A support structure that can realize cast-in-place support structure with less support for concrete box girder of elevated approach bridge without platform

A technology with support structure and no platform, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc. It can solve the problems of many structural measures, high risks, and complicated installation and dismantling, so as to reduce construction difficulty, low cost, and save steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following non-limiting examples illustrate the invention.

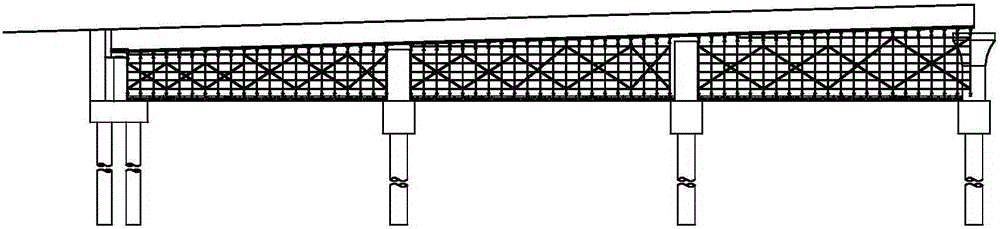

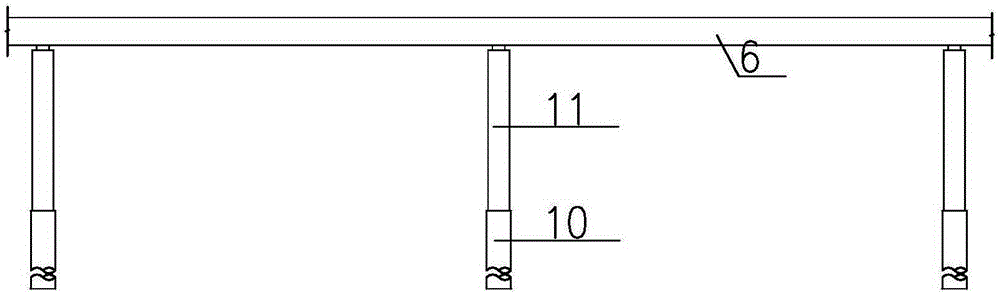

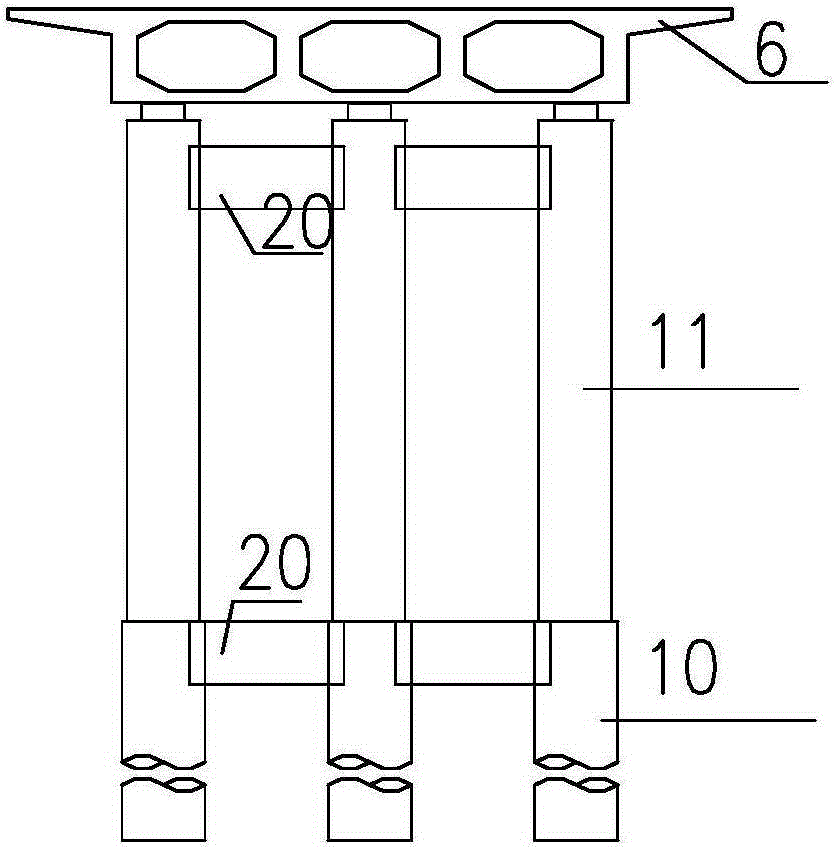

[0053] Such as Figures 1 to 22 As shown, a support structure that can realize the cast-in-place support structure of the concrete box girder of the elevated approach bridge without caps (such as figure 2 , 3 As shown, taking the elevated approach bridge with a span of 28m and a clear space under the bridge of 18m as an example), such as Figure 4 , 5 , 6, including supports for box girder cast-in-situ construction, box girder 6 is supported by cast-in-situ piles 10 and pier body 11 directly supported on it, and supports include horizontal joints 13 between rows arranged at the middle span of box girder 6 The two rows of connected middle columns 7 are symmetrically arranged in pairs on the side span columns 8 on both sides of each pier body 11, such as Figure 4 As shown, the side-span columns 8 are symmetrically arranged on both sides of the pier body 11. The trusses 15 and their connecting braces 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com