Patents

Literature

162 results about "Pallet jack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

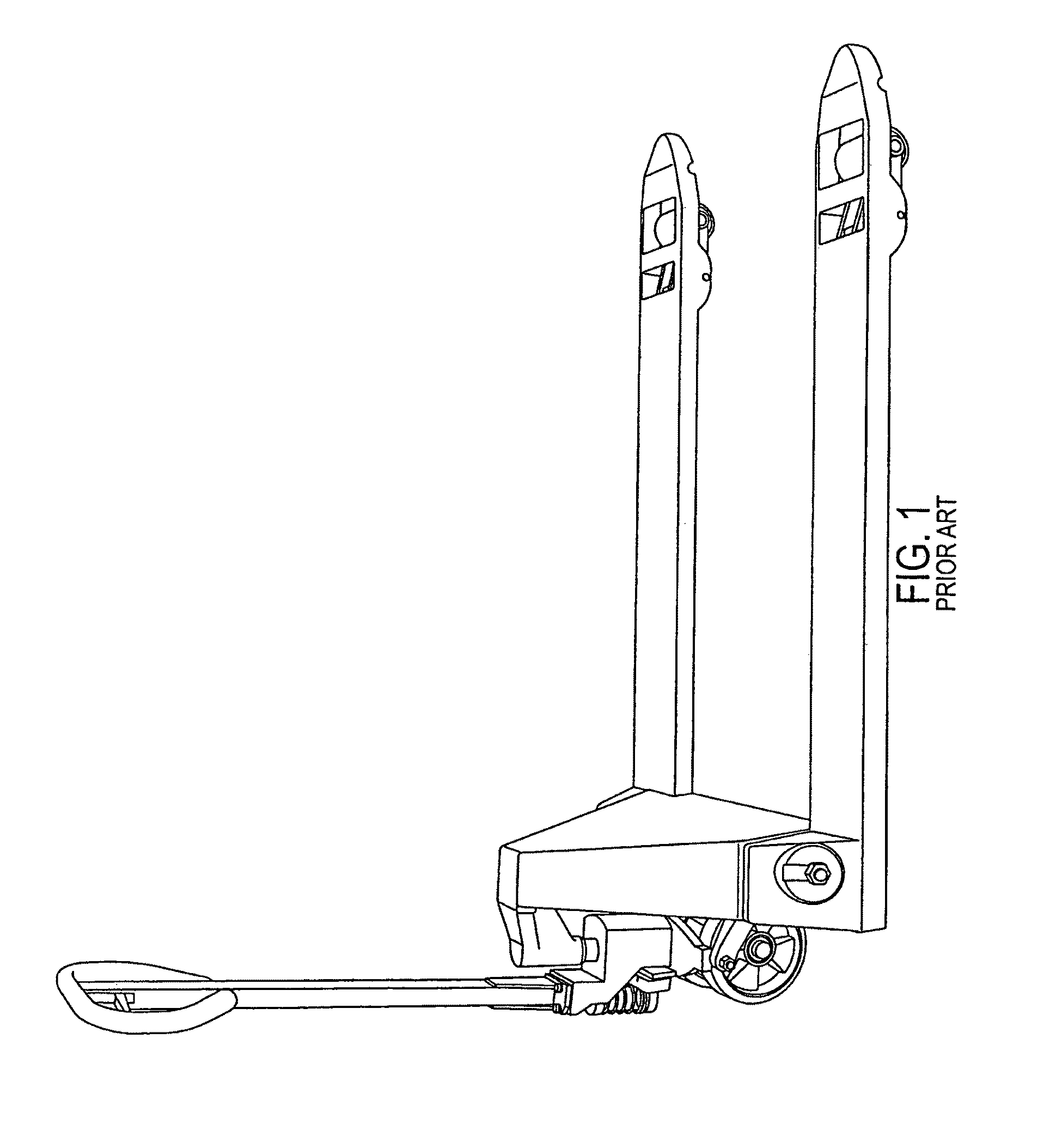

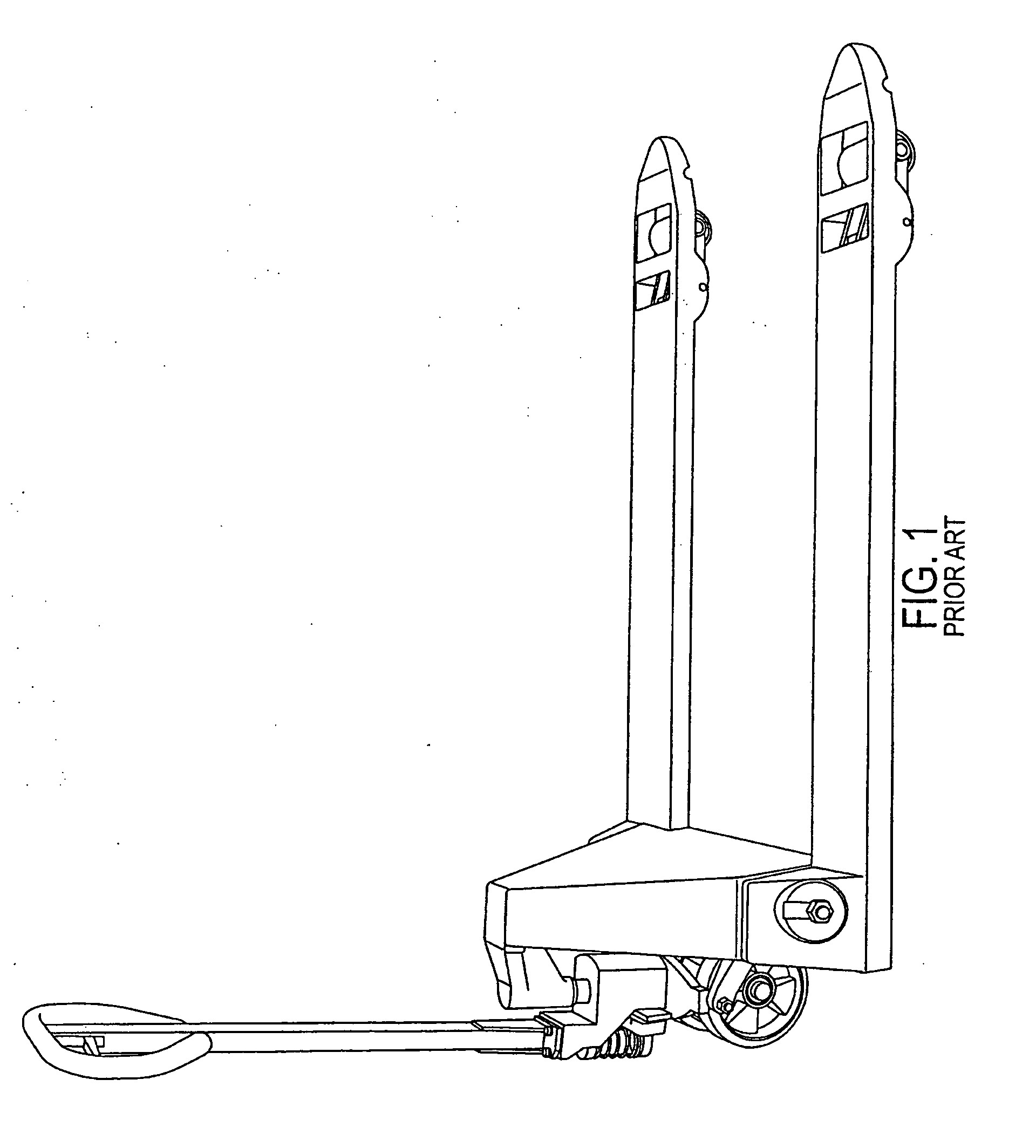

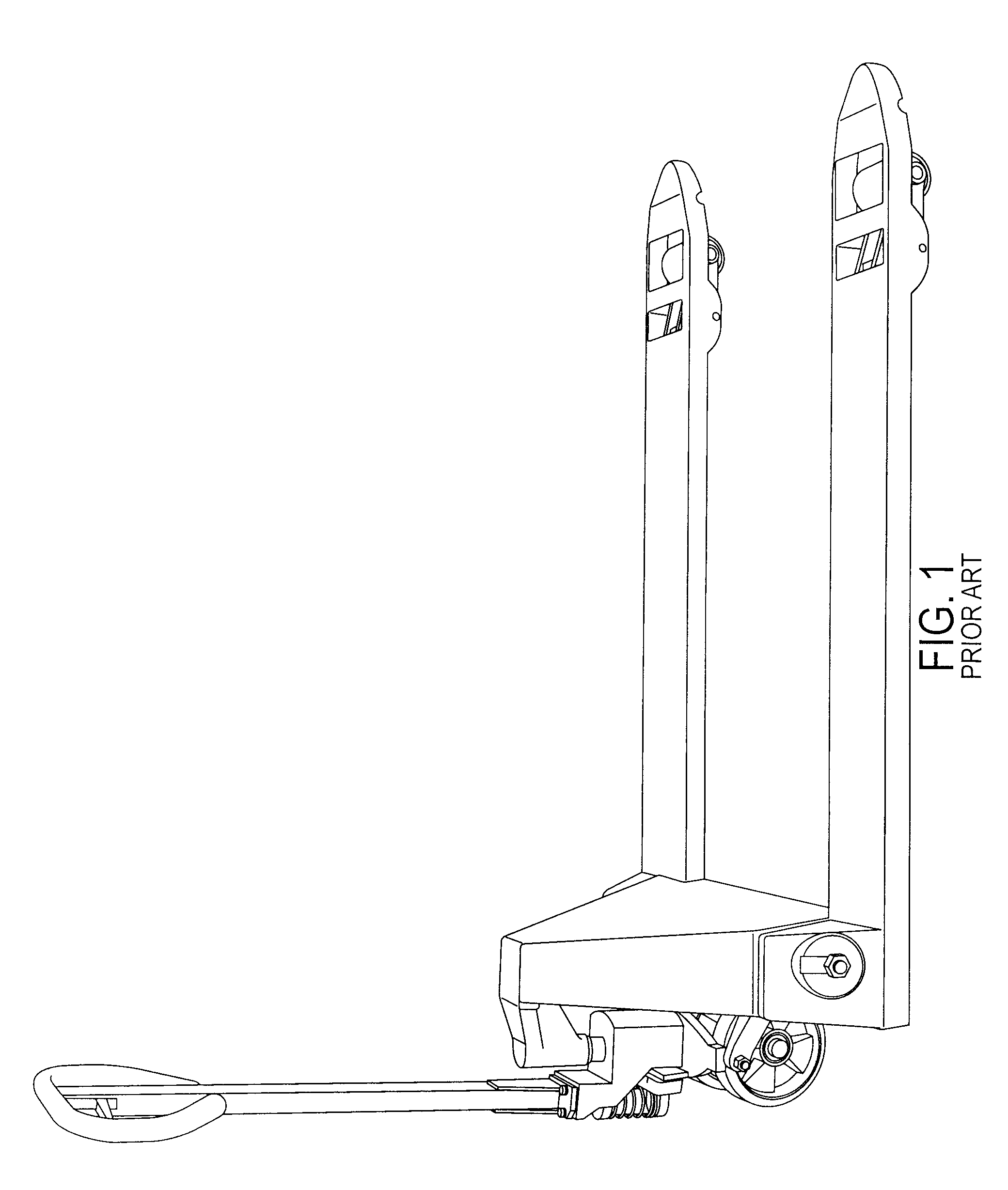

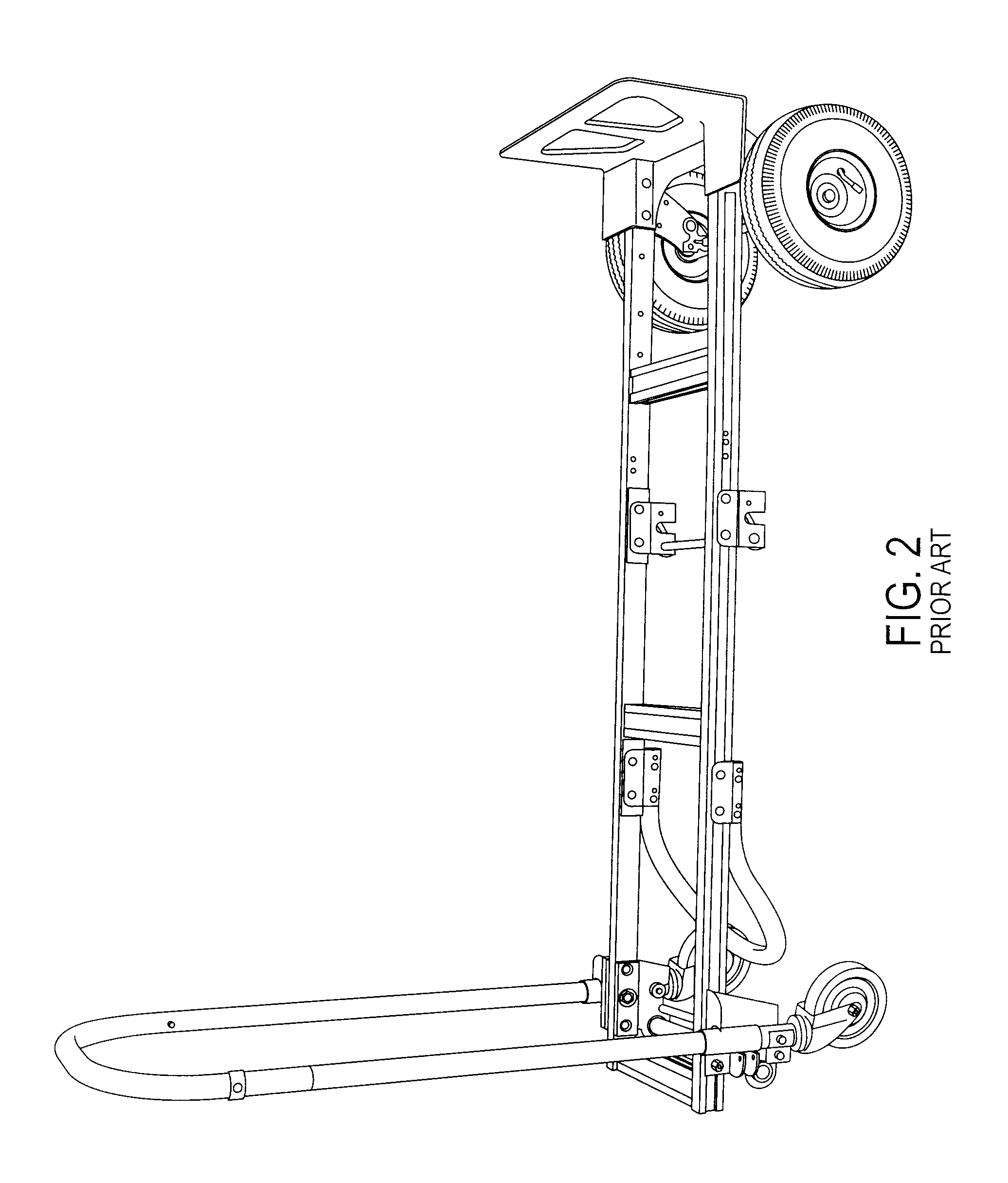

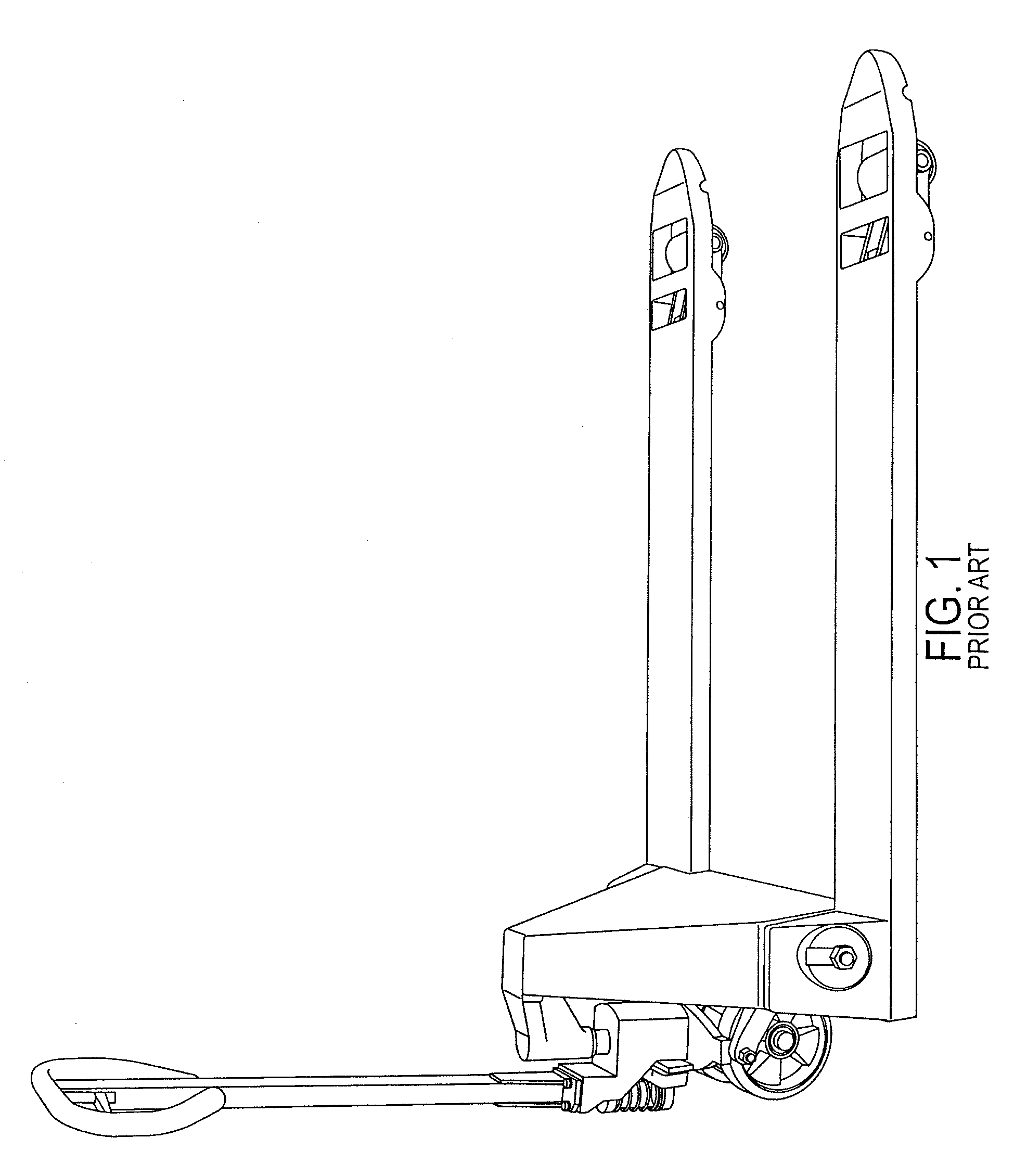

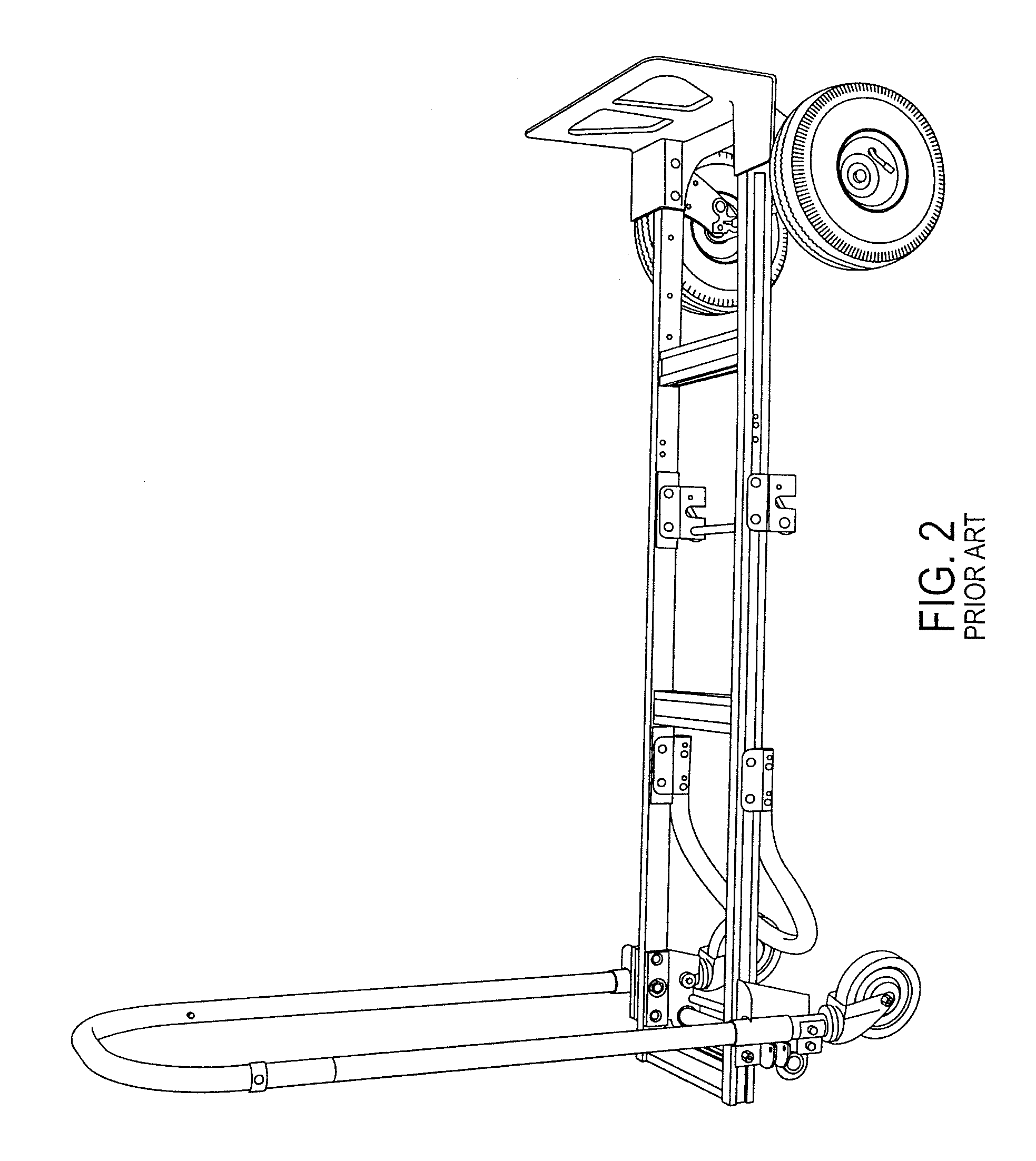

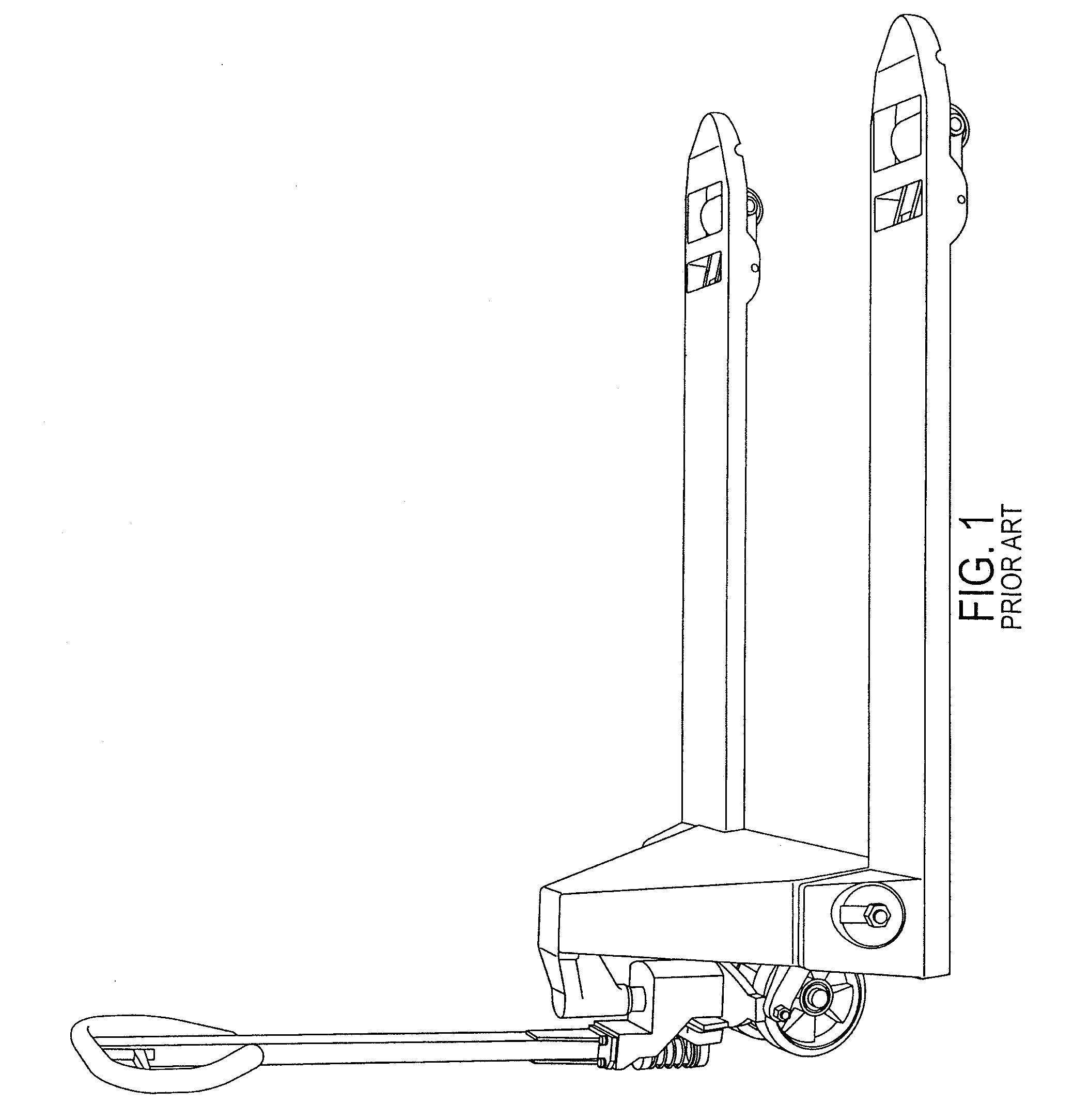

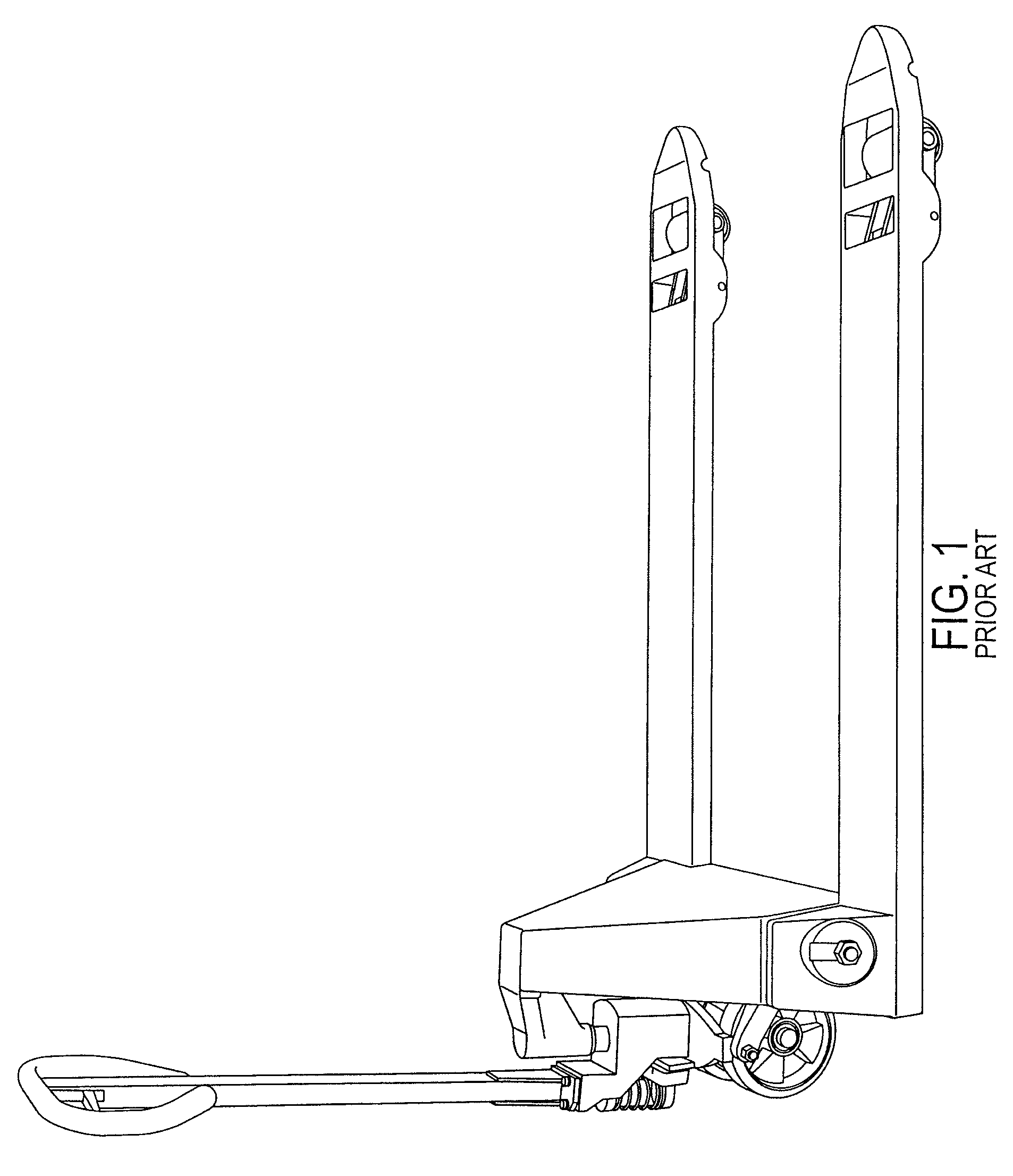

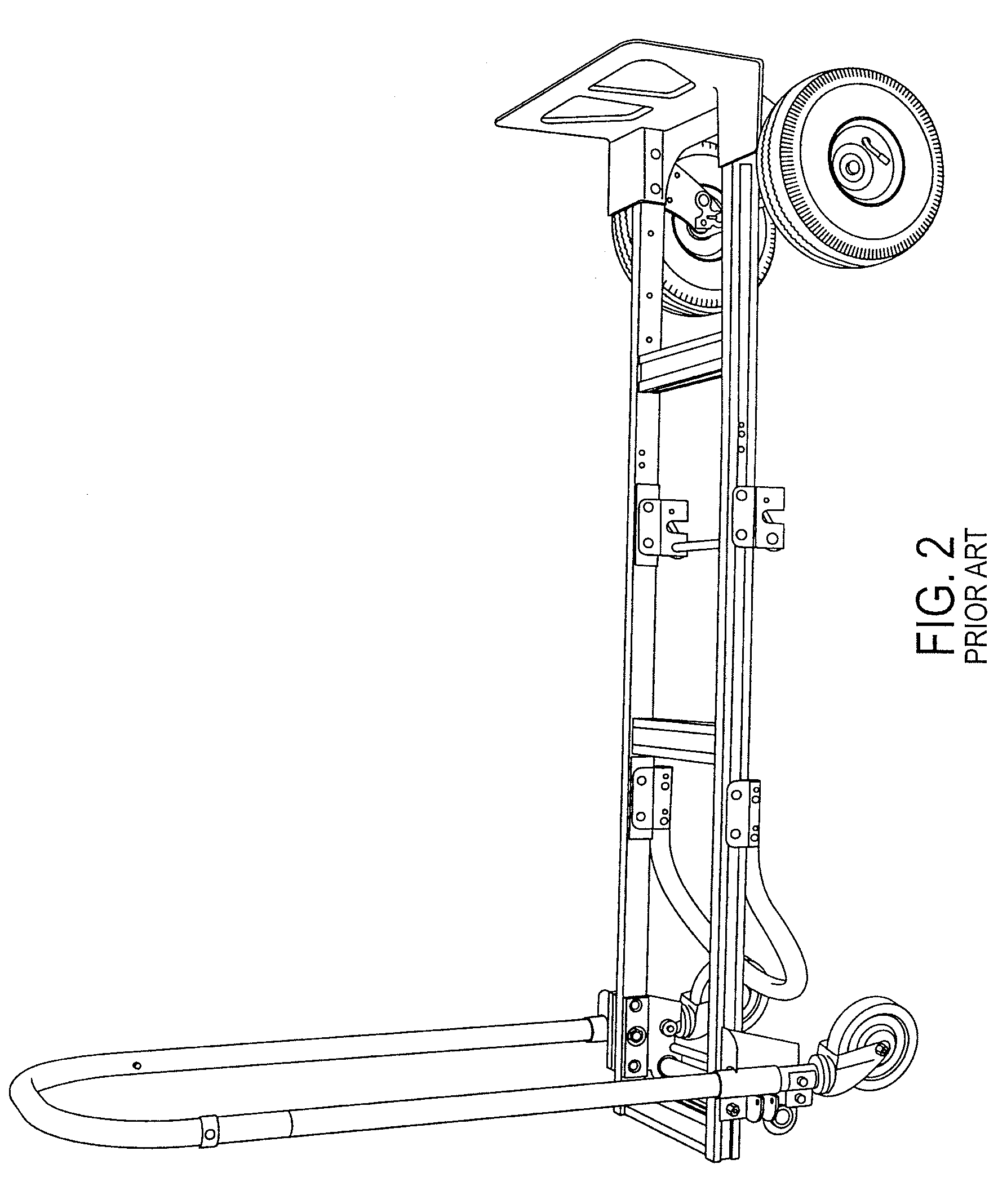

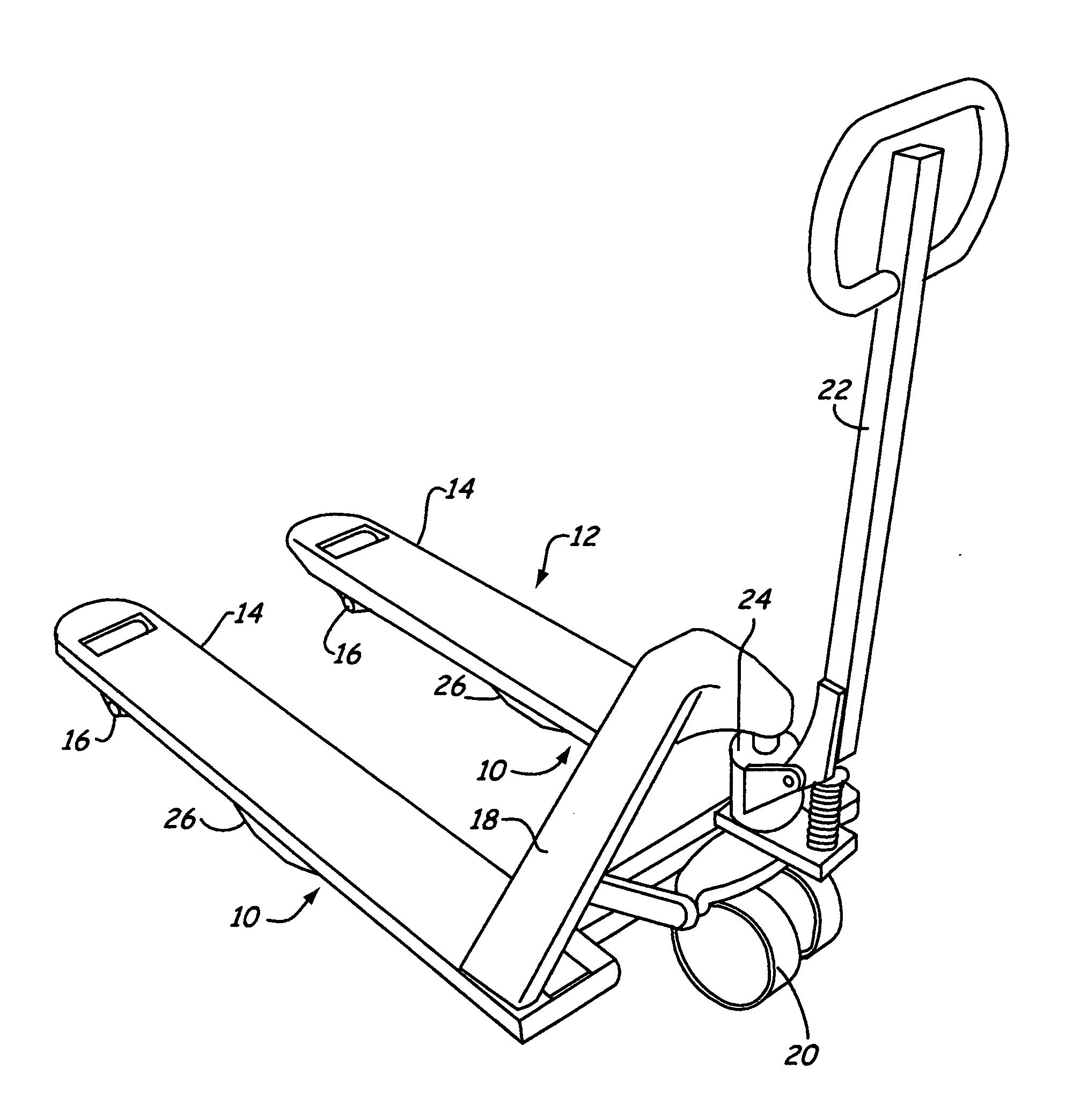

A pallet jack, also known as a pallet truck, pallet pump, pump truck, dog, or jigger is a tool used to lift and move pallets. Pallet jacks are the most basic form of a forklift and are intended to move pallets within a warehouse.

Pallet jack with independently elevatable fork arms

ActiveUS7744335B1Avoid impact damageRestore balanceUnderstructuresSupporting partsJackscrewPallet jack

A pallet jack with a pallet engaging fork having separate and independently movable first and second fork arms connected to independently controlled and operable first and second fork arm elevating means, for lifting a pallet loaded with a stack of items so that when the stack of items leans and is out of balance one fork arm can be elevated higher than the other to compensate and restore balance to the stack of items.

