Automatic production line of colored contact lenses and method thereof

An automatic production method and automatic production line technology, which can be applied to other household appliances, optical components, household appliances, etc., can solve the problems of bulky equipment, different degrees of equipment automation, and high prices, so as to achieve reasonable layout and fully automated production , the effect of reducing turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

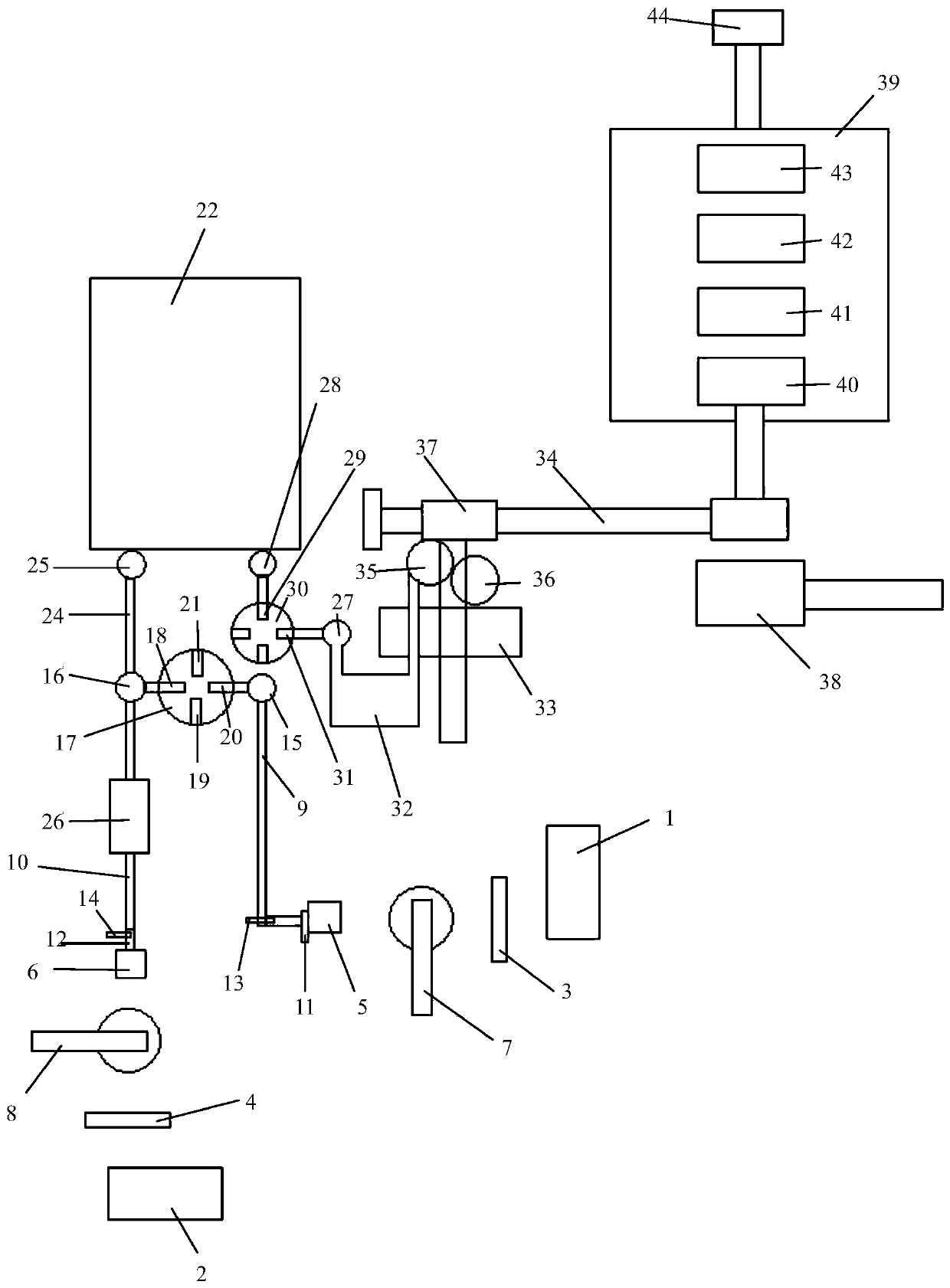

[0030] An automatic production line for color contact lenses. The production line includes: an upper mold injection molding machine 1, a lower mold injection molding machine 2. There is a first manipulator 3 beside the upper mold injection molding machine, and the first manipulator is used for injection from the upper mold. The machine clamps the connected upper mold after injection molding. There is also a second manipulator 4 beside the lower mold injection molding machine. The second manipulator is used to clamp the combined lower mold from the lower mold injection machine. ; Opposite to the first manipulator is the upper die cutting disc 5, between the first manipulator and the upper die cutting plate is an upper die transfer device 7, and opposite to the second manipulator is the lower die cutting disc 6, the first There is a lower mold transfer device 8 between the second manipulator and the lower mold cutting disc; the upper mold cutting disc is connected to the upper mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com