Light combined hanging box with recyclable baseplate steels and construction technology thereof

A bottom plate and hanging box technology, which is applied in caissons, infrastructure engineering, construction, etc., can solve the problems of increasing the rated lifting capacity of hoisting equipment and hoisting difficulty, increasing the construction period and labor costs, and the self-heaviness of reinforced concrete bottom slabs. The effect of rated lifting capacity, reducing the difficulty of hoisting and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

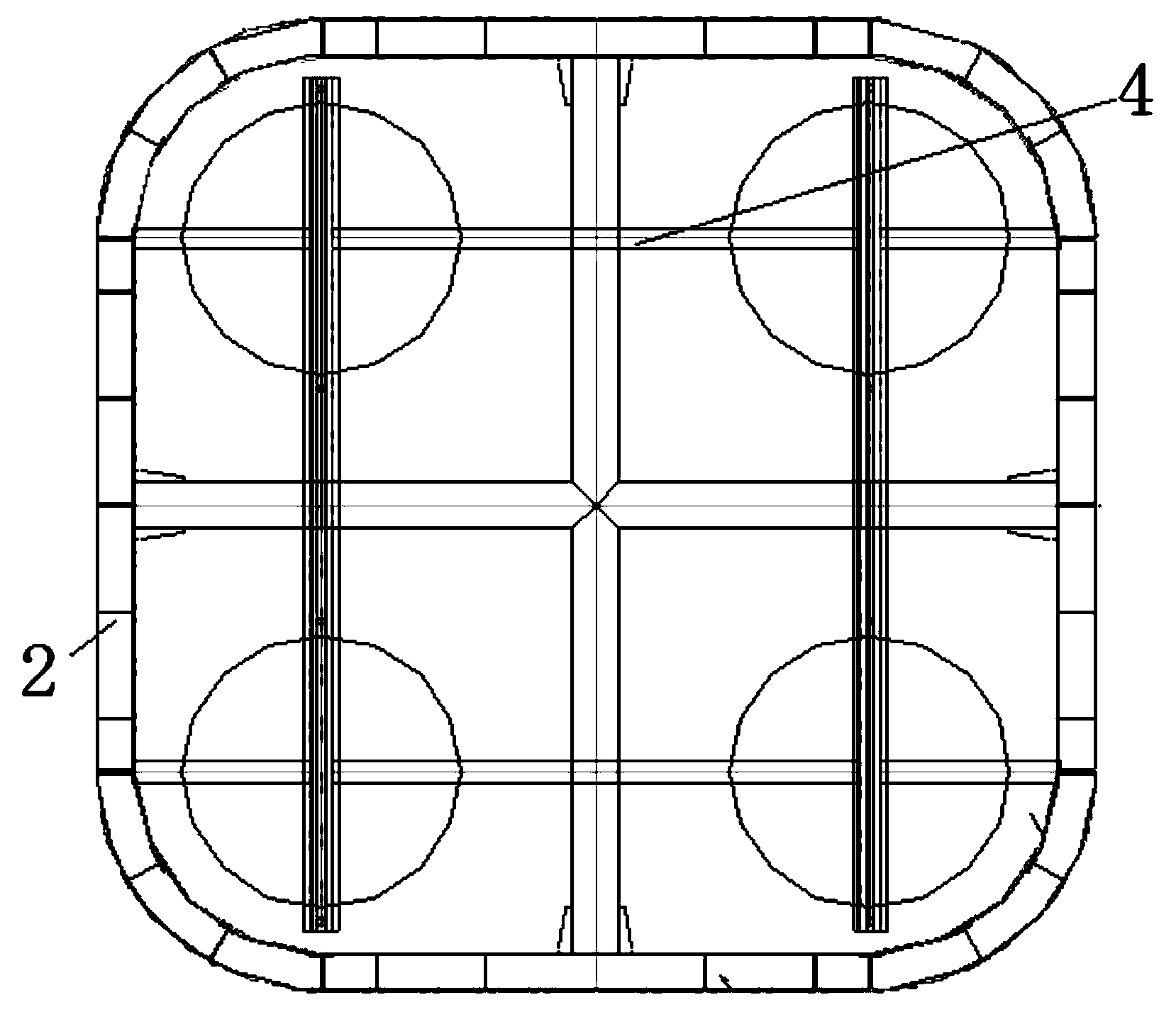

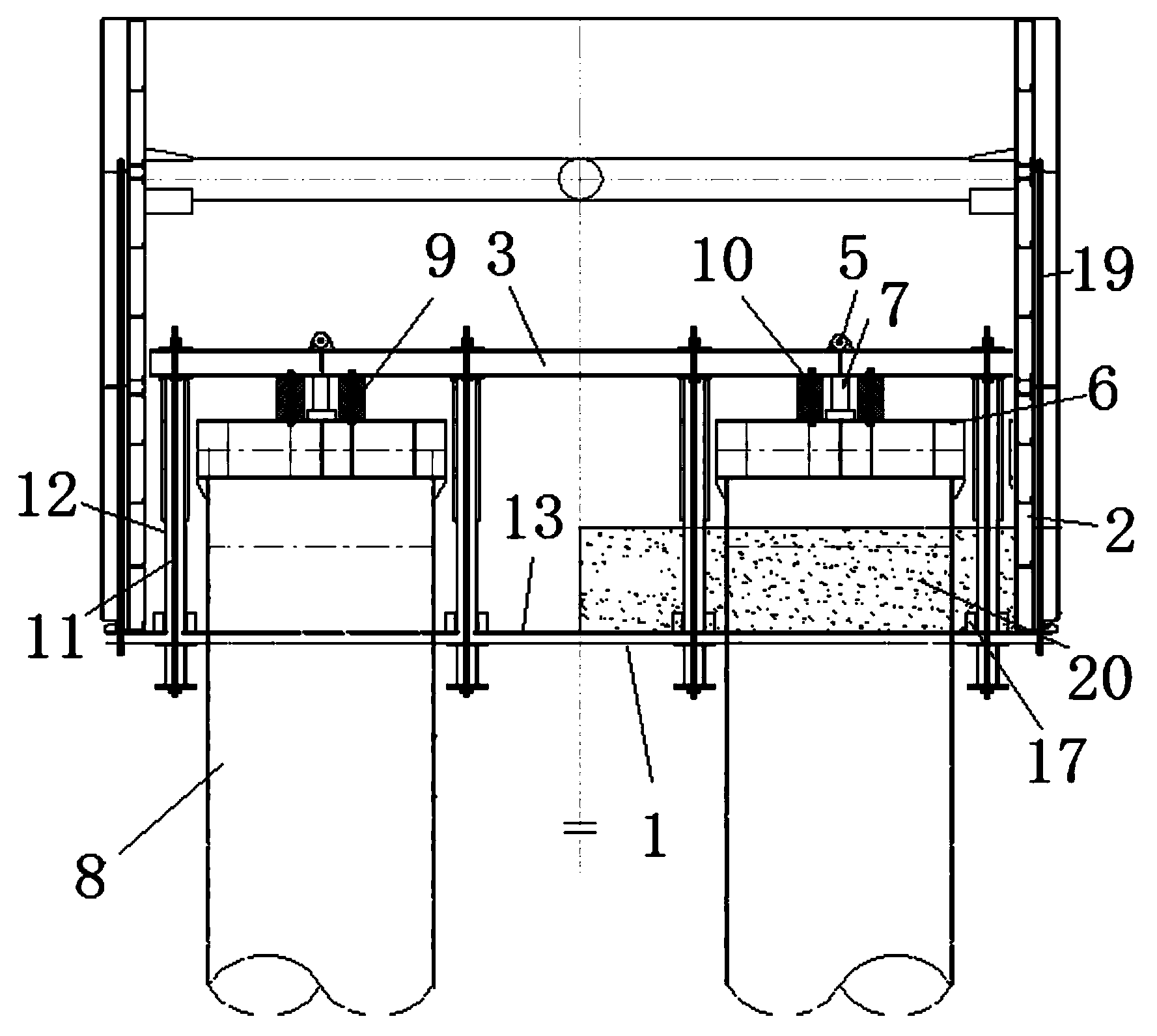

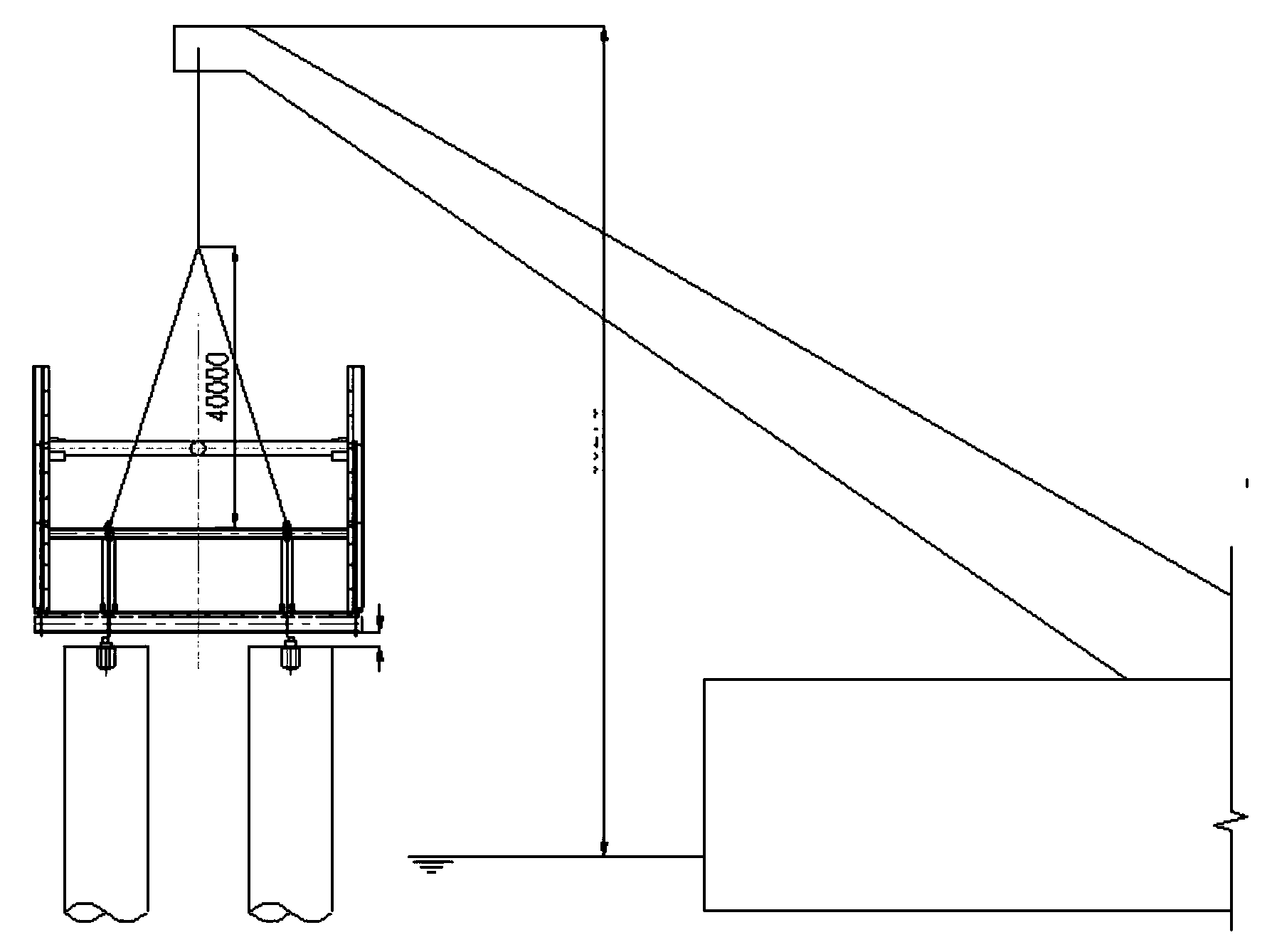

[0042] Such as Figure 1 ~ Figure 2 Shown is a light-duty combined suspension box with recyclable bottom plate steel, including a bottom plate 1, four walls 2, cantilever beams 3, and a laterally stable support beam 4 connected between the cantilever beams 3 and the wall body 2. The wall bodies 2 are connected by a support frame. The upper end surface of the cantilever beam 3 is provided with lifting lugs 5 , and the bottom of the cantilever beam 3 is provided with a jack resting beam 6 . The space is connected by supporting columns 11, and a jack 7 is arranged between the cantilever beam 3 and the jack shelving beam 6, and the lower end of the jack shelving beam 6 is connected with the top of the steel casing 8. One end of the jack 7 rests on the lower end face of the cantilever beam 3, and the other end rests on the jack shelving beam 6. The side of the jack 7 is provided with a cushion block 9 and an anti-floating bolt 10 placed between the jack shelving beam 6 and the can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com