Owner:CLEARY TAMARA

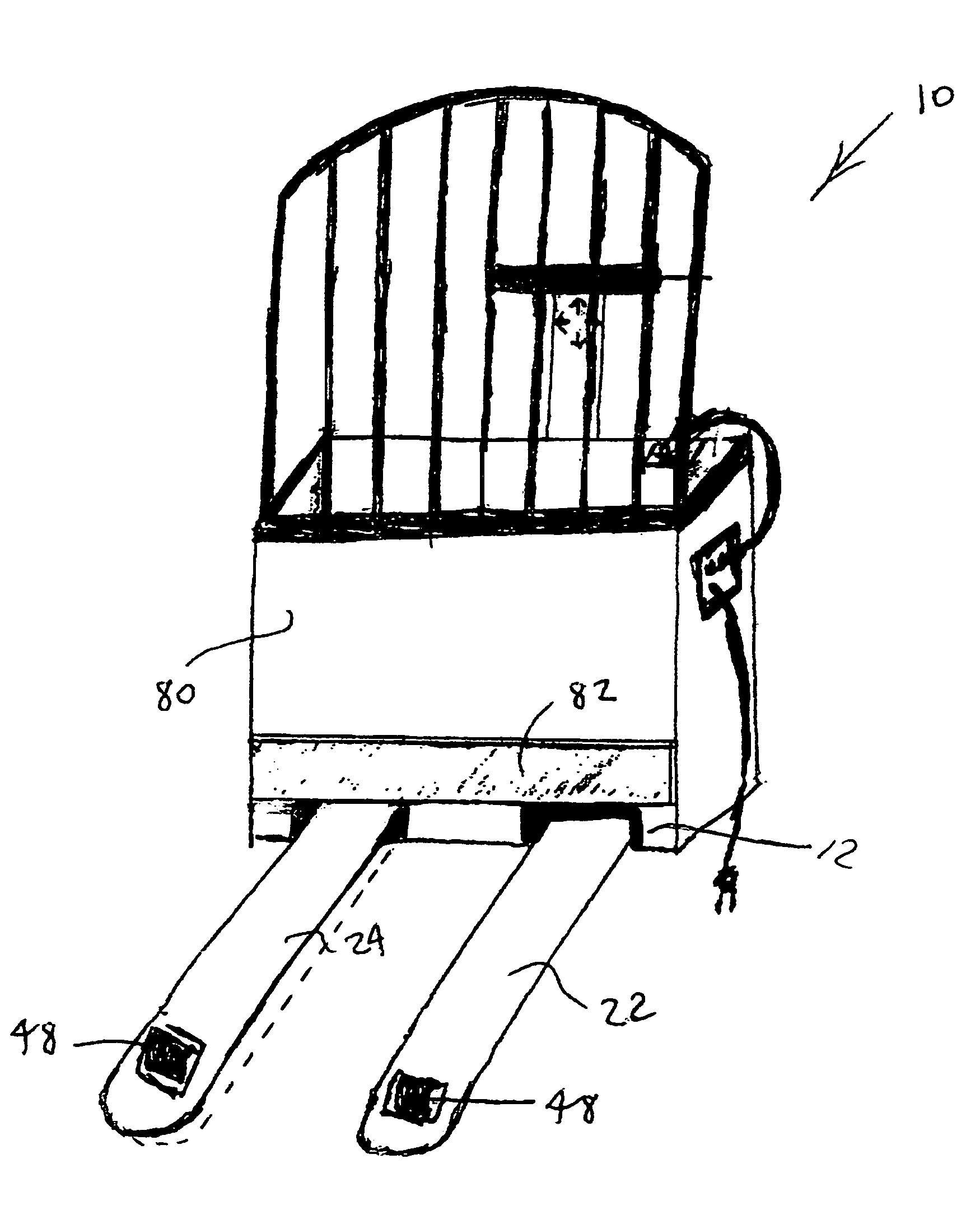

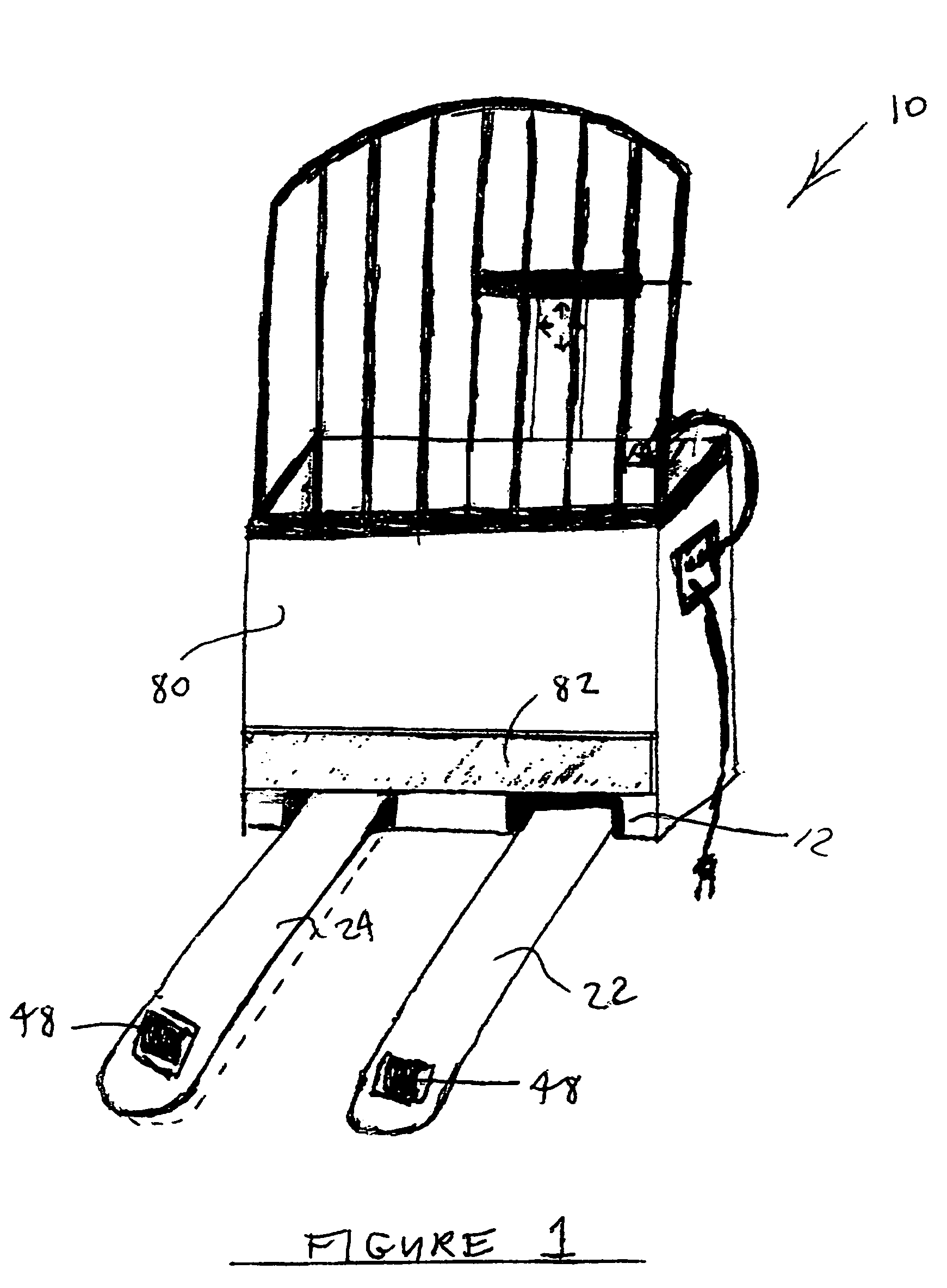

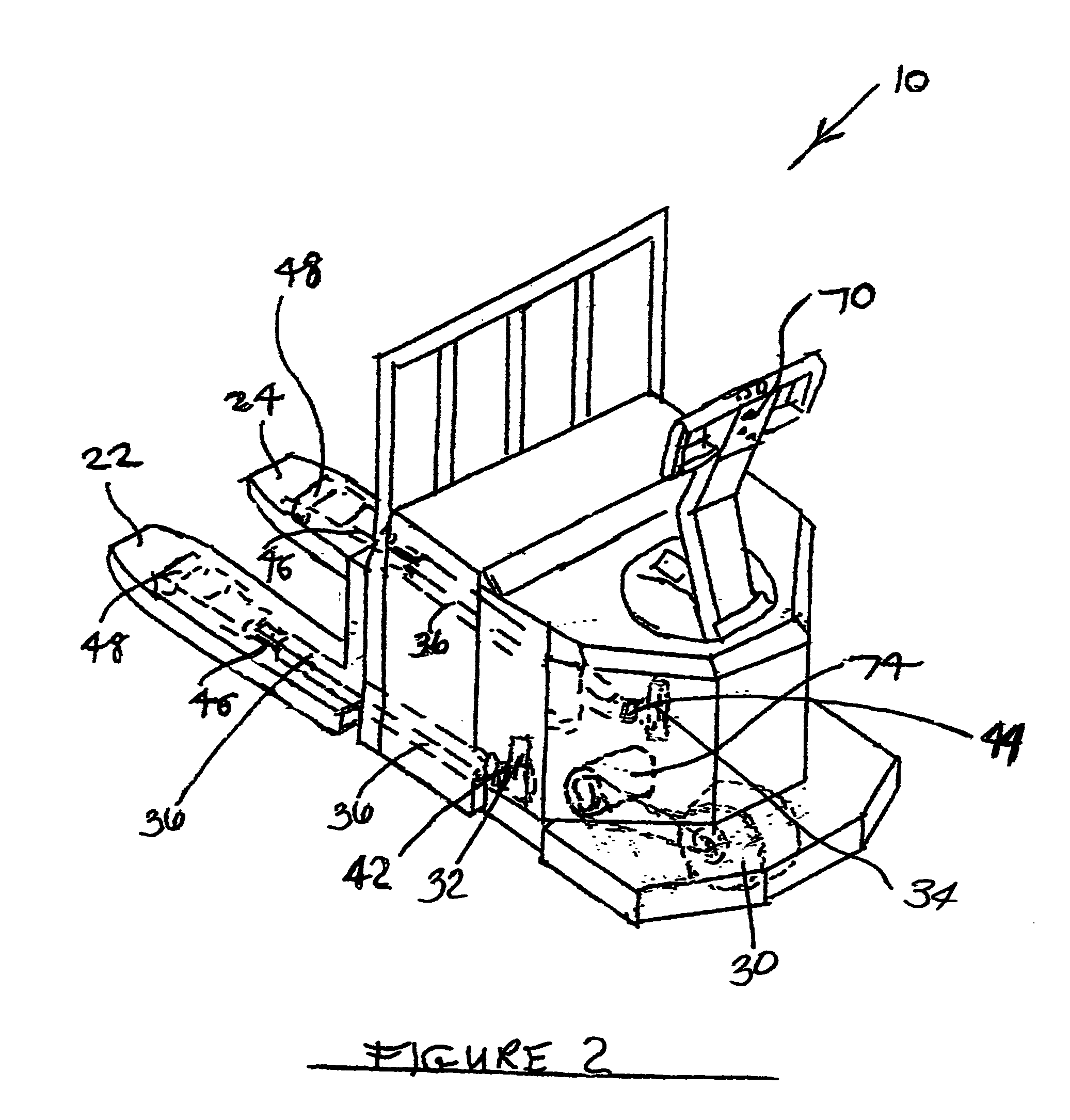

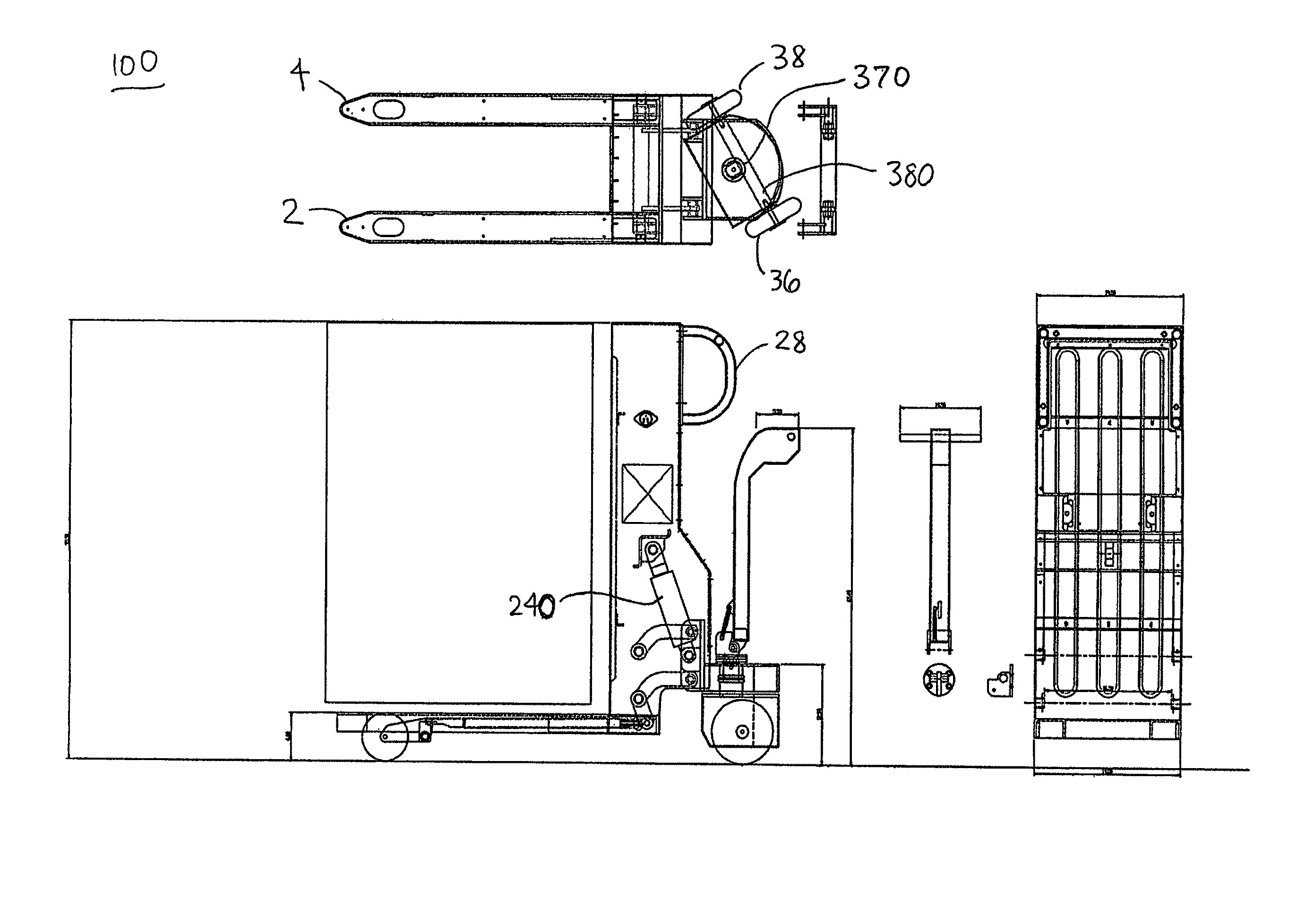

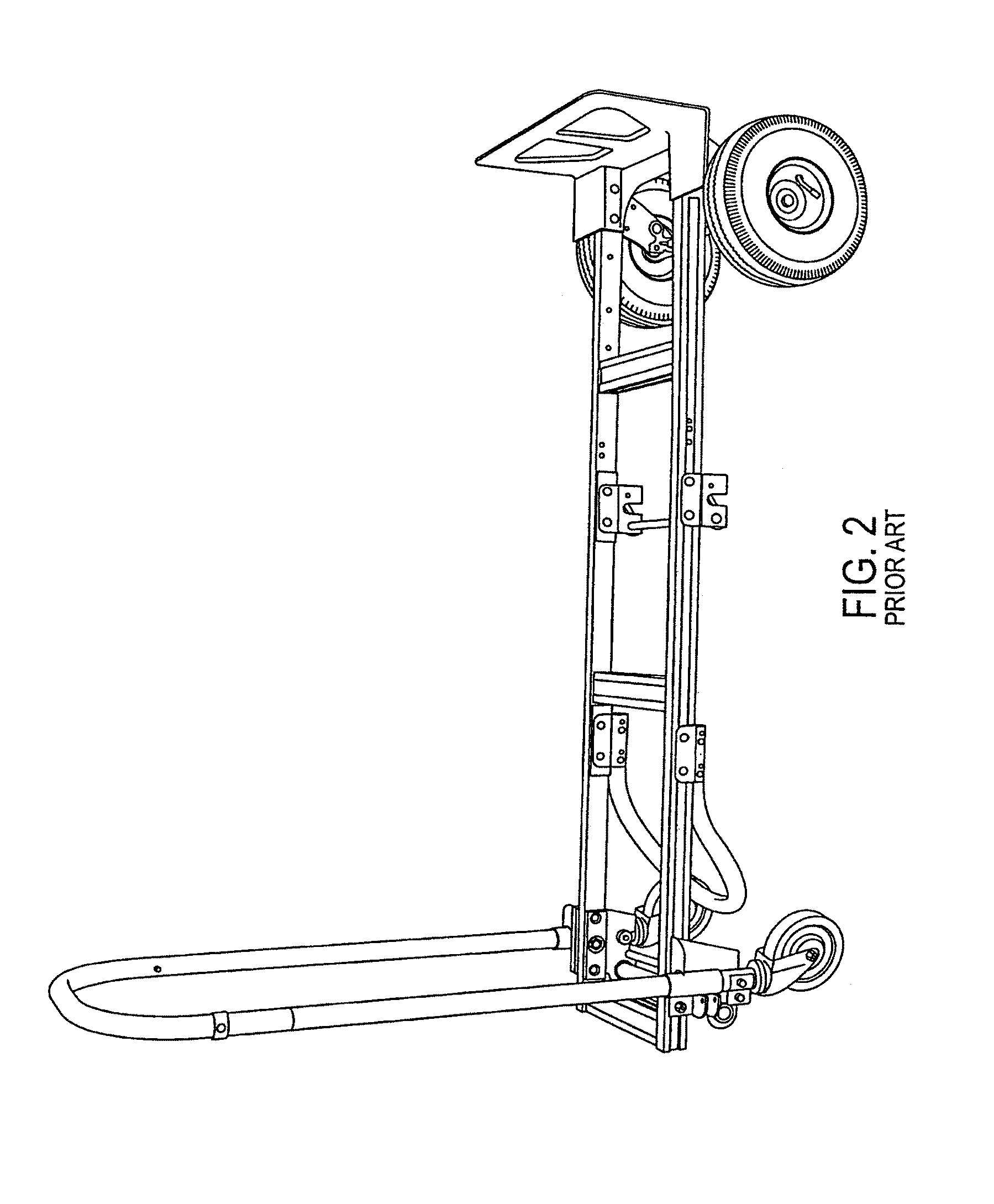

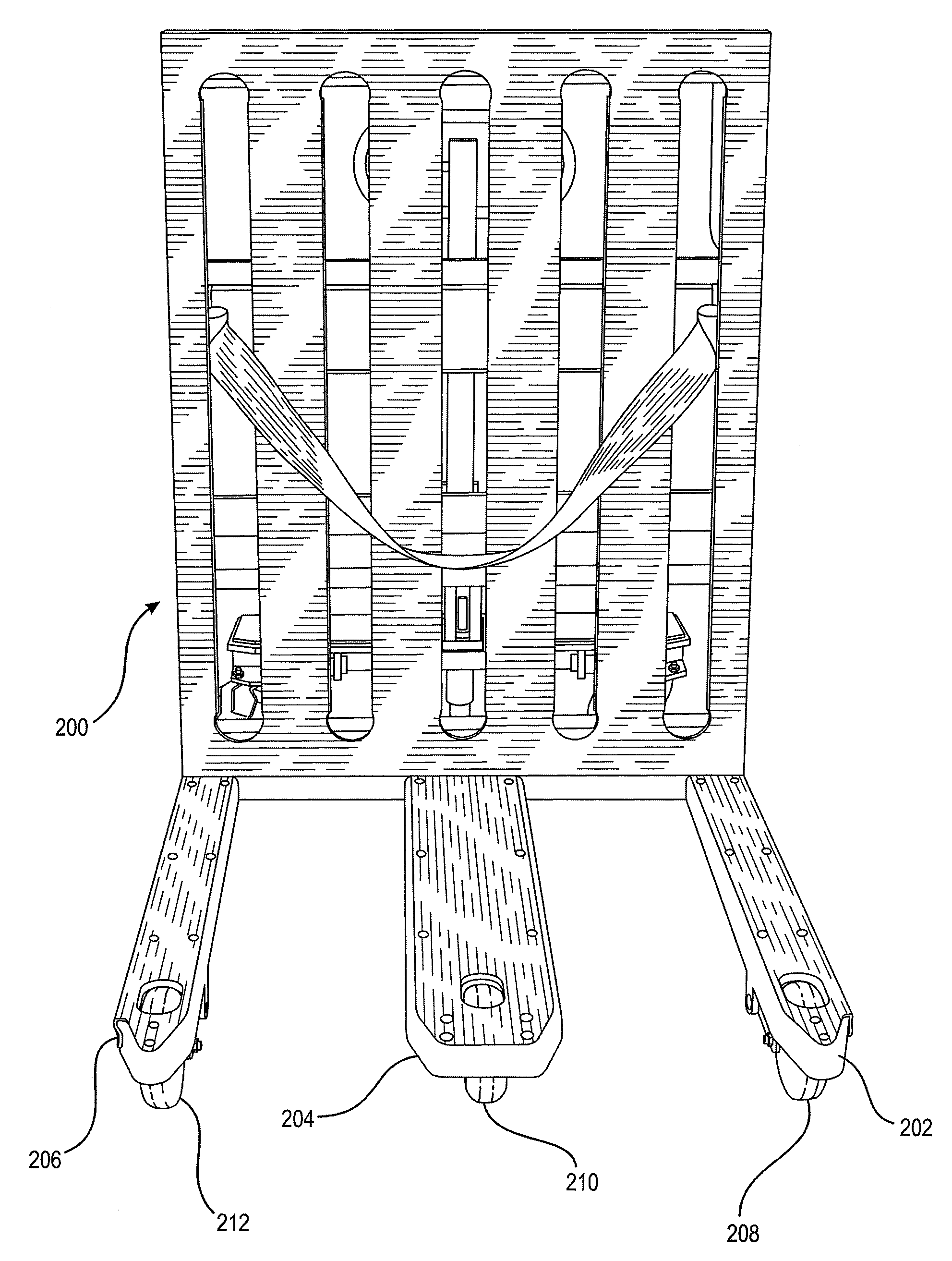

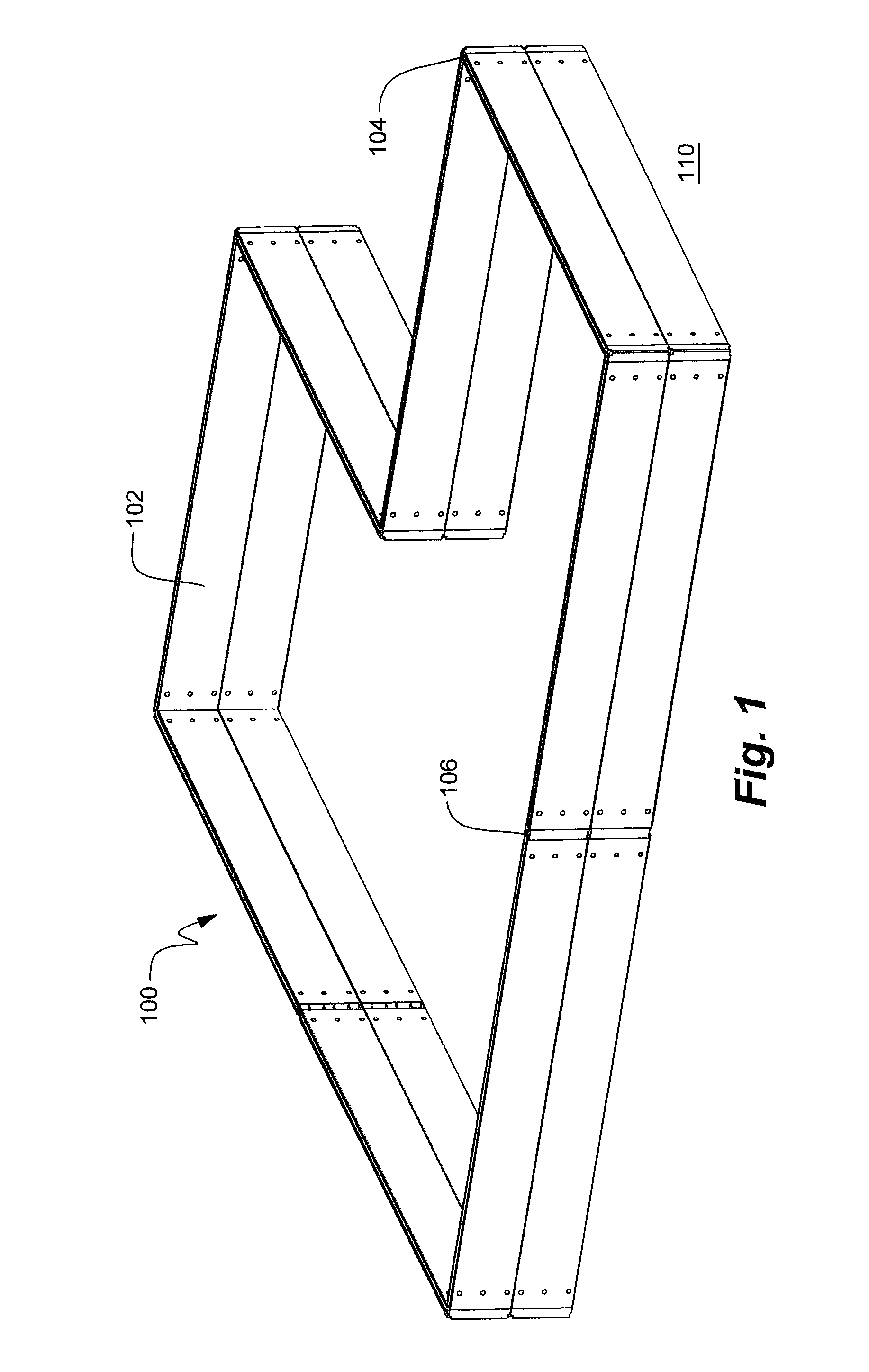

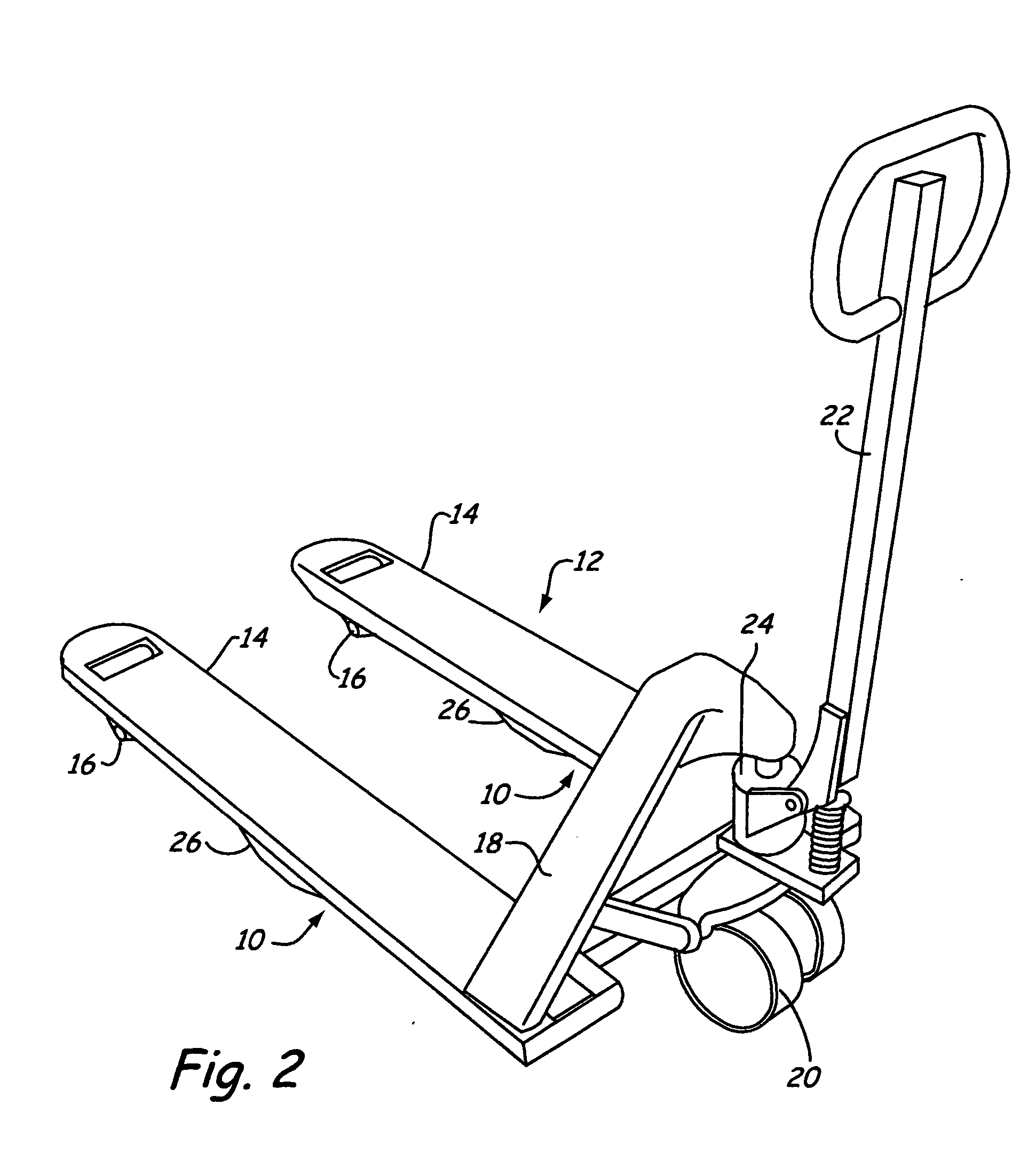

Pallet jack system and method for the transportation of stackable packaged goods pallets

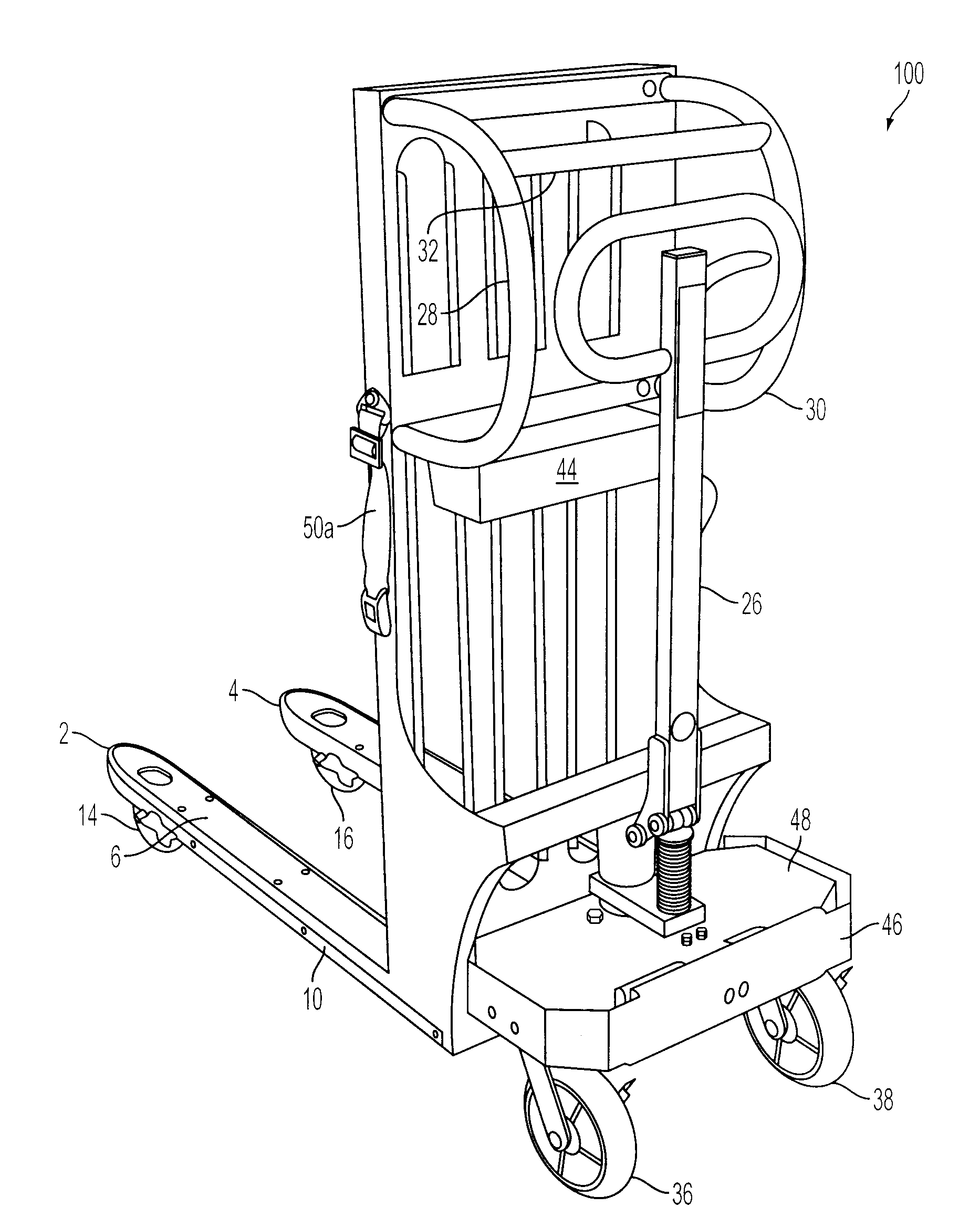

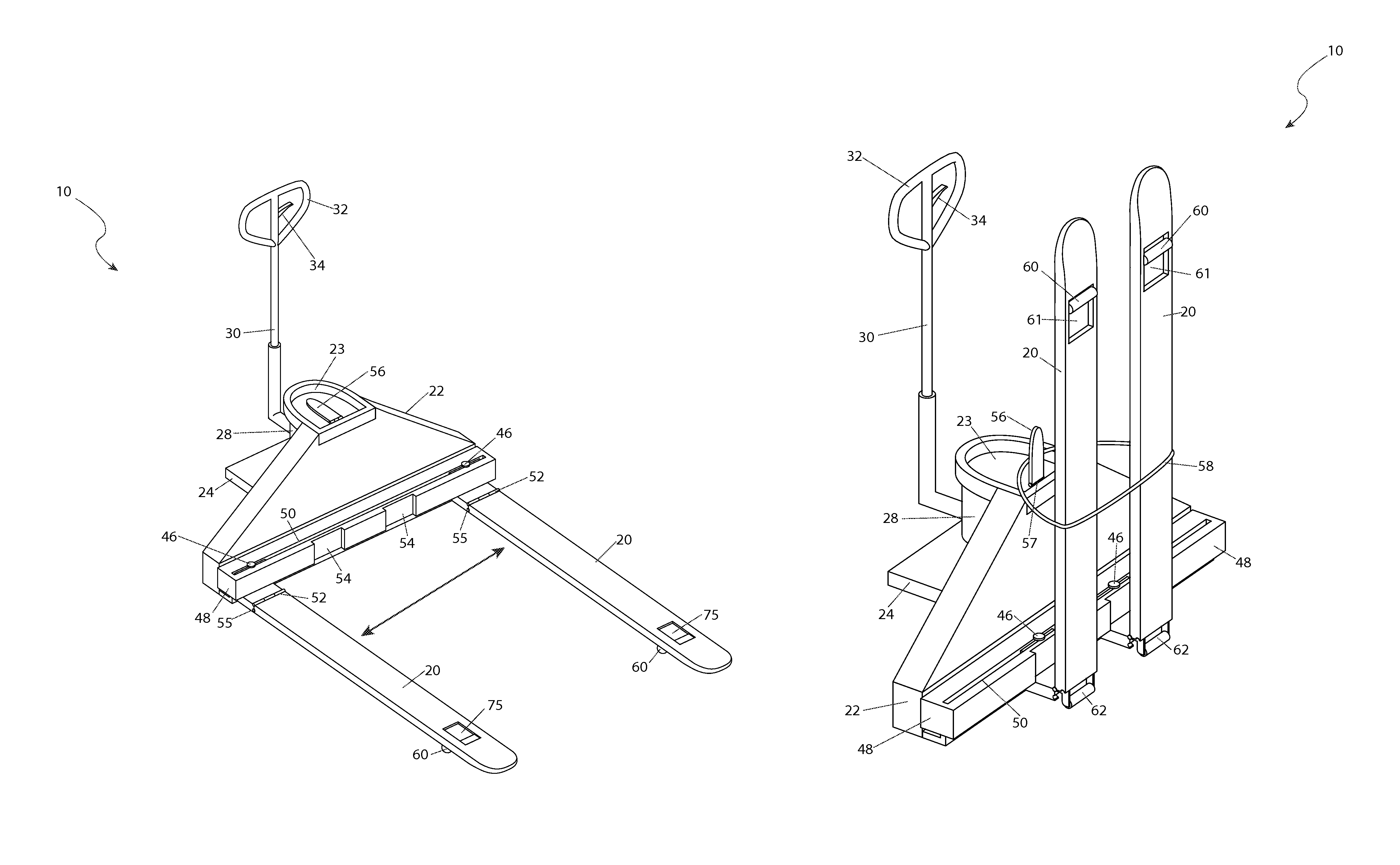

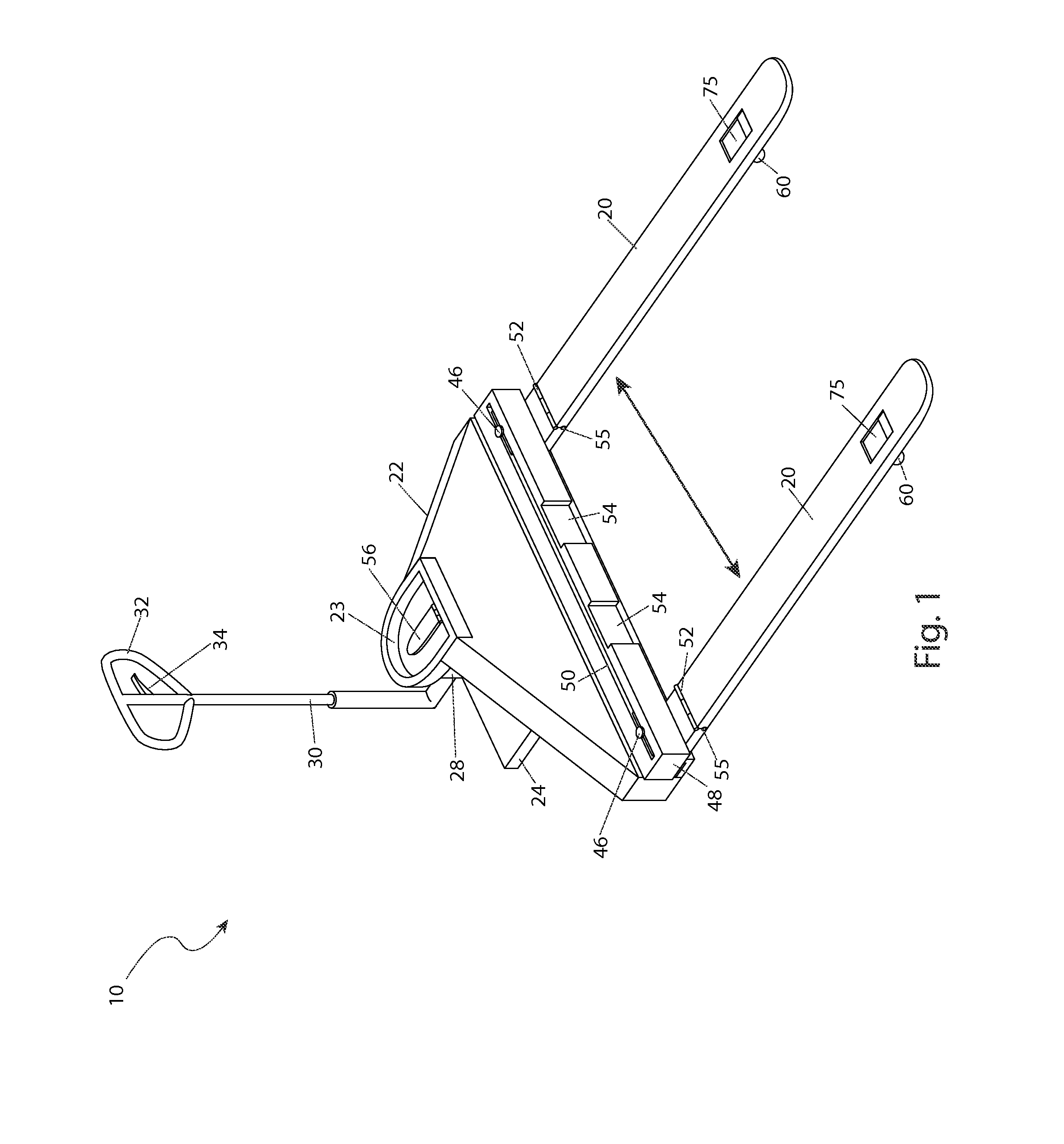

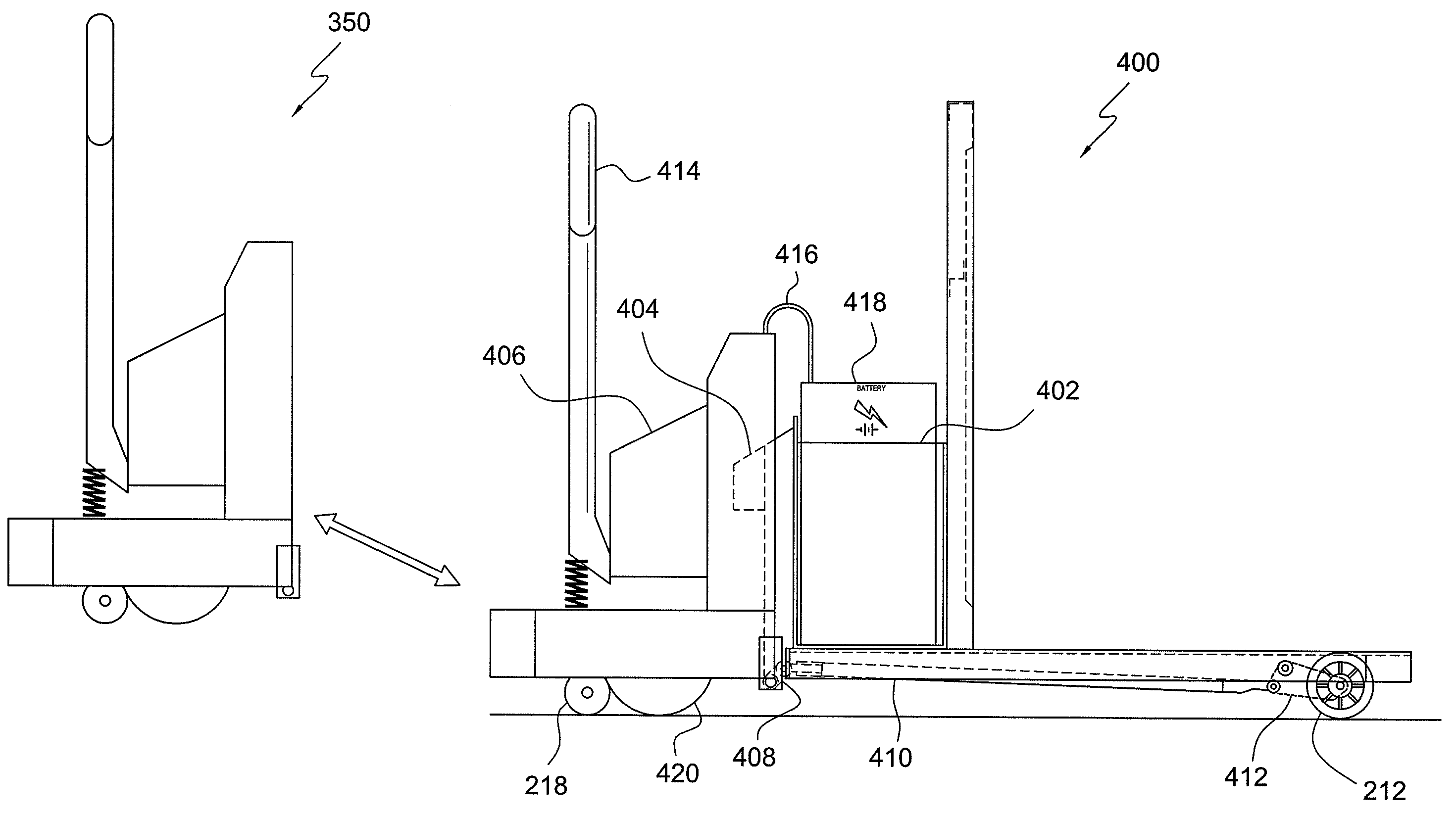

A pallet jack is disclosed that comprises a left tine and a right tine. The pallet jack includes a lifting mechanism that may include an electrically powered hydraulic pump to effectuate the lifting motion. The pallet jack may also include power-driven wheels that are connected by an axle, thereby facilitating translational motion of the pallet jack. The wheels may be maximally spaced by using a maximum-length axle that is slightly longer than the width of the pallet jack body, thereby optimizing load stability.

