Stackable Storage Apparatus

a storage apparatus and rack technology, applied in the field of storage, can solve the problems of considerable cost of purchasing and assembling and the uncertainty of how much to spend on the vertical supports and horizontal shelves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

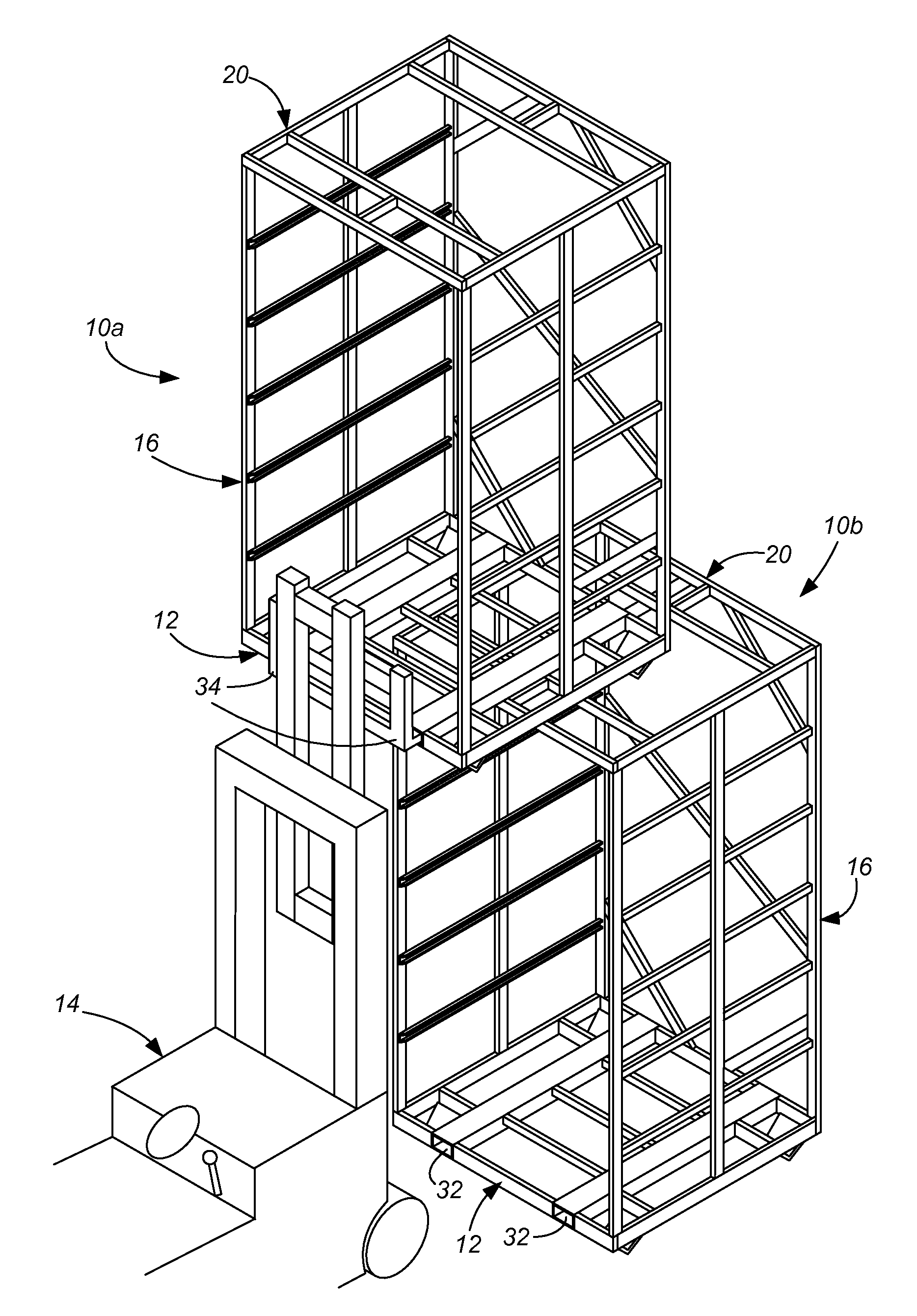

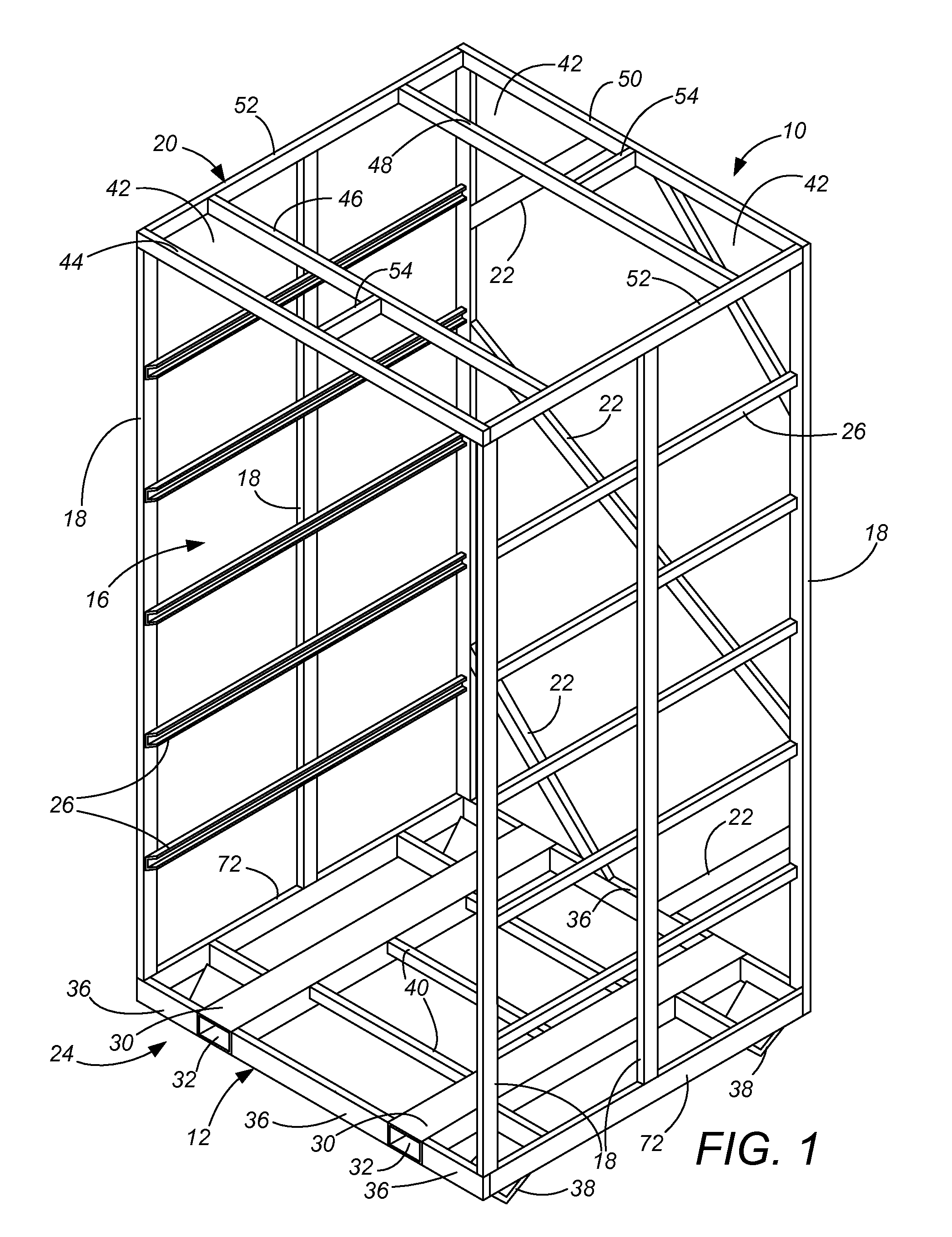

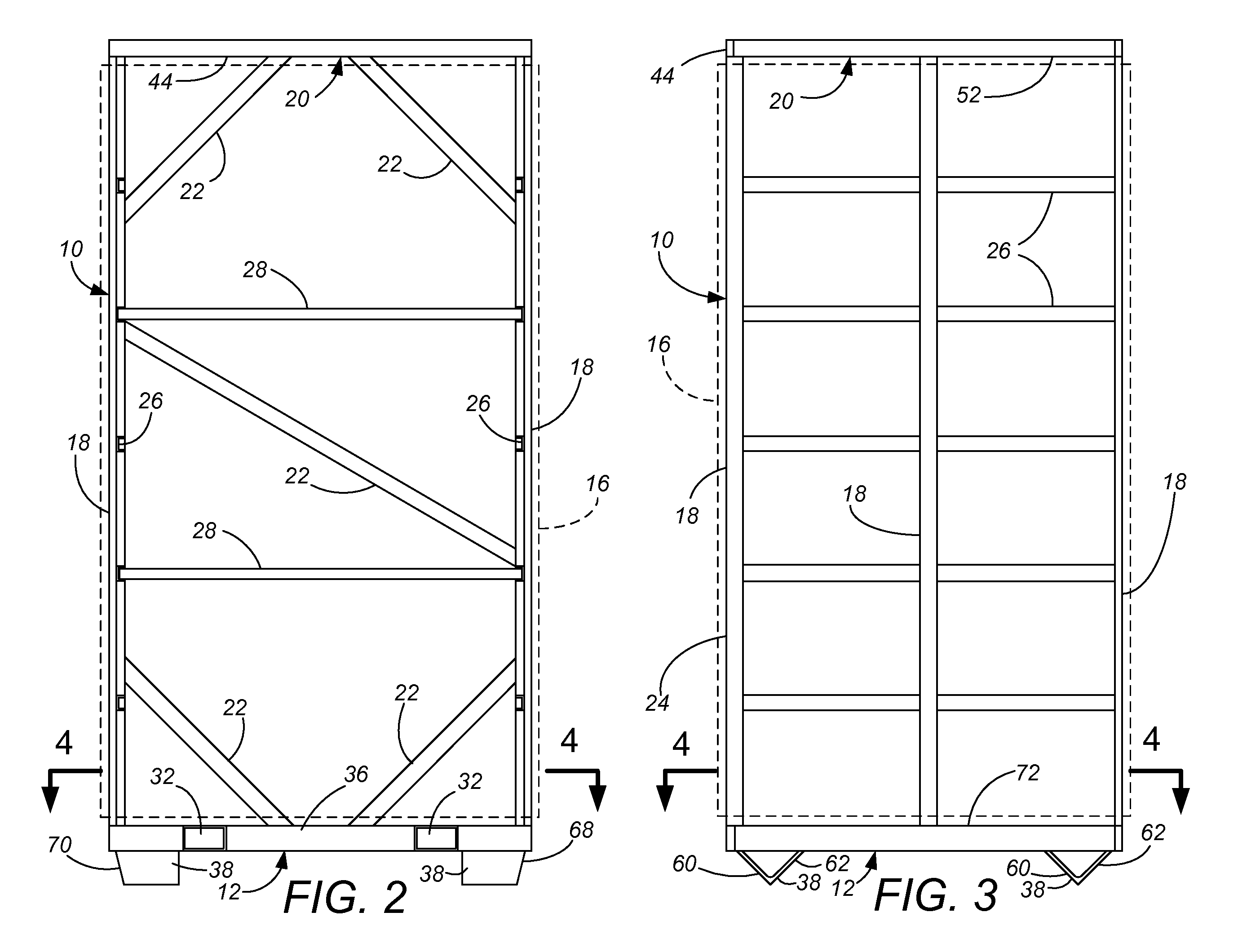

[0015]The present invention generally relates to an apparatus that is stackable. Each of the apparatus has base with targeting slopes and structures that are adapted to receive the tines of a forklift. The apparatus also includes a structure that forms the top of the apparatus, and this top structure mates with the base of an overlying structure during stacking, includes structures for receiving the targeting slopes When stacking two or more of the apparatuses, targeting slopes facilitate guiding the base of the upper apparatus onto the top structure of the lower apparatus. Furthermore, to provide support, when two apparatuses are stacked, the base of the overlying apparatus is in contact with the top structure of the underlying apparatus. Furthermore, in one embodiment, the base is configured with feet of a height that would enable a pallet jack to be placed under the base.

[0016]A first embodiment of a shelf storage apparatus 10 in accordance with one embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com