 1, and a plurality of hooks 35 are evenly distributed along the conveyor chain at the bottom of the conveyor chain. The transmission chain provides driving force through the driving device, and the driving device is arranged in the upper area between the circular tracks 1, one end of the circular track 1 is the feeding area 2, and the other end of the circular track 1 is the sizing area, so Said annular track 1 is located on the side conveyed from the feeding area 2 to the sizing area and passes through a pre-blowing device 3 , a cleaning device 4 , a spray washing device 5 and an air blowing device 6 in sequence.

[0060] The pre-blowing device 3, the spray washing device 5 and the blowing device 6 are all "U" shaped plate structures, and the inner sides of the two side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com