Lowe layer light steel structure fabricated residence

A steel structure, prefabricated technology, applied in building components, building structures, roofs, etc., can solve the problems of increased human capital investment, long engineering cycle, and many wet operations, reducing labor and mechanical costs, and shortening the construction cycle. , the effect of fast return on investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

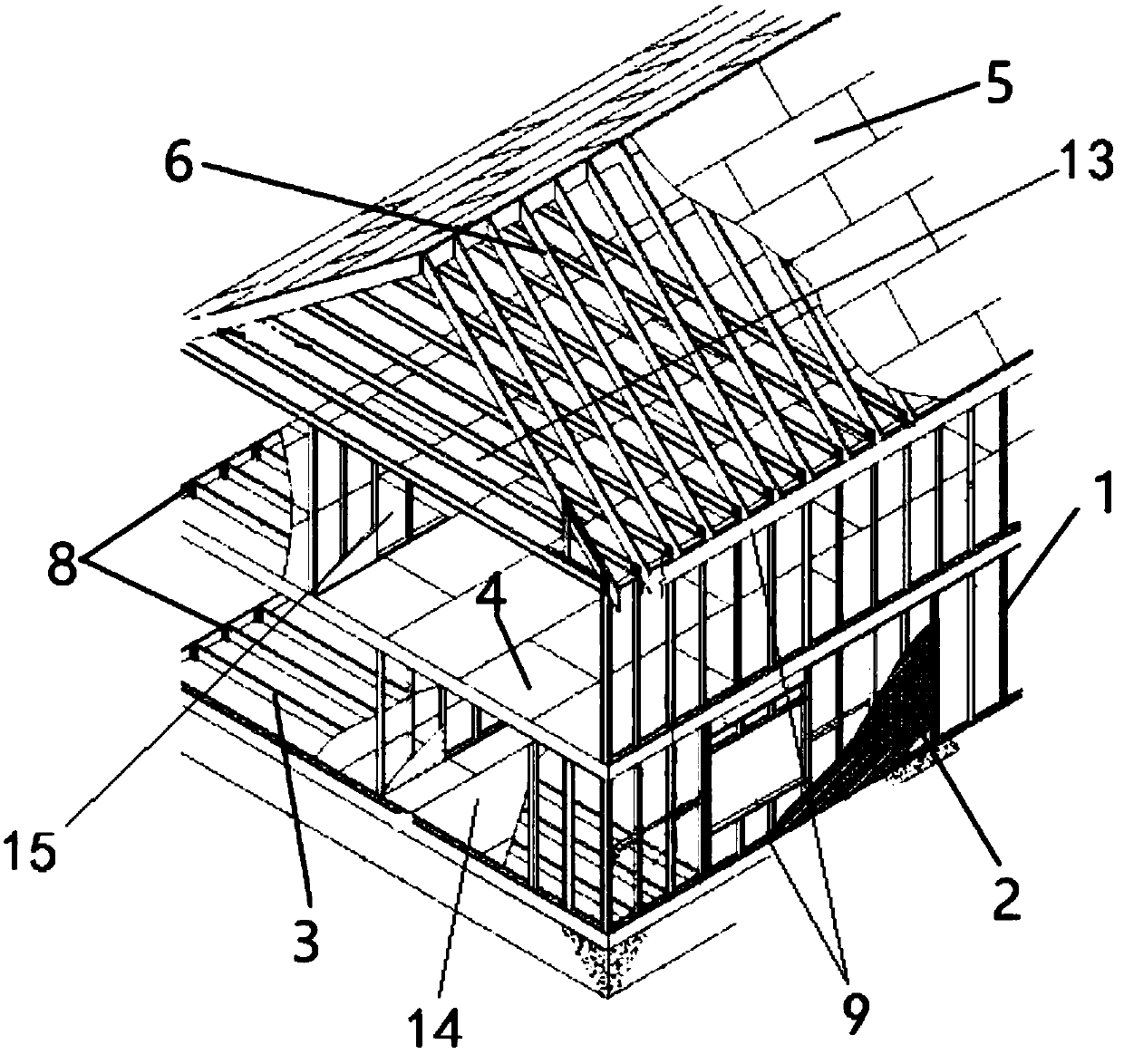

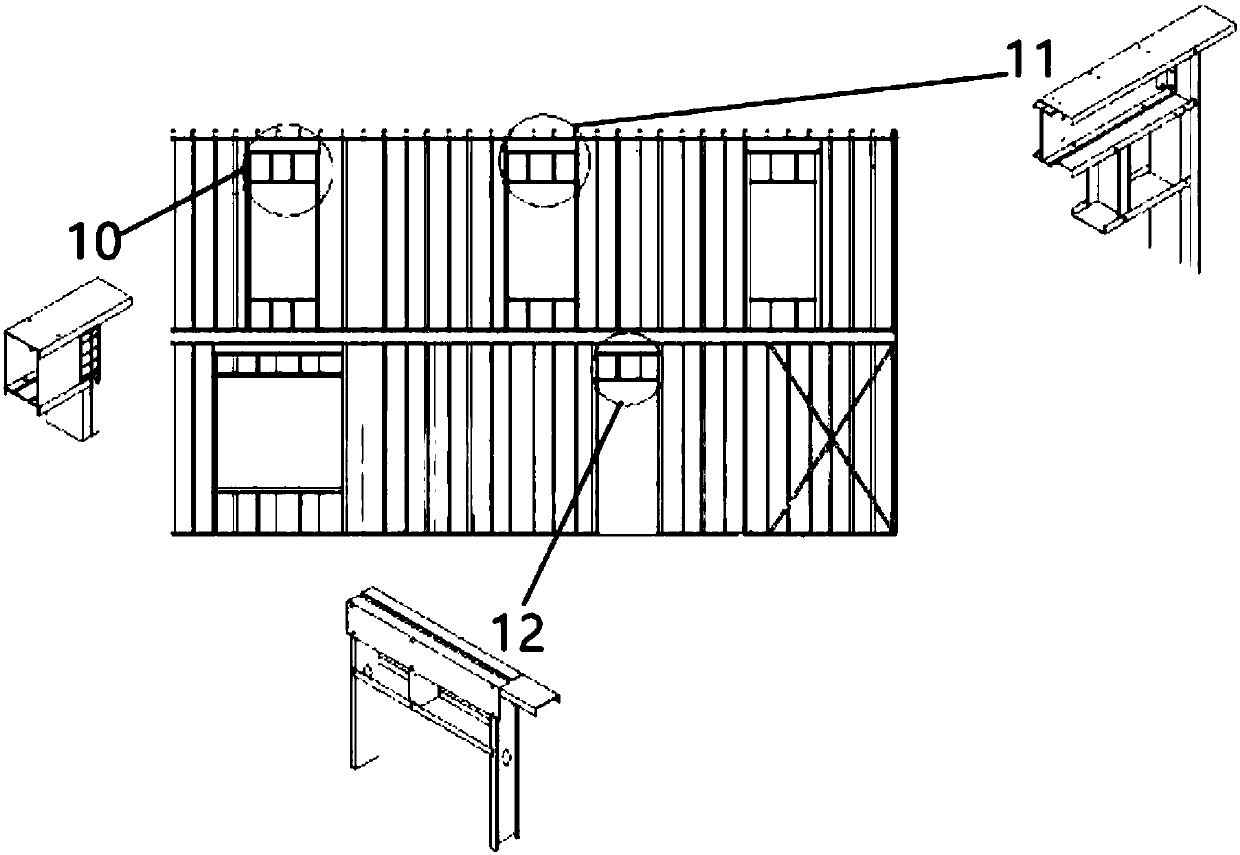

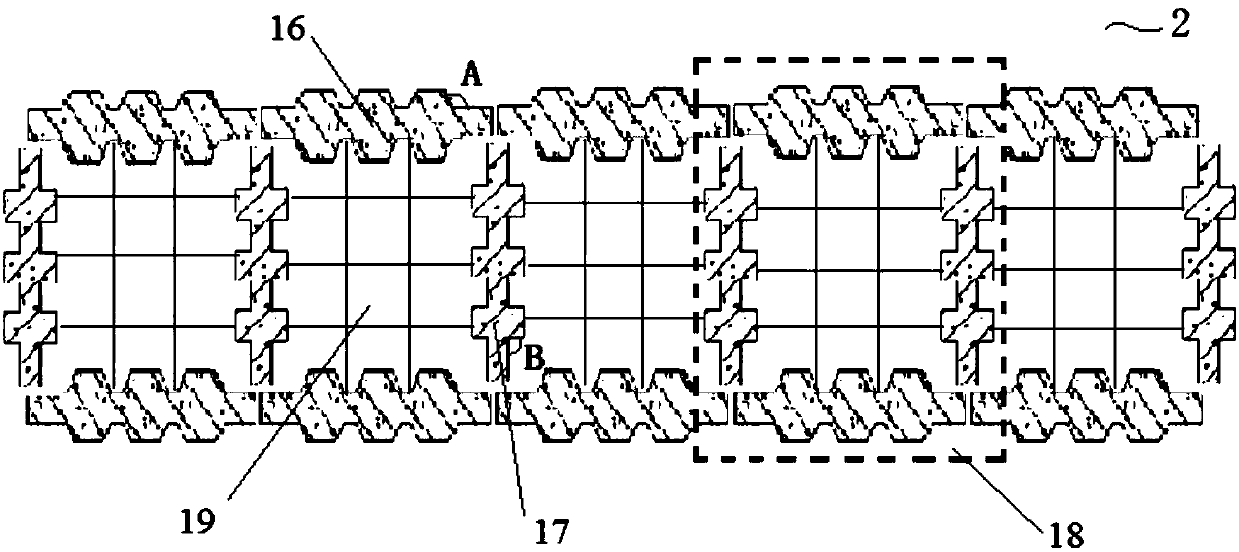

[0047] Refer to as figure 1 and figure 2 , the present invention provides a low-rise light-weight steel structure prefabricated house, which includes: at least one pair of opposite wall bodies, a plurality of flat layers, a roof, a plurality of first load-bearing members 8 and a plurality of second load-bearing members 9; each wall includes a plurality of dense columns 1 arranged vertically side by side and a plurality of wall panels 2 laid on at least one surface of the plurality of dense columns 1, the two ends of the plurality of dense columns 1 are aligned, and are respectively arranged horizontally The first load-bearing member 8 is connected; the flat body includes a top flat body 13, a bottom flat body 14 and at least one middle flat body 15, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com