Owner:COCA-COLA BOTTLING CO UNITED INC

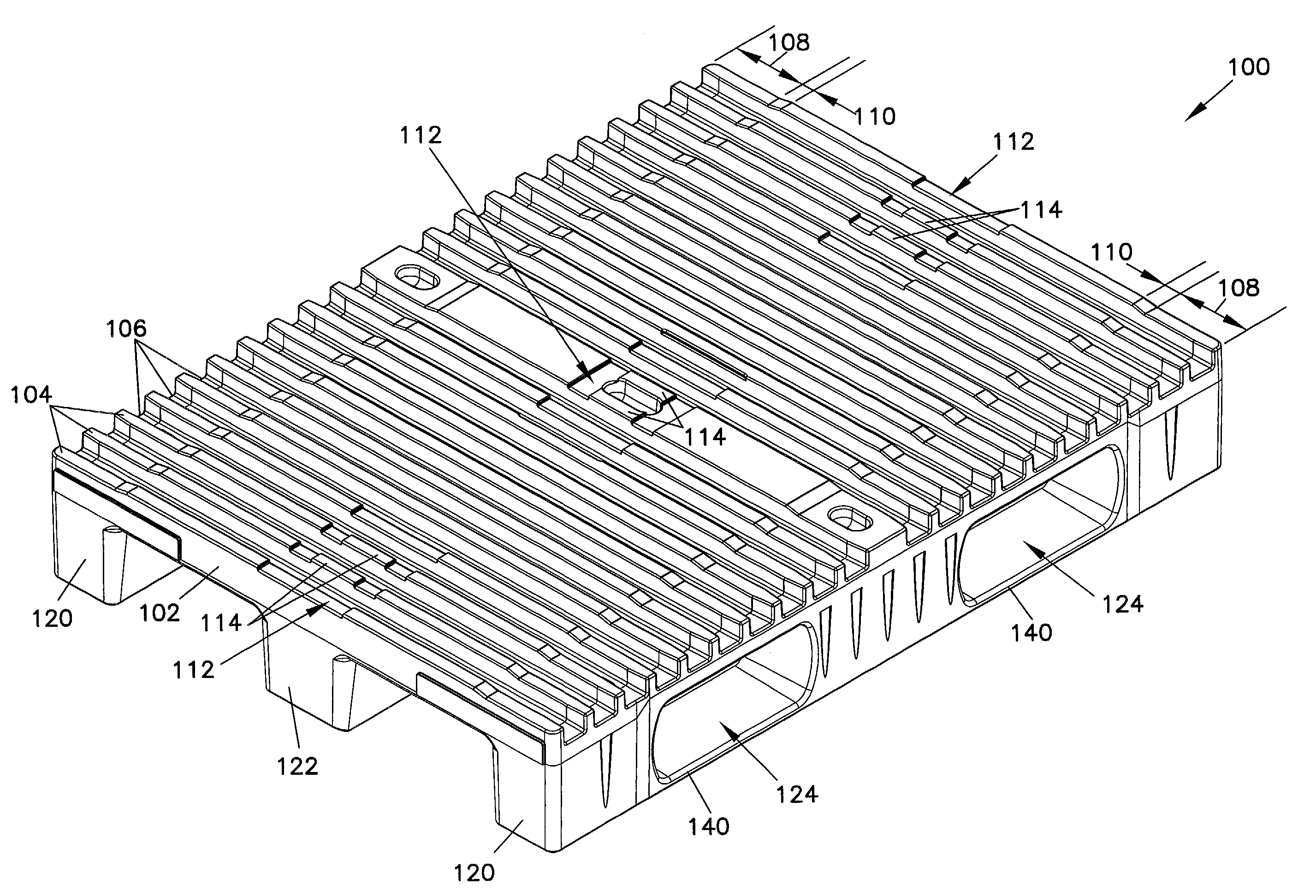

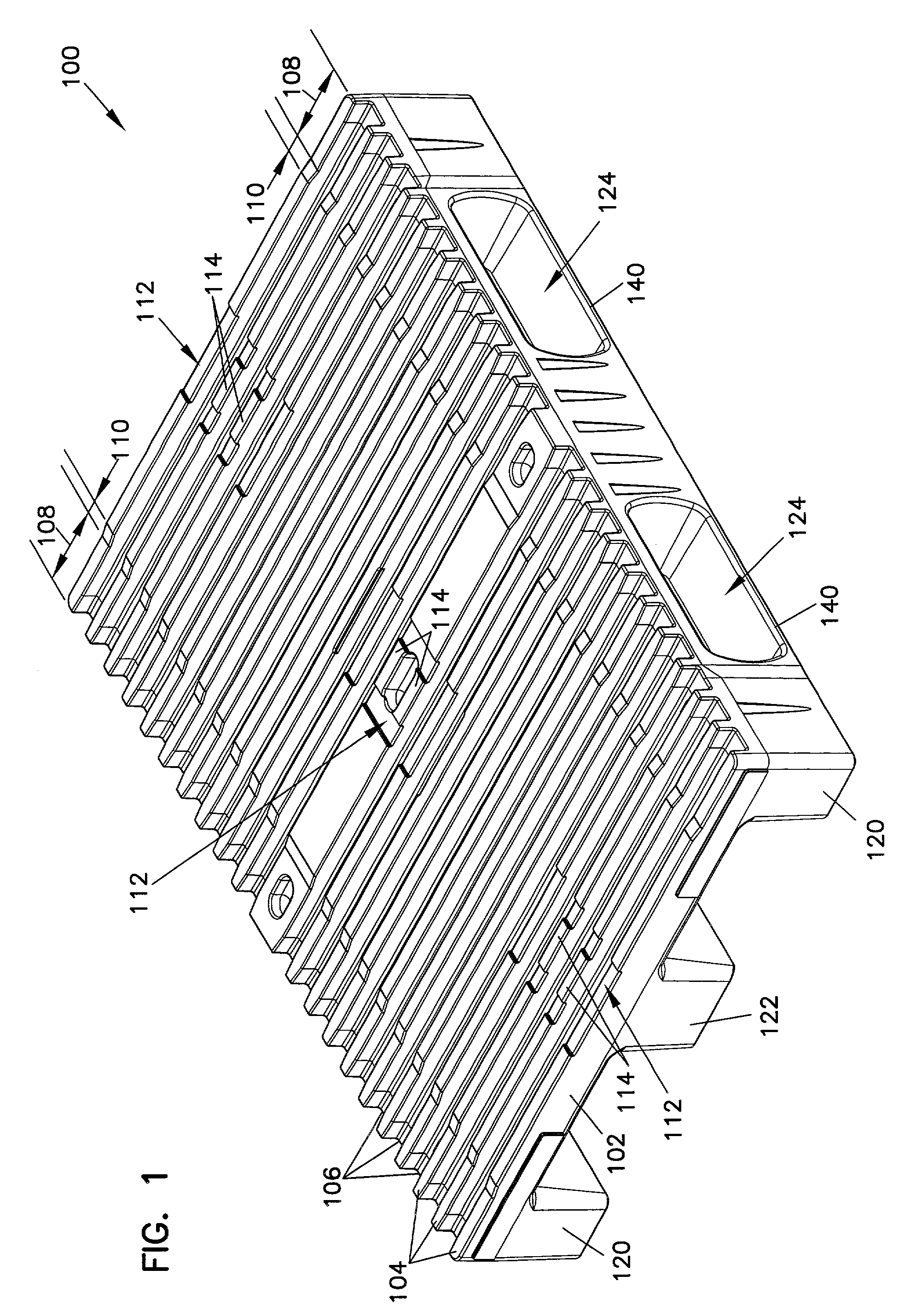

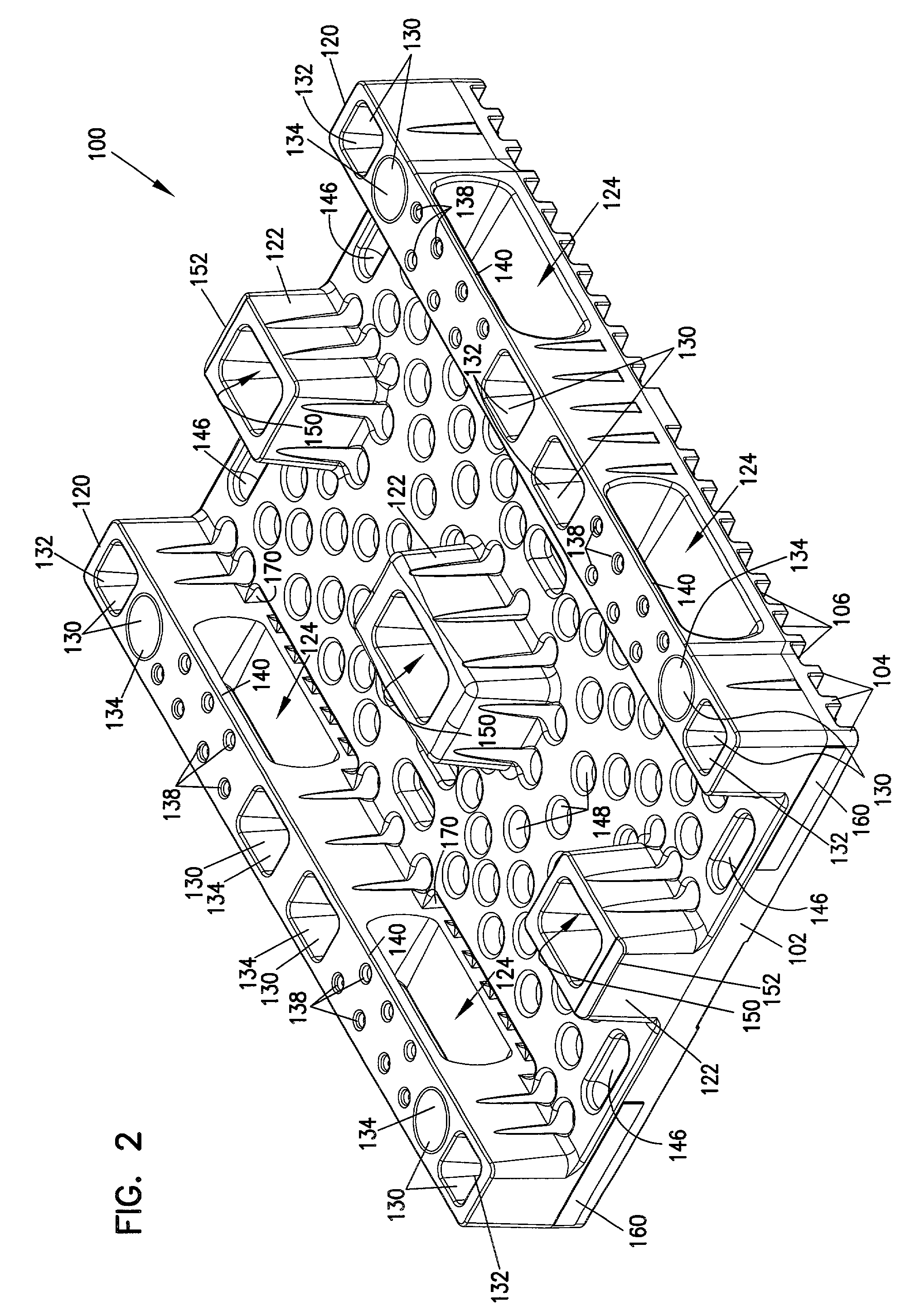

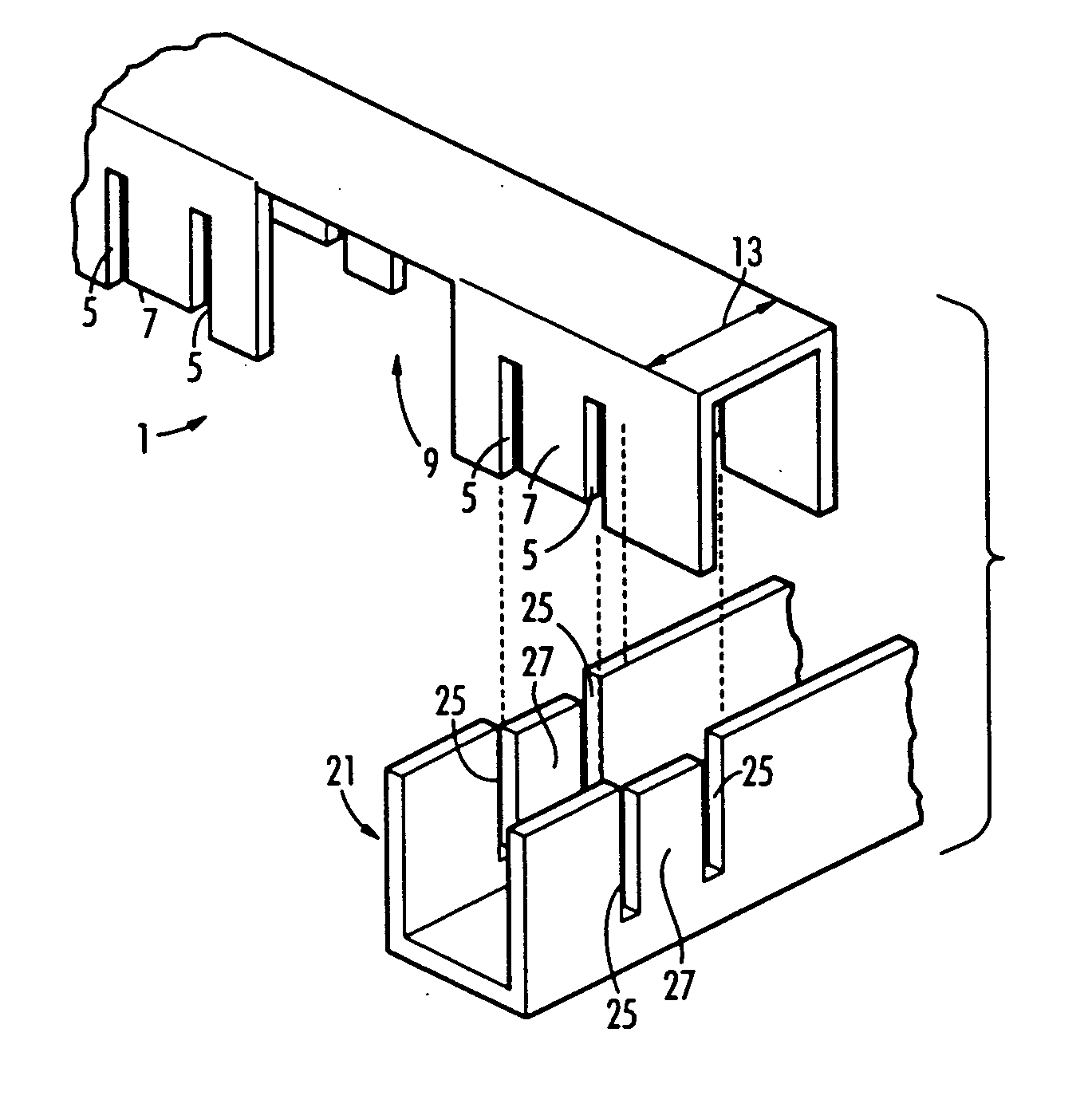

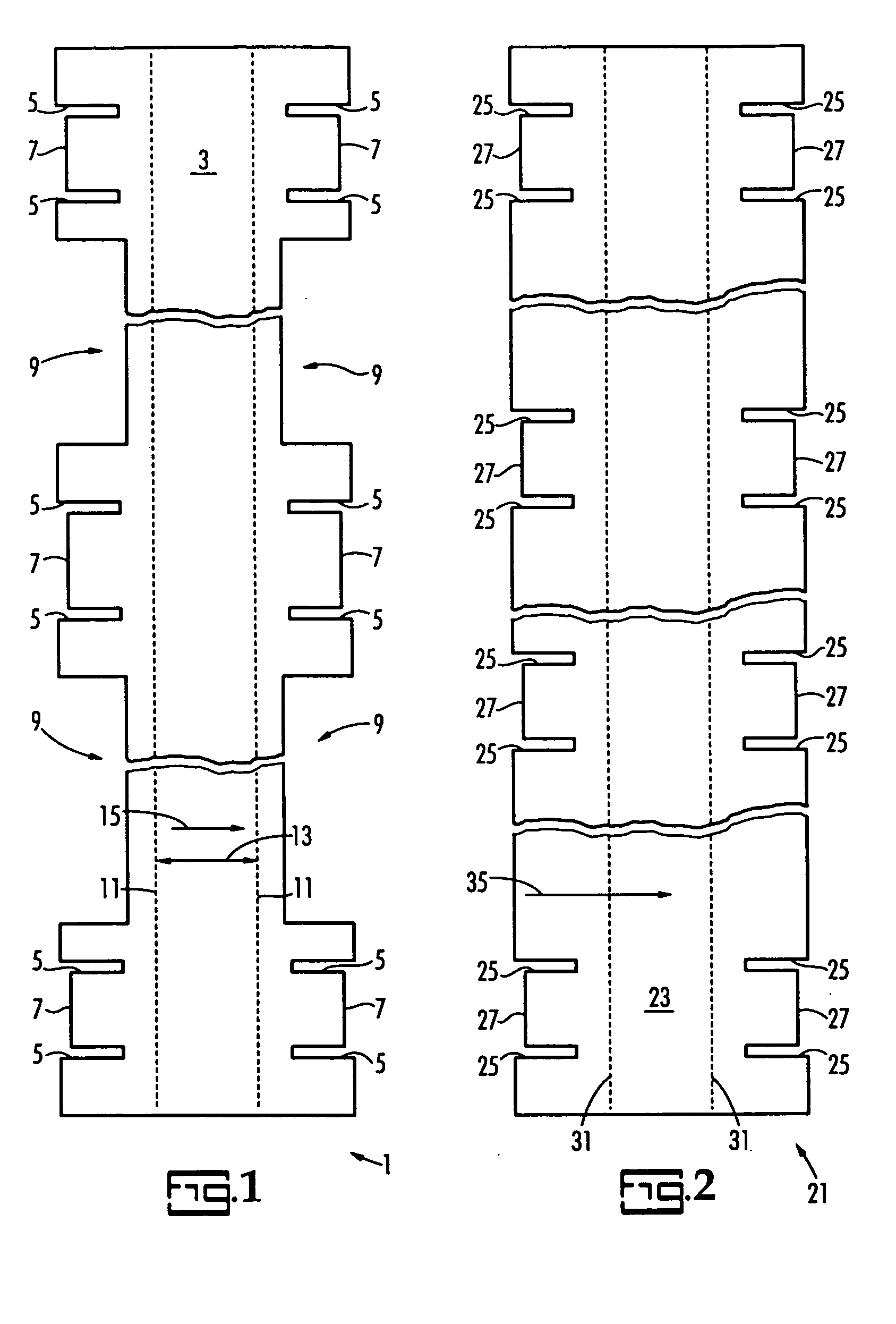

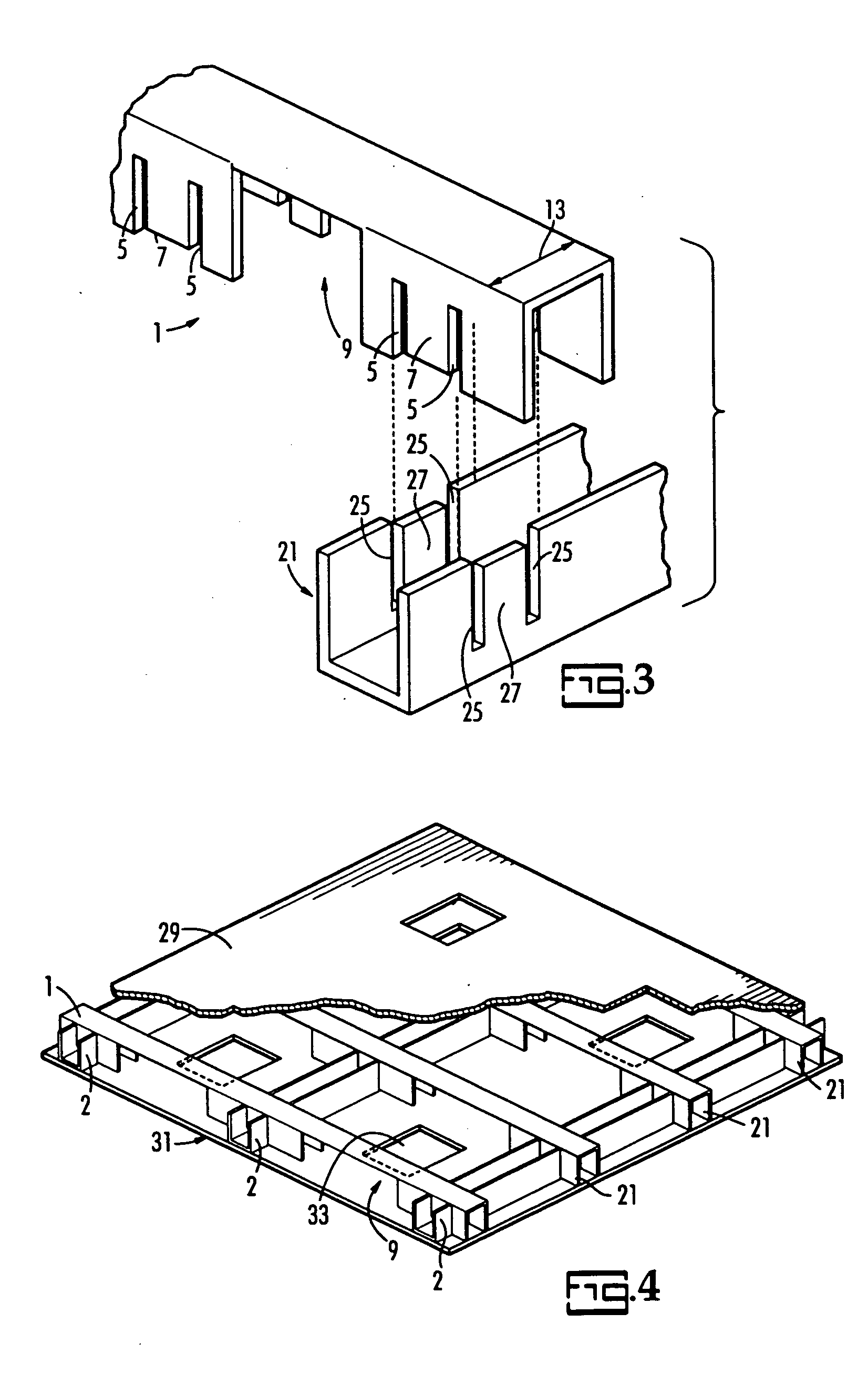

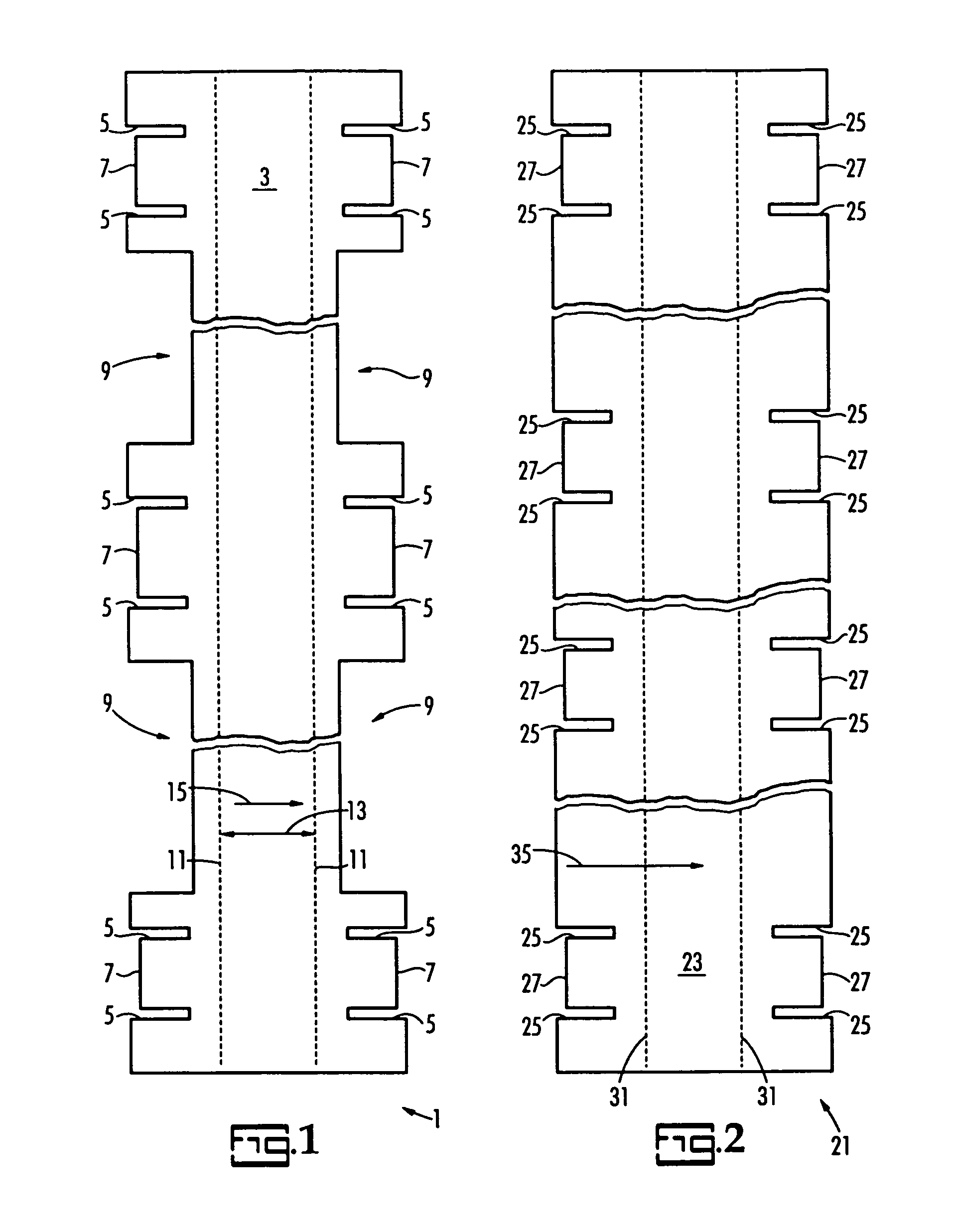

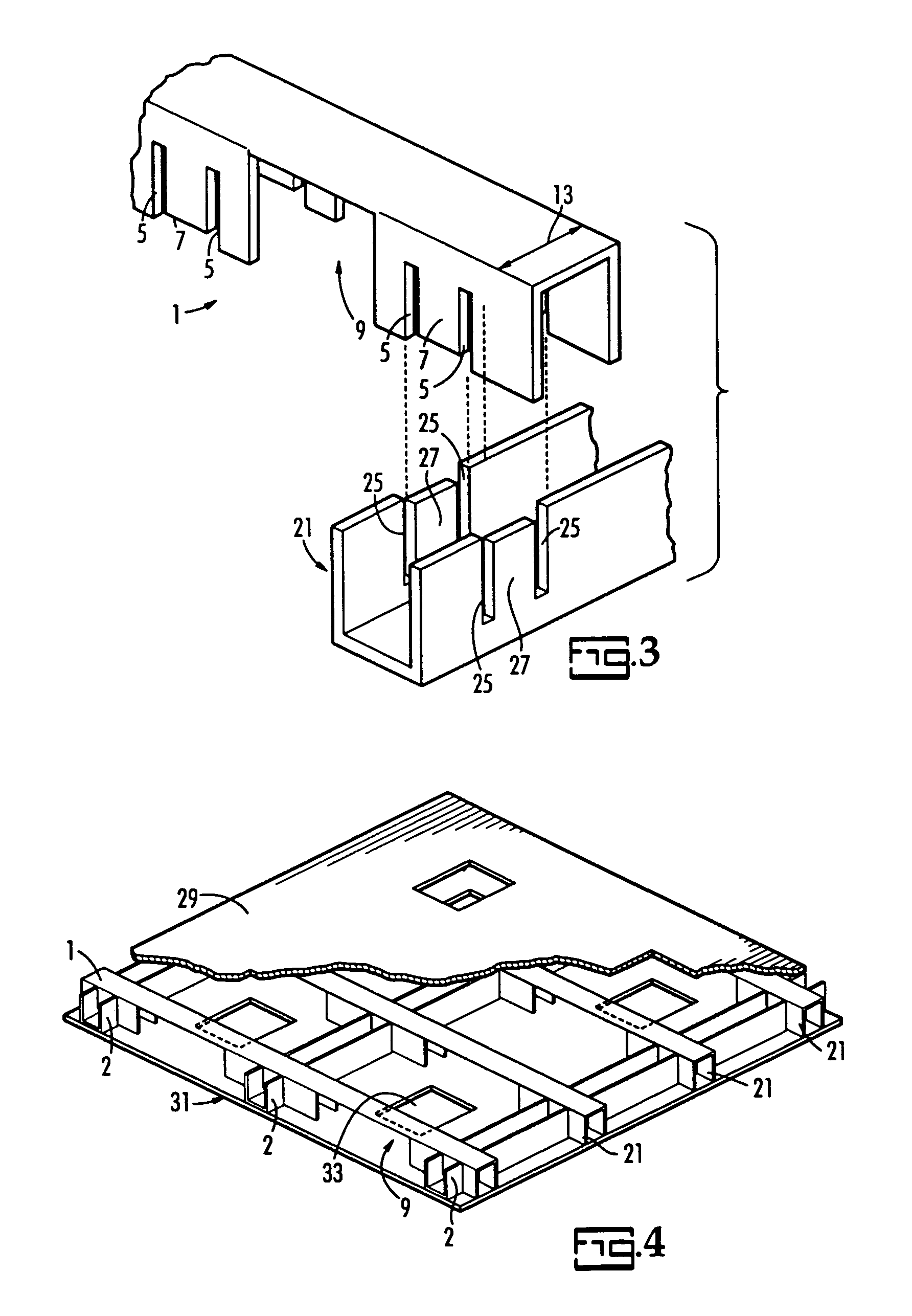

Pallet

InactiveUS7607628B2Easy alignmentIncrease engagementOther accessoriesStands/trestlesEngineeringPallet jack

A pallet includes a deck and support members extending from an underside of the deck. The deck has alignment recesses as well as lowered portions along both sides of the deck for receiving the feet and runners supporting the deck to achieve nesting when stacked. The support members include two runners with orifices extending there through and aligned to accommodate pallet jacks and forklifts. The orifices have straps extending underneath the orifices to provide structural support while allowing for insertion of pallet jacks and their wheels. The pallet has feet between the runners and spaced so that the underside of the deck is unobstructed in the area intermediate the orifices providing for four way insertion of pallet jack support units. The pallet has alignment sections machined into the sides of the pallet to provide for precise alignment with pallet handling equipment.

Owner:SNYDER PROD

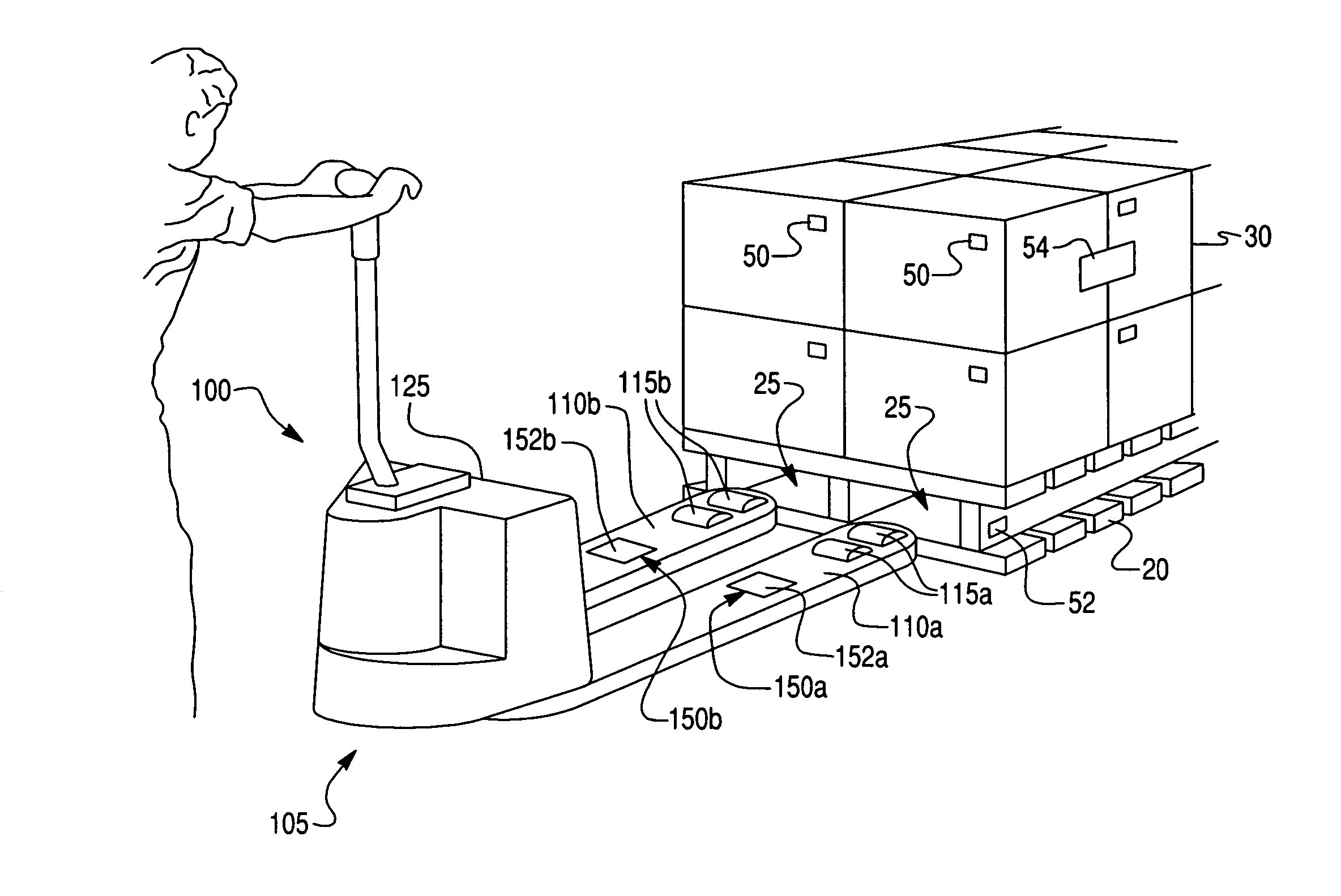

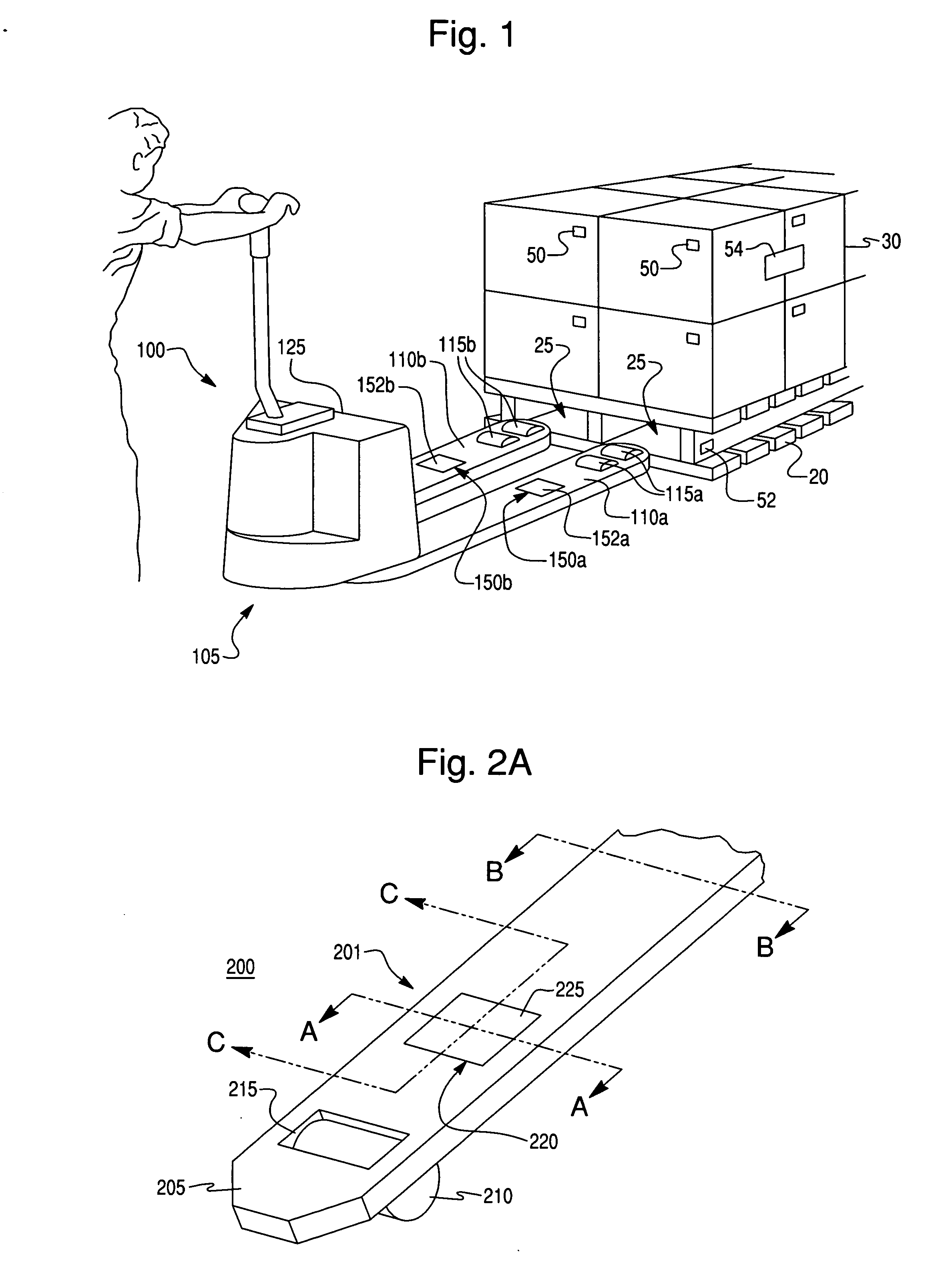

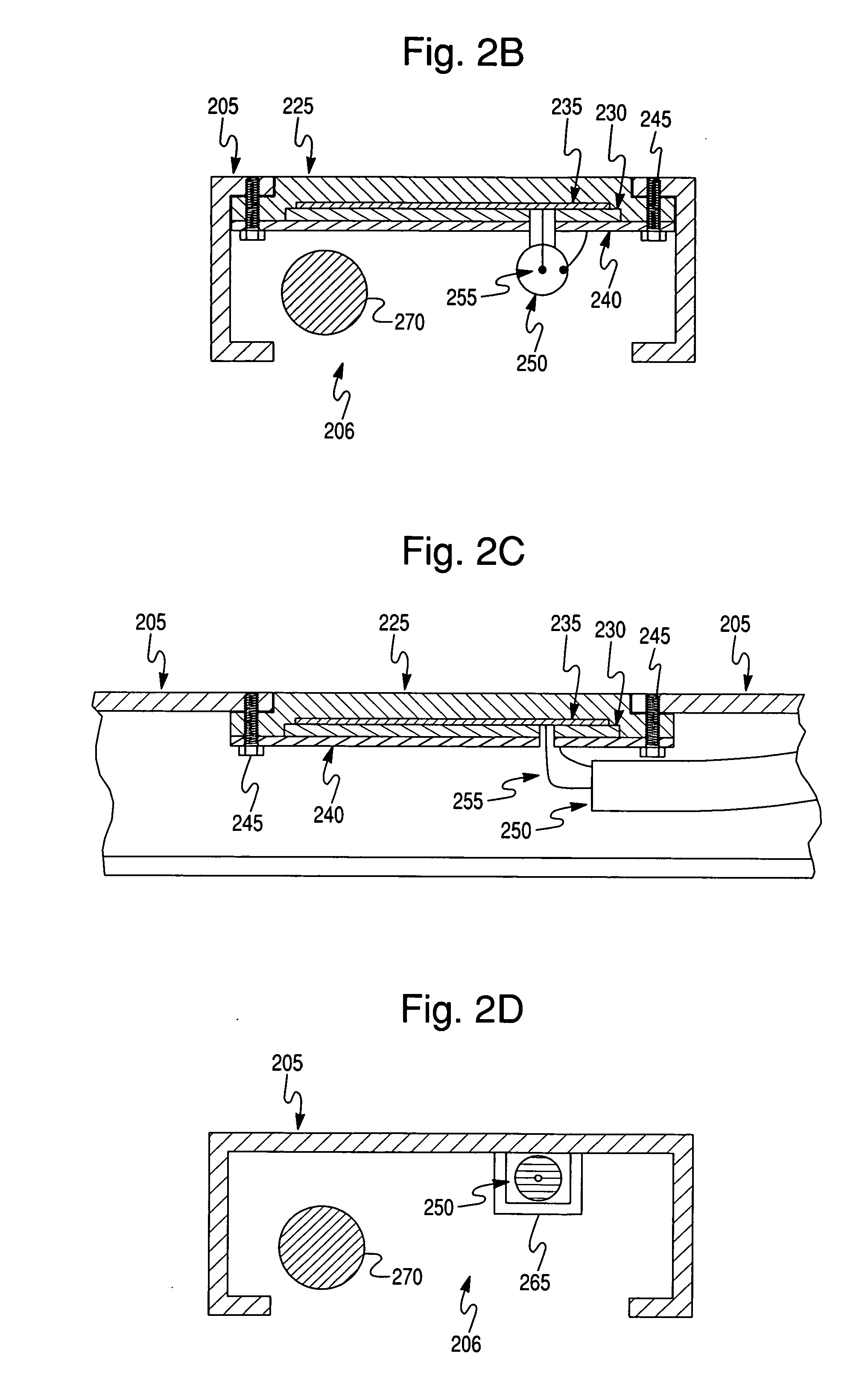

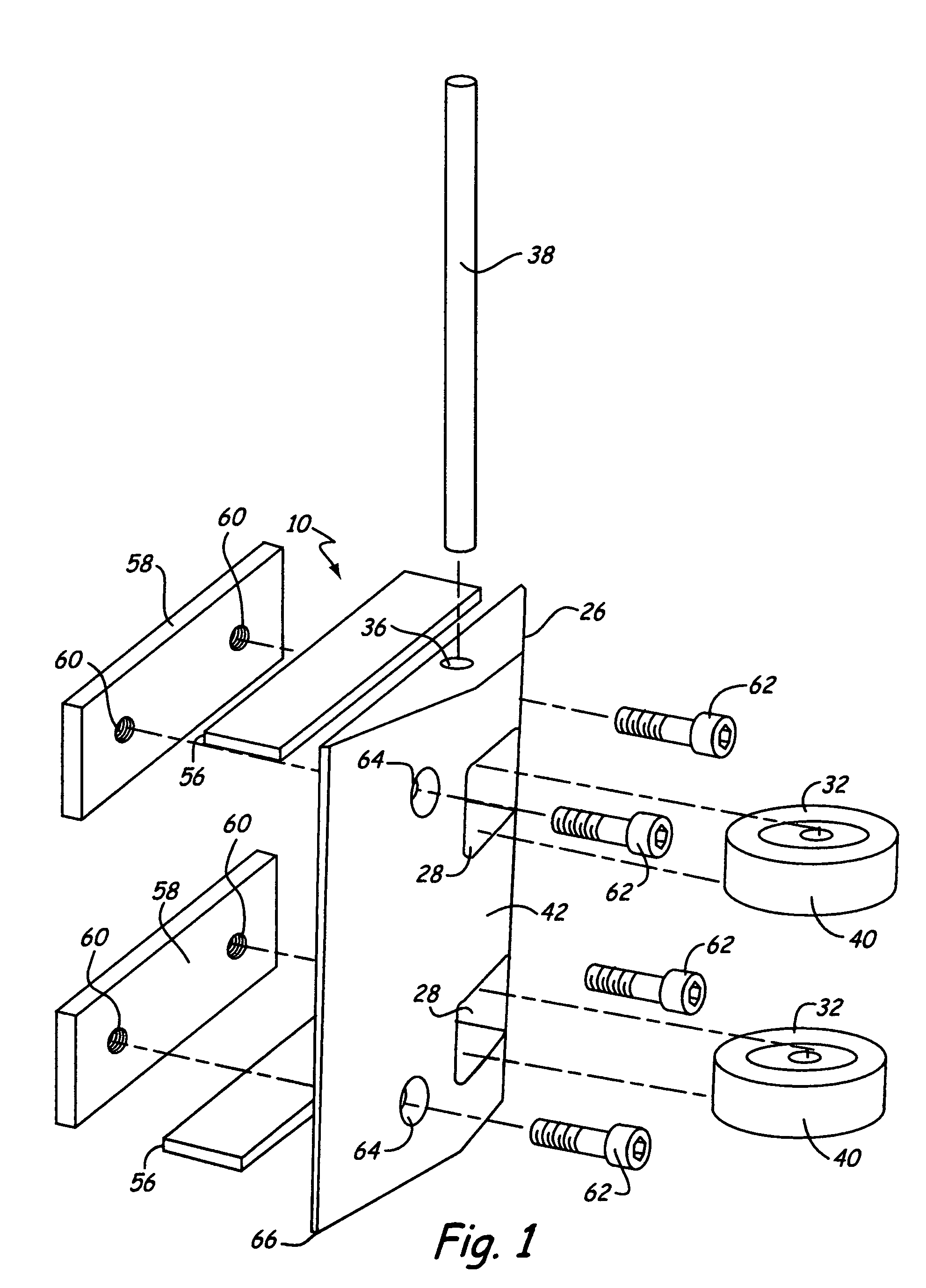

Pallet jack antenna for RFID system

ActiveUS20060255949A1Accurate readingAntenna supports/mountingsMemory record carrier reading problemsEngineeringPallet jack

