Turnover device for automatic and manual sorting equipment and application method of turnover device

A manual sorting and equipment technology, applied in sorting, motor vehicles, multi-axis trolleys, etc., can solve problems such as low efficiency and large workload, and achieve the effect of strong adaptability and convenient sorting operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

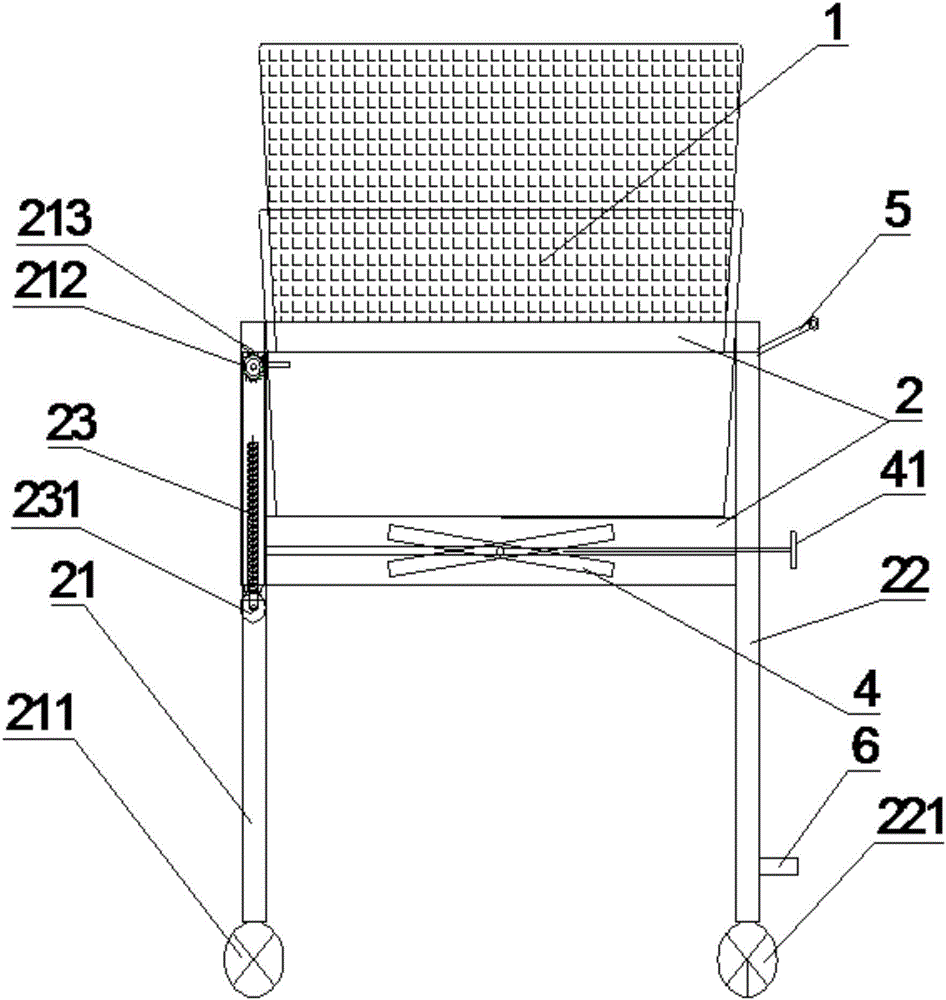

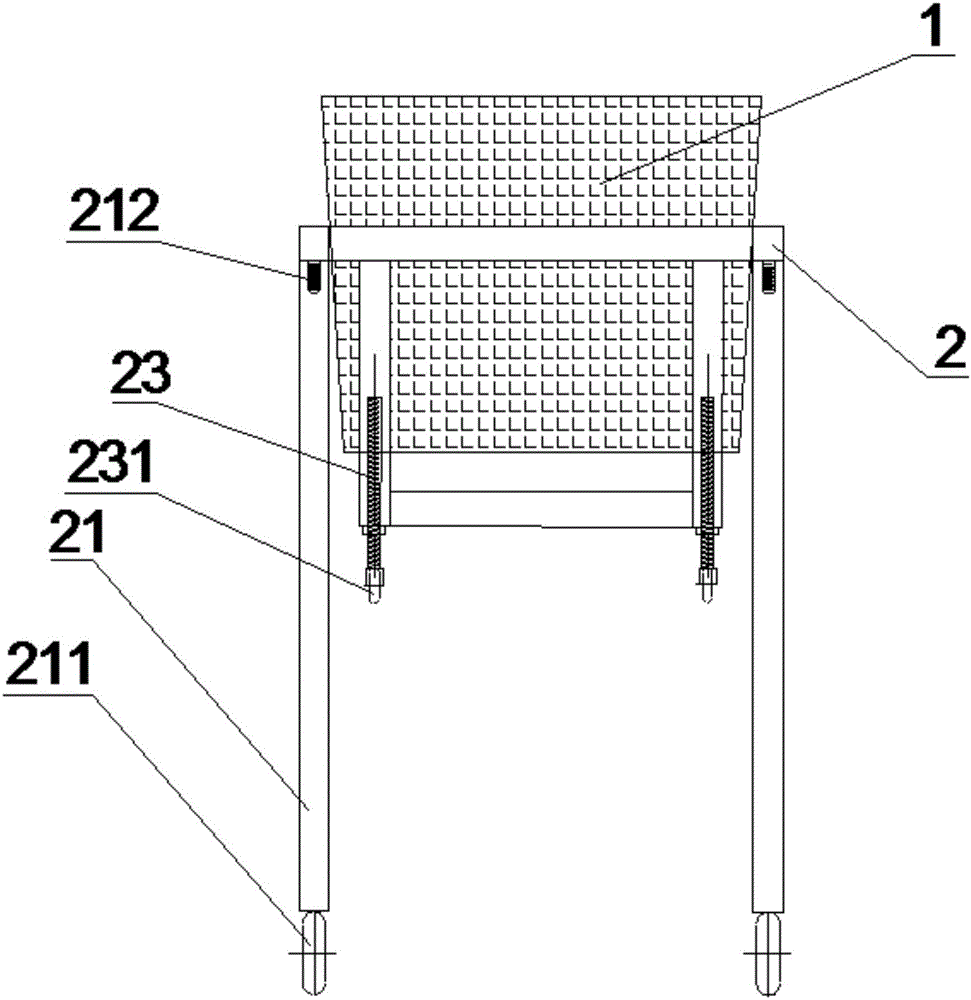

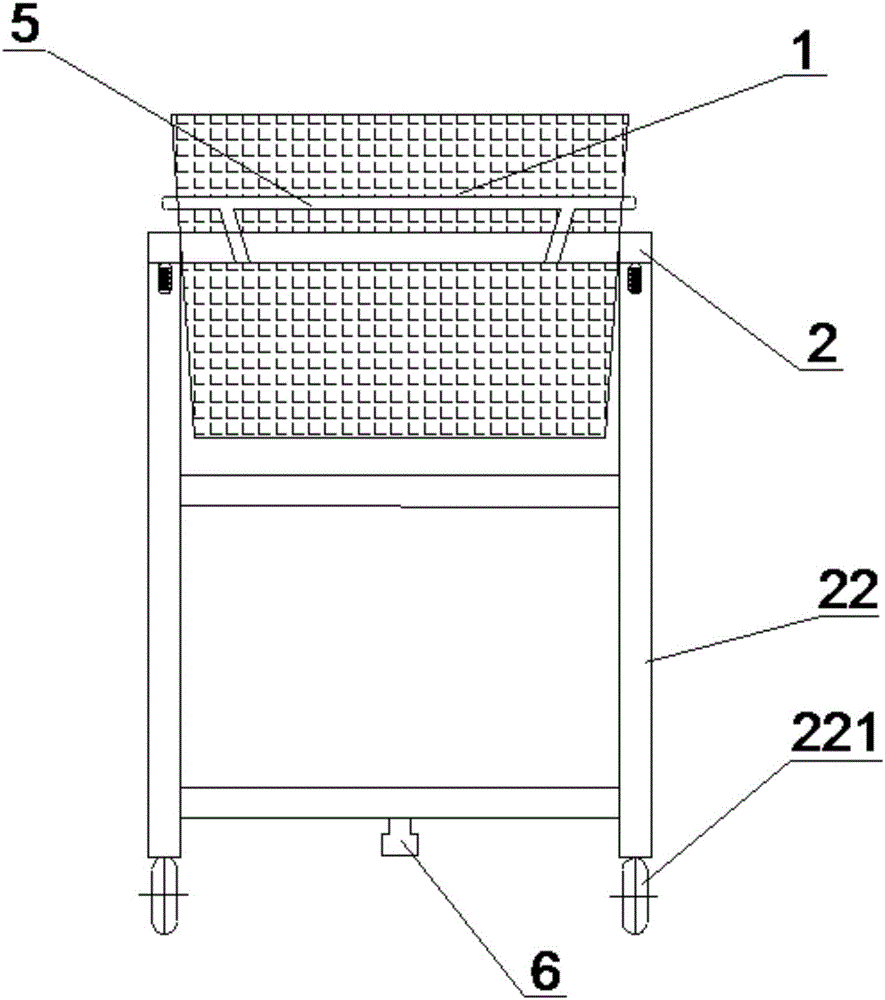

[0031] Such as figure 1 , figure 2 with image 3 As shown, a turnover device for automatic and manual sorting equipment is used for handling and transferring during the sorting process of logistics items, including a plastic frame 1 and a transfer vehicle, wherein the transfer vehicle includes a carrying frame 2 and a lifting mechanism, and the carrying vehicle The frame 2 is provided with a lifting mechanism, the four corners of the carrying frame 2 are respectively provided with supporting legs, and the bottoms of the two front legs 21 at the front side of the carrying frame 2 are respectively provided with swivel casters 211, which are located on the carrying frame 2. 2. The two rear legs 22 on the rear side are provided with castor wheels 221 with brakes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com