Steel pipe bundle and steel plate concrete combined shear wall structure system

A technology of steel plate concrete and combined shear walls, which is applied to walls, building components, building structures, etc., can solve problems such as poor economic performance, complicated fabrication, and large steel consumption, and achieve light weight, saving building materials, and lightening The effect of earthquake damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

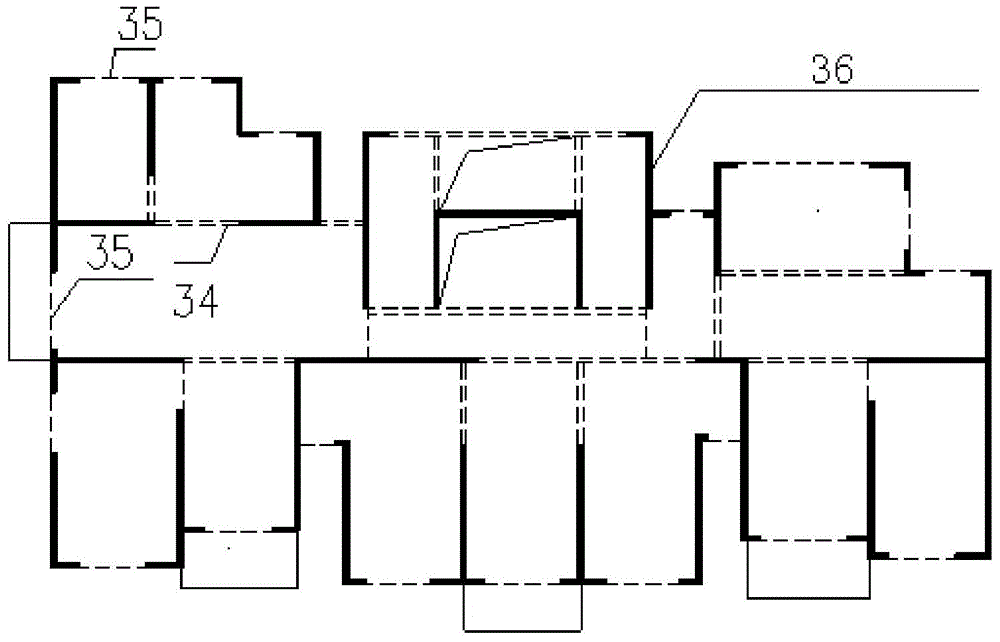

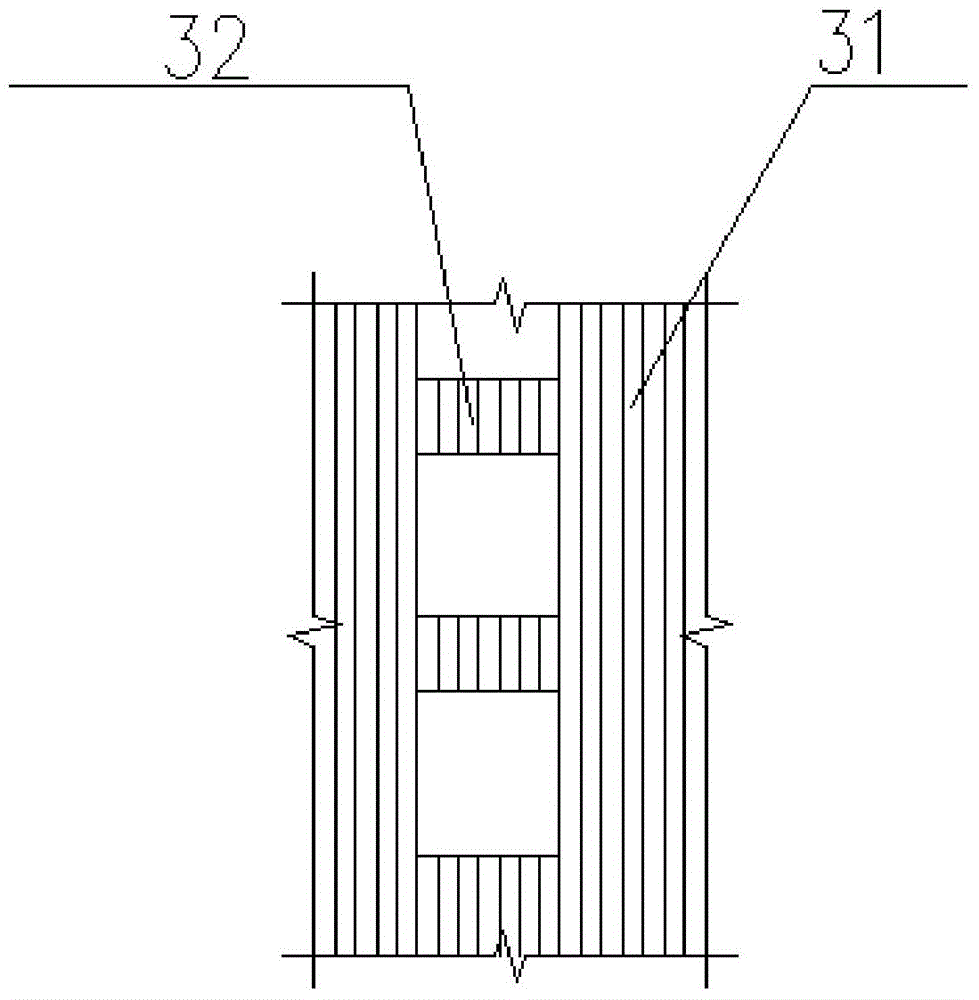

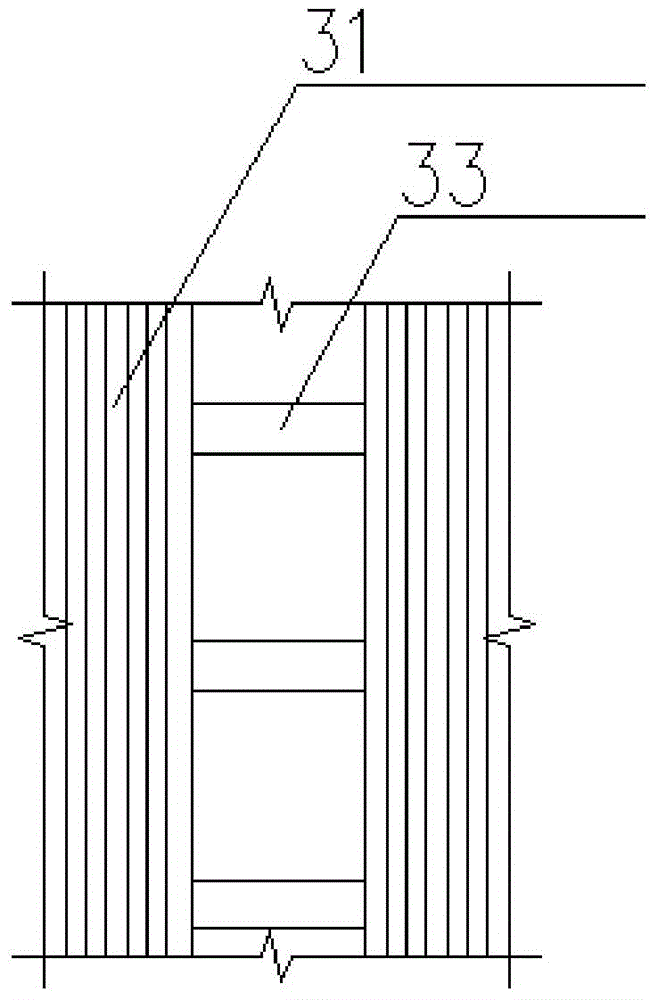

[0064] refer to Figures 1 to 10c , a steel tube bundle and steel plate concrete composite shear wall structure system, which is connected by a steel plate concrete composite shear wall 38, a steel tube bundle composite structural member 31, and an H-shaped steel beam 33 or a box beam 34 or a short steel tube bundle composite structural member 32 made;

[0065] The steel plate concrete composite shear wall 38 is connected with the steel pipe bundle composite structural member 31 to form the steel pipe bundle and the steel plate concrete composite shear wall structural member 36, and the steel steel pipe bundle and the steel plate concrete shear wall composite structural member 36 includes an intermediate Steel plate concrete composite shear wall and steel tube beam composite structural members arranged at both ends of the steel plate concrete composite shear wall;

[0066] The steel plate concrete composite shear wall 38 can be a steel plate concrete composite shear wall conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com