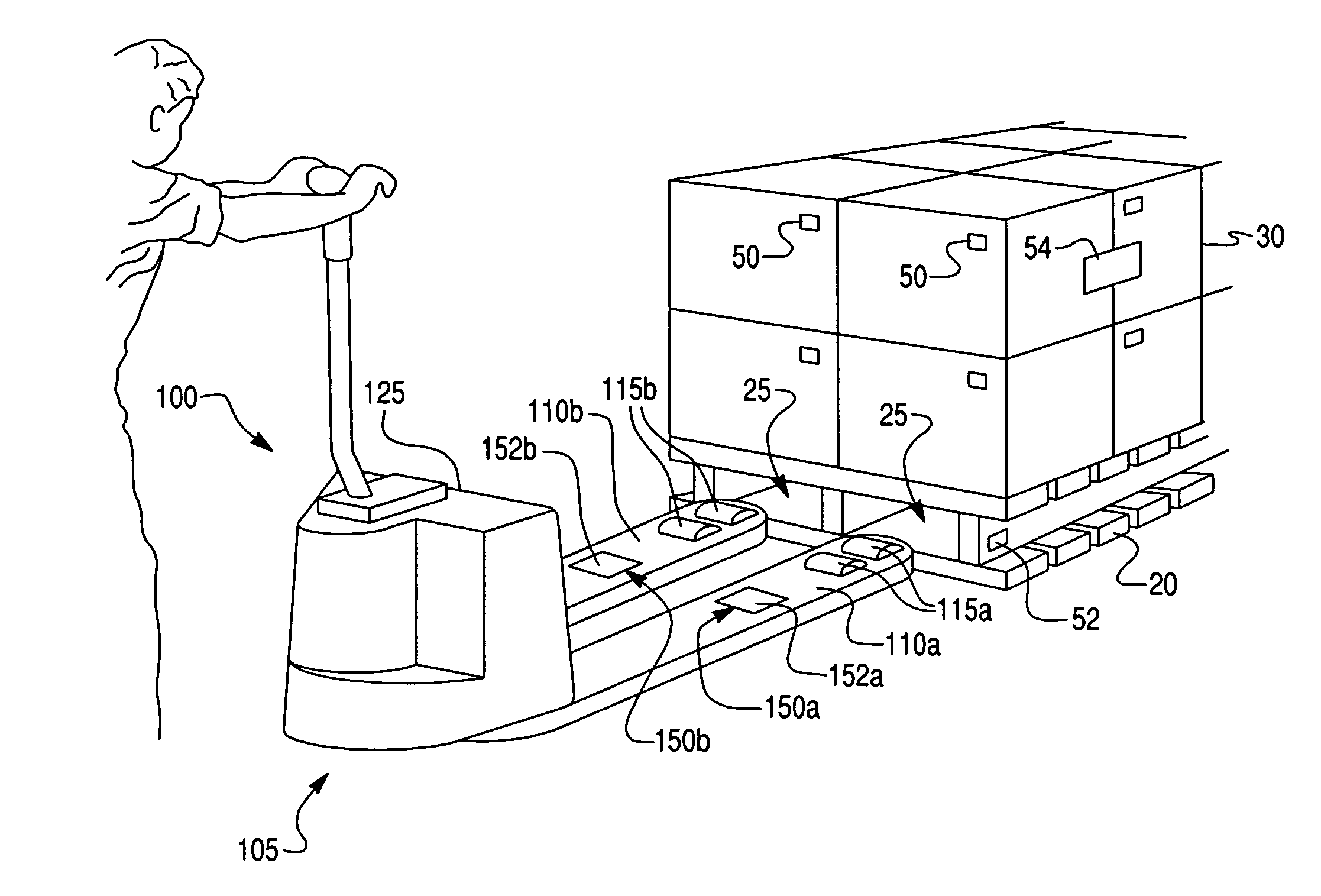

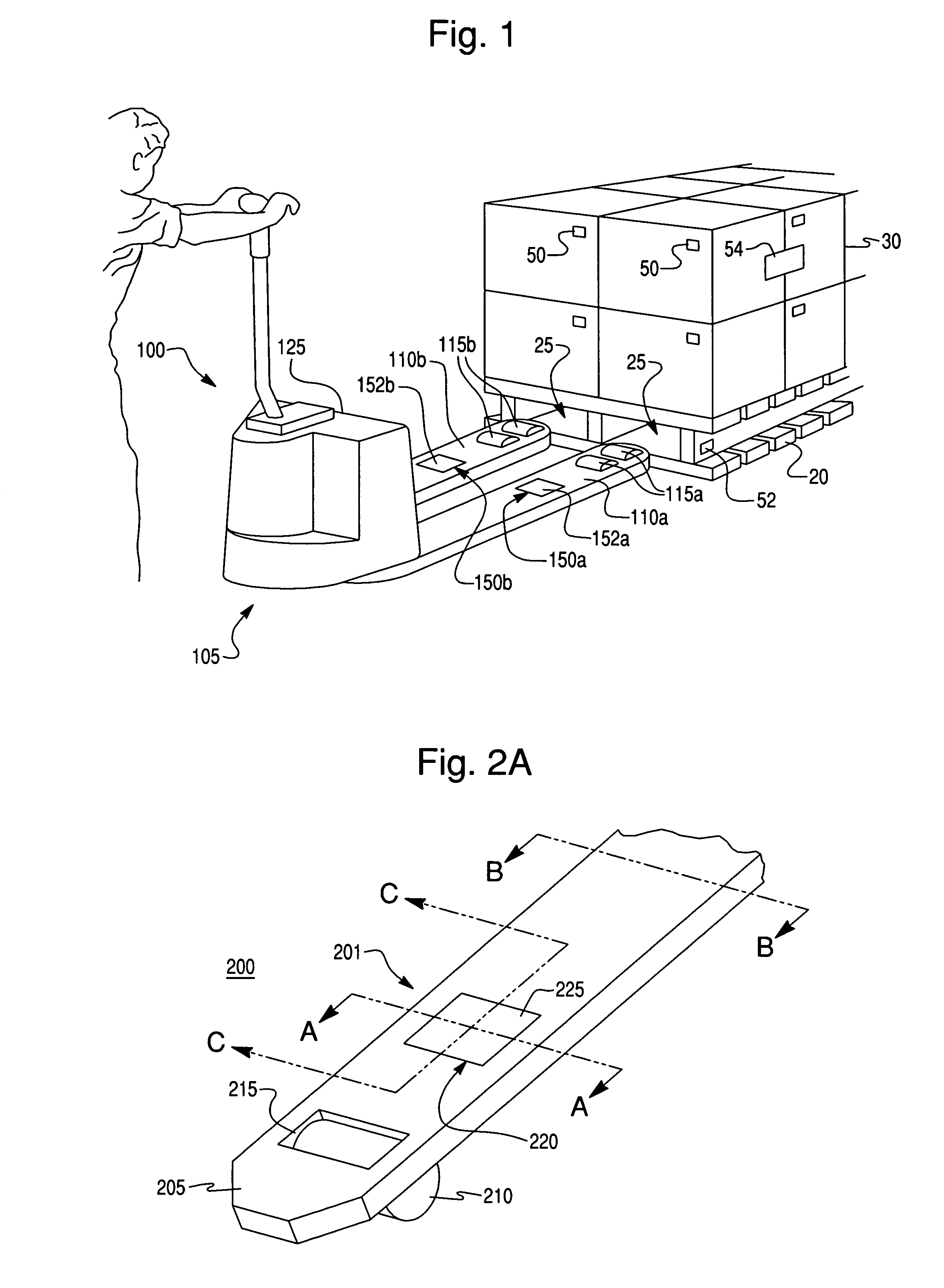

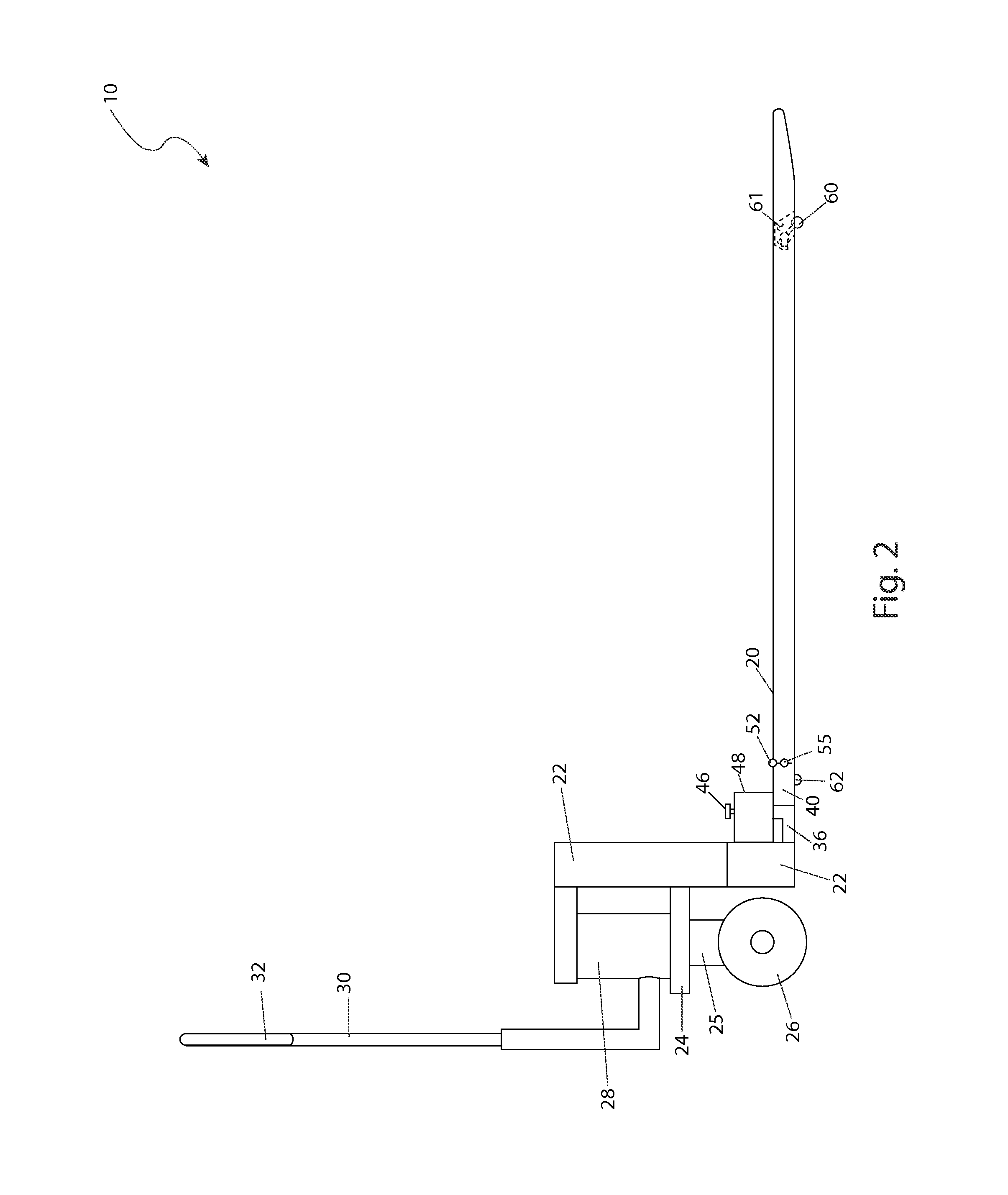

The present invention provides an antenna for reading RFID tags in a material handling environment. At least one ruggedized, upward-looking antenna is mounted on the fork (or other base-level platform) of a pallet jack or pallet truck. The antenna can be configured to read RFID tags on pallets that are loaded on the pallet jack and communicate the tag information to a warehouse management system.

Owner:EMS TECHNOLOGIES

Pallet jack antenna for RFID system

ActiveUS7557714B2Accurate readingAntenna supports/mountingsMemory record carrier reading problemsPallet jackTruck

The present invention provides an antenna for reading RFID tags in a material handling environment. At least one ruggedized, upward-looking antenna is mounted on the fork (or other base-level platform) of a pallet jack or pallet truck. The antenna can be configured to read RFID tags on pallets that are loaded on the pallet jack and communicate the tag information to a warehouse management system.

Owner:EMS TECHNOLOGIES

Pallet jack system and method for the transportation of stackable packaged goods pallets

A pallet jack is disclosed that comprises a left tine and a right tine. The pallet jack includes a lifting mechanism that may include an electrically powered hydraulic pump to effectuate the lifting motion. The pallet jack may also include power-driven wheels that are connected by an axle, thereby facilitating translational motion of the pallet jack. The wheels may be maximally spaced by using a maximum-length axle that is slightly longer than the width of the pallet jack body, thereby optimizing load stability.

Owner:COCA-COLA BOTTLING CO UNITED INC

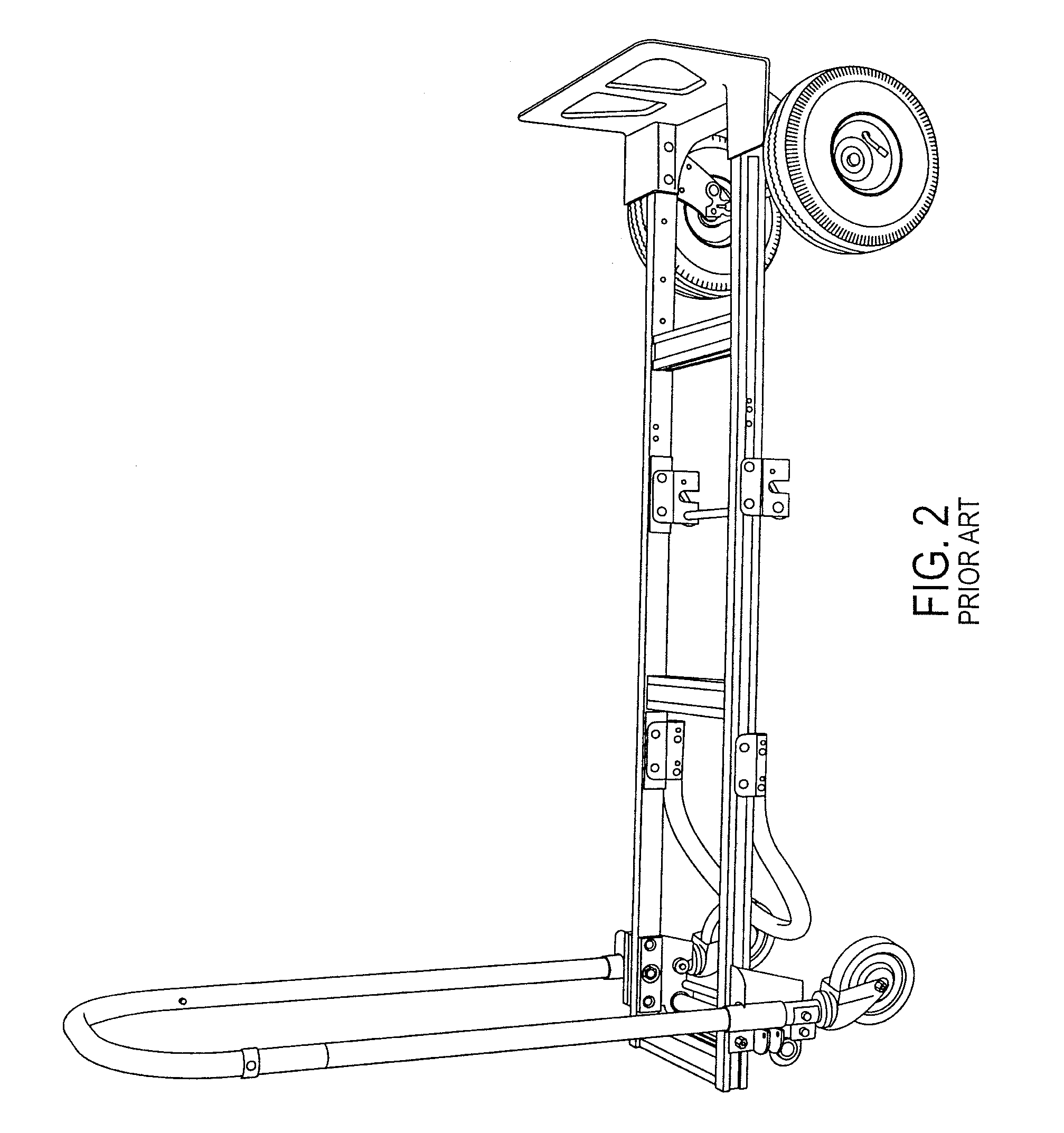

Pallet jack system and method for the transportation of stackable packaged goods pallets

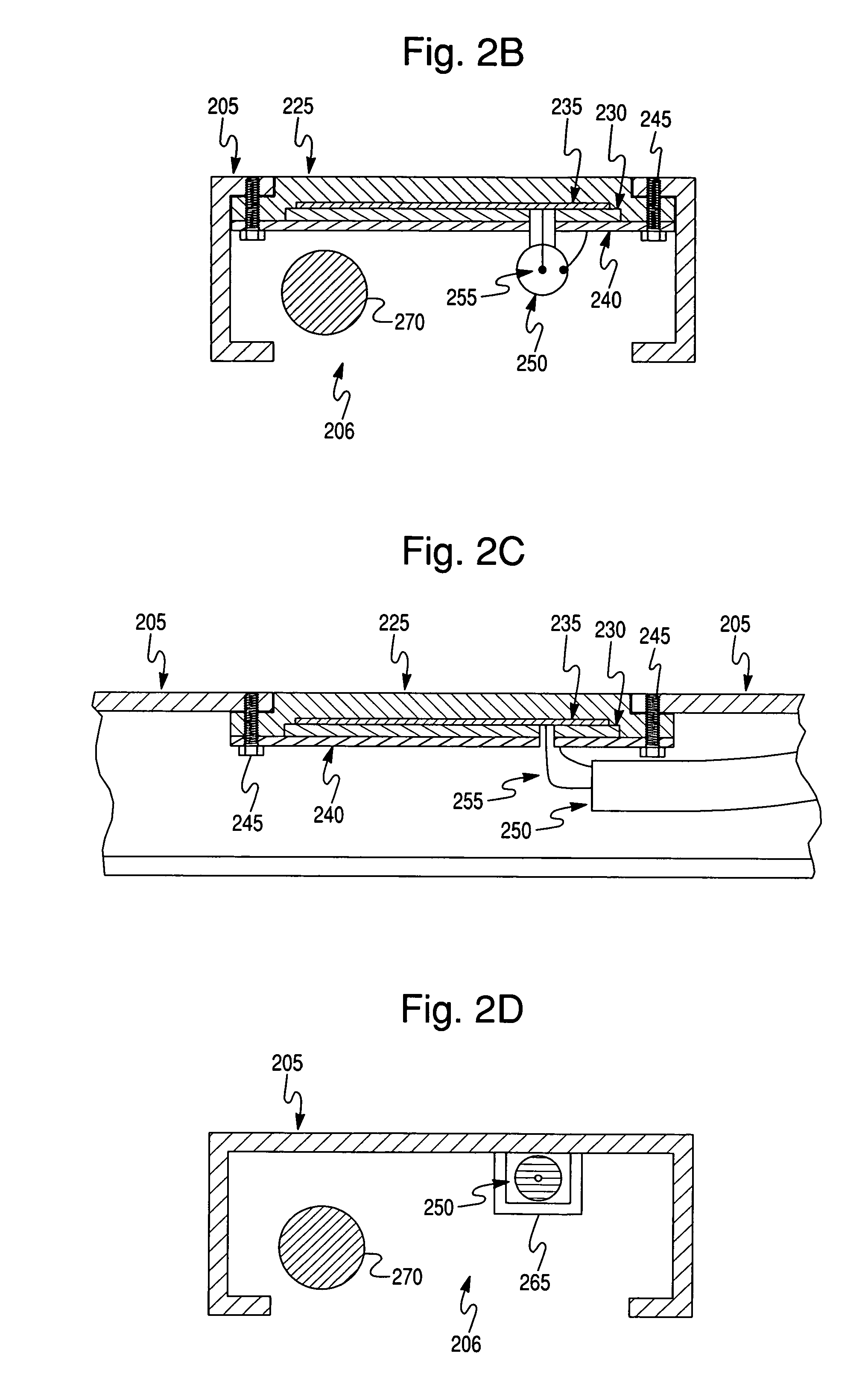

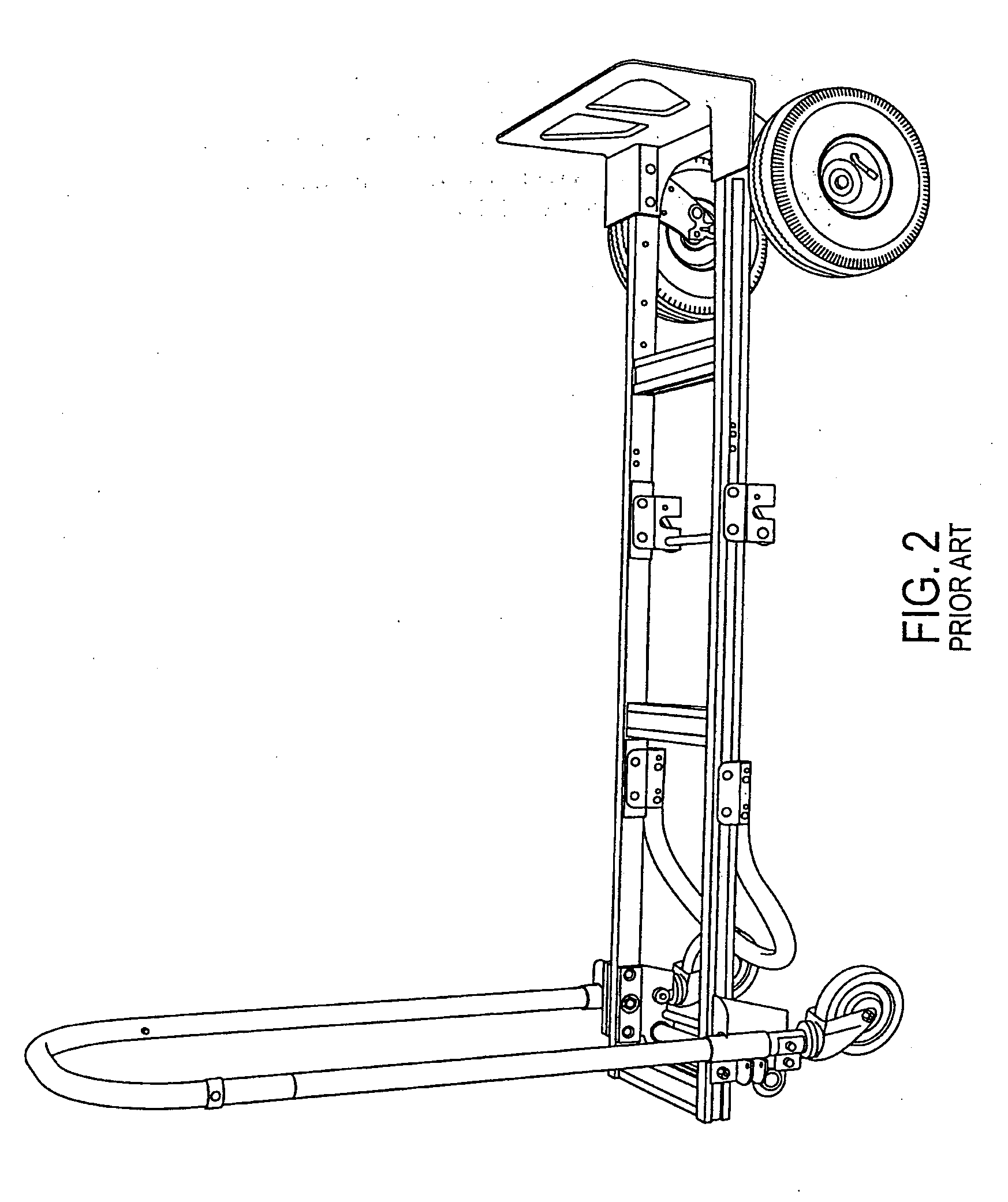

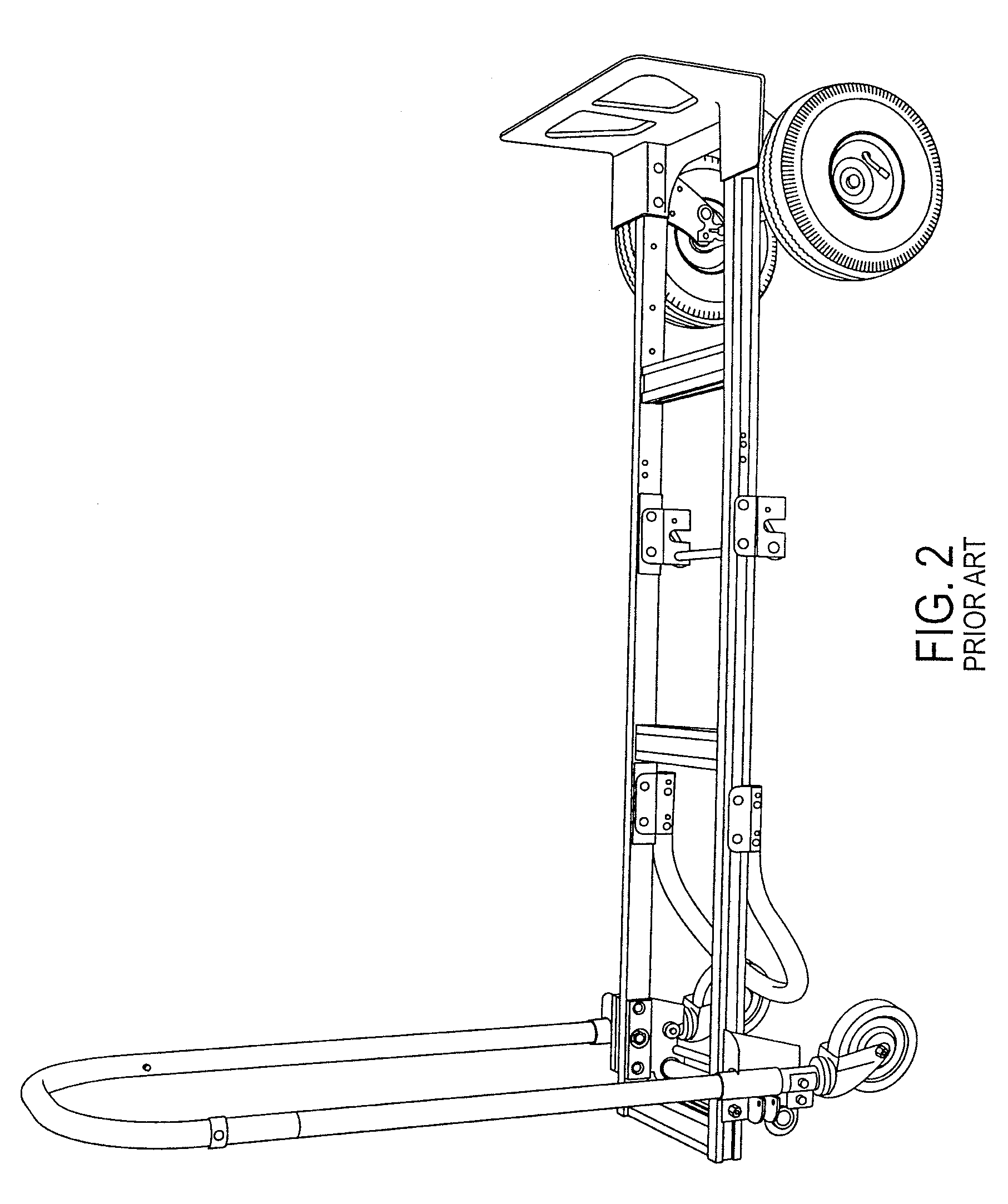

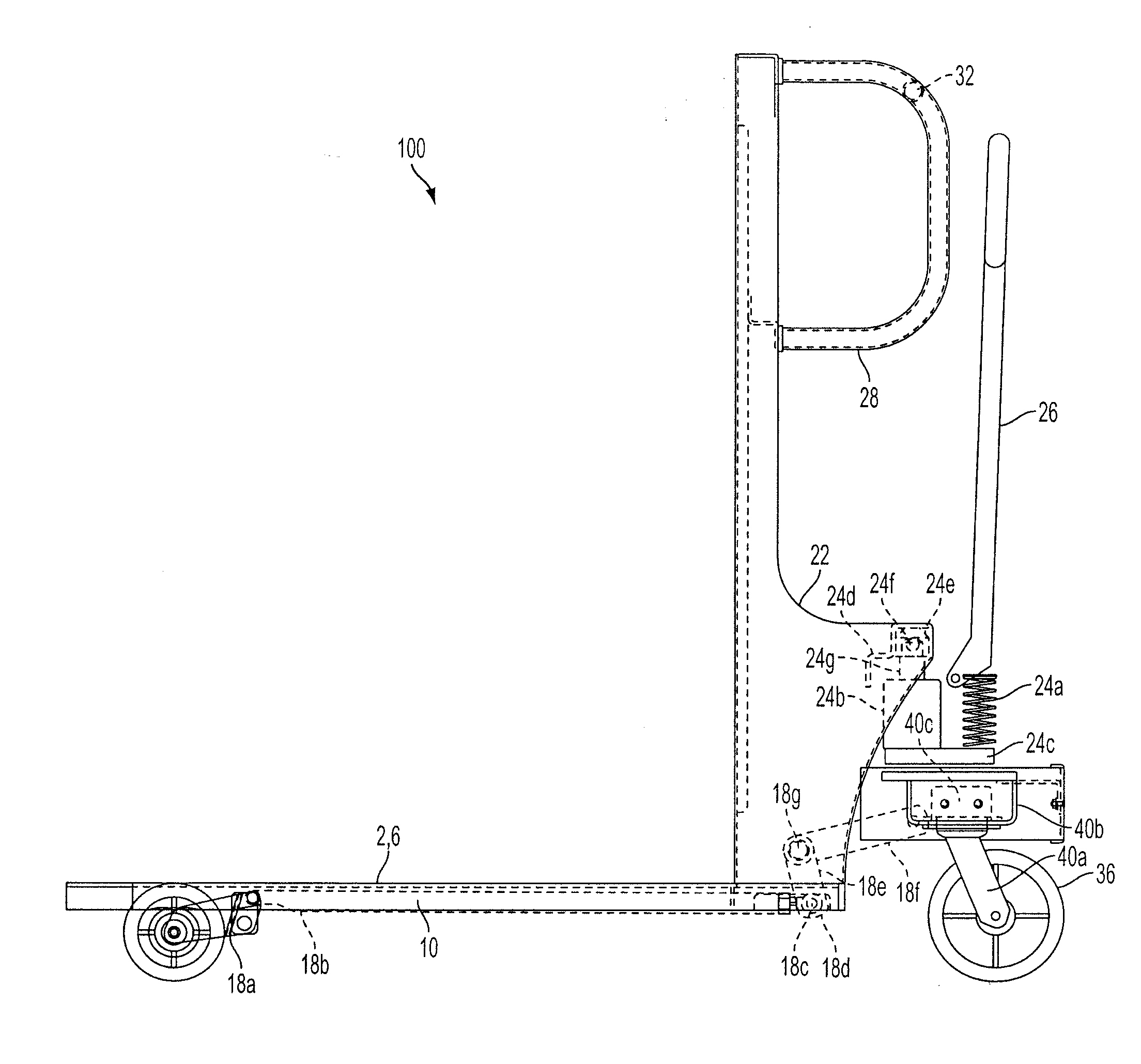

A system and method for delivery of packaged goods on a pallet with a pallet jack is described. The pallet jack enables substantially easy navigation over rough terrain through the configuration and placement of the left and right rear wheels and the configuration and placement of the left and right front wheels, as well as the design and implementation of handle bars. Other useful features include a basket for holding personal items, and jacks for retaining hand held devices that can be used to track and update deliveries and orders for goods. Accordingly, the pallet jack is preferably used to deliver consumer soft drink beverages but can be used to deliver any type of packaged product, goods and / or raw materials.

Owner:COCA-COLA BOTTLING CO UNITED INC

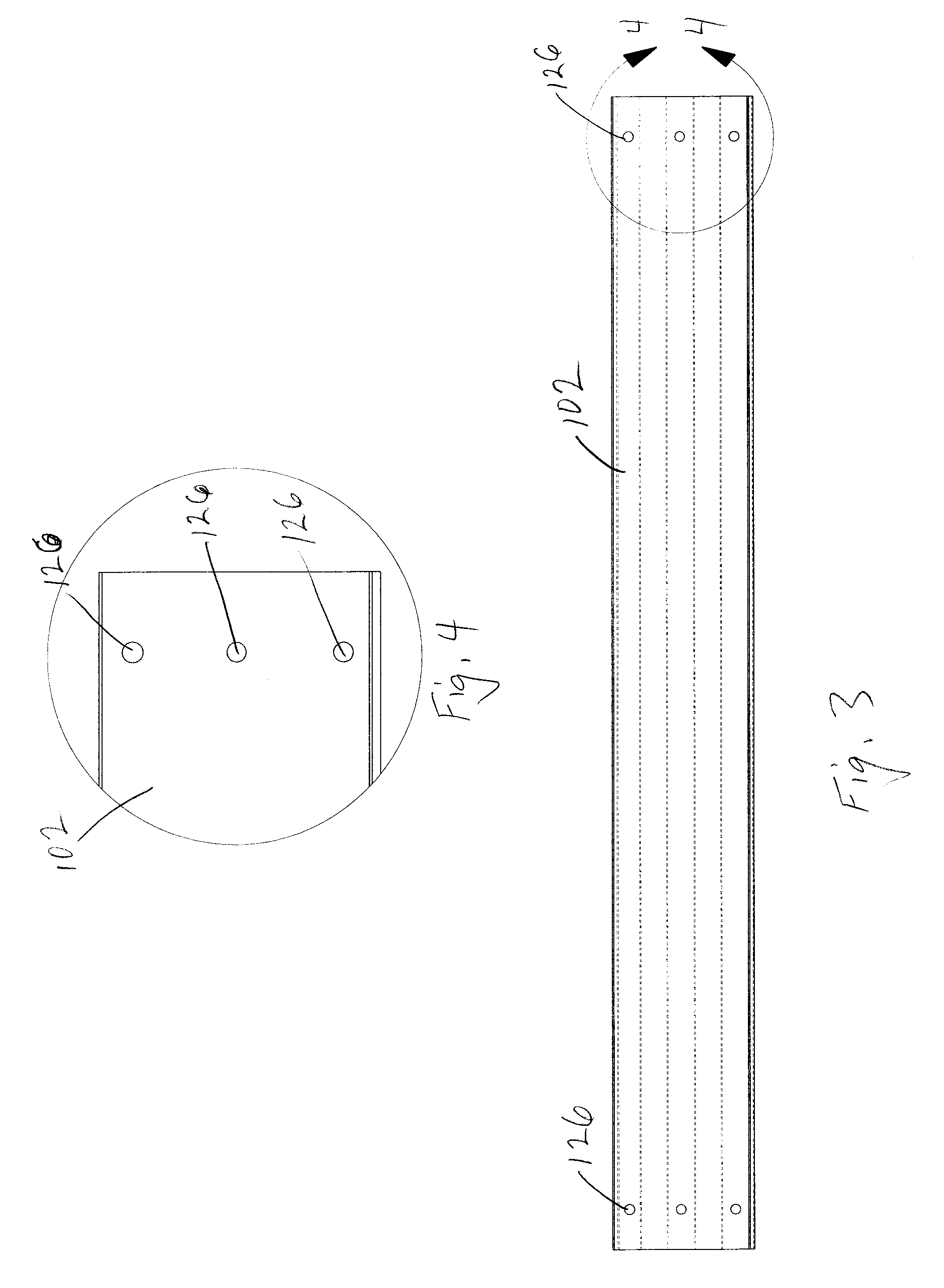

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

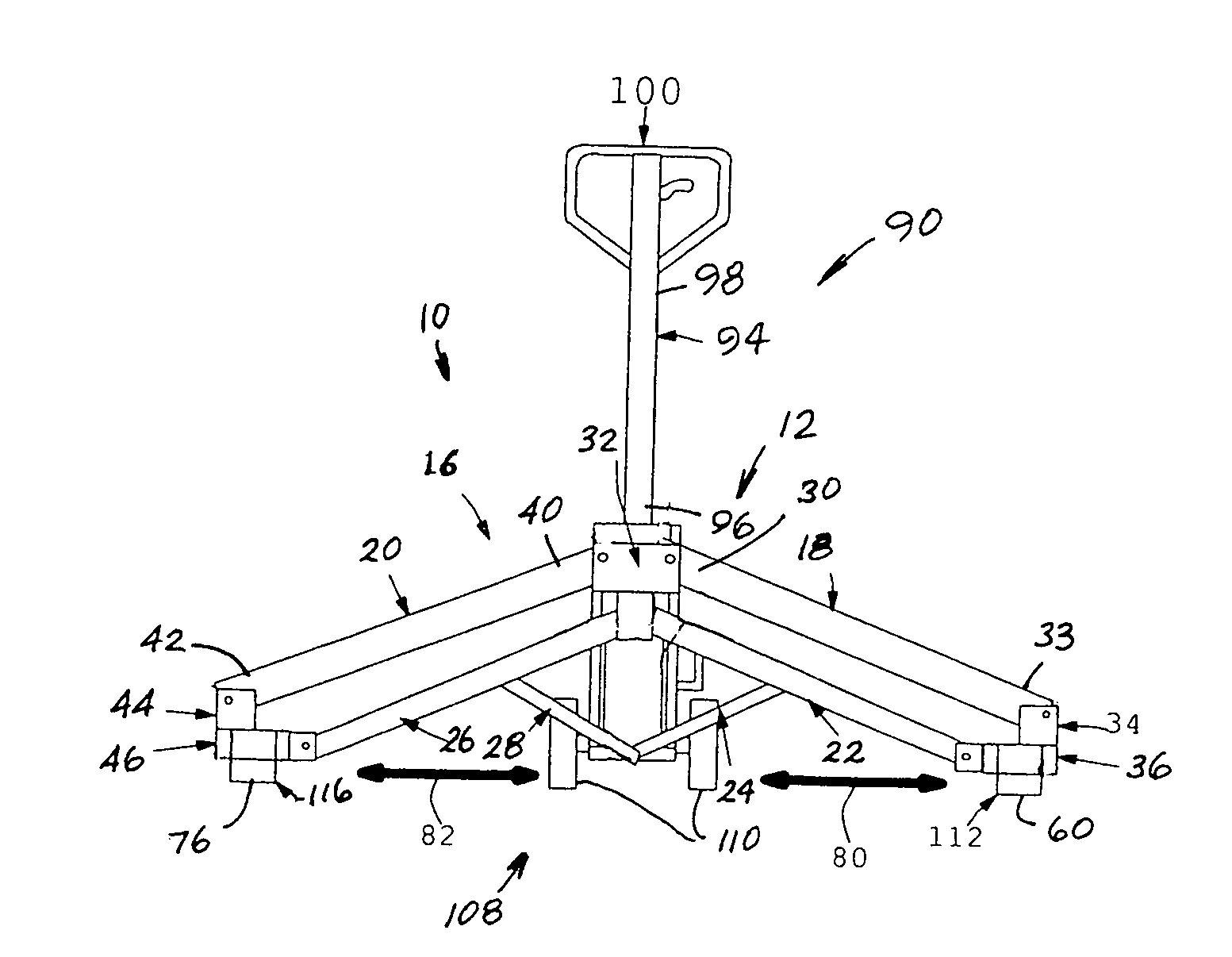

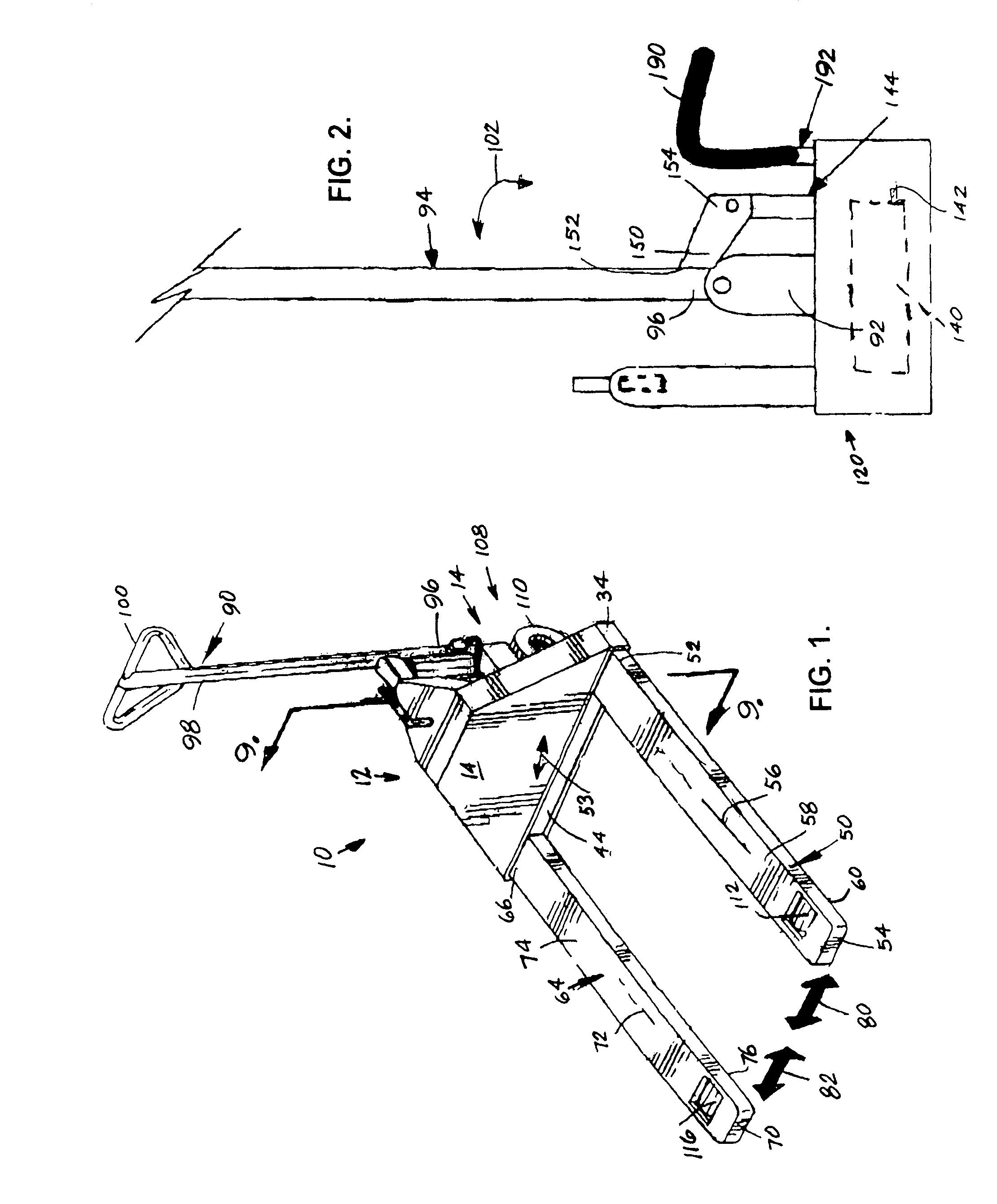

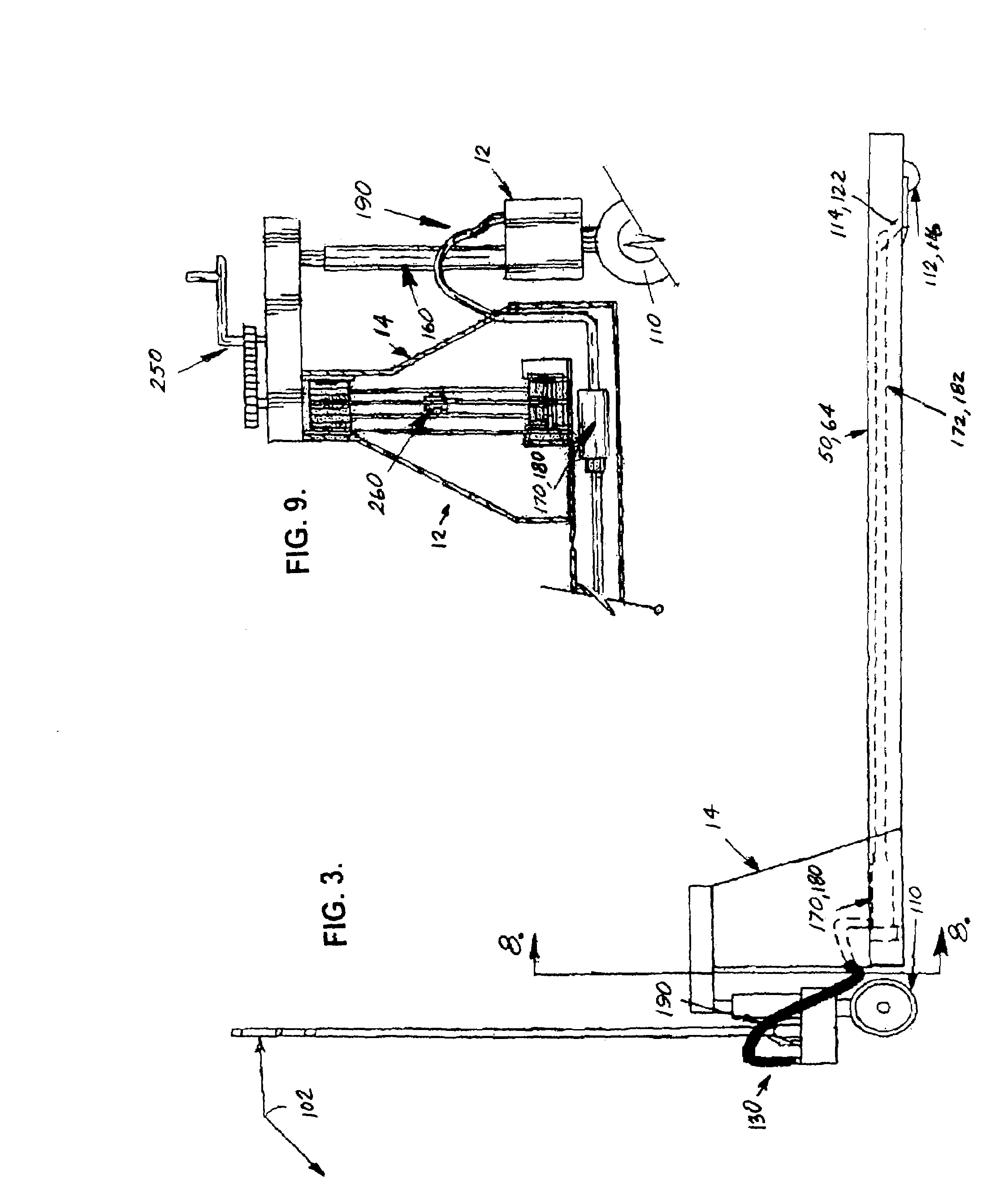

Hydraulic pallet jack

A pallet jack includes a hydraulic system that allows for adjustment of the pallet-engaging portion of the jack using a mechanical adjusting system whereby a large variety of pallet sizes can be accommodated. Once the desired width is achieved, the hydraulic system is used to raise the pallet engaging portion of the pallet jack once the pallet is engaged.

