High-precision tooth dividing machine

A gear dividing machine and high-precision technology, which is applied in the tool manufacturing, feeding device, and manufacturing tool of the sawing machine device, can solve the problems of low degree of automation, low positioning accuracy and positioning efficiency, and asymmetric left and right teeth. High degree of automation, compact structure, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

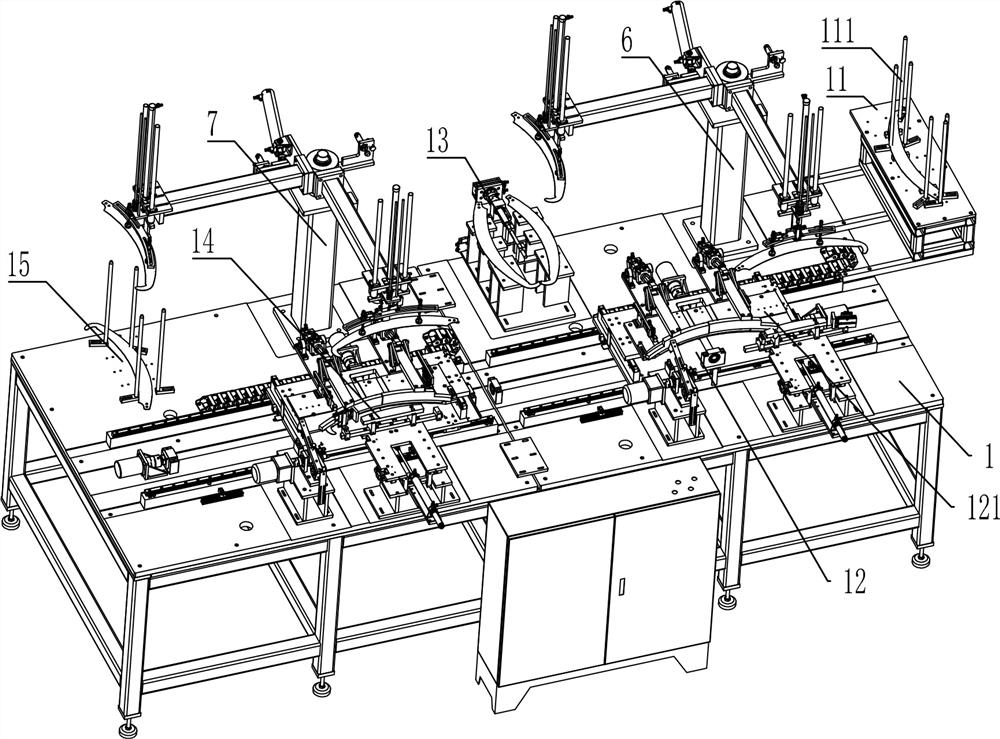

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as Figure 1-11 As shown, a high-precision gear dividing machine includes a workbench 1, and the workbench 1 is provided with a loading station 11, a gear dividing station 12, a turning station 13, a gear dividing station 2 14 and a blanking station. Station 15.

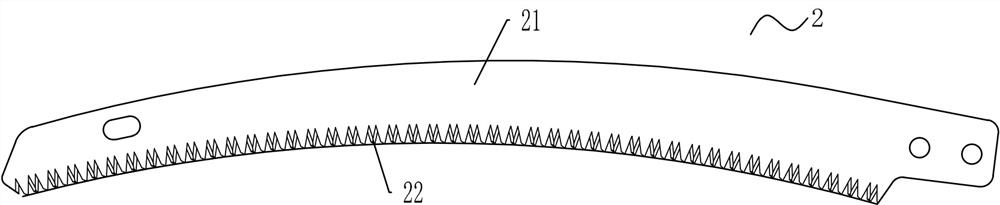

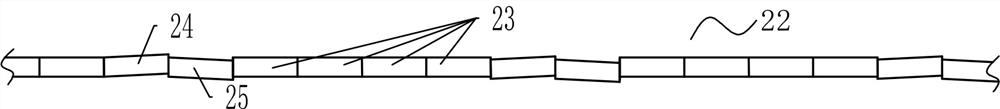

[0037] Here, for the convenience of description, the length direction of the band saw blade 2 is the X-axis direction, the width direction of the band saw blade 2 is the Y-axis direction, and the thickness direction of the band saw blade 2 is the Z-axis direction. 22 are curved saw structures with radians, and of course the gear splitter is also suitable for straight saw-like band saw blades 2 .

[0038]The loading station 11 is fixedly arranged on the right end of the workbench 1, and the unloading station 15 is fixedly arranged on the left end of the workbench 1. The feeding station 11 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com