Four-station industrial scene motion control application training practice platform

A motion control, four-station technology, applied in the direction of comprehensive factory control, educational equipment, transportation and packaging, etc., can solve the problems of specificity, lack of professionalism, insufficient teaching and display functions, shortage of technical personnel, etc., and achieve improved storage effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, the content of the present invention is described in further detail:

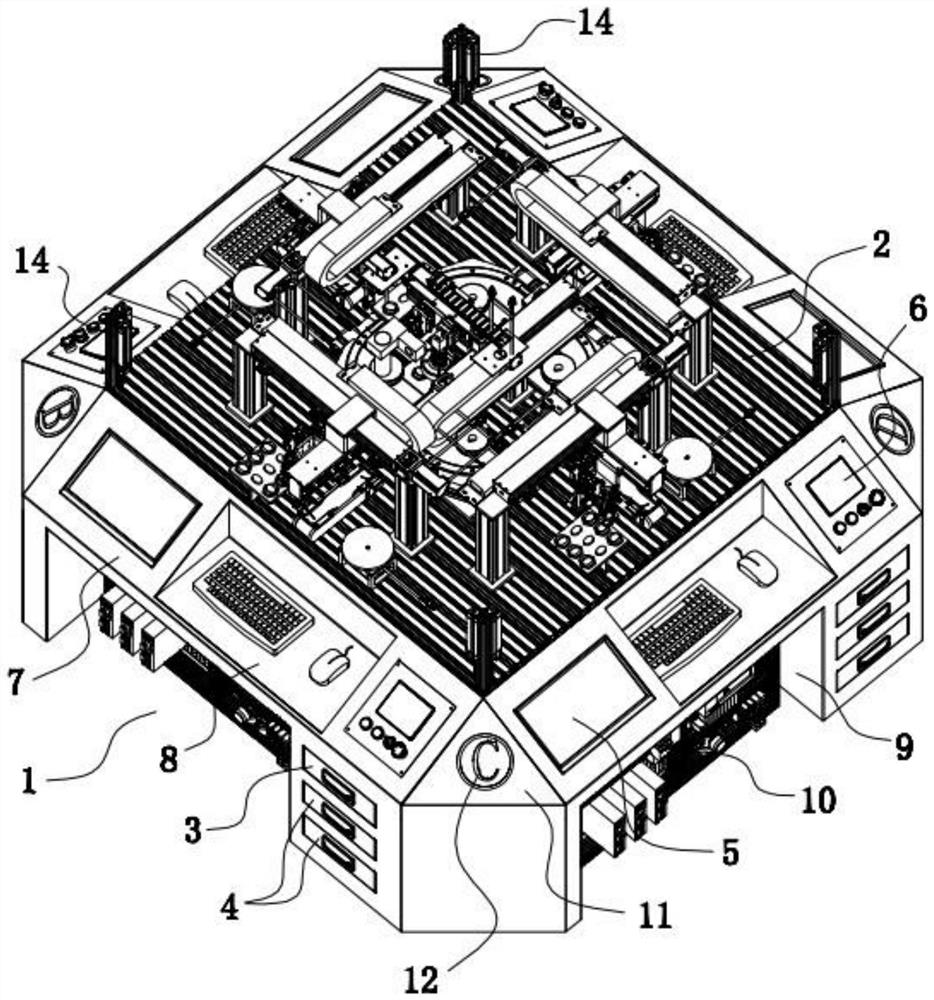

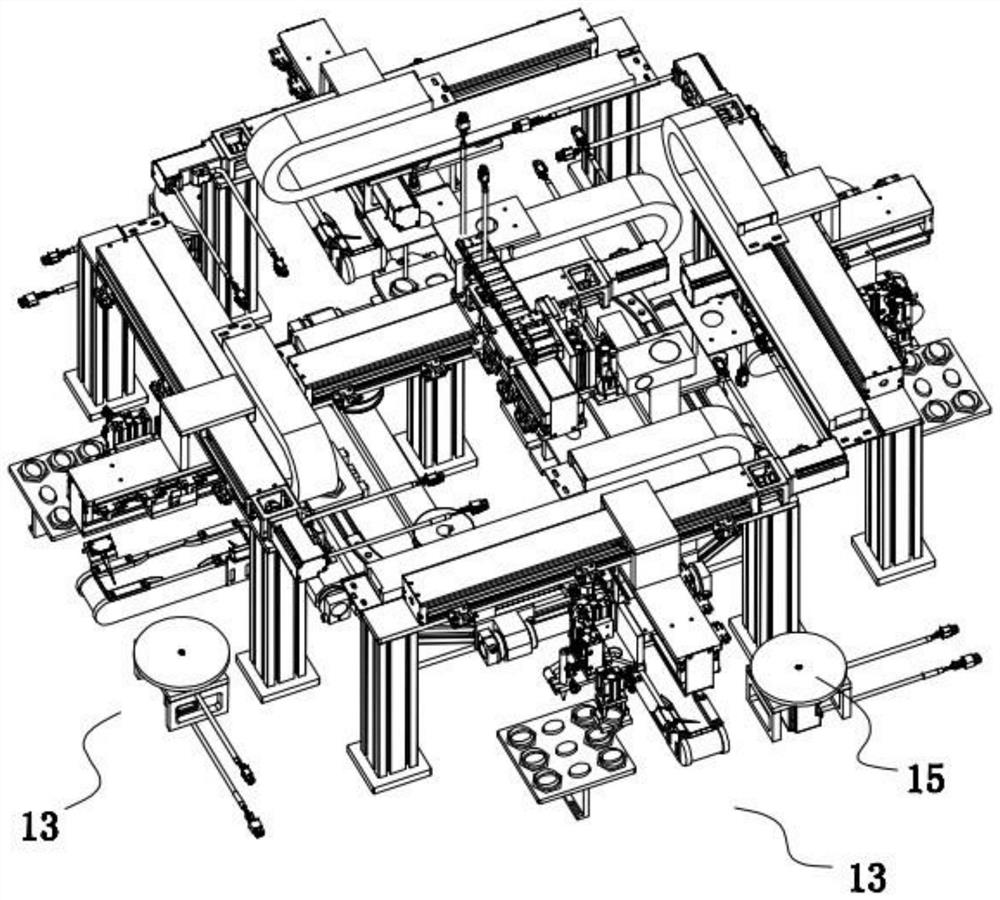

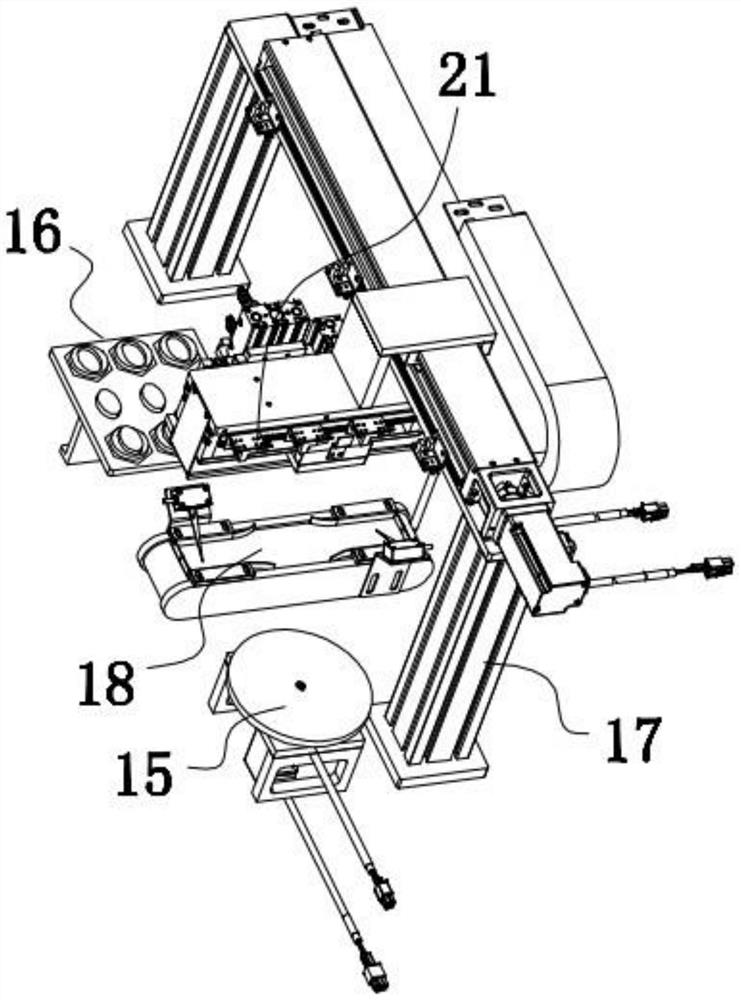

[0037]In order to achieve the purpose of the present invention, a four-station industrial scene motion control application training practice platform includes: a table body structure, the edges constitute a total of four control tables 1, and the adjacent control tables 1 are placed vertically to each other; Mechanism, a workbench is arranged between the tops of the four control tables 1, and a scene simulation mechanism is arranged on the workbench; the scene simulation mechanism includes a central turnover mechanism group 23, four side turnover mechanism groups 13; four side turnover mechanism groups The mechanism group 13 is arranged in a circular array, and the middle turnover mechanism group 23 and the four side turnover mechanism groups 13 each include a two-axis manipulator; the side turnover mechanism group 13 also has a rotating tray 15 and a lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com