Owner:BAUMGARNER CHUCK +1

Pallet jack system and method for the transportation of stackable packaged goods pallets

ActiveUS20090183953A1Prevent inadvertent rollingUnderstructuresSupporting partsPallet jackEngineering

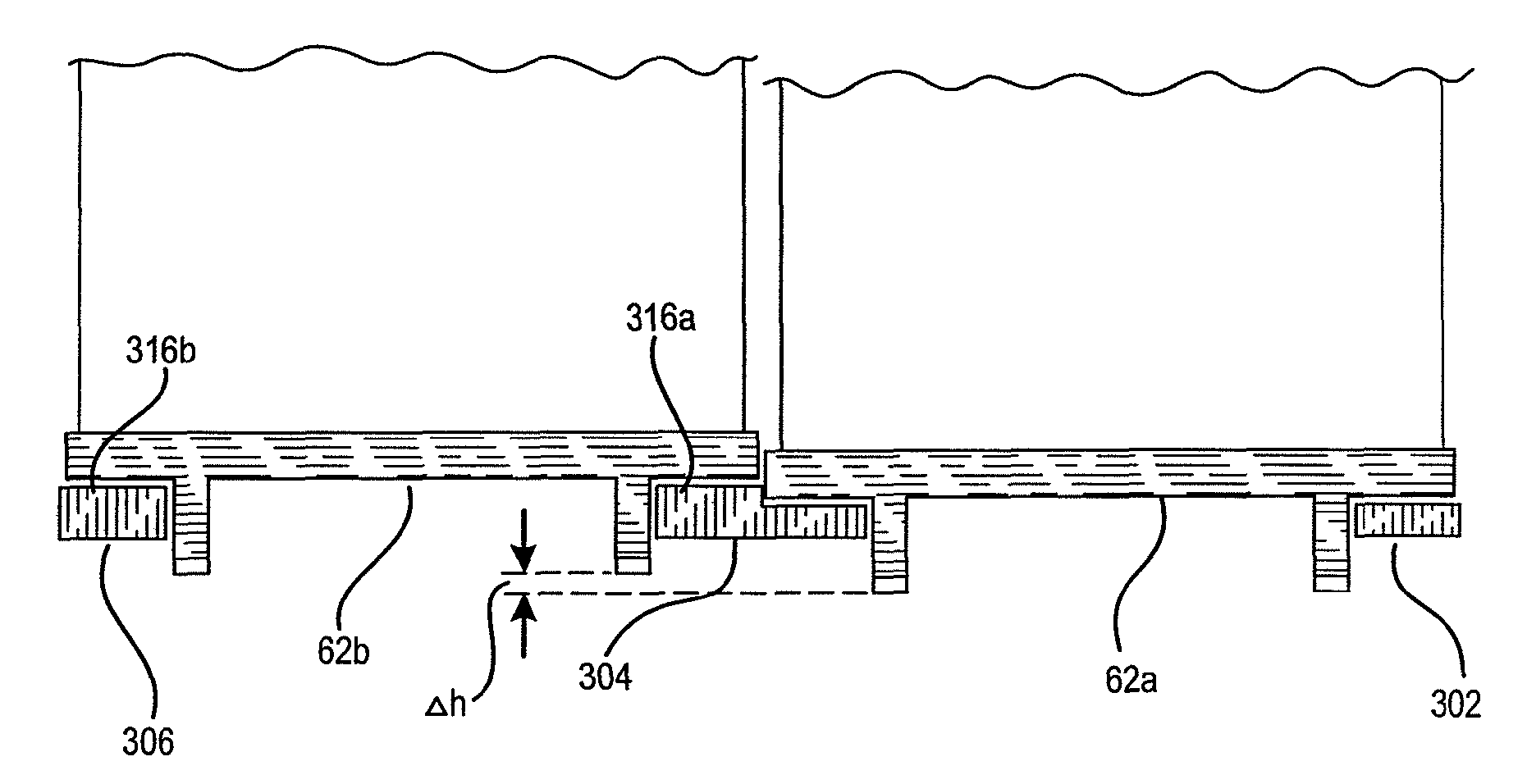

A motorized pallet jack comprises one or more motors that can propel the pallet jack and lift each of the tines. The pallet jack has three tines, and the center tine can be about 2 times the width of each of the left and right tines, though other widths of the center tine can also be implemented. Because the center tine is about twice the width of the left and right tines, two pallets, side-by-side, can be carried simultaneously with only three tines. A portion of the center tine (a right-most portion) and the right tine can have raised areas that enable an operator of the pallet jack to lift a right pallet that sits on the raised areas higher than the left pallet. The left pallet sits on the left tine and center tine without the raised areas (at a lower height). The operator of the pallet jack can place the left pallet in a first location without disengaging the tines from the right pallet, or without lowering the right pallet all the way to the ground (or a first location surface). Alternatively, the raised areas can be located on the left tine and the left-most portion of the center tine, in which case, the operator of the pallet jack can place the right pallet in a first location without disengaging the tines from the left pallet, or without lowering the left pallet all the way to the ground (or a first location surface).

Owner:COCA-COLA BOTTLING CO UNITED INC

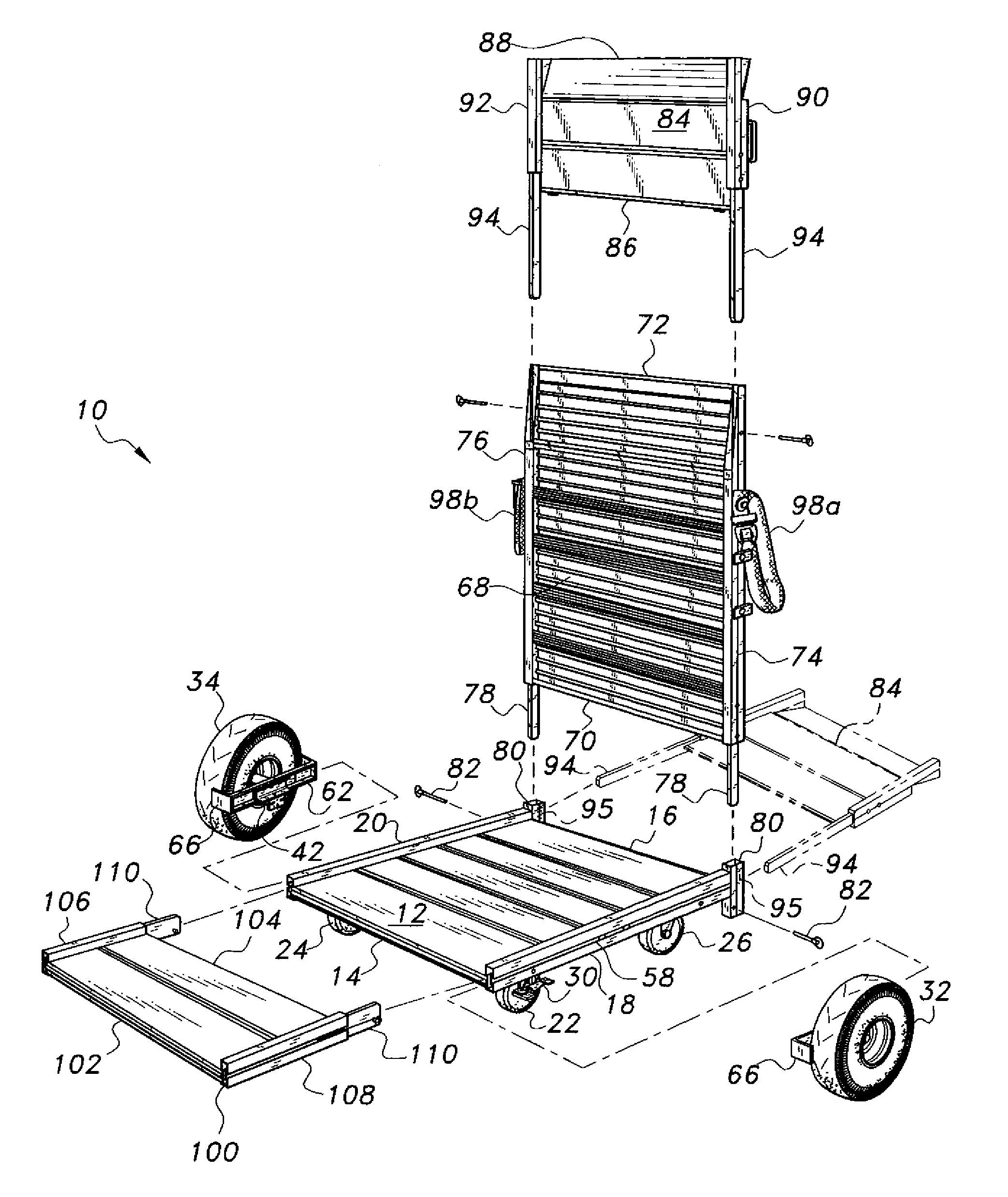

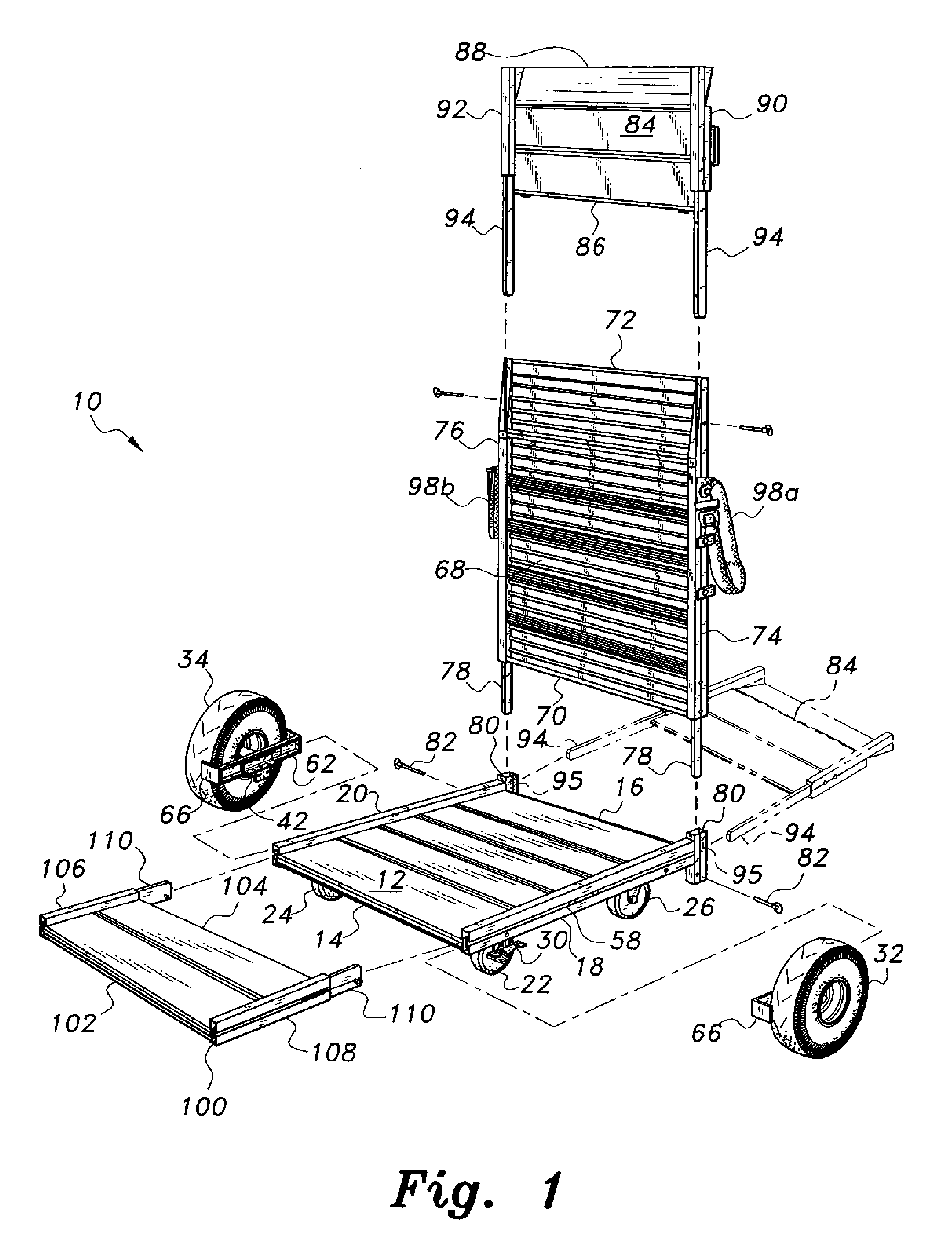

Foldable and width adjustable pallet jack

InactiveUS8979099B1Easy to transportSufficient weightUnderstructuresSupporting partsPallet jackEngineering

A foldable and portable pallet jack for transporting pallets comprises width-adjustable and folding forks. The skid forks adjust to different sized pallets or materials. The skid forks also fold upright against the handle section of the pallet jack allowing it to be compactly transported and stored. With the forks in a horizontal and locked position, the pallet jack provides normal lifting and transporting of heavy pallets or material in a conventional manner.

Owner:ELLIS BRUCE G

Pallet jack system and method for the transportation of stackable packaged goods pallets

ActiveUS7988405B2Prevented from inadvertently coming into contactPrevent inadvertent rolling of the pallet jackSemiconductor/solid-state device manufacturingUnderstructuresEngineeringPallet jack

Owner:COCA-COLA BOTTLING CO UNITED INC

Pallet jack system and method for the transportation of stackable packaged goods pallets

ActiveUS20090185890A1Prevent inadvertent rollingSemiconductor/solid-state device manufacturingUnderstructuresPallet jackEngineering

A pallet jack is disclosed that comprises a left tine, center tine, and a right tine. The center tine is about 2 times the width of each of the left and right tines, though other widths of the center tine can also be implemented. Because the center tine is about twice the width of the left and right tines, two pallets, side-by-side, can be carried simultaneously with only three tines. According to another embodiment of the pallet jack, a portion of the center tine (a right-most portion) and the right tine can have raised areas that enable an operator of the pallet jack to lift a right pallet that sits on the raised areas higher than the left pallet. The left pallet sits on the left tine and center tine without the raised areas (at a lower height). Thus, the operator of the pallet jack can place the left pallet in a first location without disengaging the tines from the right pallet, or without lowering the right pallet all the way to the ground (or a first location surface). Alternatively, the raised areas can be located on the left tine and the left-most portion of the center tine, in which case, the operator of the pallet jack can place the right pallet in a first location without disengaging the tines from the left pallet, or without lowering the left pallet all the way to the ground (or a first location surface).

Owner:COCA-COLA BOTTLING CO UNITED INC

Pallet jack system and method for the transportation of stackable packaged goods pallets

Owner:COCA-COLA BOTTLING CO UNITED INC

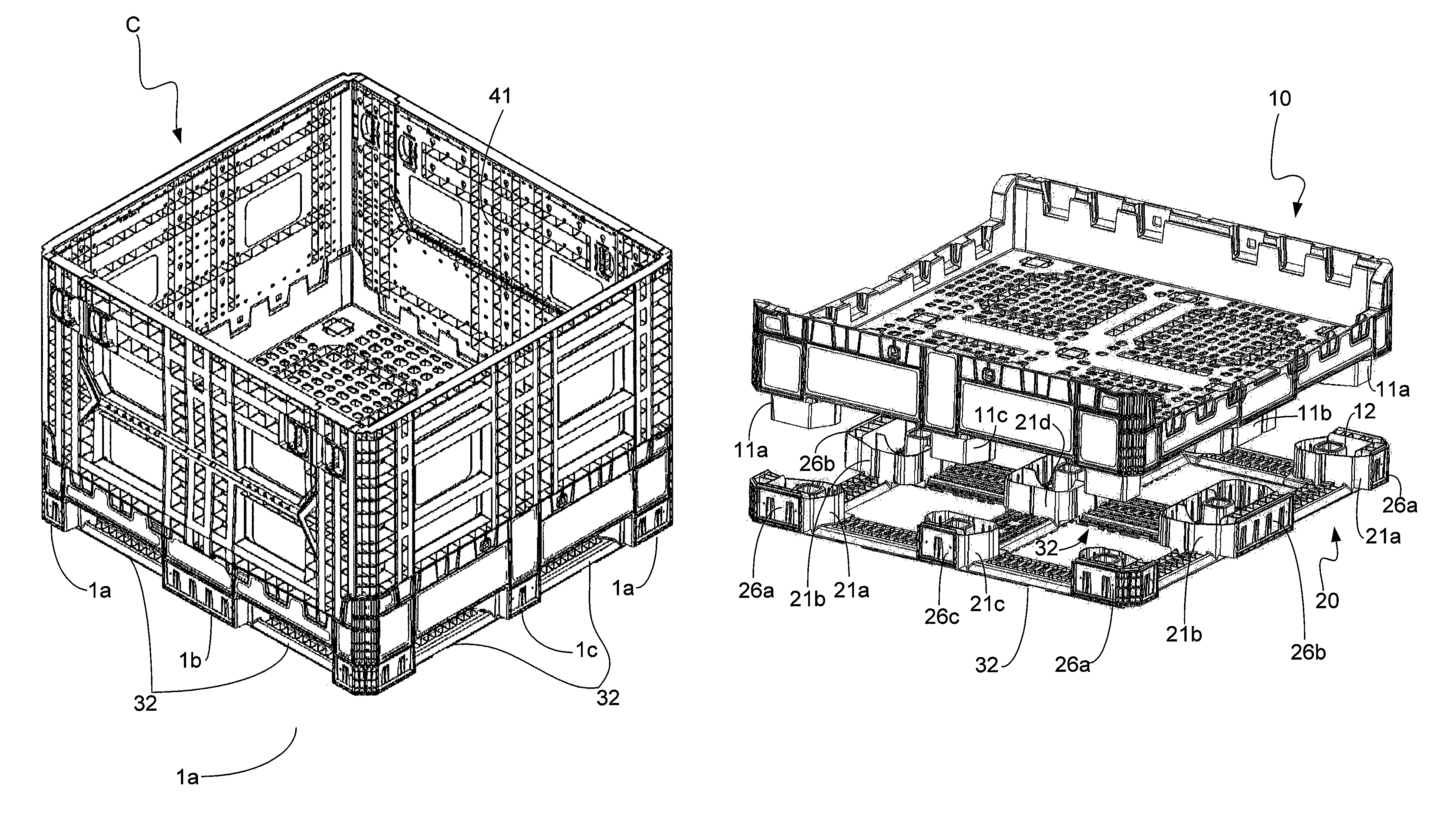

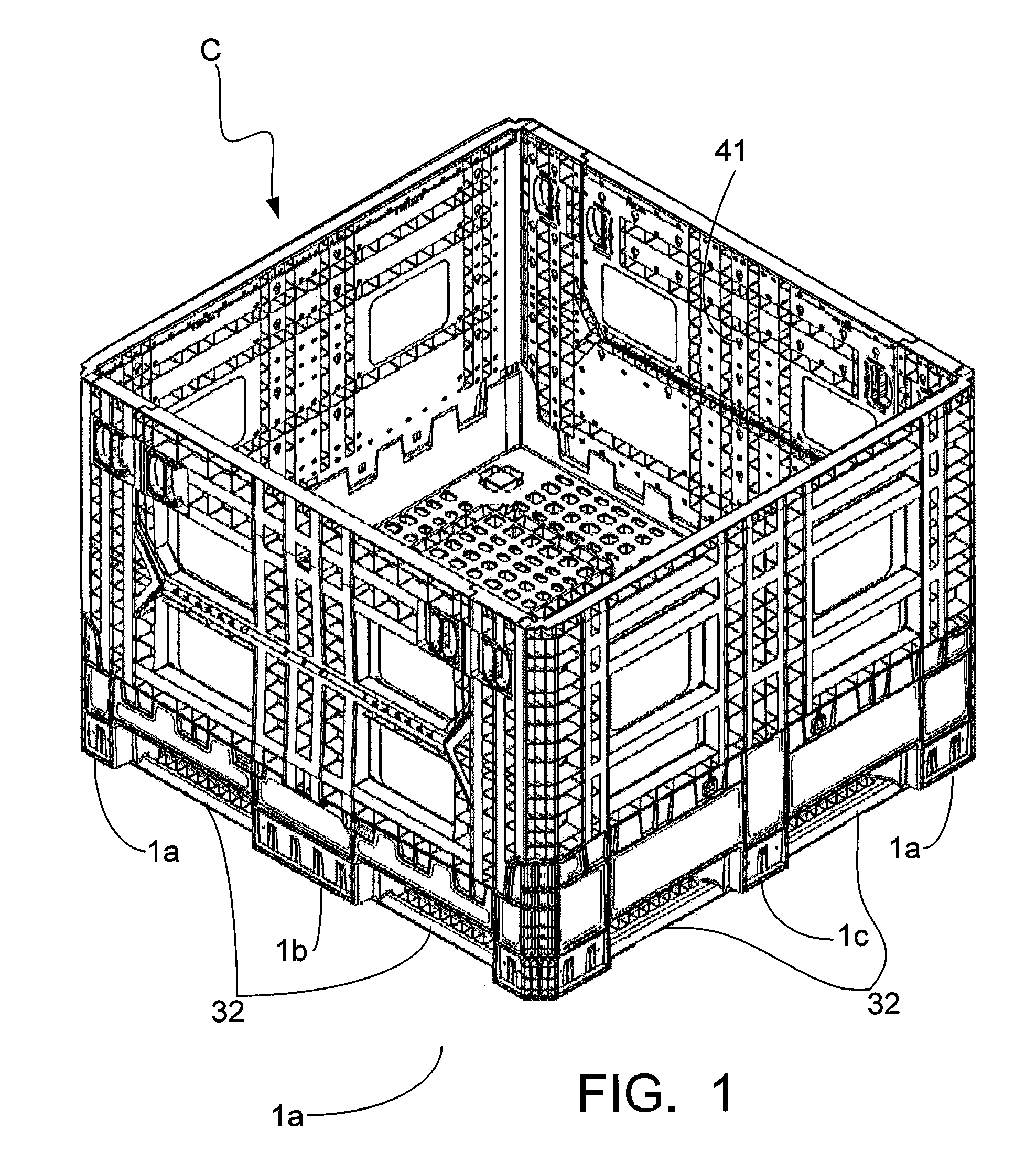

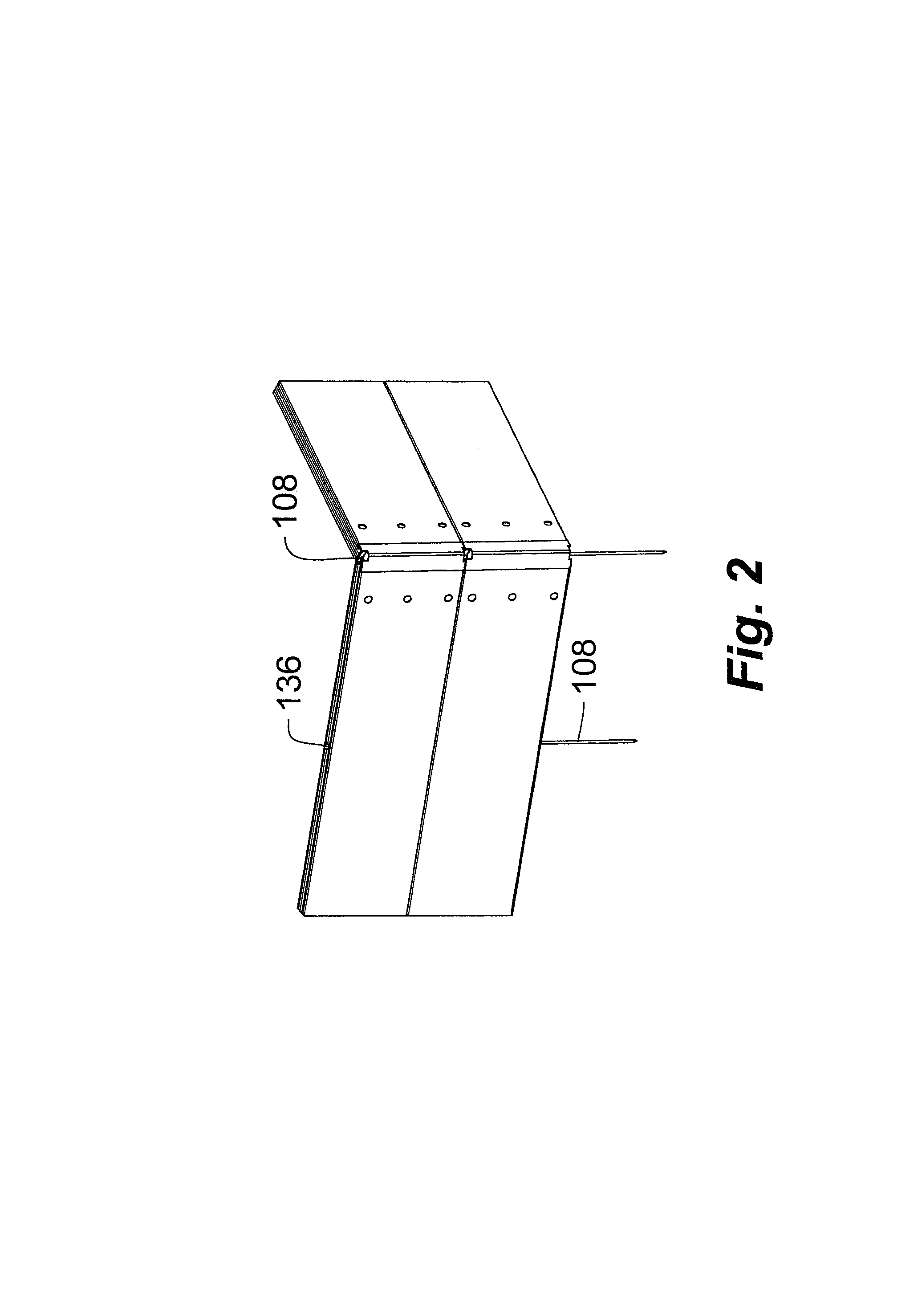

Shipping container

ActiveUS8434618B2Without lessening capacity of containerAdding additional weight and costPackage recyclingLarge containersDunnageEngineering

A reusable shipping container adapted to resist damage to the feet of the container and to allow the fork straps to be replaced if the fork straps or the feet are damage. The container can also easily be adapted to accommodate the use of pallet jacks without reducing the capacity of the container or increasing the weight of the container. The container is also adapted to easily receive dunnage required to protect the material being shipped in the container.

