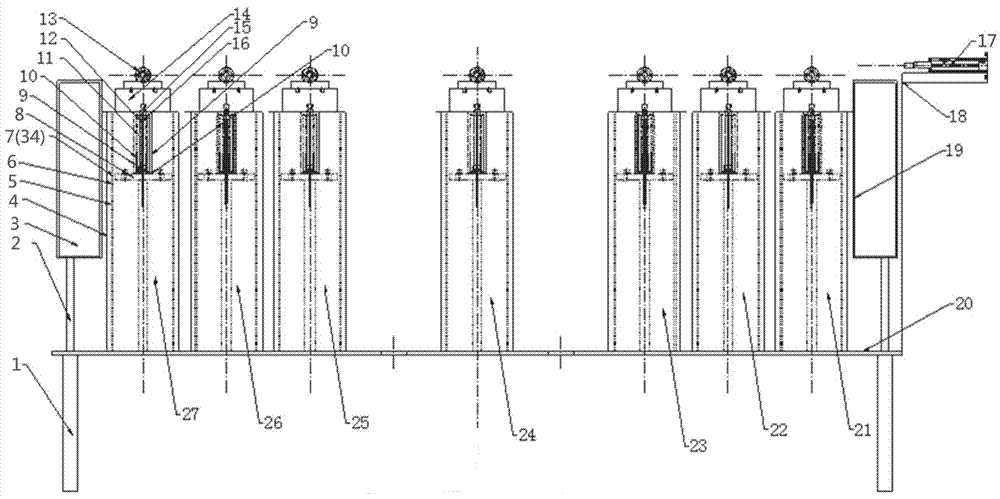

Automatic float-and-sink test apparatus with linear structure

An experimental device and straight line technology, applied in the direction of measuring devices, chemical instruments and methods, wet separation, etc., can solve the problems of increasing the labor intensity of artificial floating and sinking experiments, difficult preparation of high-density heavy liquid, and low work efficiency, so as to save experiments The effect of time and speed controllable and simple stirring structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

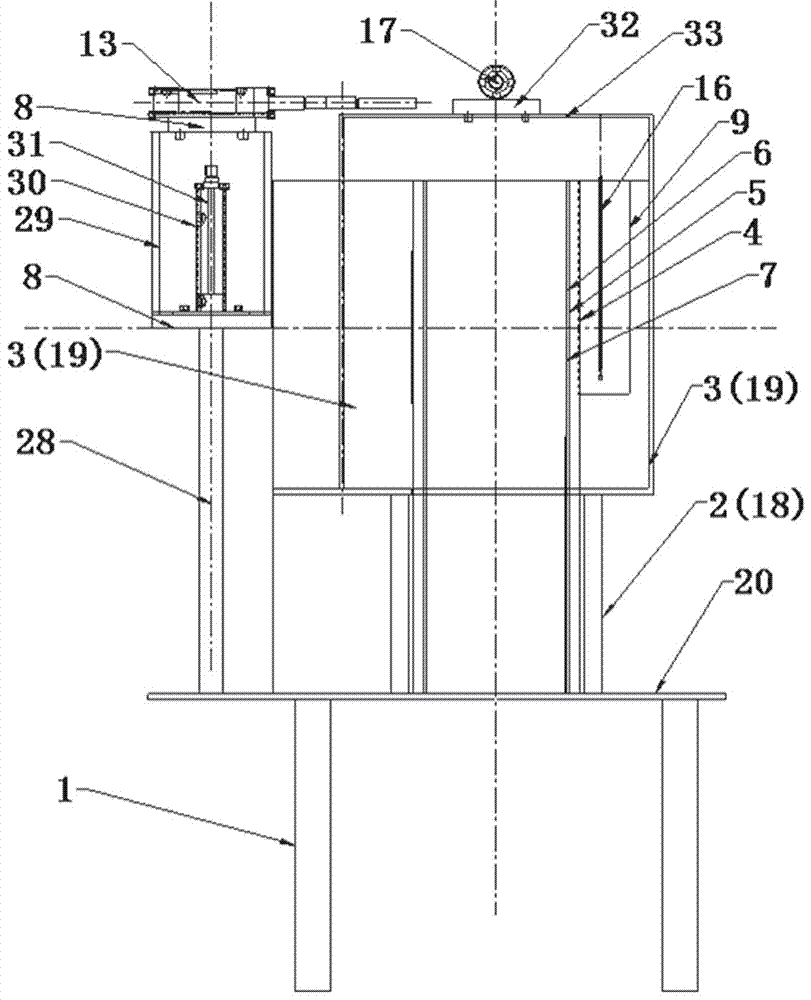

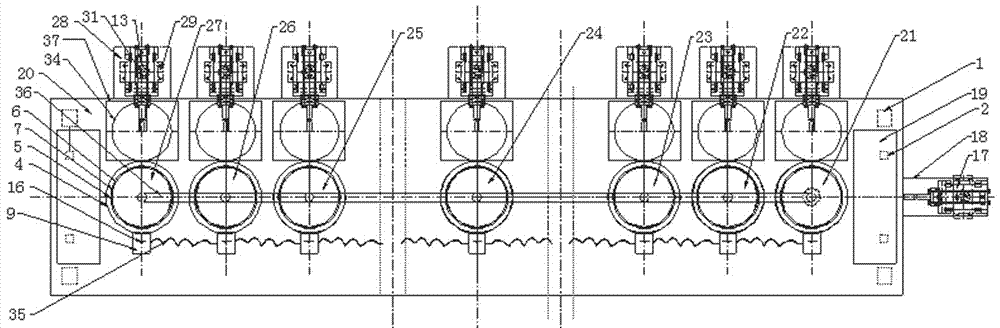

[0034] Such as figure 1 , 2 As shown in , 3, the linear structure automatic ups and downs test device of the present invention is based on hydraulic transmission and automatic control technology and adopts a "one" type mechanical structure linear arrangement, that is, it is arranged in the pretreatment tank 3 and the gangue collection tank in sequence from left to right Between 19, several density level devices are arranged from low density level to high density level; each density level device includes an external water bath heating tank composed of water bath heating tank outer wall 4 and water bath heating tank inner wall 5, And the floating heavy liquid bucket that is arranged in the water bath heating tank by the floating heavy liquid bucket outer wall 6 and the floating heavy liquid bucket inner wall 7 is respectively provided with a floating object coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com