Polishing wheel device and automatic deburring machine with same

A technology of deburring machine and polishing wheel, which is applied to wheels with flexible working parts, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the problem of incomplete removal, low removal efficiency, etc. Deburring instability and other problems, to achieve the effect of reducing labor costs, improving work efficiency, superior deburring performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

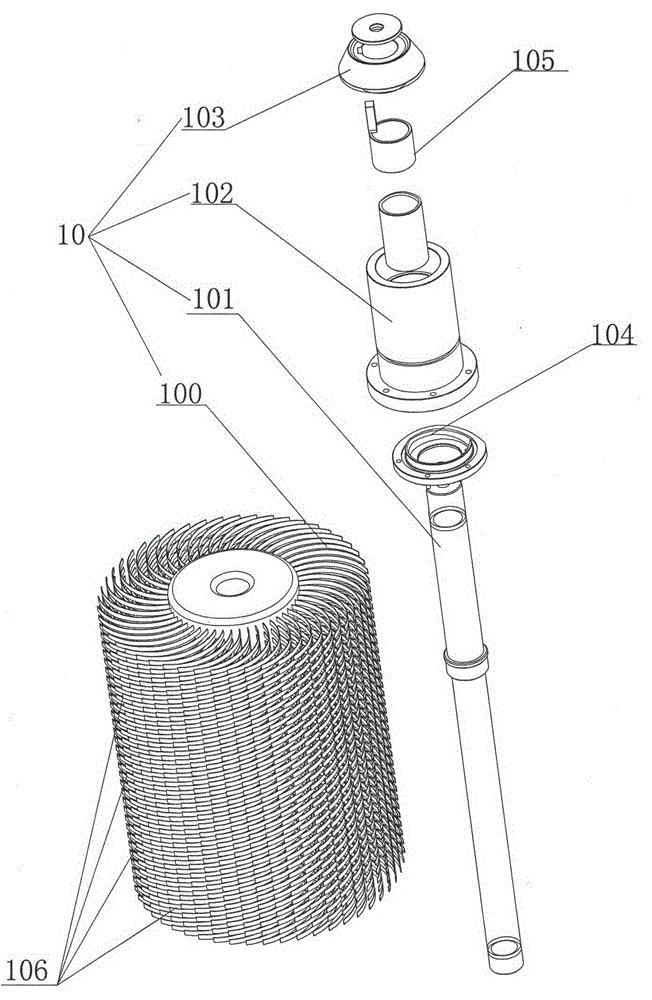

[0058] see figure 1 , the polishing wheel device provided by the present invention; comprising a polishing wheel 100, a polishing wheel shaft 101, a wheel shaft sleeve 102 and a gear washer 105; one end of the polishing wheel shaft 101 is sleeved in the polishing wheel 100, and the other end of the polishing wheel shaft 101 is sleeved in the wheel shaft sleeve 102, and the other end top of the polishing wheel shaft 101 is equipped with a small bevel gear 103, and the small bevel gear 103 is installed on the polishing wheel shaft 101 by a gear washer 105, and the polishing wheel 100 is a flexible polishing wheel. The polishing wheel 100 is covered with emery cloth strips 106. The sand grains on the emery cloth strips 106 include brown corundum, white corundum and silicon carbide. The emery cloth strips 106 are divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com