Owner:MACROPLASTICS

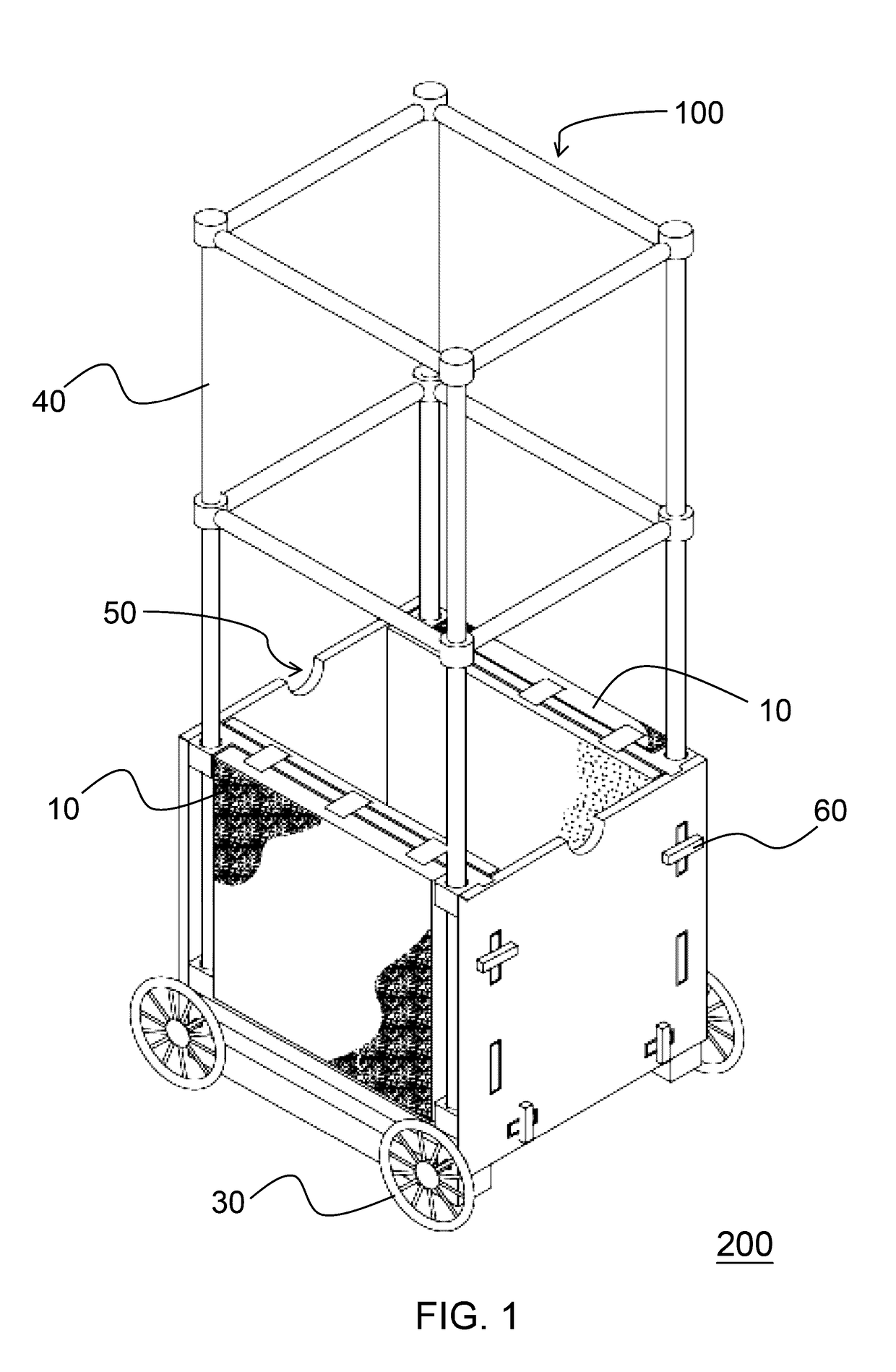

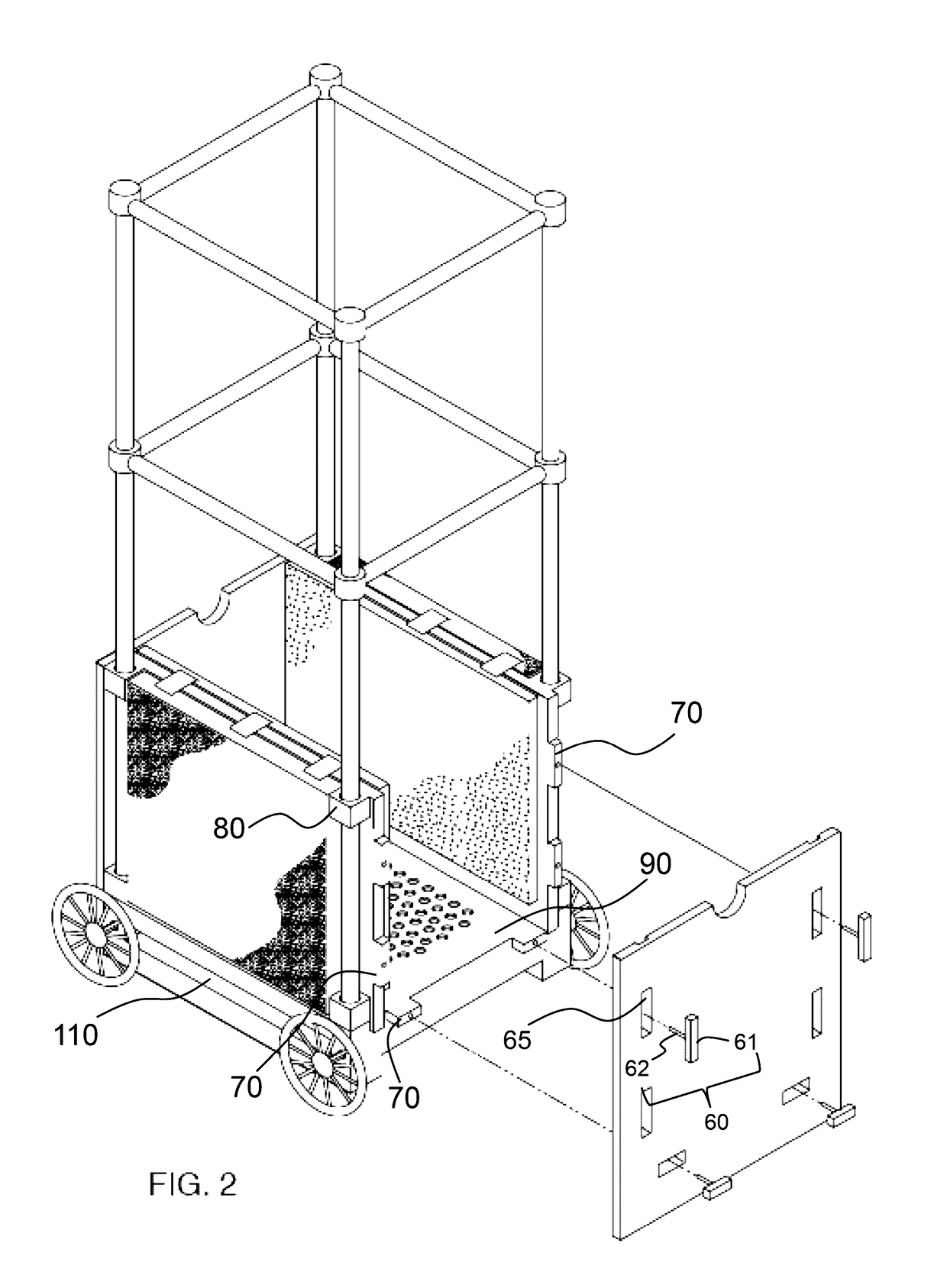

Modular dolly

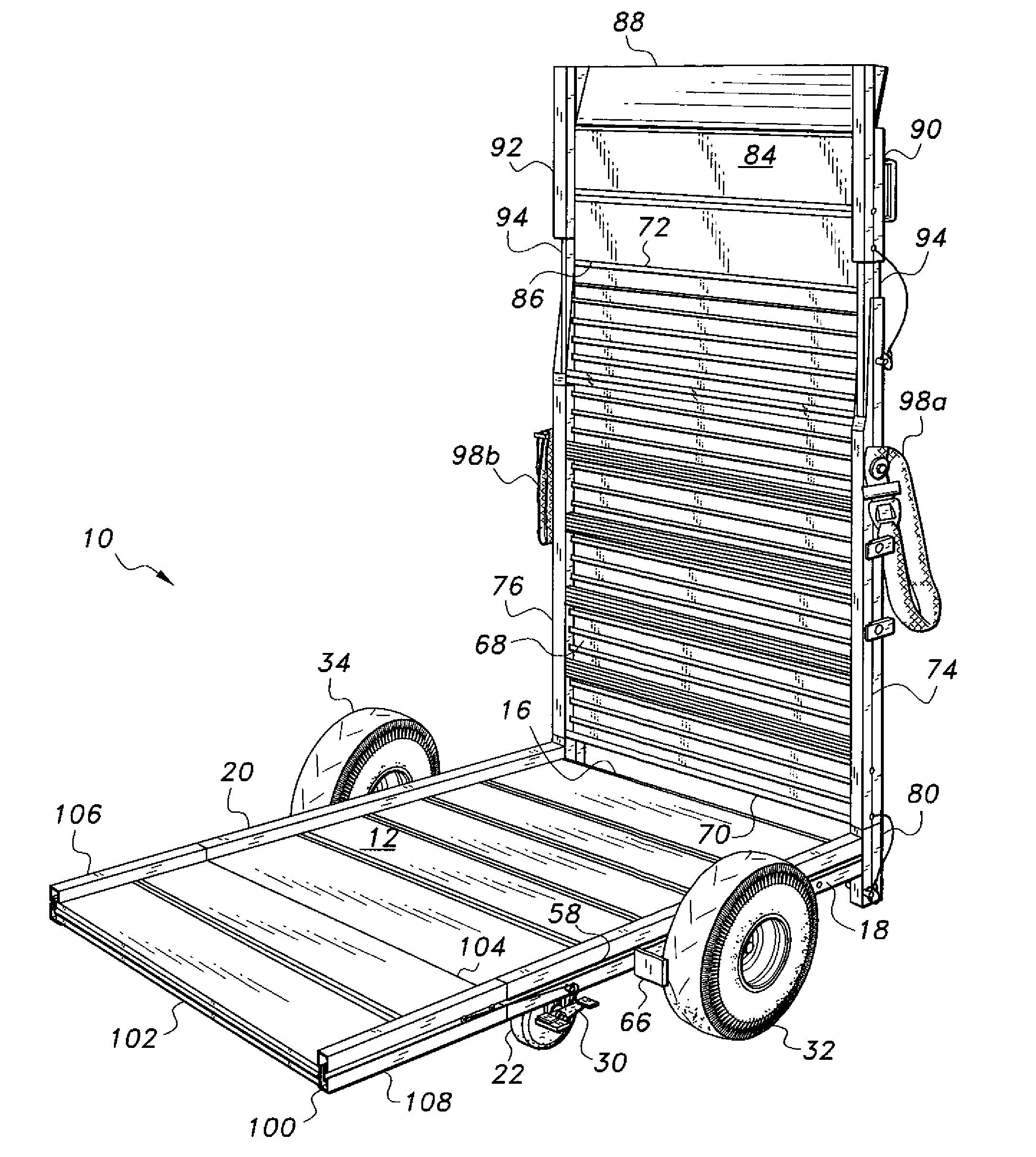

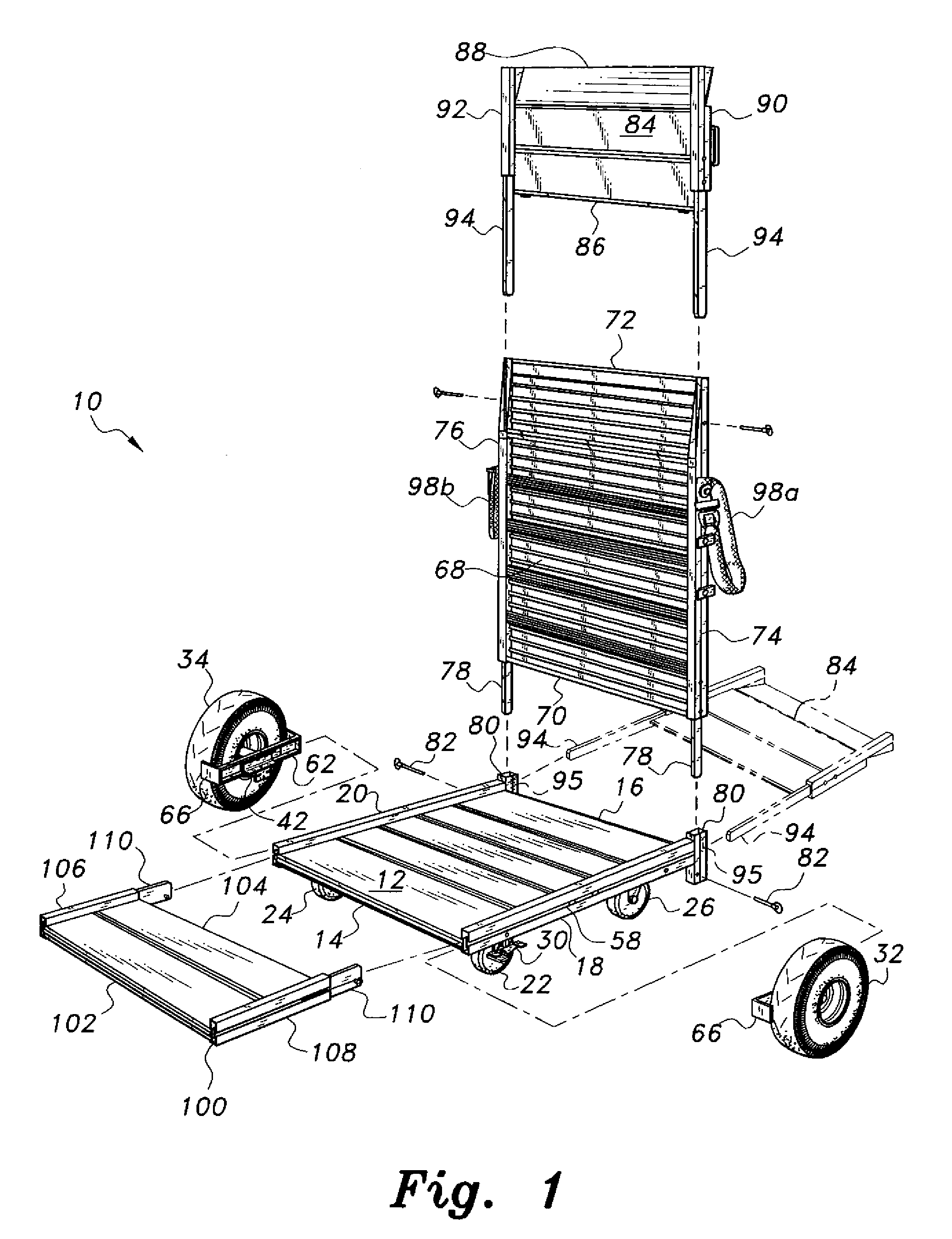

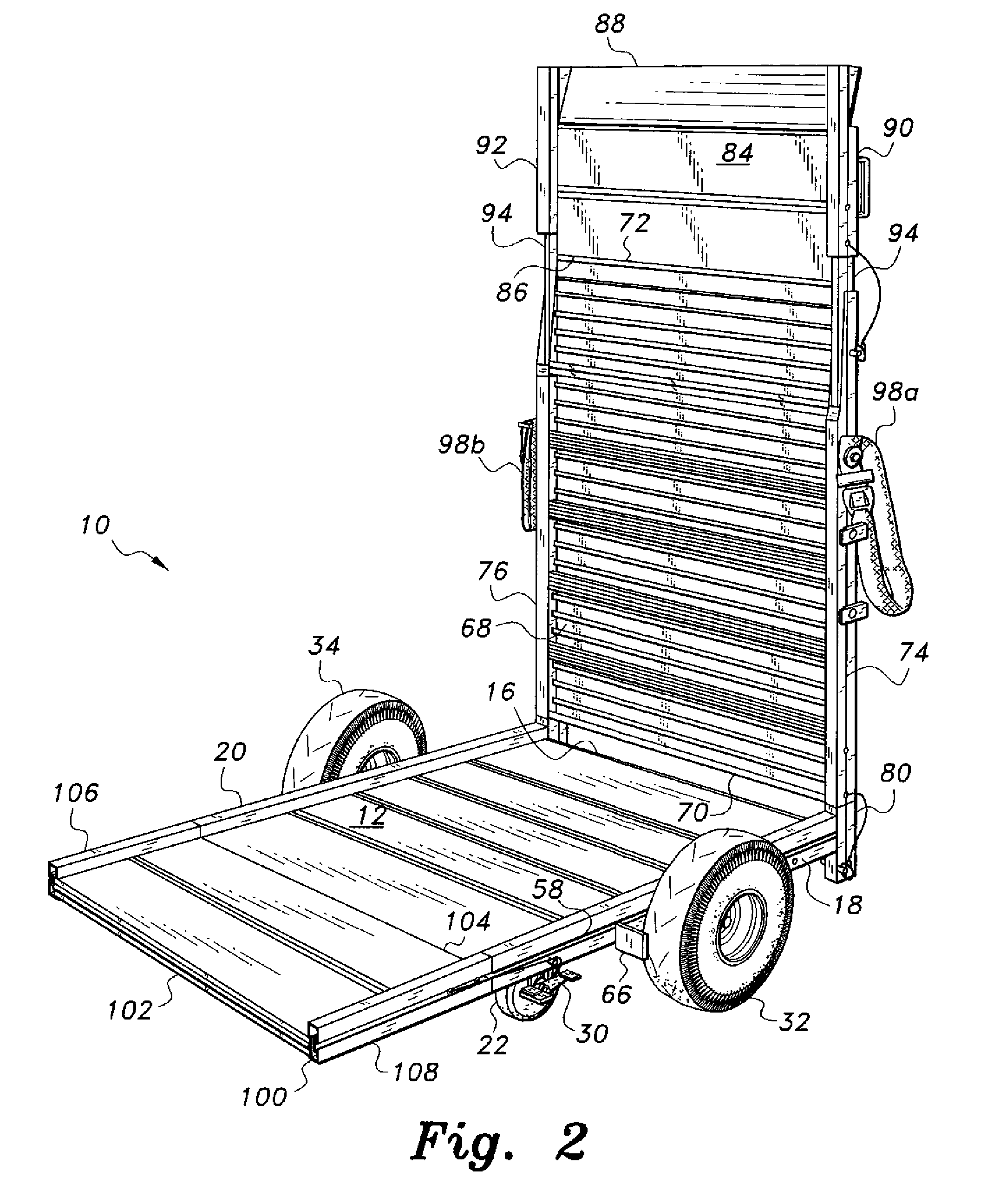

ActiveUS20110052357A1Promote sportsCarriage/perambulator accessoriesCarriage/perambulator with single axisModularityEngineering

The modular dolly is a manually operated device facilitating the transport of large, heavy, and / or bulky objects. The dolly includes four smaller wheels and two larger diameter wheel and brake assemblies for temporary installation to the sides of the dolly platform for movement over soft, rough, and / or uneven surfaces. A ramp is removably attachable to the loading end of the platform coplanar therewith to facilitate loading the dolly. The ramp also attaches removably to the opposite anchor end of the platform and normal thereto, to serve as a backstop or anchor for a load placed on the platform. A smaller secondary panel may be installed in the anchor end when the ramp is in use during loading, or may be assembled coplanar to the ramp or platform to lengthen the ramp or platform. The dolly may also be used with a stair-climbing hand truck, forklift, pallet jack, or the like.

Owner:ESCALERA

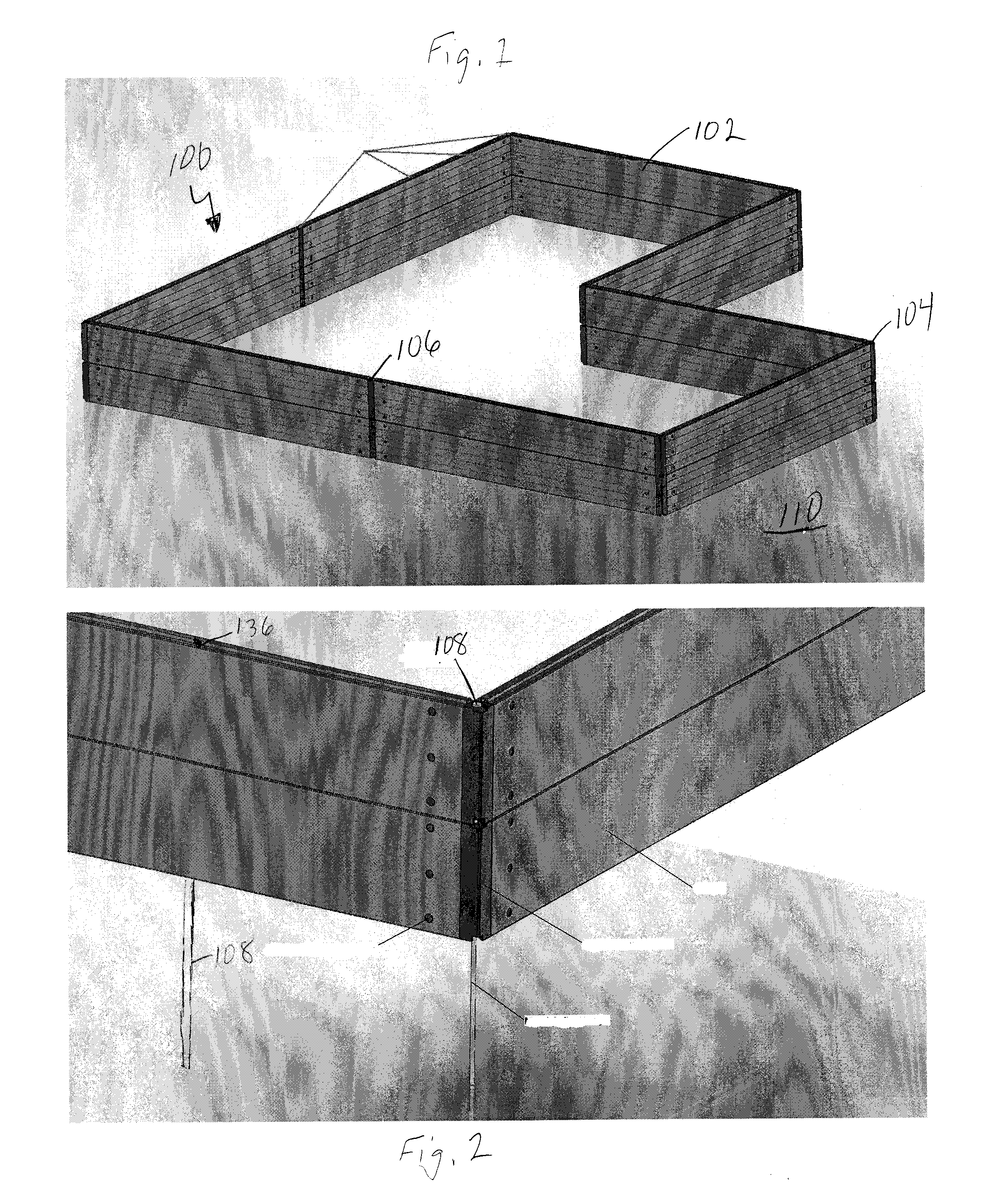

Raised garden bed kit

InactiveUS7966766B2Reduce bowing and twistingImprove rigidityPlanting bedsEdging using tilesEngineeringPallet jack

The instant invention provides a kit for assembly of a raised garden bed. The raised garden bed includes panel members, corner connector members, and linear connector members constructed of a polymeric material and adapted to be snapped together into a substantially rigid raised garden bed without the need for special tools or excessive strength. A tongue and groove arrangement is also provided to allow for panel member stacking for increased garden bed height. The components of the kit are constructed and arranged to be packed into a relatively small profile for shipping and transport and are generally light enough to be loaded and unloaded without the need for equipment such as a forklift or pallet jack.

Owner:SUNCAST TECH

Corrugated pallet

InactiveUS7000549B2Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces from an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

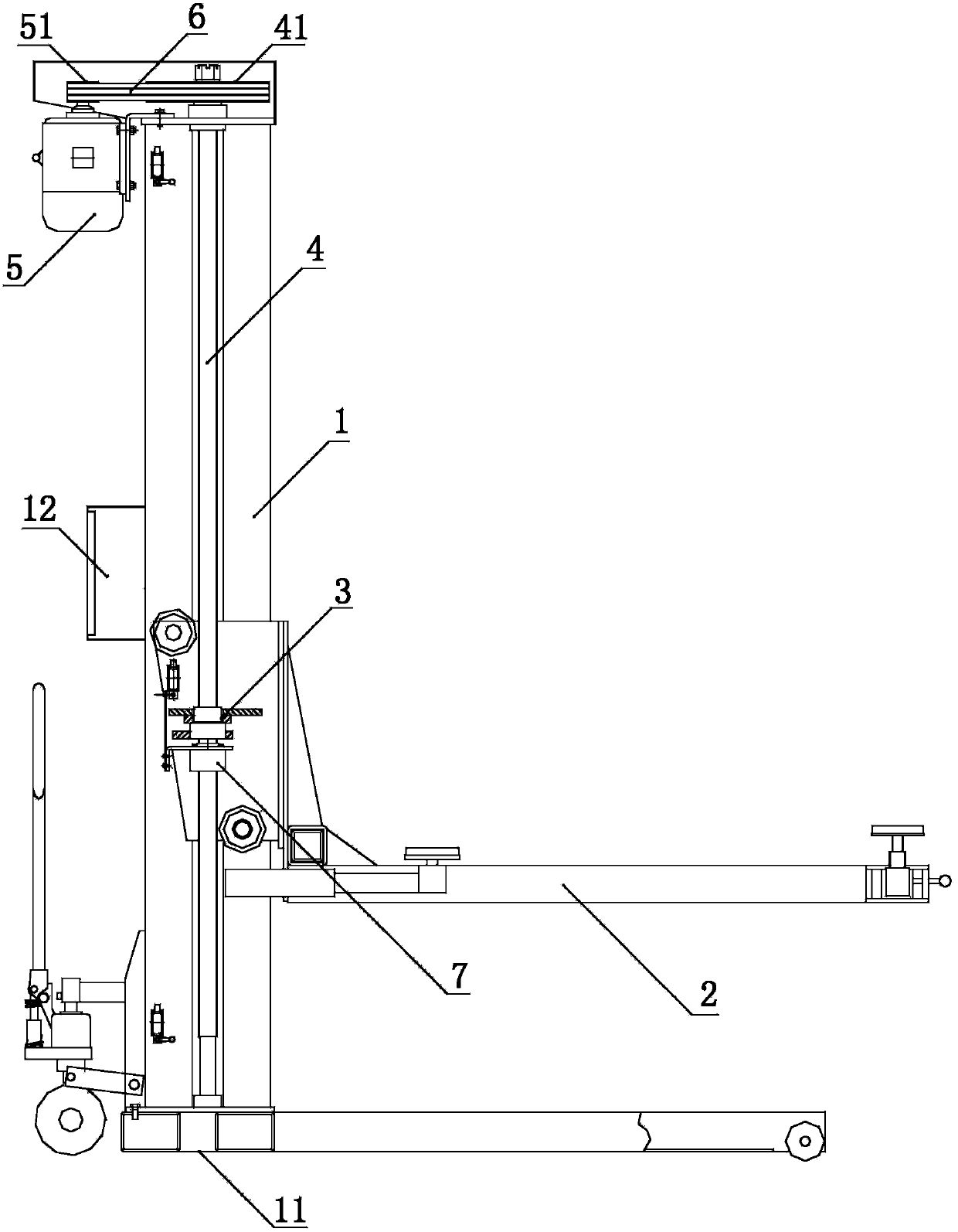

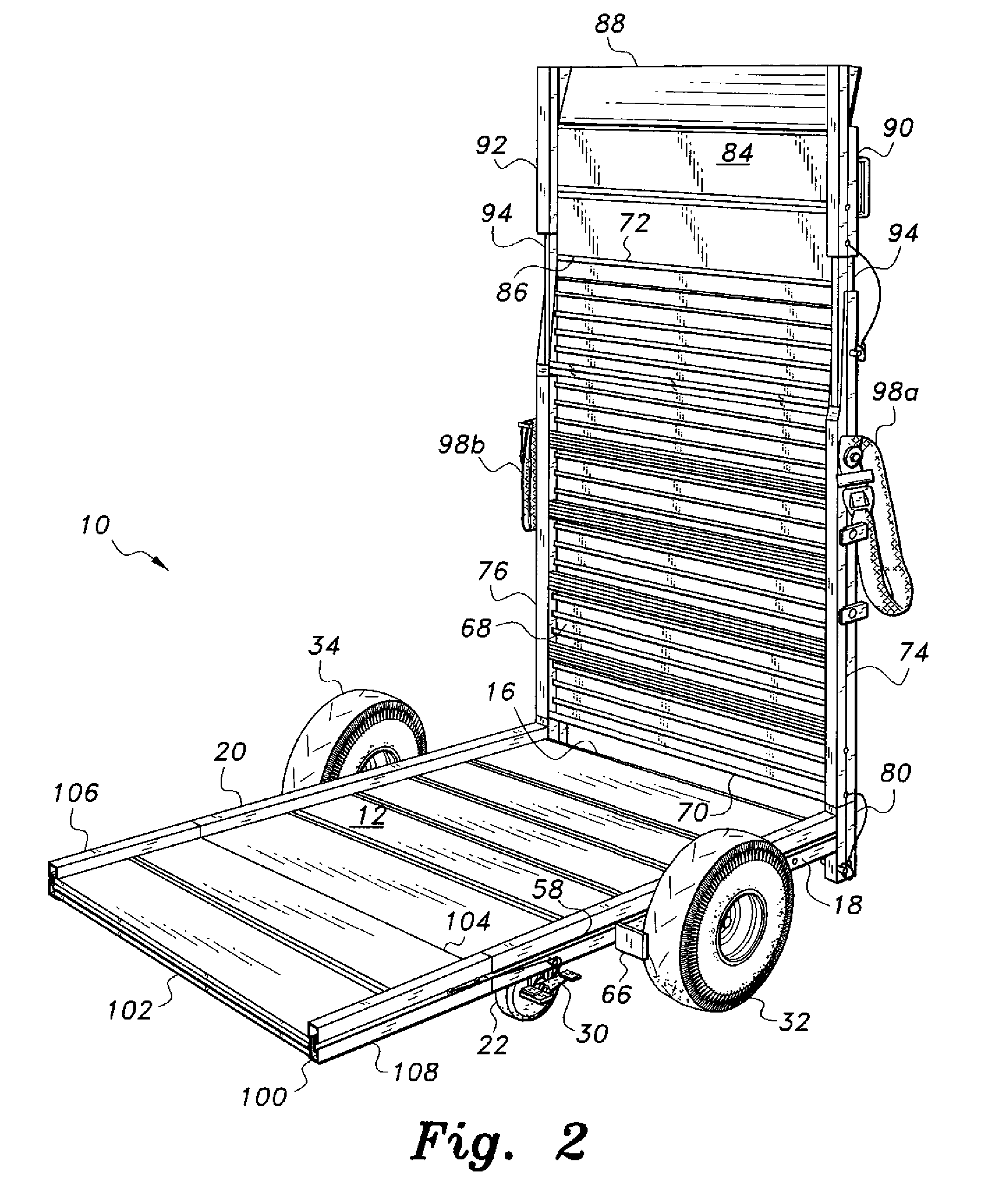

Single-column movable lifting machine for car

The invention discloses a single-column movable lifting machine for a car. A lifting arm, a main lifting nut, a lead screw and a motor are arranged on a stand column, the lifting arm is arranged on the main lifting nut in a sitting mode, the main lifting nut is screwed on the lead screw, the upper end of the lead screw is sleeved with a lead screw belt wheel, a motor shaft of the motor is sleeved with a motor shaft belt wheel, and the lead screw belt wheel and the motor shaft belt wheel are connected through a belt. Through the single-column movable lifting machine, the area of the occupied workplace is reduced, and the lifting machine can be fixed to the ground without an expansion bolt. The lower end of the stand column is provided with a manual pallet jack, and one machine achieves multiple purposes. When the lifted car waits for the next procedure, the ifting machine can retreat and move to the work position of another car to be repaired for lifting work. Due to the fact that the lifting machine is simple in structure and convenient to move, the use requirement of a rapid car repair shop is met. The lifting machine can be used as parking equipment of a household garage, a small passenger car is lifted by more than 1.6 m to 1.8 m, a second car can be parked below the small passenger car, space is saved, the structure is simple, and the lifting machine is very practical.

Owner:上海欧珀机电设备有限公司

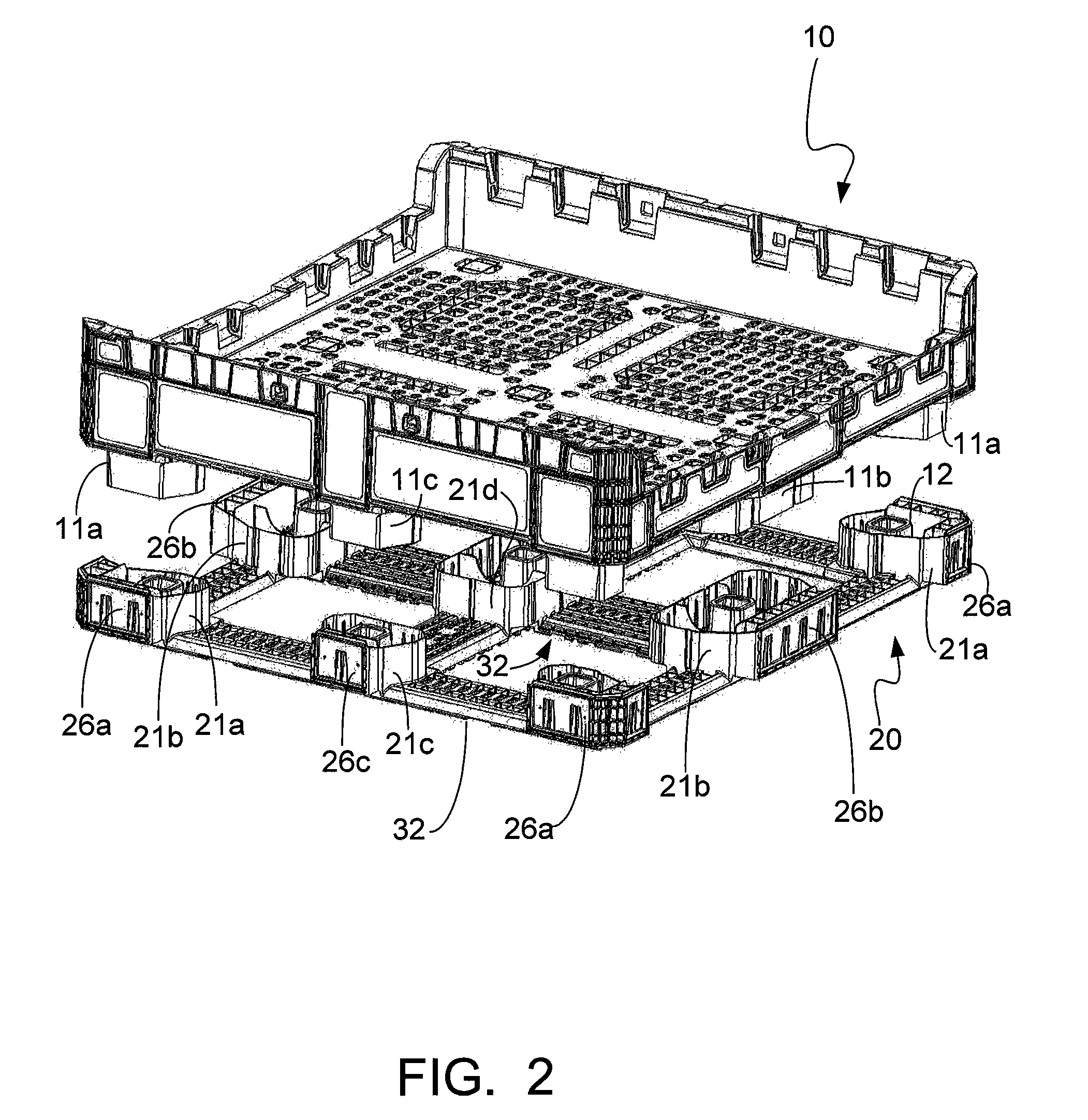

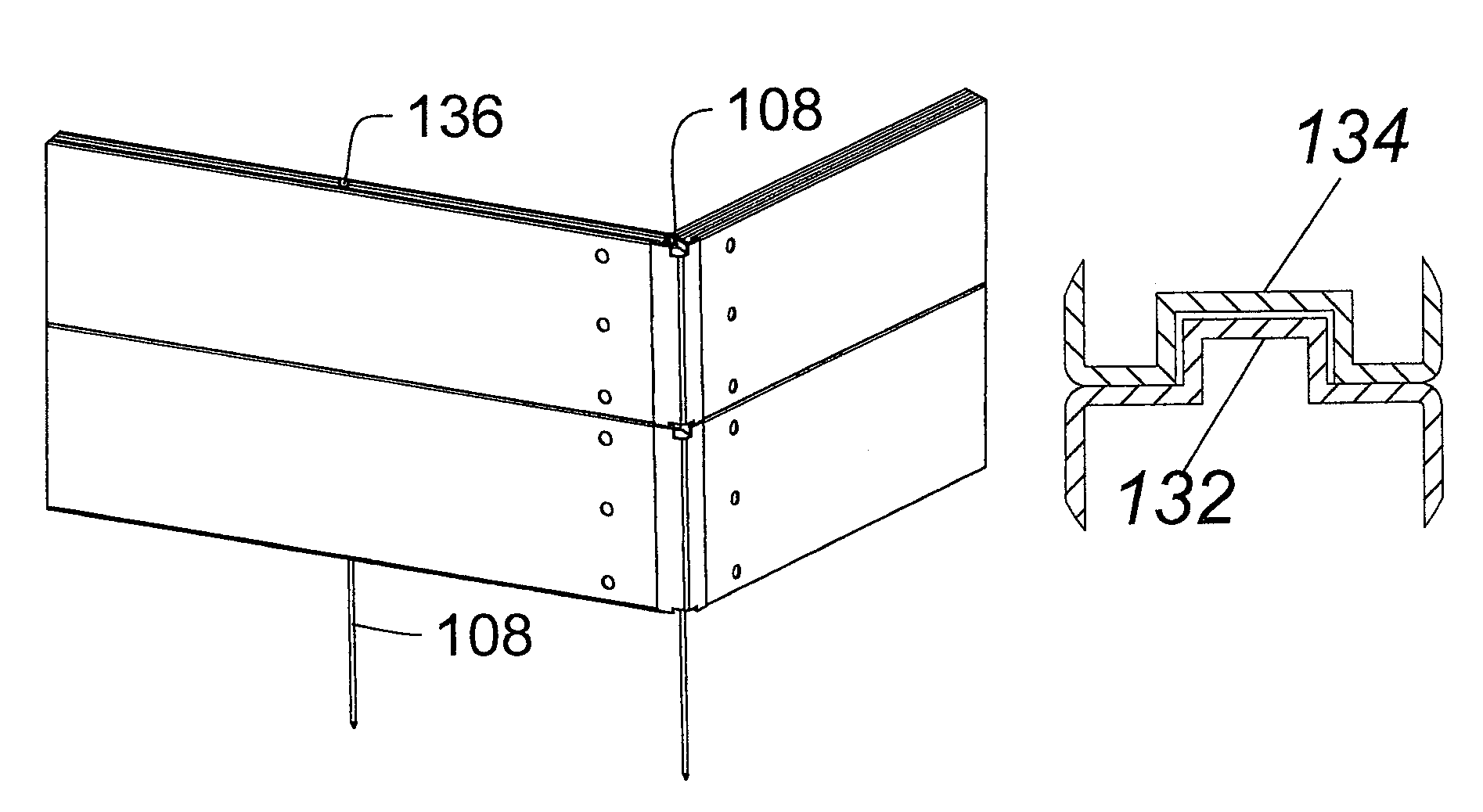

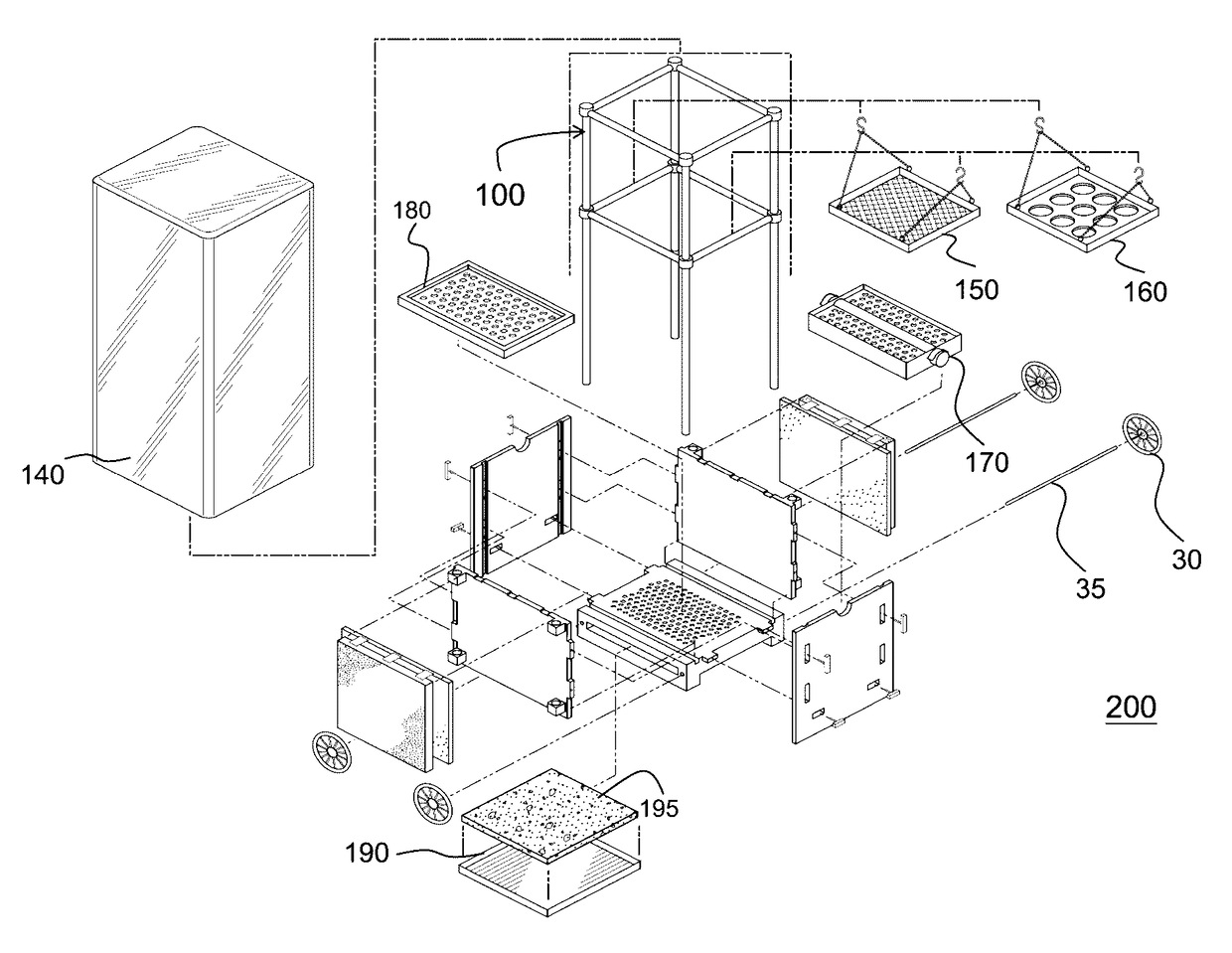

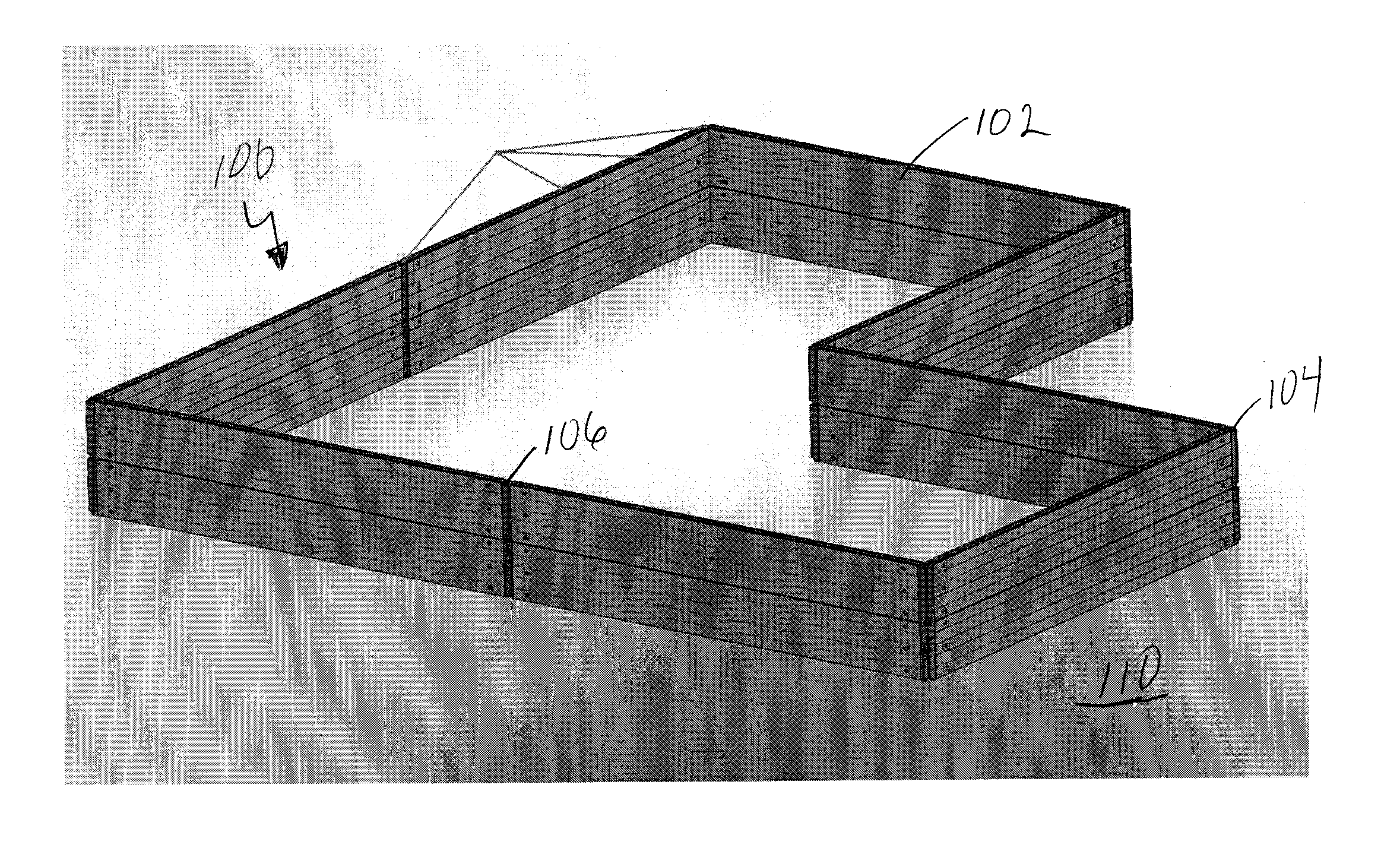

Detachable and collapsable planter box being of a pallet box assembly

ActiveUS9655307B2Simple methodEasy to transportCultivating equipmentsReceptacle cultivationLocking mechanismEngineering

Pallet box assembly configured as planter box or workman's utility box is disclosed. The pallet box assembly includes a pallet base, two side panels, a front panel, and a rear panel, which are collapsible and reusable. Pallet base has tenon joint parts with locking mechanisms that extend out. Pallet base has an opening extending therethrough for ease of handling by pallet jack or hand truck. The side panels include grooves. Front and rear panels include tenon joint part with locking mechanism. The side panels are identical and interchangeable, the front panel is identical and interchangeable with the rear panel. Each locking mechanism includes a winged bolt threadedly inserted and engaged into the tenon joint part, and a wing which is rotated by about 45 to 135 degrees to engageably and securely attach the corresponding tenon joint part in the corresponding groove, so that the pallet box assembly is securely installed.

