Cantilever steel beam system scaffold moving positioning pile and construction method

A mobile positioning and scaffolding technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problems of labor and time, save costs, improve construction efficiency and construction accuracy requirements, and ensure construction safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

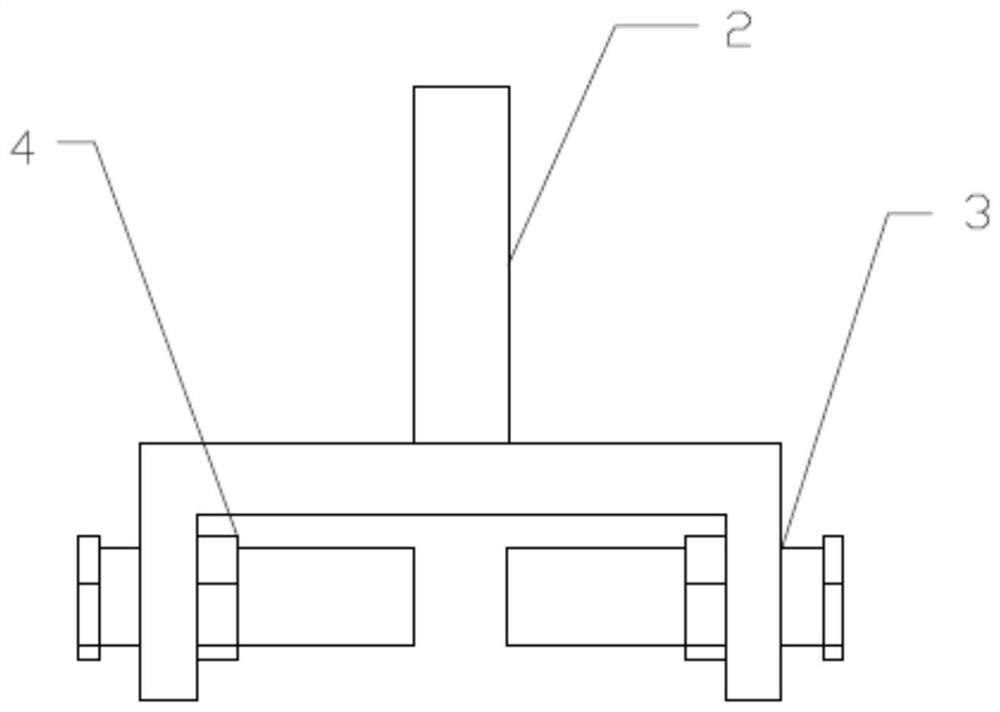

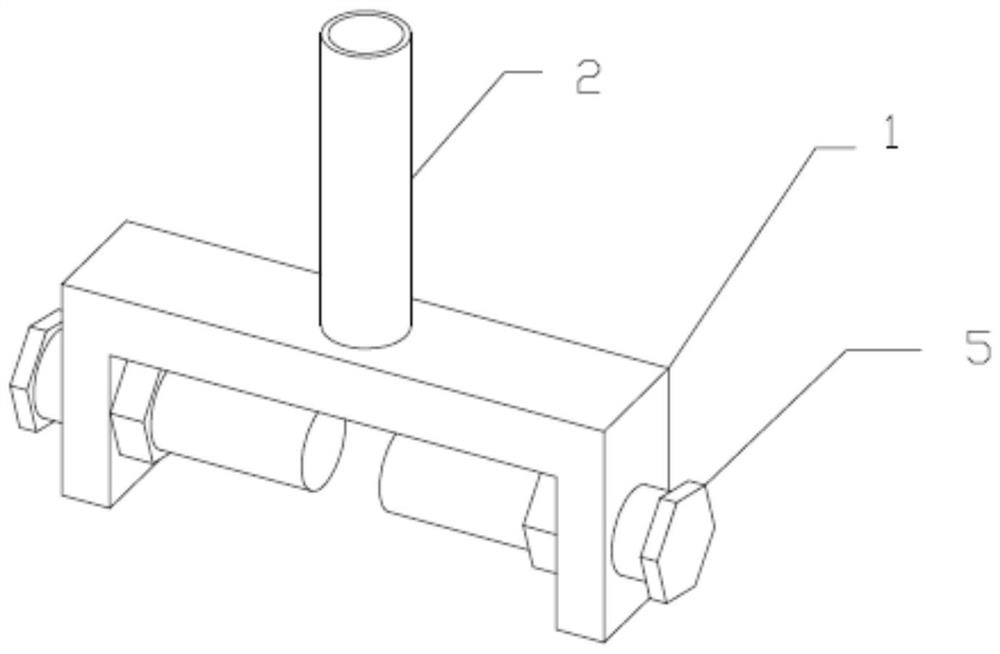

[0028] combined with figure 1 and 2 , a mobile positioning pile for scaffolding of a cantilevered steel beam system, comprising an inverted U-shaped base 1, a connecting pipe 2 is fixedly connected to the upper part of the base 1, bolt holes 3 are arranged on both sides of the base 1, and the central axes of the bolt holes 3 are collinear A nut 4 is fixedly connected to the inner surface of the base 1 and corresponding to the position of the bolt hole 3, and the inner diameter of the nut 4 is smaller than the inner diameter of the bolt hole 3; a bolt 5 is pierced in the bolt hole 3, and the bolt 5 and the nut 4 are screwed together ; The length of the bolt 5 is greater than half of the width of the base 1 .

[0029] The connecting pipe 2 is located at the center of the upper part of the base 1, and the connecting pipe 2 is fully welded on the base 1 along its circumferential direction.

[0030] The inner diameter of the bolt hole 3 is larger than the inner diameter of the nu...

Embodiment 2

[0032] In the present embodiment, the method of using the positioning piles in the first embodiment to carry out construction is proposed:

[0033] S1. Erection of cantilevered steel beams:

[0034] According to the requirements of the floor plan in the construction plan, the line is measured and set out, and the anchor rings are drilled and pre-embedded at the corresponding positions of the steel beams. The distance between the anchor rings is the same as the content of the plan; Ensure that the tightening torque of the nut at the anchorage end meets the requirements of the plan, the distance between the cantilevered steel beam and the anchor ring has been plugged tightly with wooden squares, and the next step can only be carried out after the construction of the cantilevered steel beam has passed the acceptance;

[0035] S2. Place the positioning pile:

[0036] Loosen the bolts on both sides of the positioning pile in advance, and then insert the positioning pile from the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com