Flexible automatic feeding and blanking mechanism of manual pallet truck

A technology of automatic loading and unloading and manual pallets, applied in cranes, load hanging components, rail systems, etc., can solve the problems of high labor intensity, high labor intensity and low added value of workers, saving processing site area and reducing labor. Number of people, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and example.

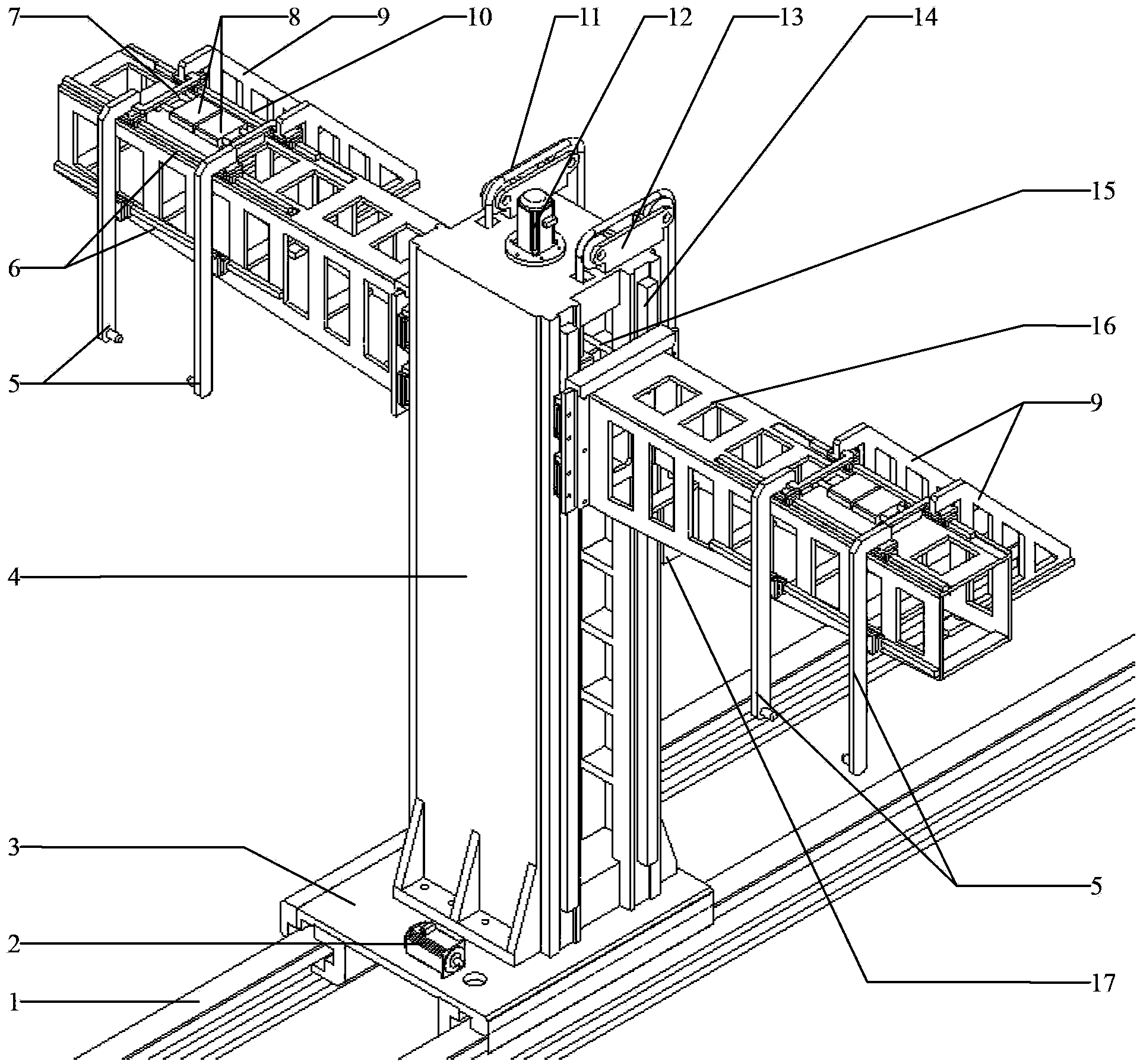