Owner:BURMANN FR JOSEPH

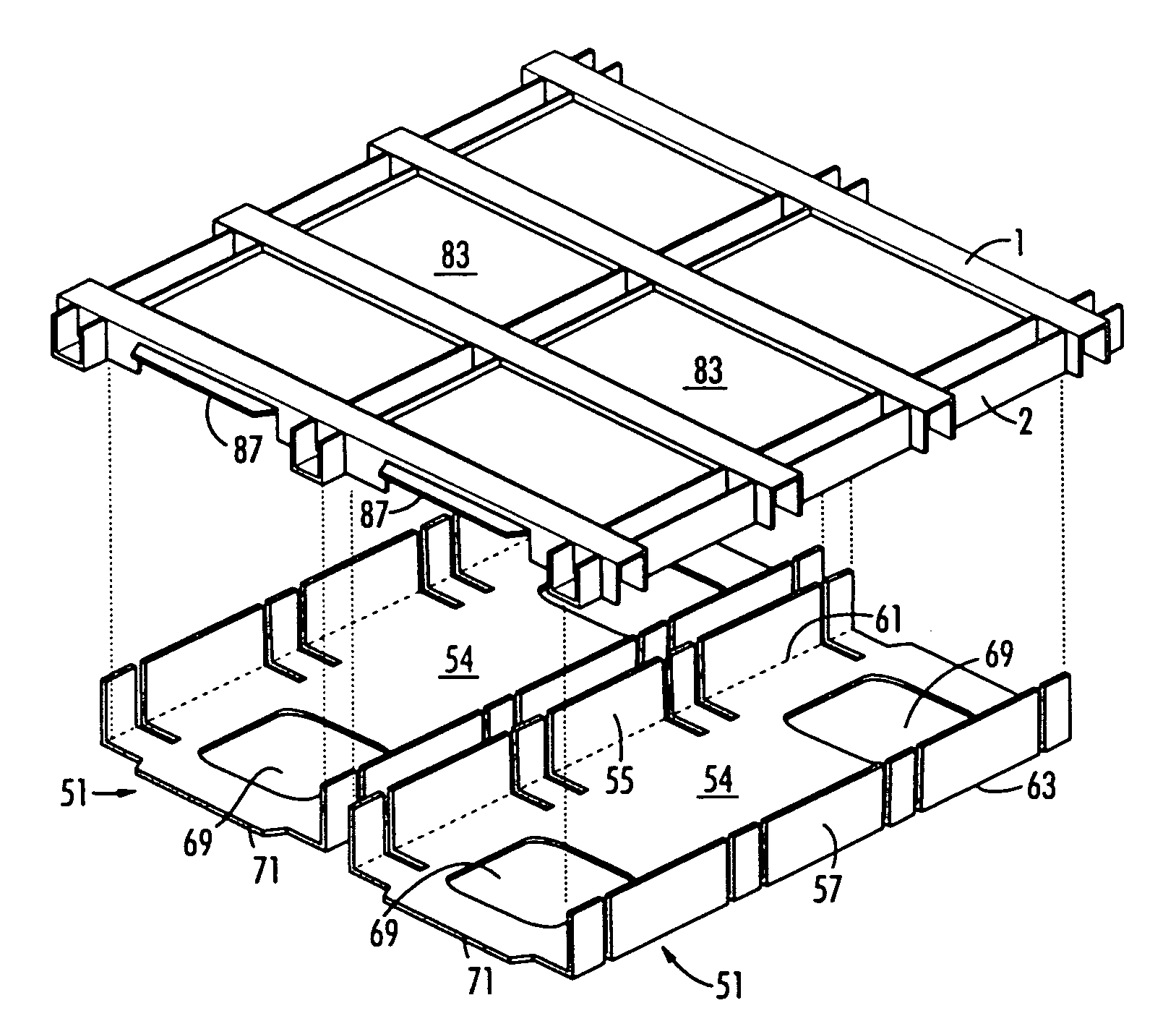

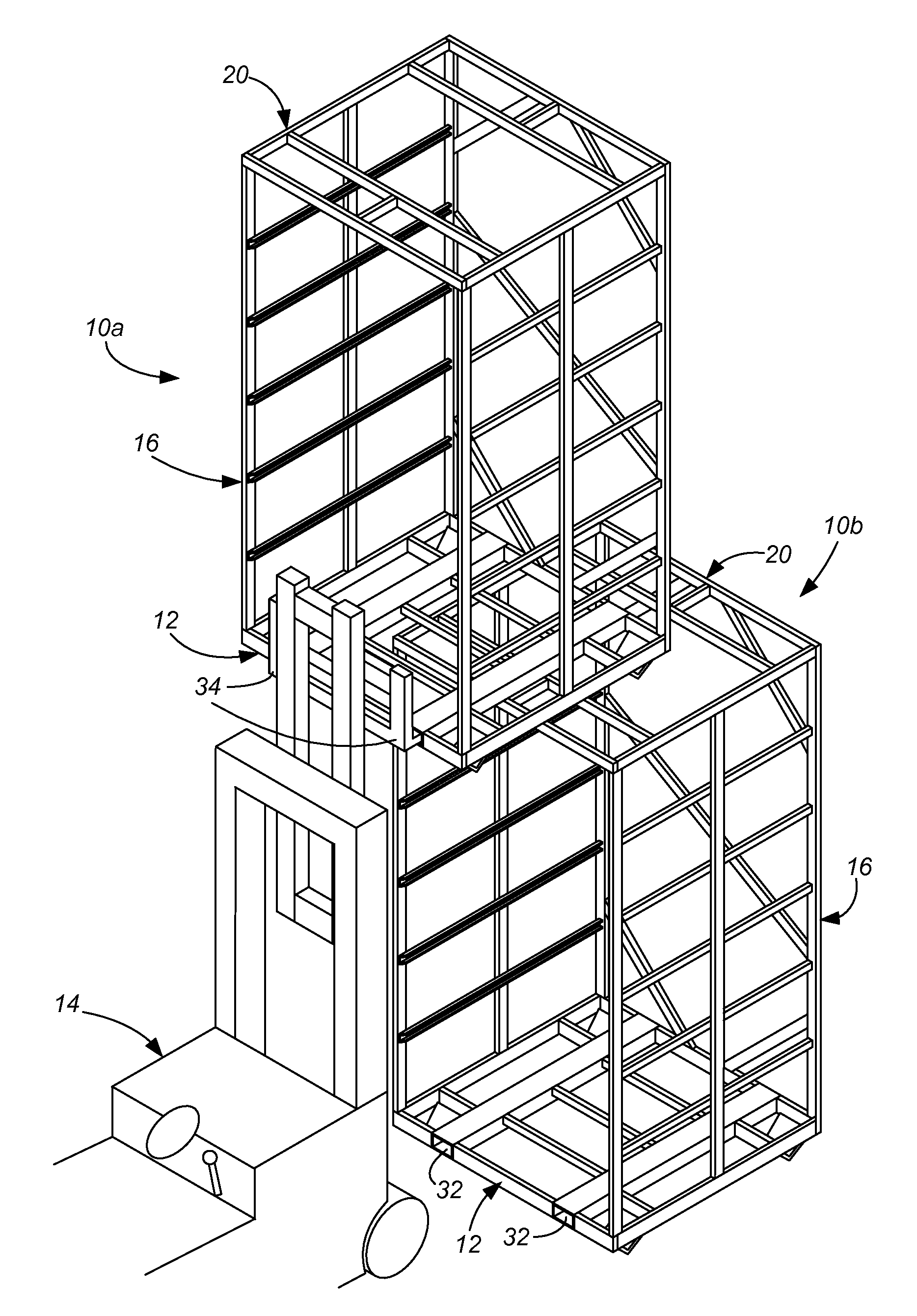

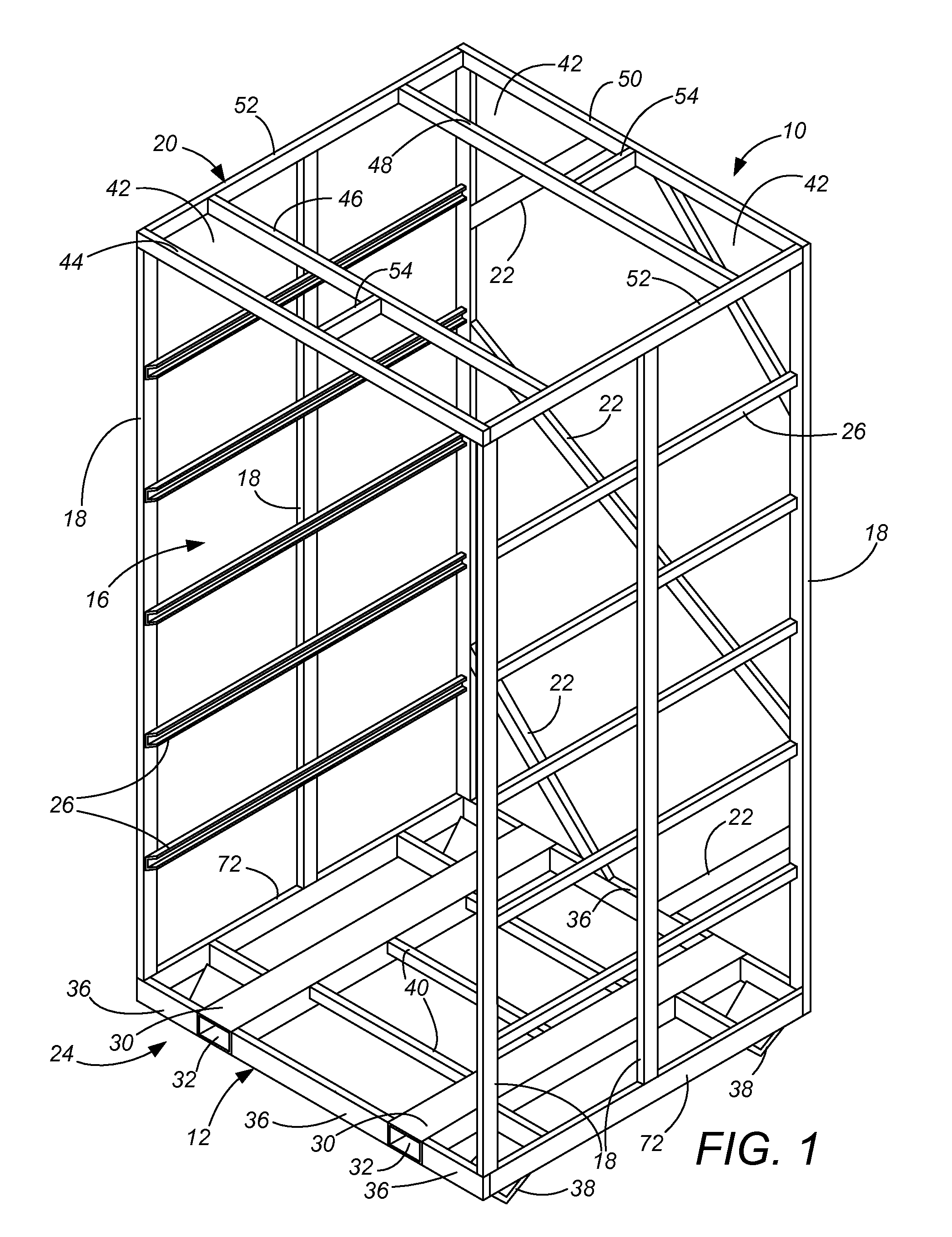

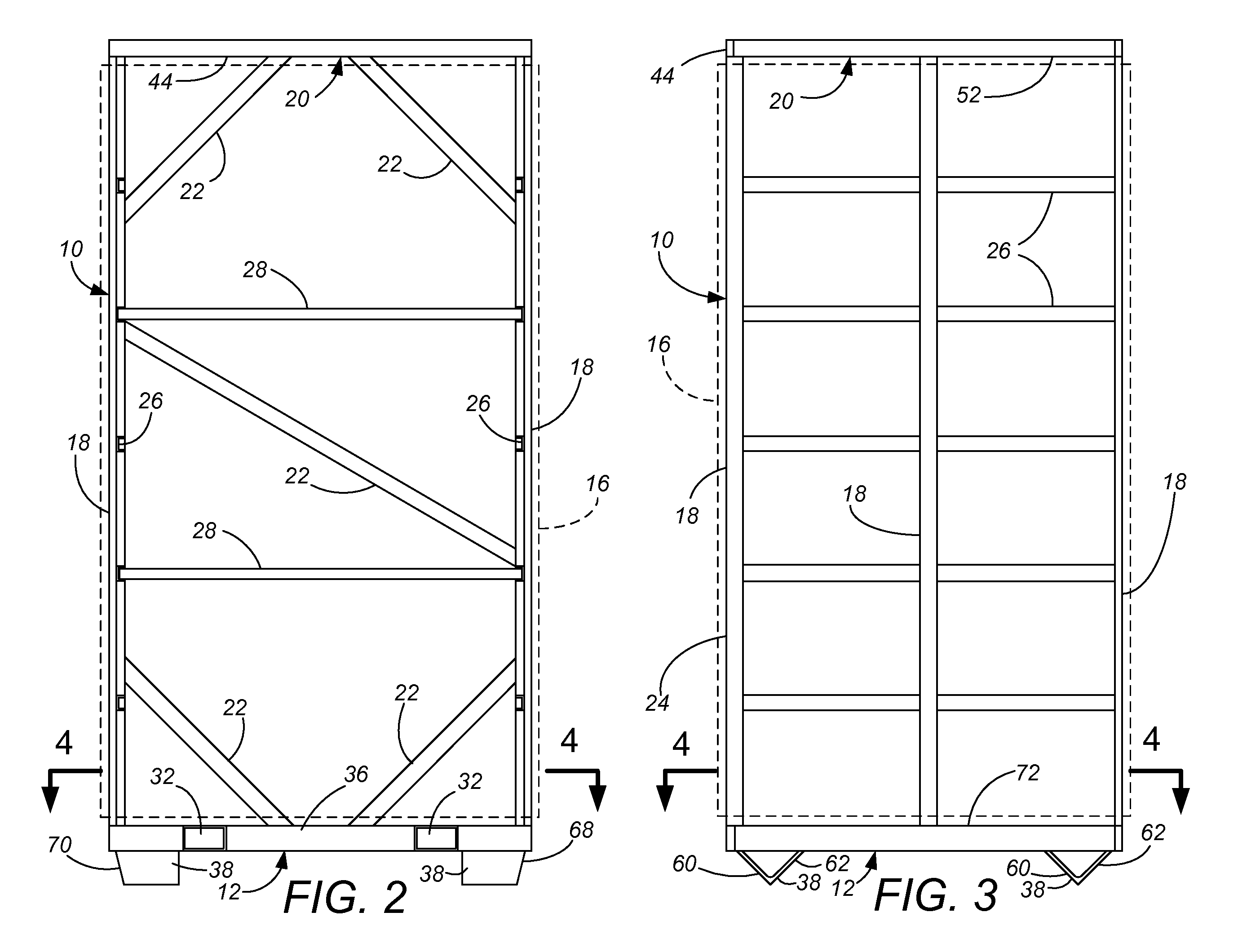

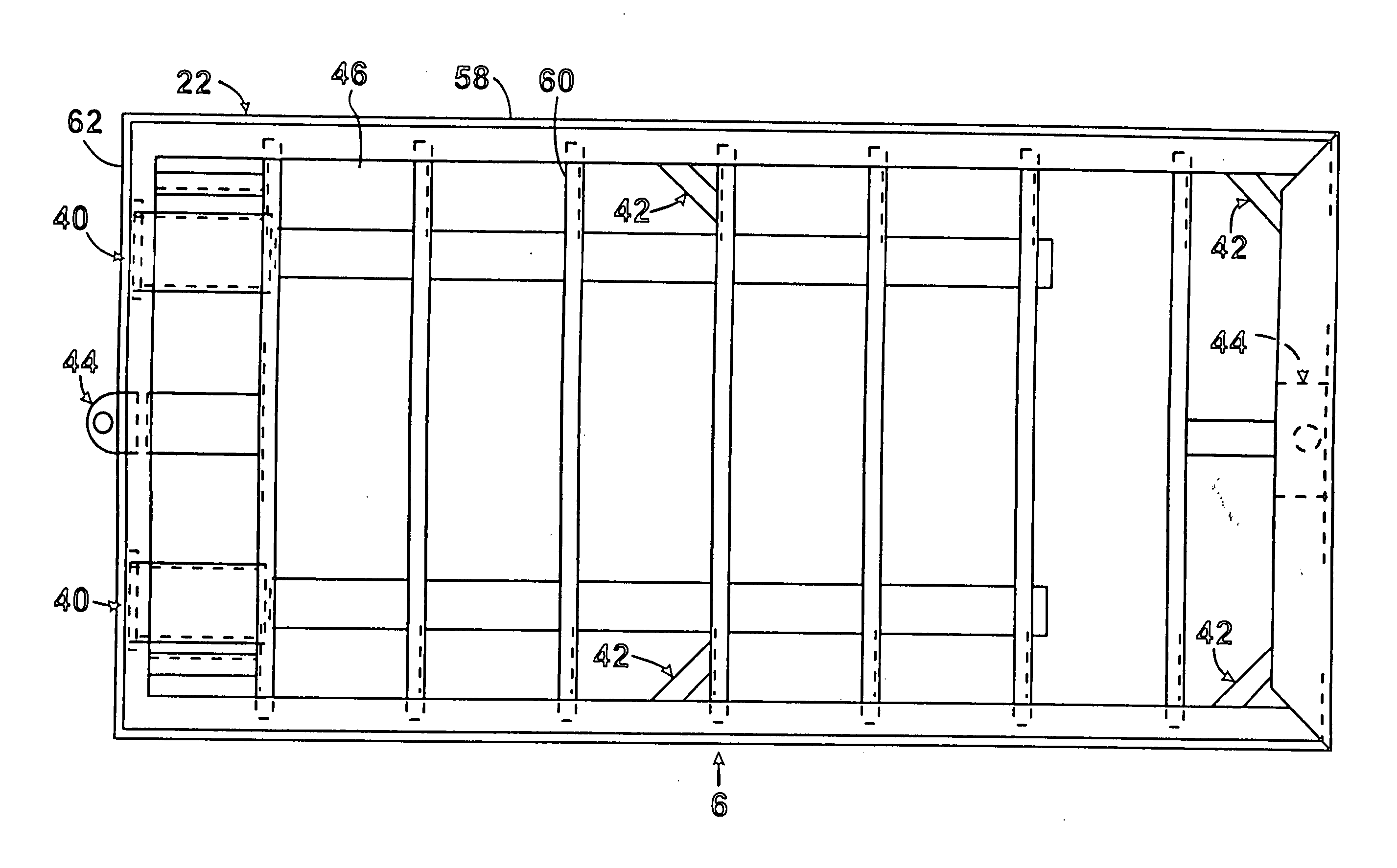

Stackable Storage Apparatus

Shelf support apparatus can be moved and stacked with a tined lift such as a forklift. The apparatus has based feet disposed lower than a front base cross member, and support uprights extend upward therefrom to a generally horizontal top structure. The front base cross member has two tine openings with lift tubes for receiving lift tines of a fork lift, and a bottom surface for receiving lift tines of a floor pallet jack. The top structure includes feet-receiving openings corresponding in location to the base feet, such that the apparatus can be stacked. The base feet have targeting slopes both in a front-to-back direction and in a side-to-side direction, to guide the second, upper shelf support apparatus down onto the first, lower shelf support apparatus with the base feet received in a nesting relationship. The targeting slopes in the front-to-back direction acts over a targeting area which is greater than the targeting area in the side-to-side direction. The top structure also provides a top support perimeter which makes substantially perimetrical contact with the base of the apparatus stacked thereon.

Owner:BUSINESS SYST INT

Raised Garden Bed Kit

InactiveUS20100242357A1Avoid bowingReduce shipping costsPlanting bedsGreenhouse cultivationEngineeringPallet jack

The instant invention provides a kit for assembly of a raised garden bed. The raised garden bed includes panel members, corner connector members, and linear connector members constructed of a polymeric material and adapted to be snapped together into a substantially rigid raised garden bed without the need for special tools or excessive strength. A tongue and groove arrangement is also provided to allow for panel member stacking for increased garden bed height. The components of the kit are constructed and arranged to be packed into a relatively small profile for shipping and transport and are generally light enough to be loaded and unloaded without the need for equipment such as a forklift or pallet jack.

Owner:SUNCAST TECH

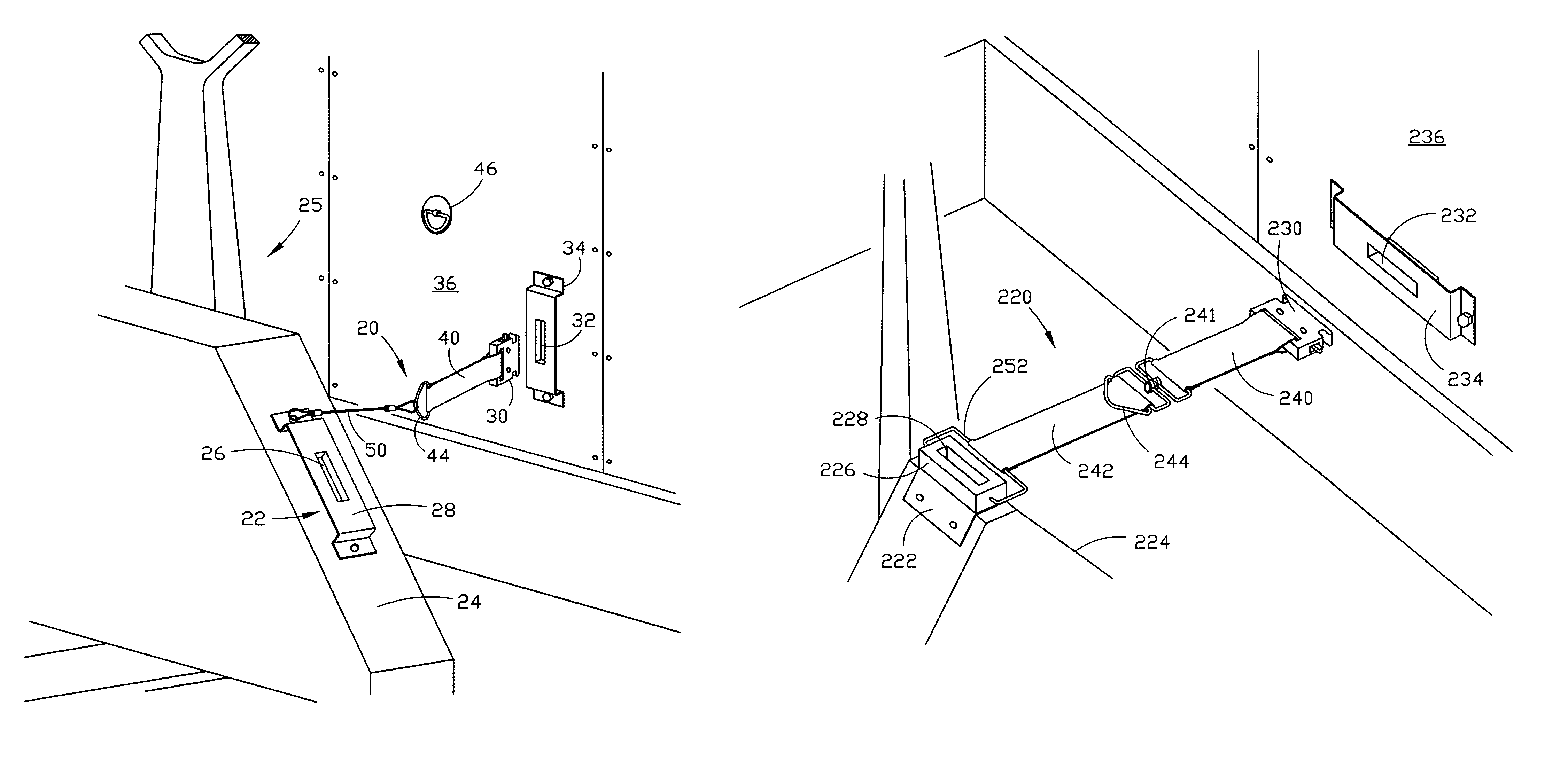

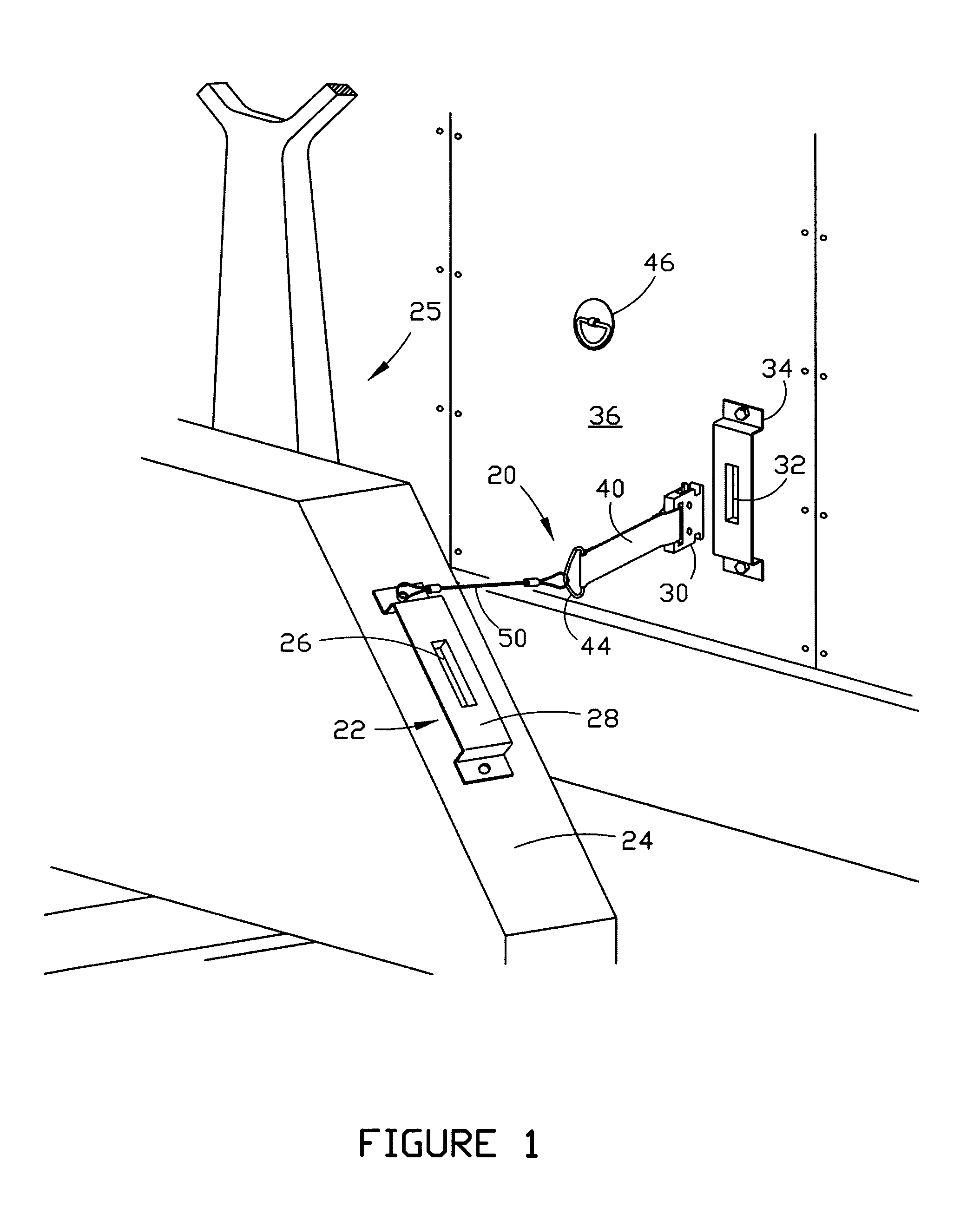

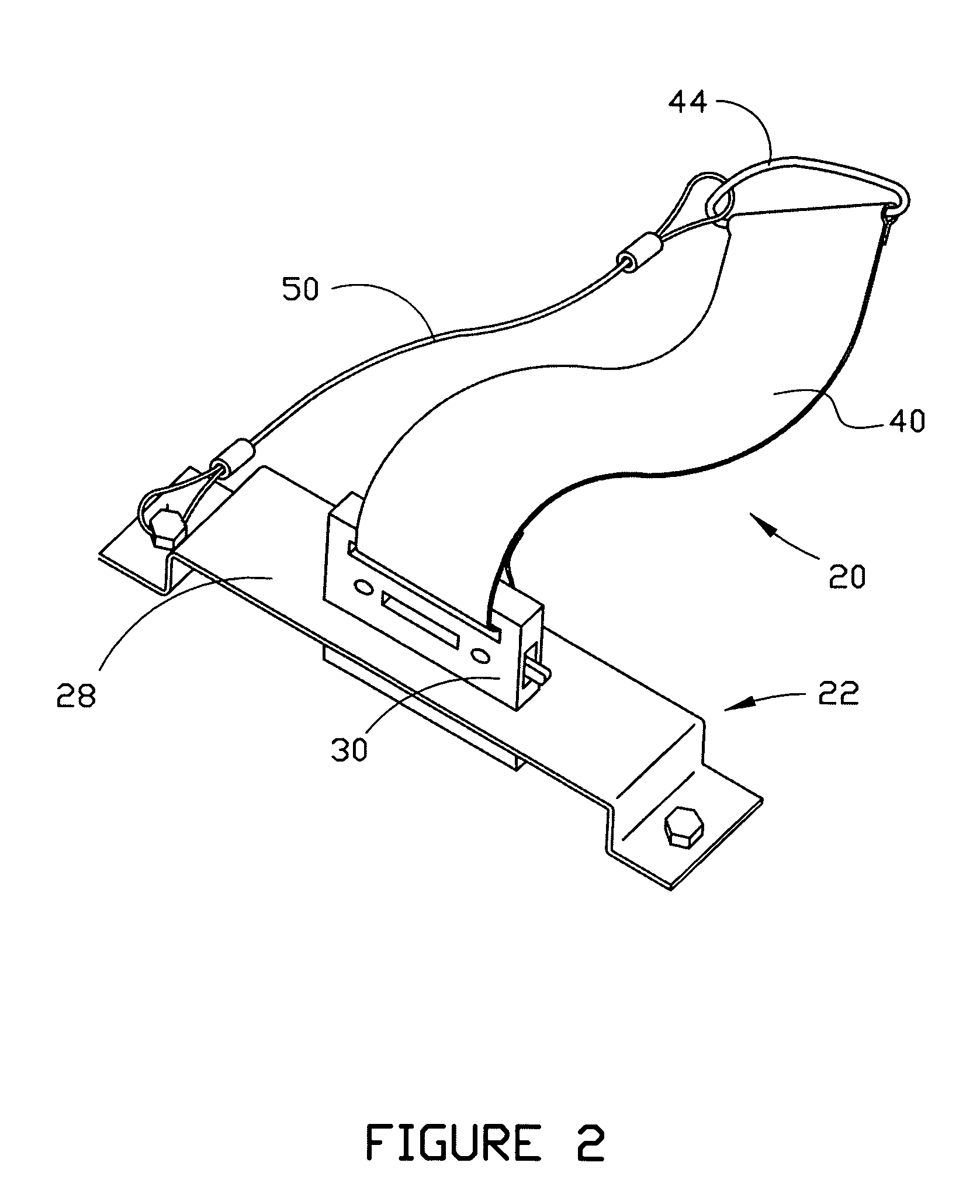

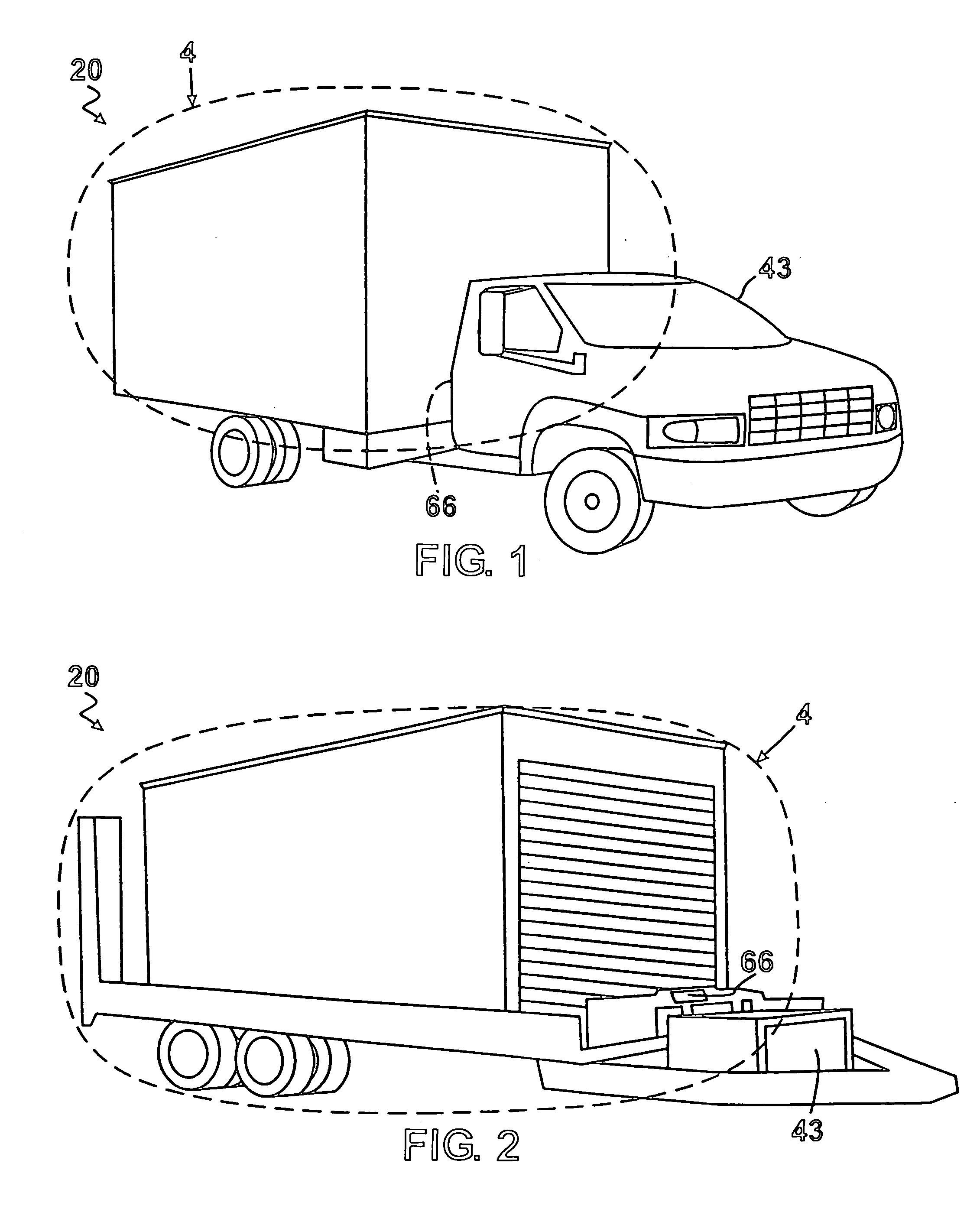

Apparatus and method for securing a pallet jack

An anchoring device including a mounting bracket adapted to be attached to an object. The mounting bracket has a slot. The anchoring device also includes an end clip adapted to be removably connected to a first mounting structure. The anchoring device further includes a strap extending between the end clip and the mounting bracket and an anchoring ring adapted to be connected to a second mounting structure. The anchoring ring is attached to the strap between the mounting bracket and the end clip. The end clip is adapted to be removably retained in the slot of the mounting bracket when the object is secured to the second mounting structure by the anchoring ring. In addition, a method for removably securing a pallet jack to an inside wall of a tractor trailer. The method includes providing a pallet jack anchoring device, securing the pallet jack mounting bracket to a pallet jack, and securing the end clip to a first mounting structure.

Owner:LEDFORD WADE M

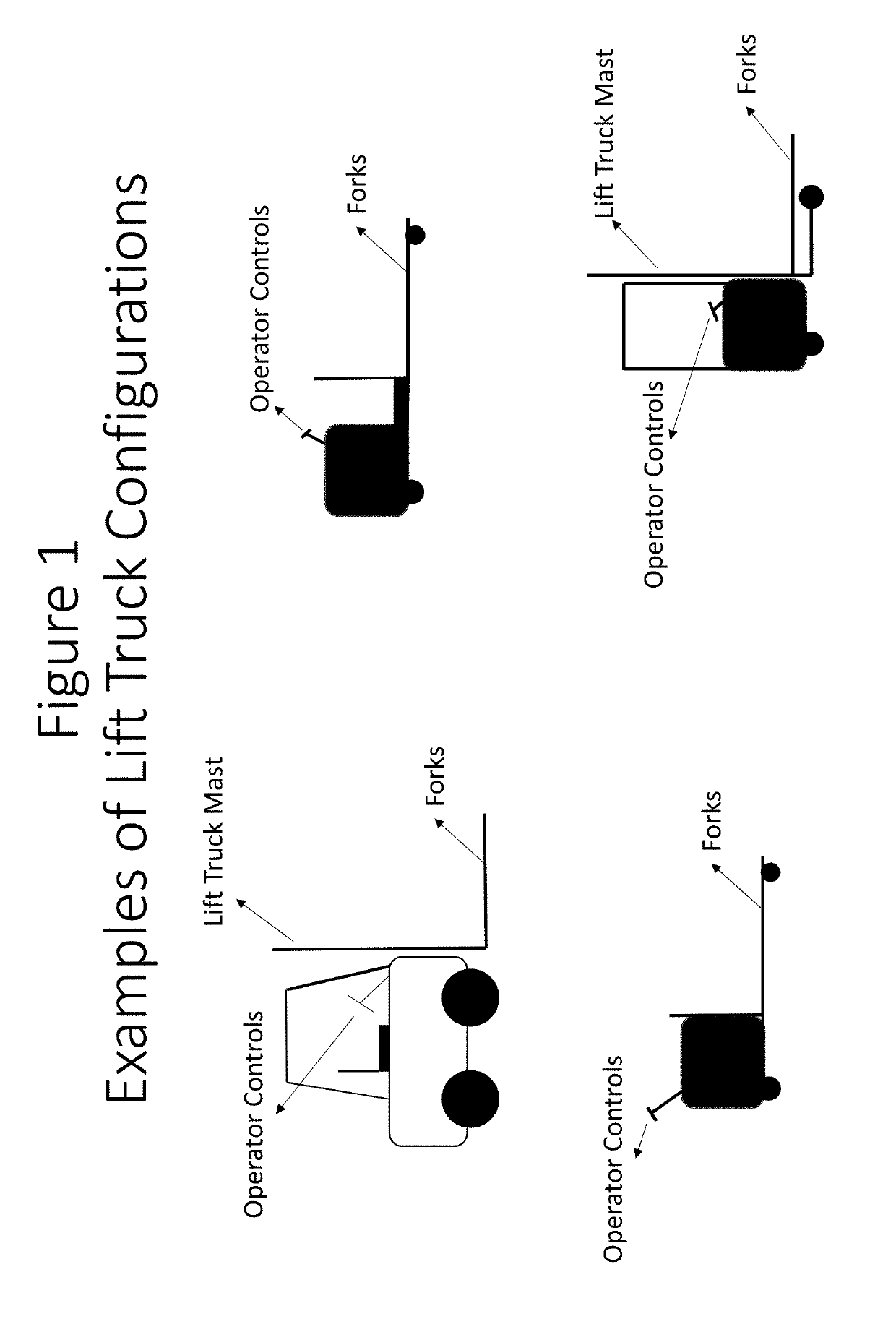

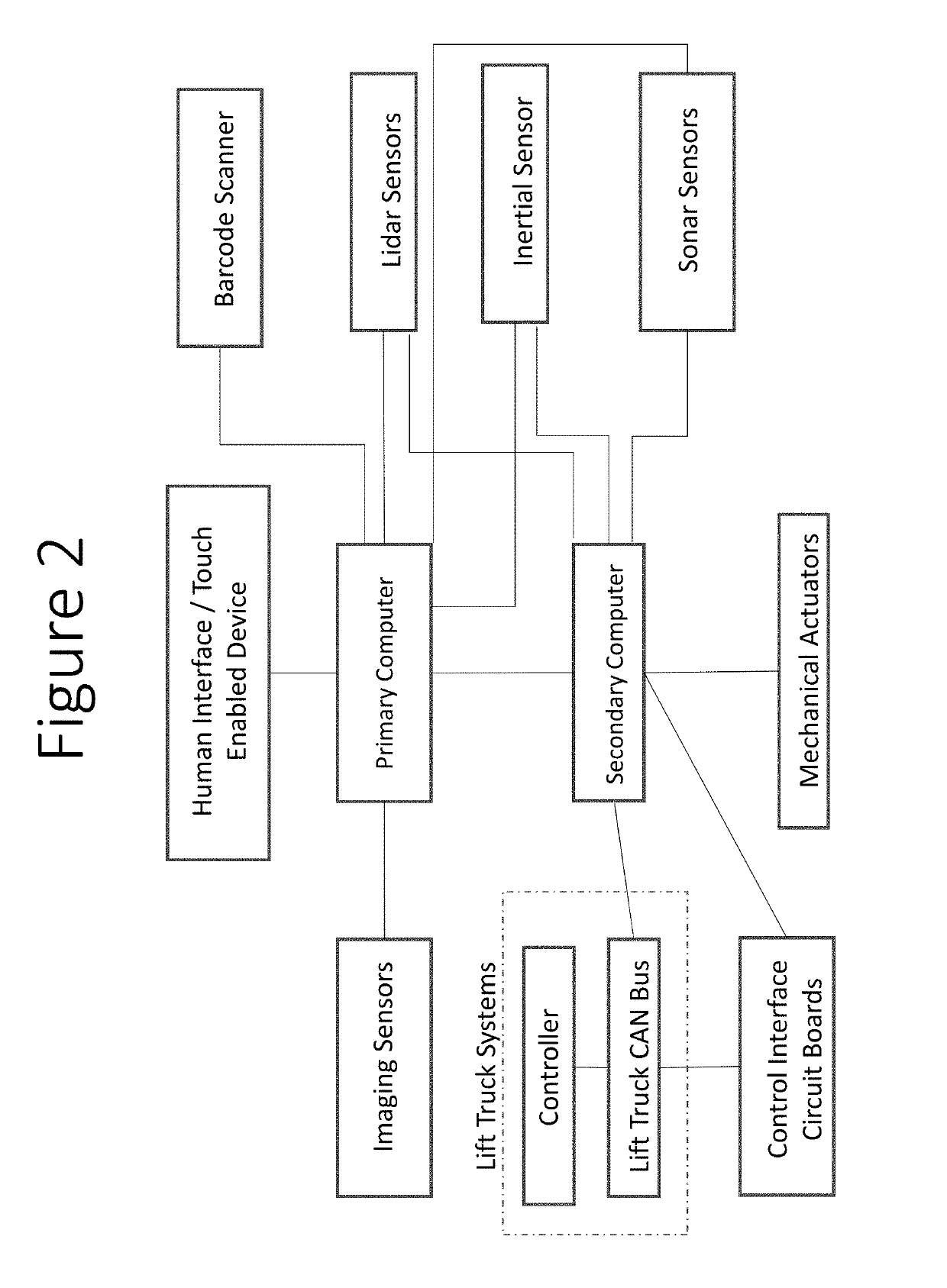

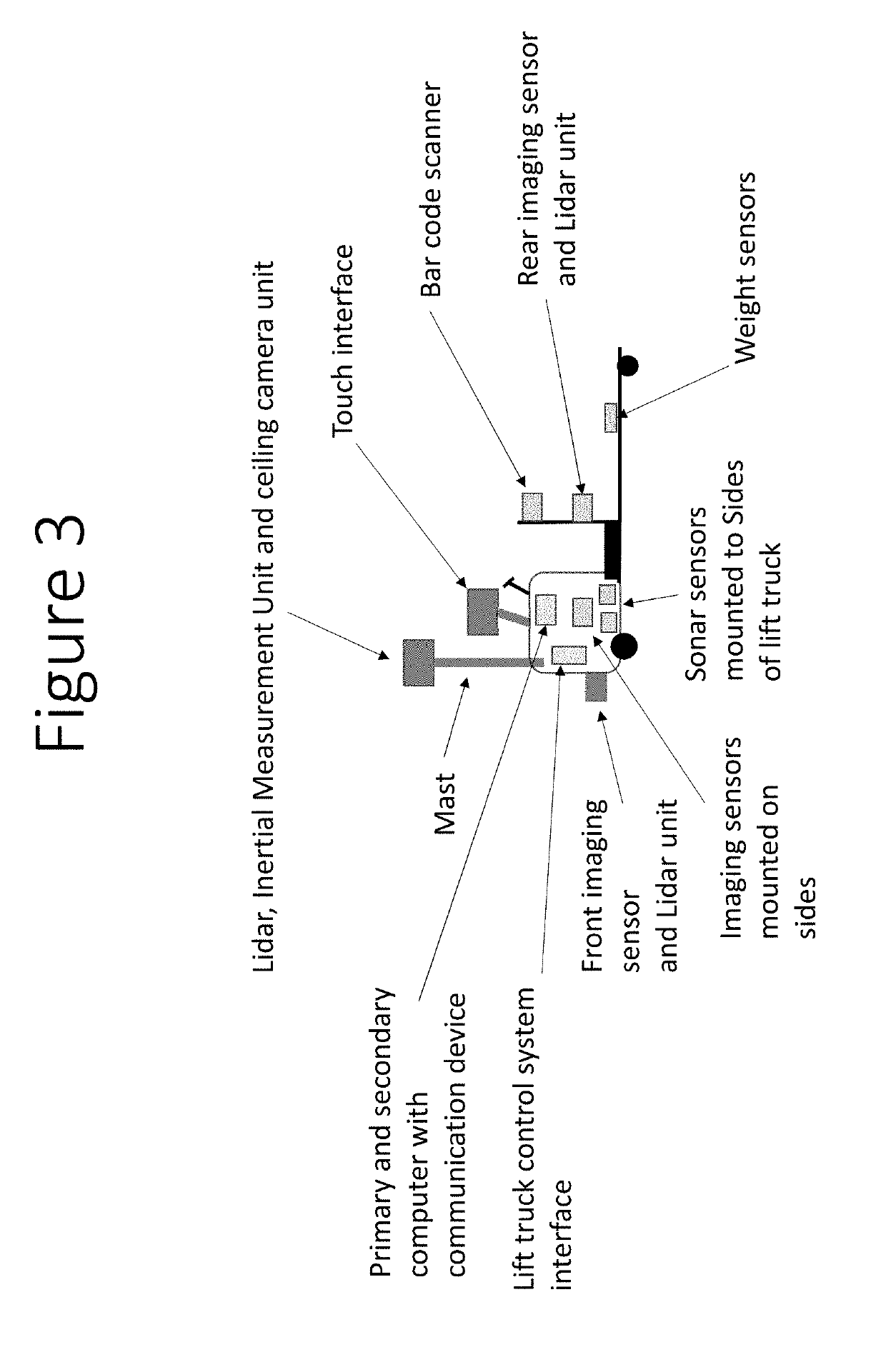

Method and system to retrofit industrial lift trucks for automated material handling in supply chain and logistics operations

Material handling vehicles also known as lift trucks, e.g., forklifts, pallet jacks, reach trucks etc., are an essential component of any supply chain and logistics operation. These vehicles are typically driven by human operators and are used to move goods inside factories, warehouses etc. We develop a system and method to retrofit manual lift trucks with a supplemental control system (retrofit kit) that includes sensors, communication devices, computers, electrical circuits and mechanical actuators such that a lift truck can carry out material handling tasks autonomously without the presence of a human operator. The retrofit also allows the lift truck to be controlled remotely by a human tele-operator and can transmit and receive data from a remote computer.

Owner:STOCKED ROBOTICS INC

Steering device for pallet truck

InactiveUS20060125196A1Easy steeringEasy positioningSledge wheelsUnderstructuresBraced framePallet jack

A steering device for decreasing a turning radius of a pallet jack includes a ground engaging member connected to a support member of the pallet jack between a main wheel and an extensible wheel. The load supporting member of the pallet jack is positionable between a raised position and a lowered position. A first turning radius of the pallet jack is defined by the distance between the main wheel and the extensible wheel. While the extensible wheel engages the ground when the support frame is positioned towards the raised position, positioning the support member towards the lowered position engages the ground engageable member with the ground causing the extensible wheel to disengage the ground. The main wheel and the ground engageable member then define a second turning radius which is less than the first turning radius.

