Transfer cart with crankshafts

A turnover car and crankshaft technology, which is applied to multi-axis trolleys, trolleys, motor vehicles, etc., can solve the problems of waste of handling time, low turnover efficiency, and increased handling costs, and achieve reasonable structure, low handling costs and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

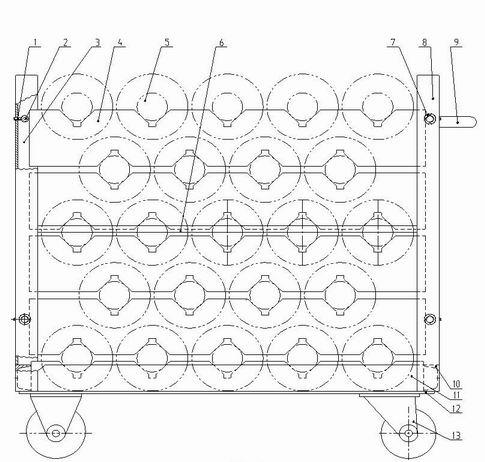

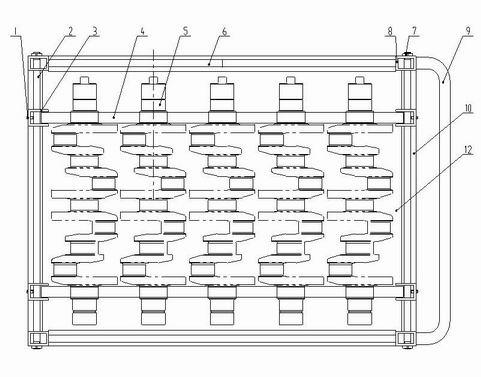

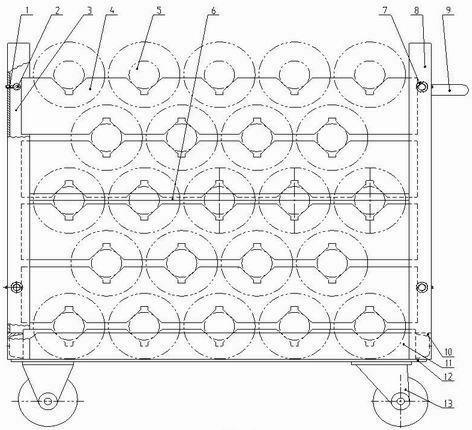

[0017] From figure 1 , figure 2 As can be seen in the figure, a crankshaft turnover vehicle is provided with a base plate 12 and a wheel set 13, and the four corners below the base plate 12 are welded and fixed to the upper plane of the wheel set 13. The specific composition and structure of the wheel set 13 belongs to the prior art and will not be repeated. .

[0018] Four uprights 8 are vertically welded on the four corners of the bottom plate 12 of the present invention, including two front uprights and two rear uprights. Around the outer surface of the lower end of the column 8 and around the base plate 12 , a frame 10 is welded on the base plate 12 . Column 8 is processed by square steel pipe, and frame 10 is processed by channel steel. Between the two front columns and between the two rear columns, two horizontally arranged guide connecting rods 2 are respectively arranged up and down, and an intermediate connecting rod 6 is arranged between the front and rear column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com