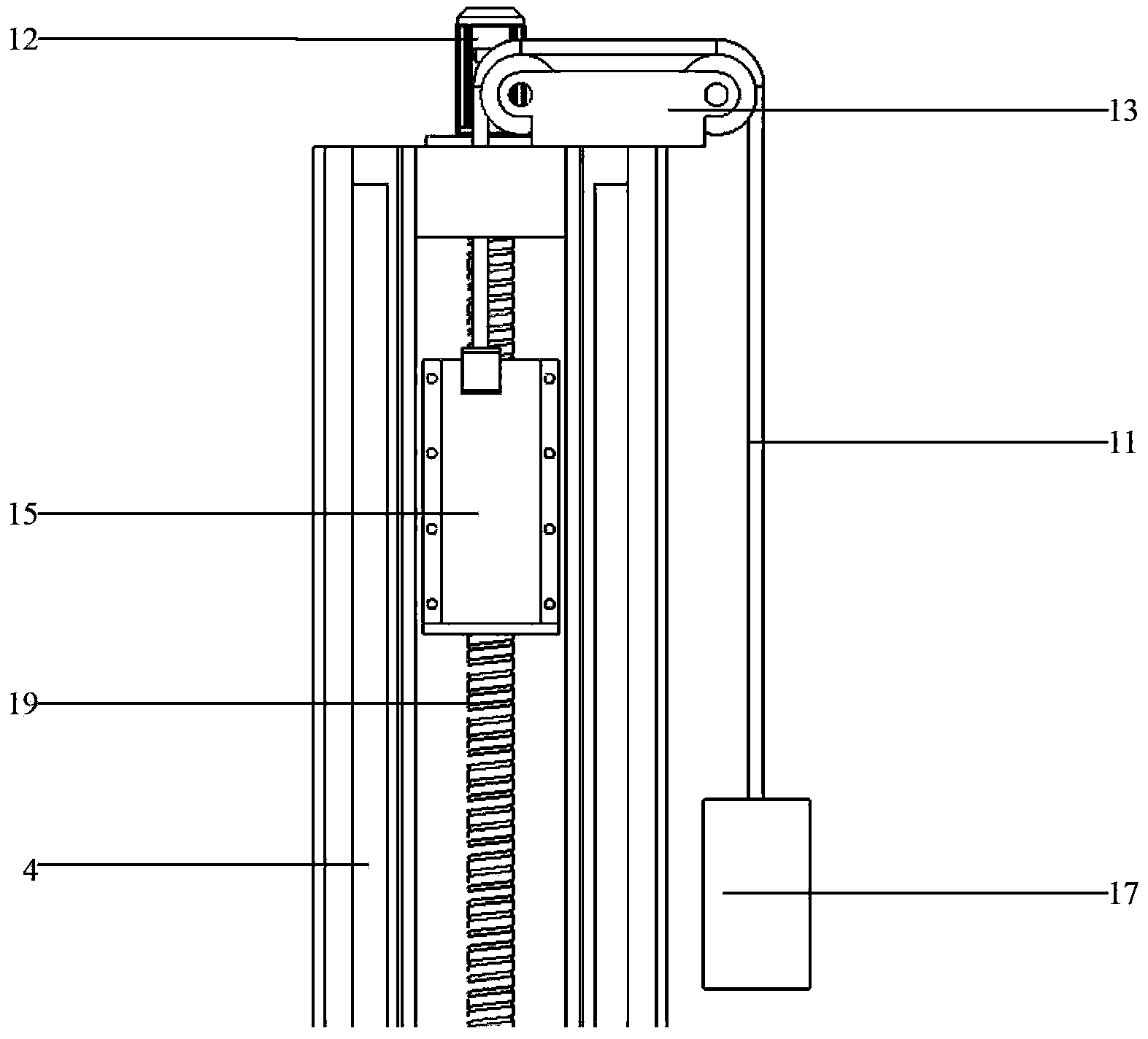

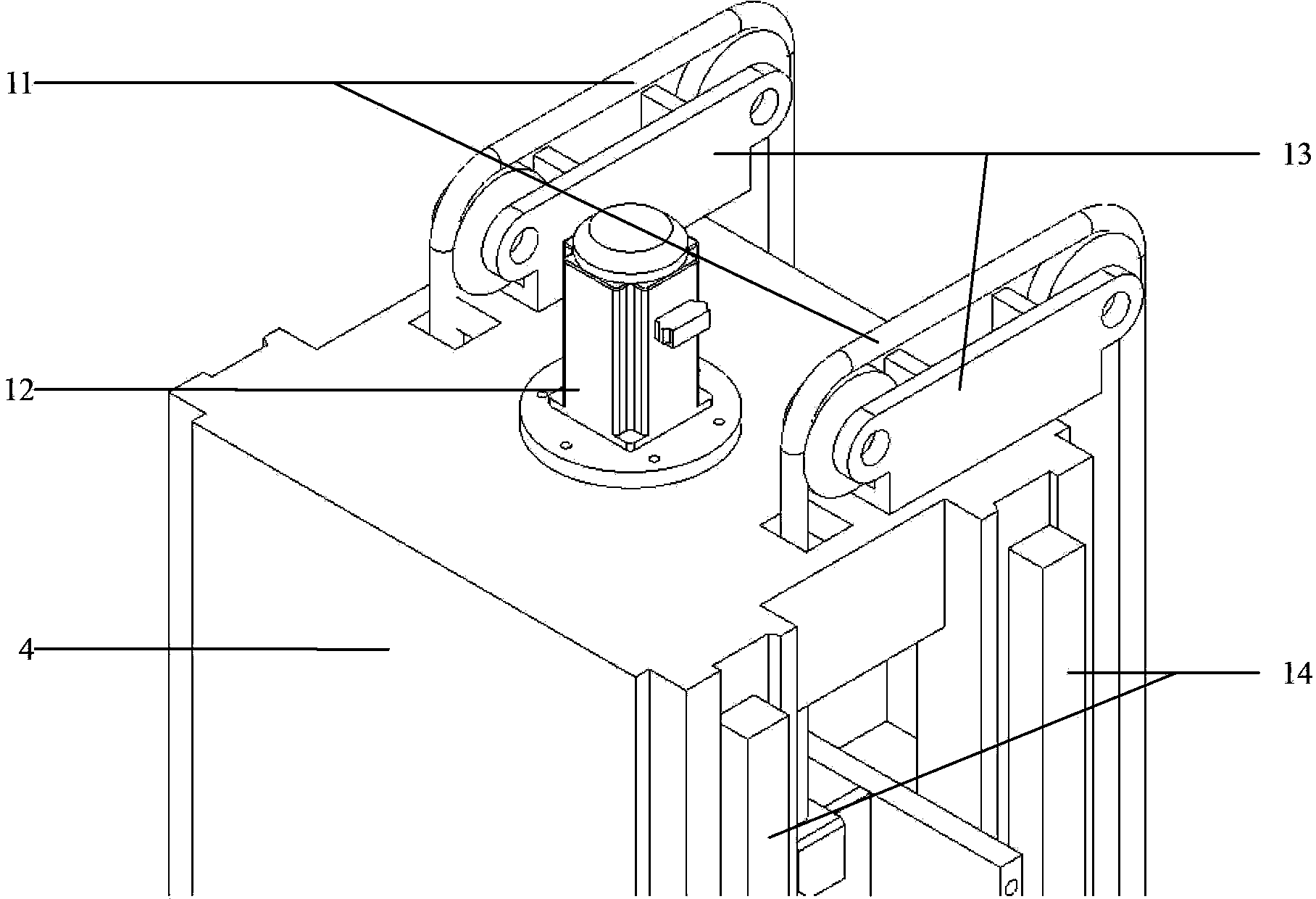

[0030] Such as figure 1 - Figure 5 , the present invention includes a slide rail 1, a traveling motor 2, a base 3, a column 4, a hanging claw 5, a hanging claw guide rail 6, a connecting rod 7, a drive cylinder 8, an electromagnetic suction arm 9, an electromagnetic suction arm guide rail 10, a chain 11, a lifting Motor 12, chain wheel seat 13, lifting guide rail 14, boom seat 15, boom 16, counterweight 17, lifting slider 18, ball screw mechanism 19.

[0031] The column 4 is installed and fixed on the base 3, the travel motor 2 is installed and fixed on the base 3, the base 3 is driven by the travel motor 2 to slide along the slide rail 1, and the direction in which the column 4 moves along the slide rail 1 is the travel direction;

[0032] The center of the column 4 is installed with a ball screw mechanism 19 along the vertical direction, and a pair of lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com