Owner:GRAND STEER

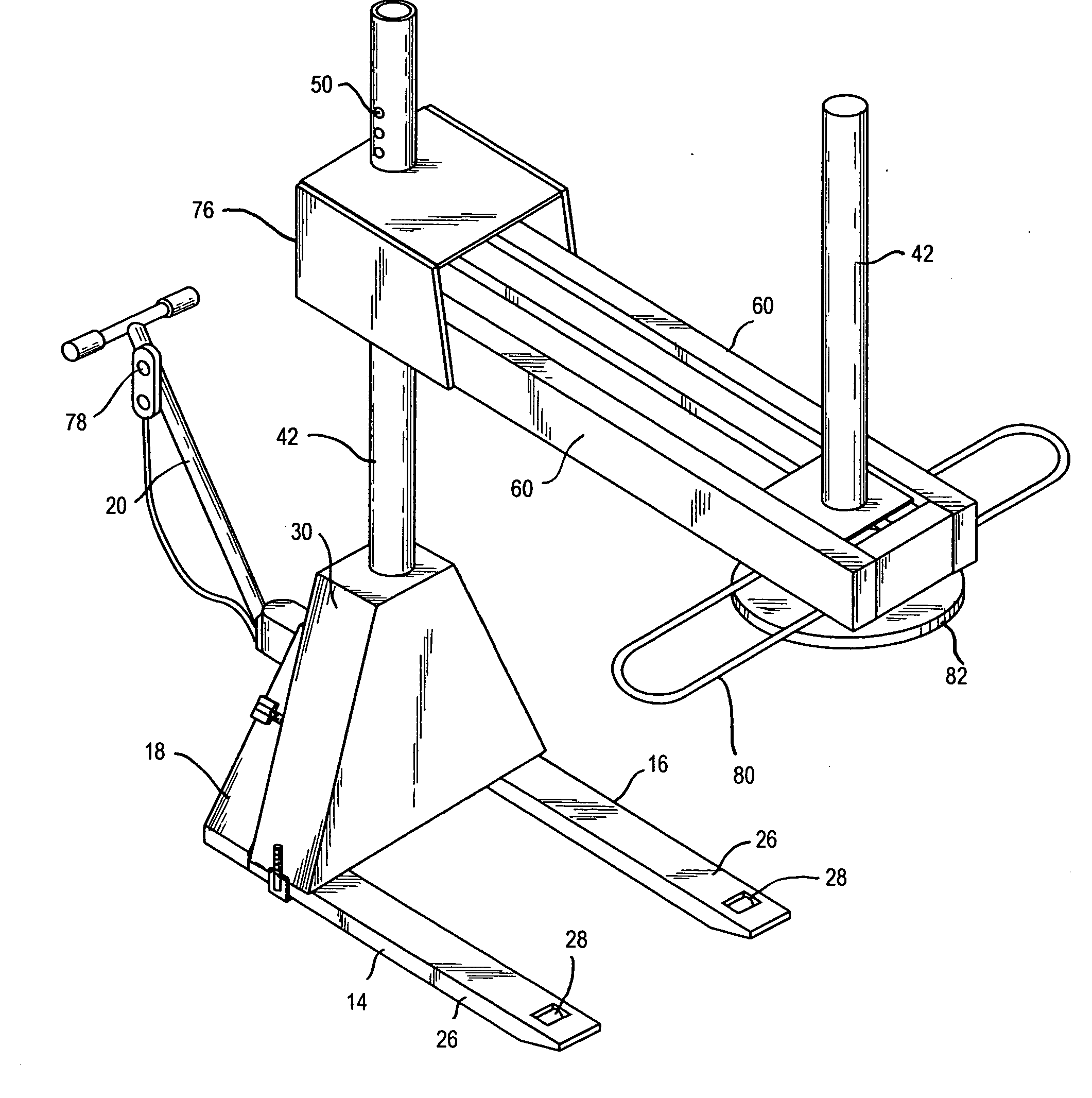

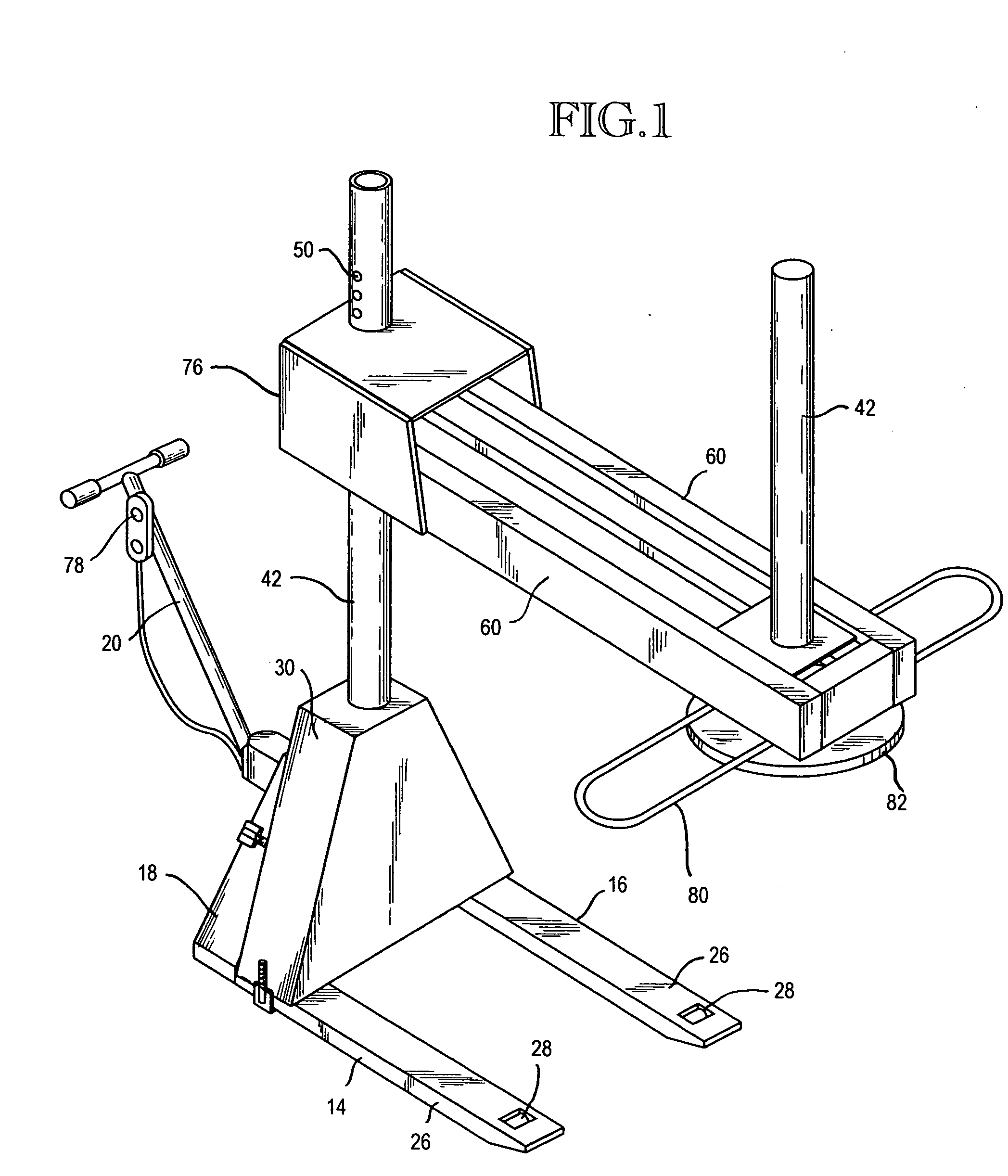

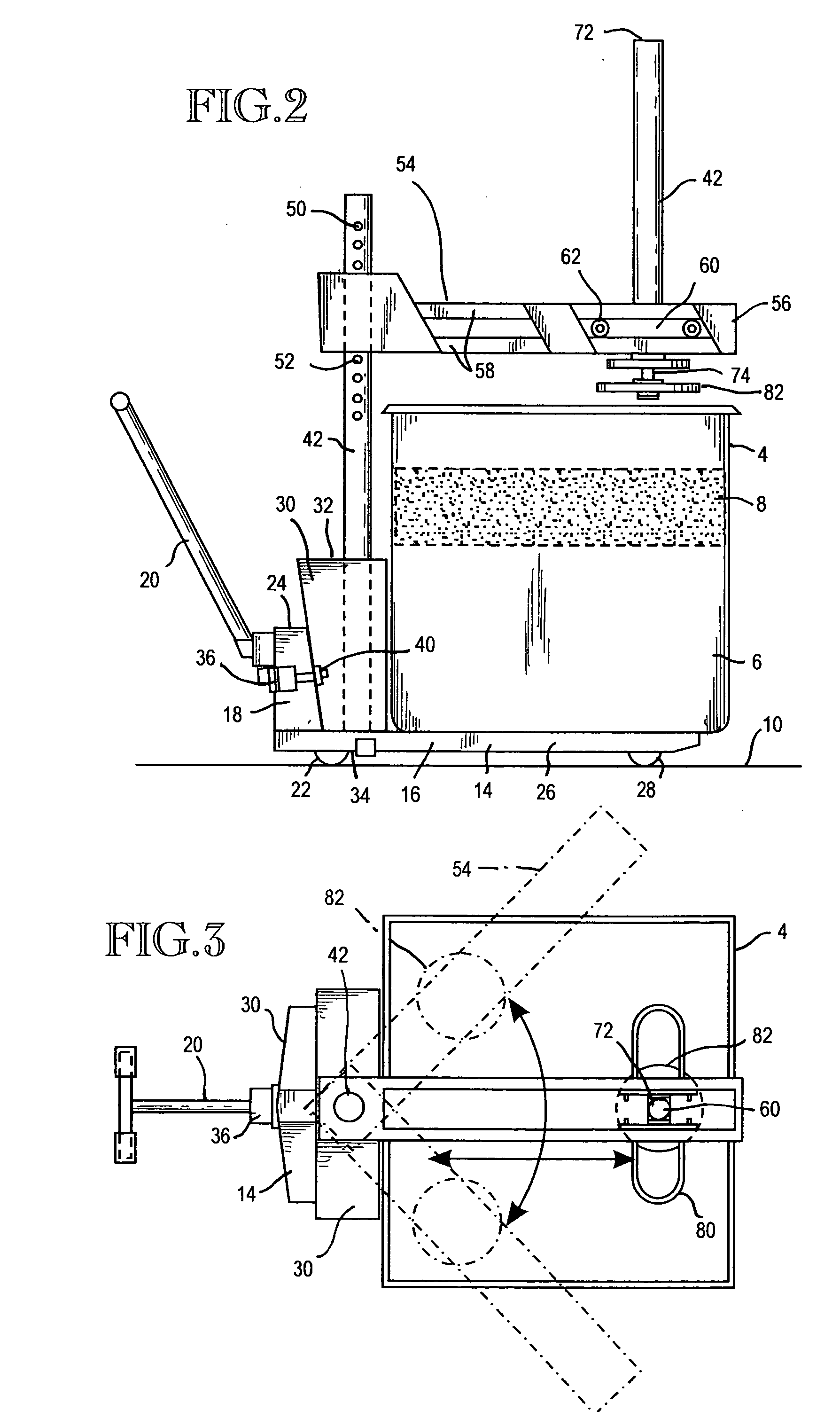

Wine punch down unit

A wine punch down unit and method for processing fermenting wine by punching down a cap formed from buoyant skins, seeds, pulp, and stems within a batch of fermenting wine, and mixing the cap material with the fermenting wine to improve contact between the wine and the cap in order to extract a requisite amount of color and flavor. The wine punch down unit has a platform for placement under a vessel of fermenting wine, a vertical shaft mounted to the platform supporting a positionable arm that holds a vertically extendible agitator accessory. The agitator accessory is operational in an upward and downward and side-to-side manner for punching down the cap and mixing the cap material with the fermenting wine. This invention further relates to a vertical shaft adaptor as used by a wine maker for adapting a pallet jack or similar lift platform to securely hold a vertical shaft for supporting a device such as a wine punch down unit.

Owner:AMERICAN BASKET PRESS

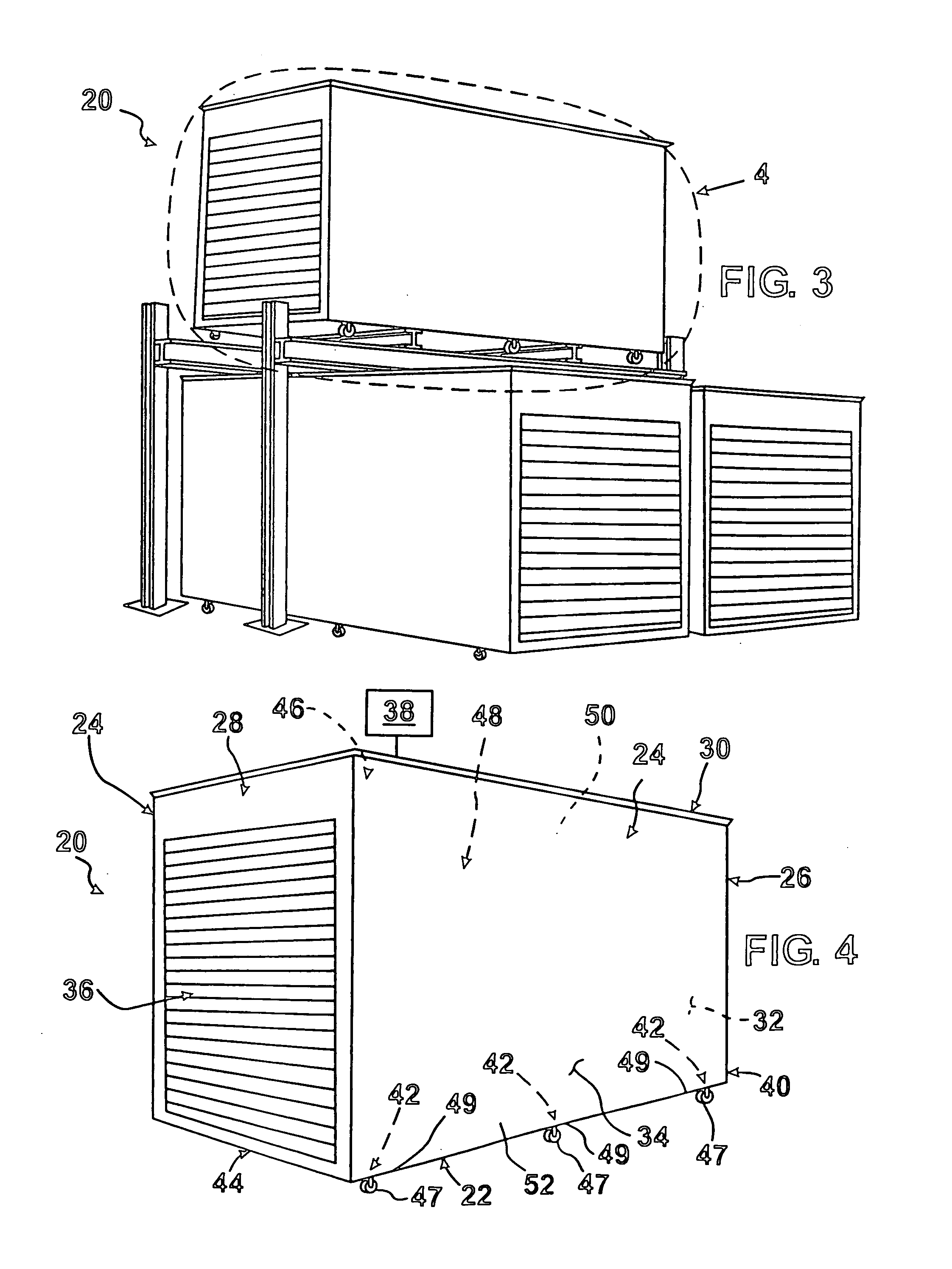

Storage unit for being portable, towable, liftable, rackable, and weatherproof

ActiveUS20060045682A1Avoid disadvantagesEasy to useLarge containersArticle unpackingTransport systemEaves

An improved storage unit of the type having an interior surface, an exterior surface, a floor, a pair of side walls, a front wall, a rear wall, and a roof. The roof is translucent, attaches without any puncturing thereto, and has overhanging eaves and bows with centers that are bowed thereat. A ventilation system allows the storage unit to benefit from storing in a climate controlled warehouse and provides airflow when the storage unit is stored outside. The rear wall has a roll-up door. The pair of side walls, the front wall, and the rear wall are attached from the exterior surface and the interior surface is smooth and non-abrasive. The floor is plastic undercoated plywood. Towing brackets front and rear provide a safe, strong, and secure method to attach a winch system of a transport system for maneuvering the storage unit on and off the transport system and to maneuver the storage unit with forklifts or pallet jacks in a yard or warehouse. Butyl tape seals the roof and all connecting panels and structures.

Owner:GO MINIS

Modular dolly

ActiveUS8475109B2Promote sportsCarriage/perambulator with single axisRefuse receptaclesModularityPallet jack

The modular dolly is a manually operated device facilitating the transport of large, heavy, and / or bulky objects. The dolly includes four smaller wheels and two larger diameter wheel and brake assemblies for temporary installation to the sides of the dolly platform for movement over soft, rough, and / or uneven surfaces. A ramp is removably attachable to the loading end of the platform coplanar therewith to facilitate loading the dolly. The ramp also attaches removably to the opposite anchor end of the platform and normal thereto, to serve as a backstop or anchor for a load placed on the platform. A smaller secondary panel may be installed in the anchor end when the ramp is in use during loading, or may be assembled coplanar to the ramp or platform to lengthen the ramp or platform. The dolly may also be used with a stair-climbing hand truck, forklift, pallet jack, or the like.

Owner:ESCALERA

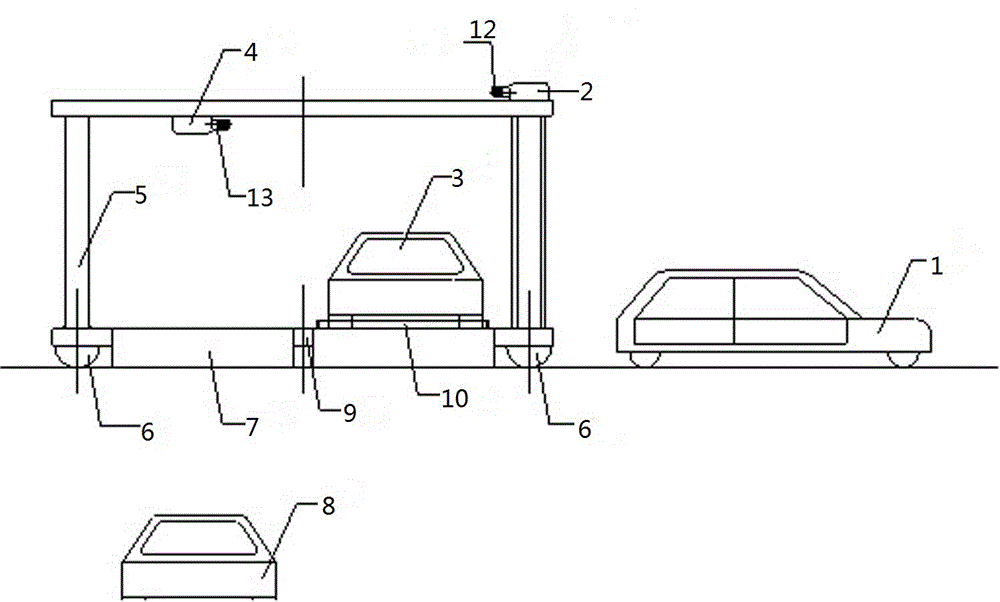

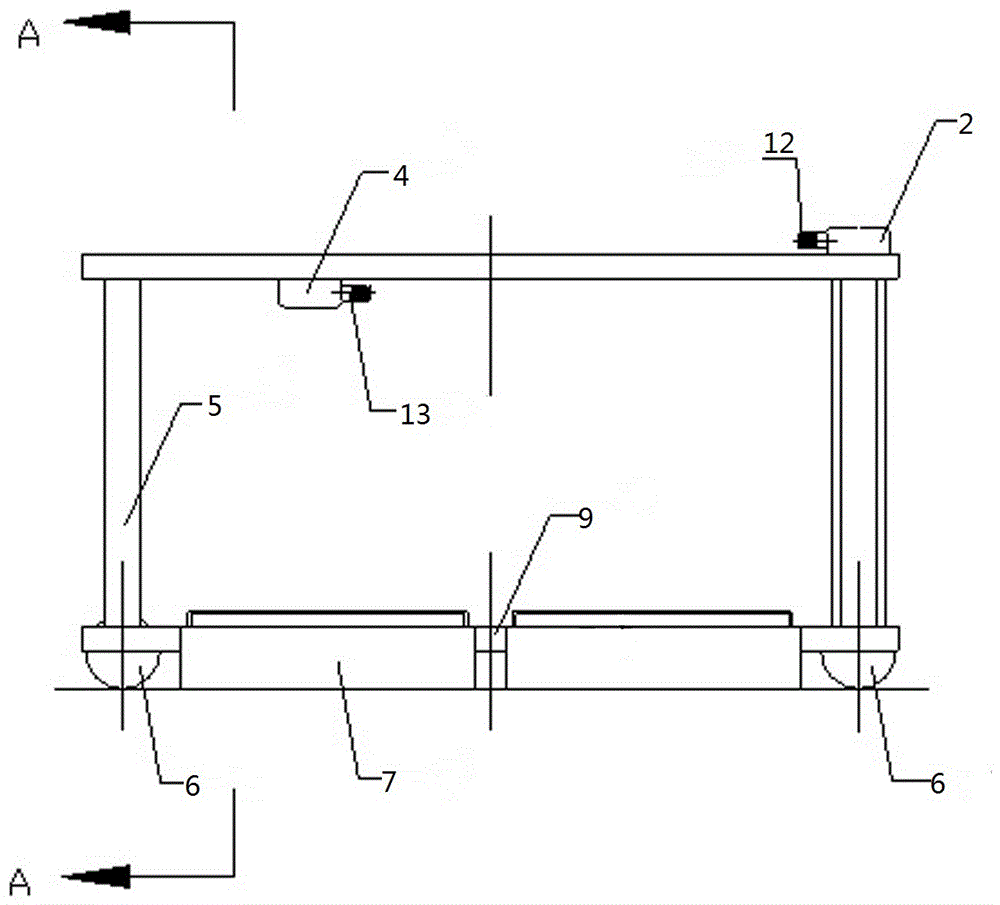

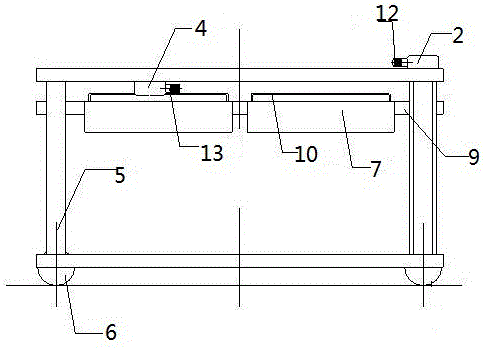

Three-dimensional parking device

The invention relates to a three-dimensional parking device increasing vehicle parking places. The device is especially suitable to be used for a garage which needs to increase vehicle parking places and has space on a height direction. The device mainly comprises a framework 5, a tray 9, vehicle wheels 6, a translation motor 12, and a lifting motor 13. The translation motor 12 and the lifting motor 13 are installed on the top or the side wall of the framework 5. The vehicle wheels 6 are installed on the lower part of the framework 5. The lifting motor 13 drives the tray 9 to slide up and down along a stand column. The translation motor 12 drives the vehicle wheels 6. Under the condition of not increasing land occupation area, parking number can be increased.

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD

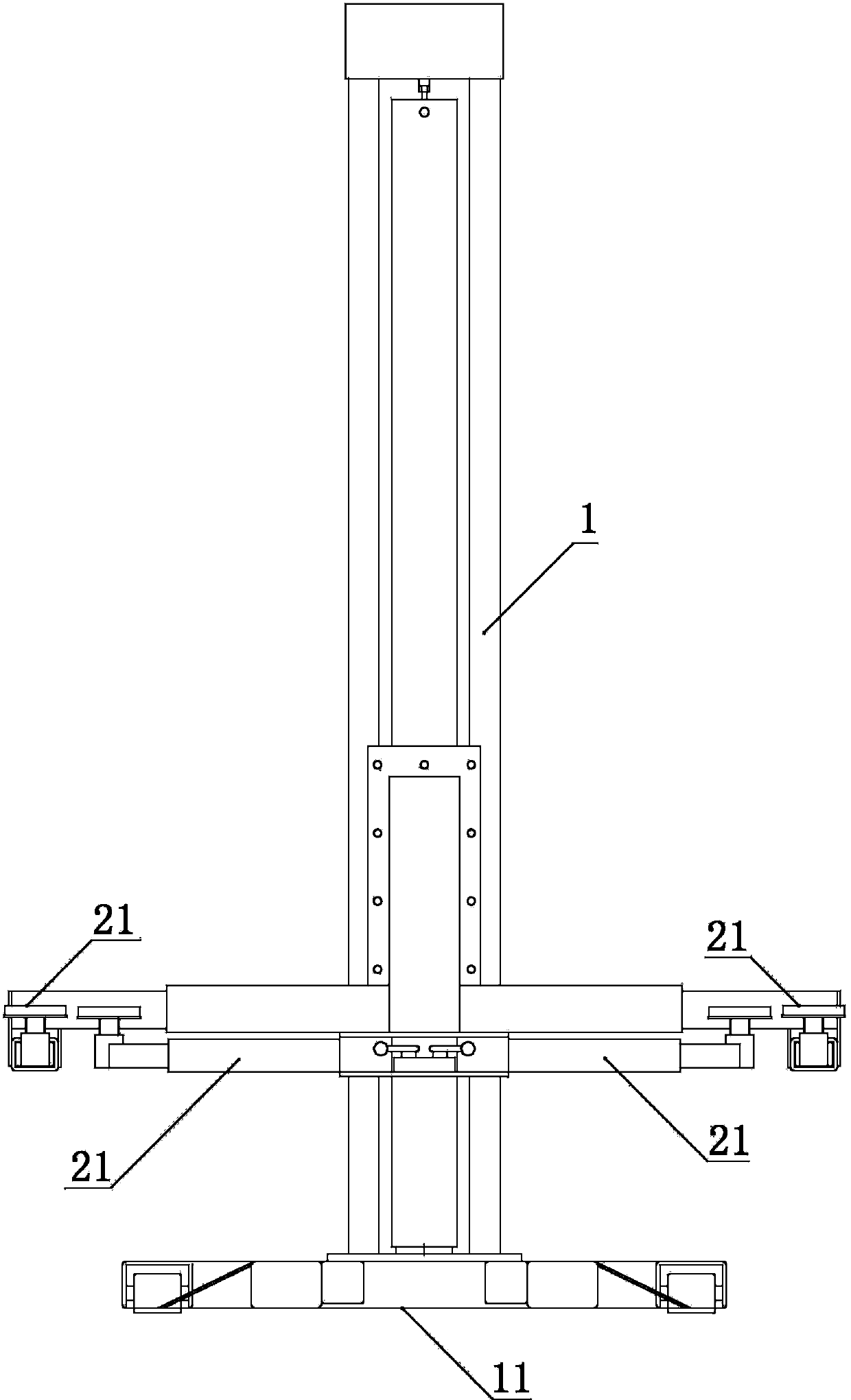

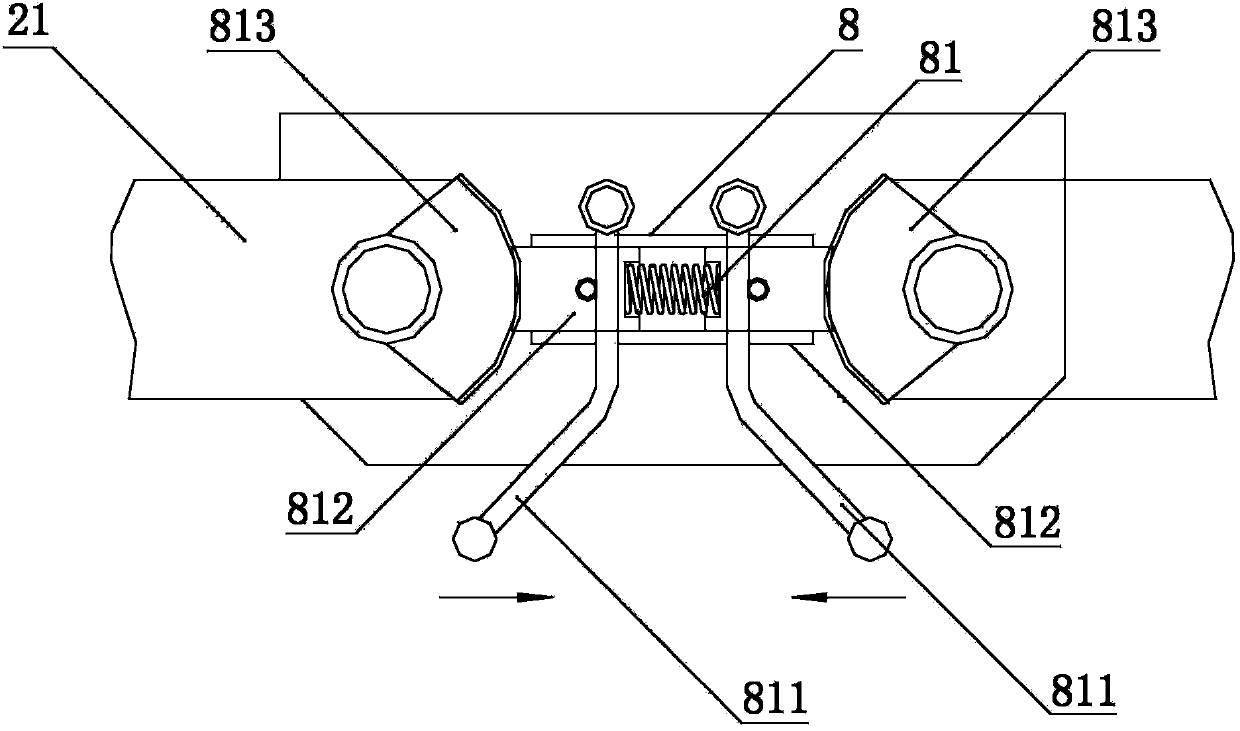

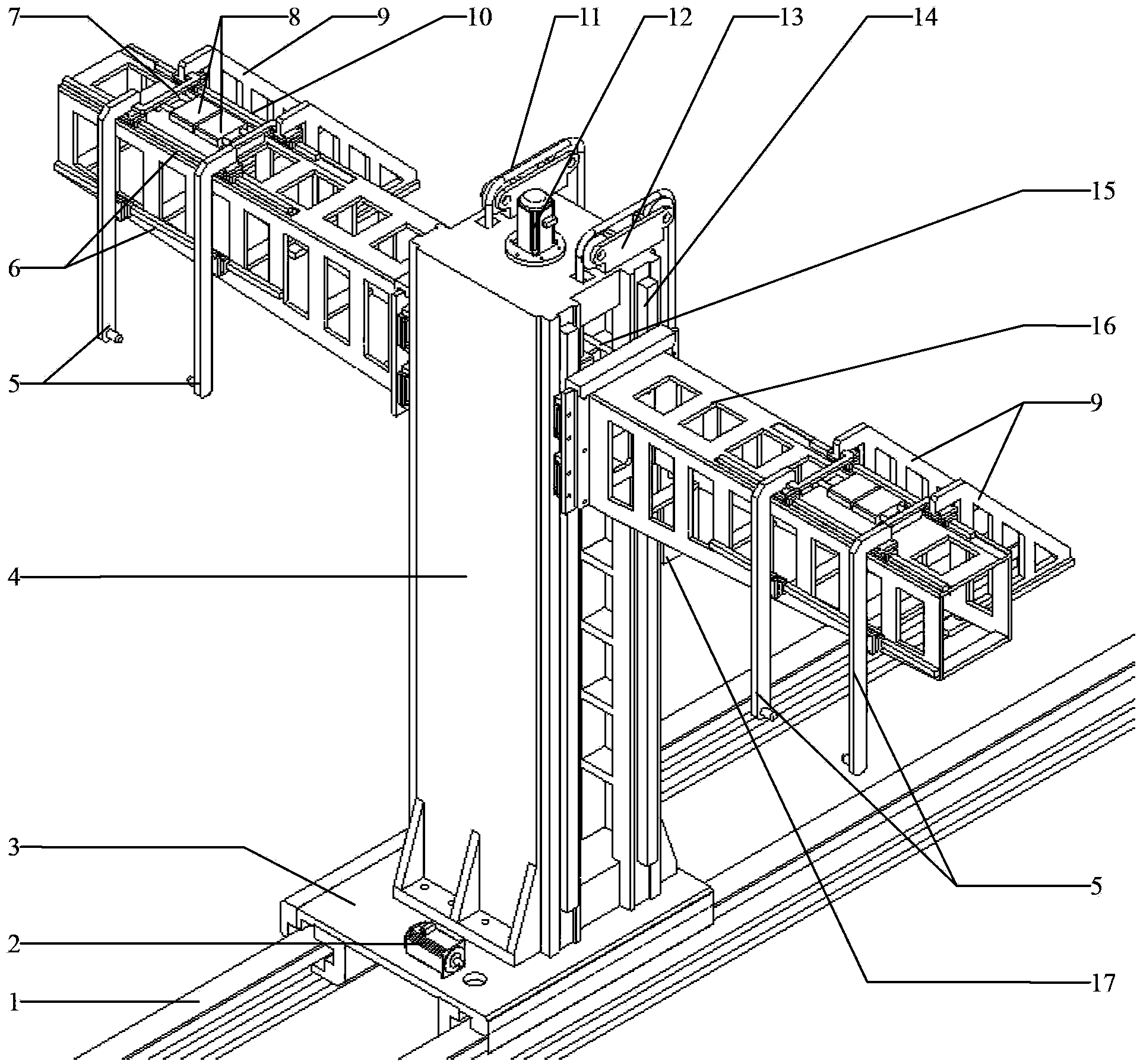

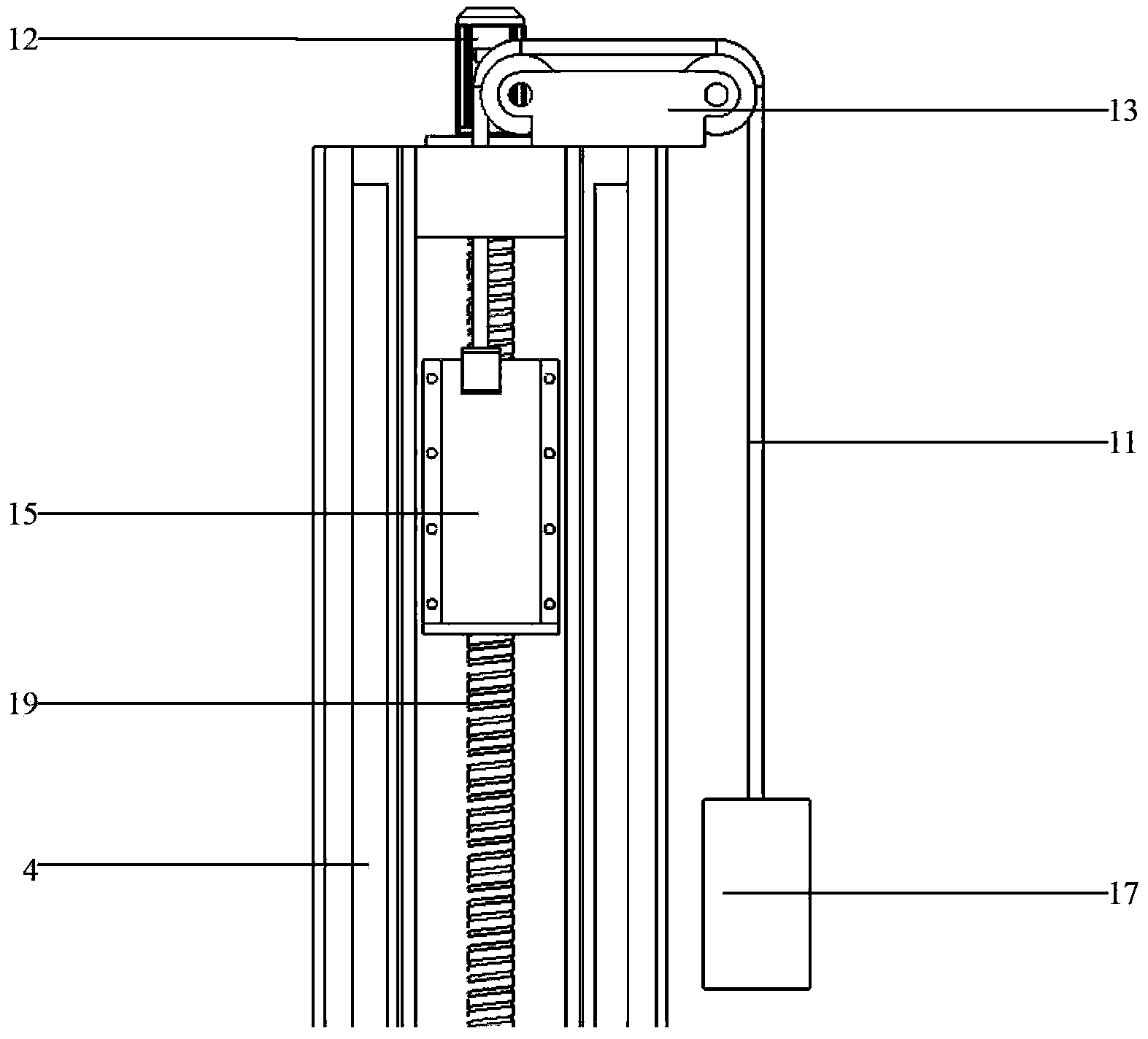

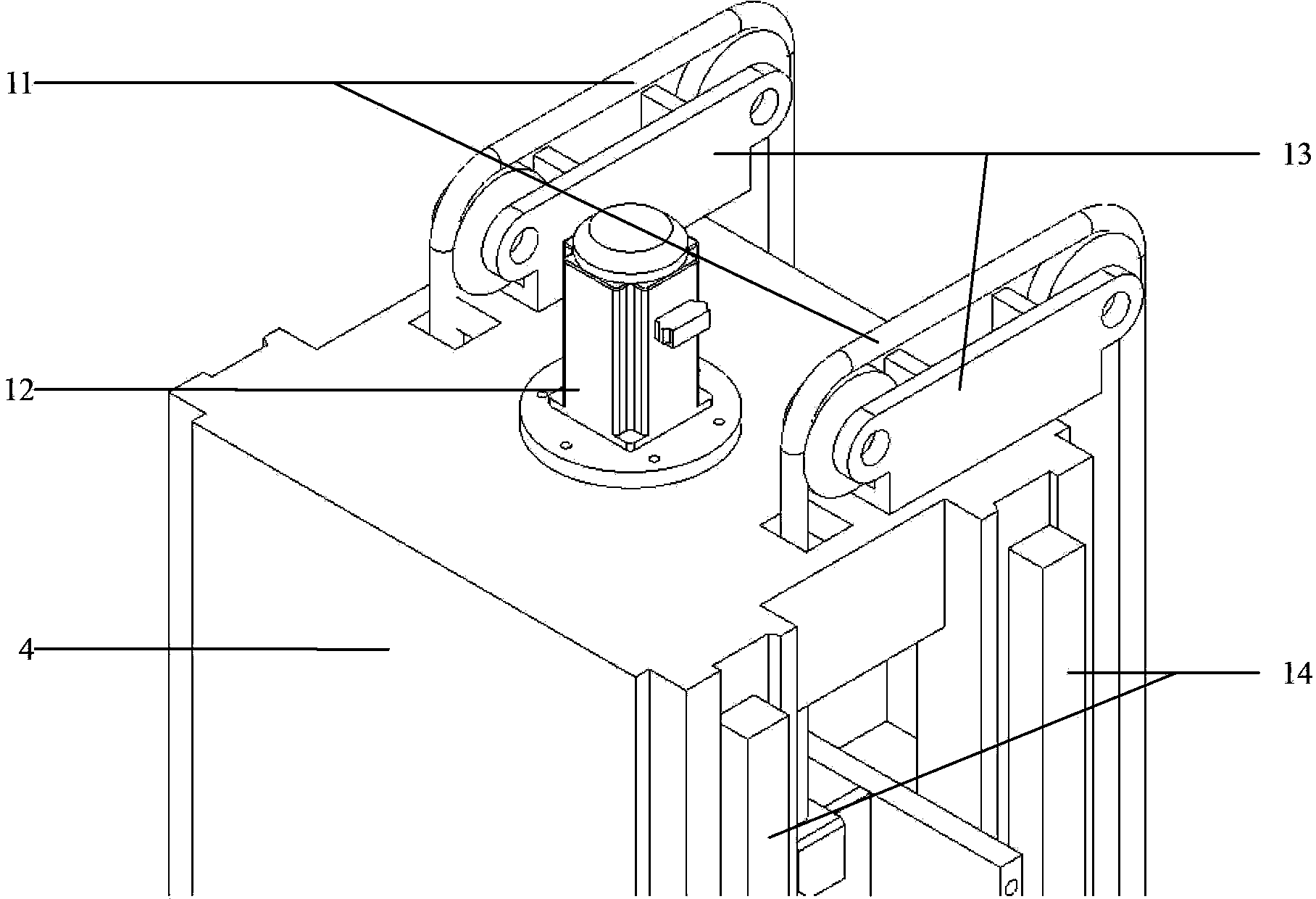

Flexible automatic feeding and blanking mechanism of manual pallet truck

The invention discloses a flexible automatic feeding and blanking mechanism of a manual pallet truck, which is a full-automatic mechanical device used for feeding and blanking of the manual pallet truck. The flexible automatic feeding and blanking mechanism comprises a pillar which can move along a sliding rail, wherein a ball screw mechanism is arranged at the center of the pillar in the vertical direction, a suspension arm seat is connected with a movable nut in the ball screw mechanism, two sides of the suspension arm seat are symmetrically provided with suspension arms which stretch outwards, the suspension arms move in sliding fit with the pillar simultaneously when vertically moving along with the suspension arm seat, two connecting rods which can move in different directions along the stretching direction are arranged on each suspension arm, the arrangement direction of the two connecting rods is parallel to the movement direction of the sliding rail, and at least one end of each connecting rod is connected with a part taking manipulator which is a hanging claw or an electromagnetic suction arm. The flexible automatic feeding and blanking mechanism has the characteristic of flexibility, is compact in structure, and can be used for meeting needs of feeding and blanking of the manual pallet trucks of various specifications, so that the welding quality and production efficiency of the manual pallet trucks are effectively improved, the labor intensity of workers is alleviated, and a labor environment of the workers is improved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com