Toilet ground and laying method

A bathroom and floor technology, applied in the field of architectural decoration, can solve the problems of difficult construction, complicated operation steps, and high technical level requirements of workers, and achieve the effect of rapid construction and avoiding mess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The bathroom floor provided in this embodiment includes a waterproof bottom box and floor tiles.

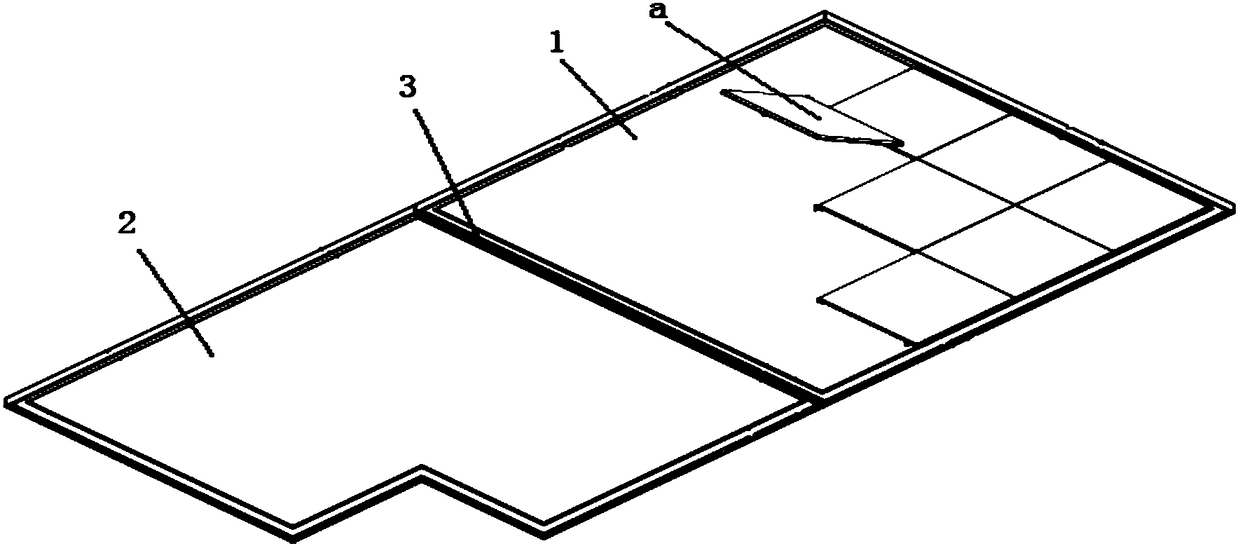

[0031] like figure 1 As shown, the floor of the bathroom includes a waterproof bottom box and floor tile a, and the shape and area of the waterproof bottom box are the same as those of the original building floor of the bathroom to be renovated. Dry section 1 and wet section 2; floor tile a is laid inside the waterproof bottom box.

[0032] The bathroom floor provided in this embodiment includes a waterproof bottom box and floor tiles. All components are industrially produced in the factory, and only simple installation is required on the decoration site. There is no need for skilled technical workers or too much construction time on site, and rapid construction is realized. , and avoid the mess of the traditional decoration effect site.

Embodiment 2

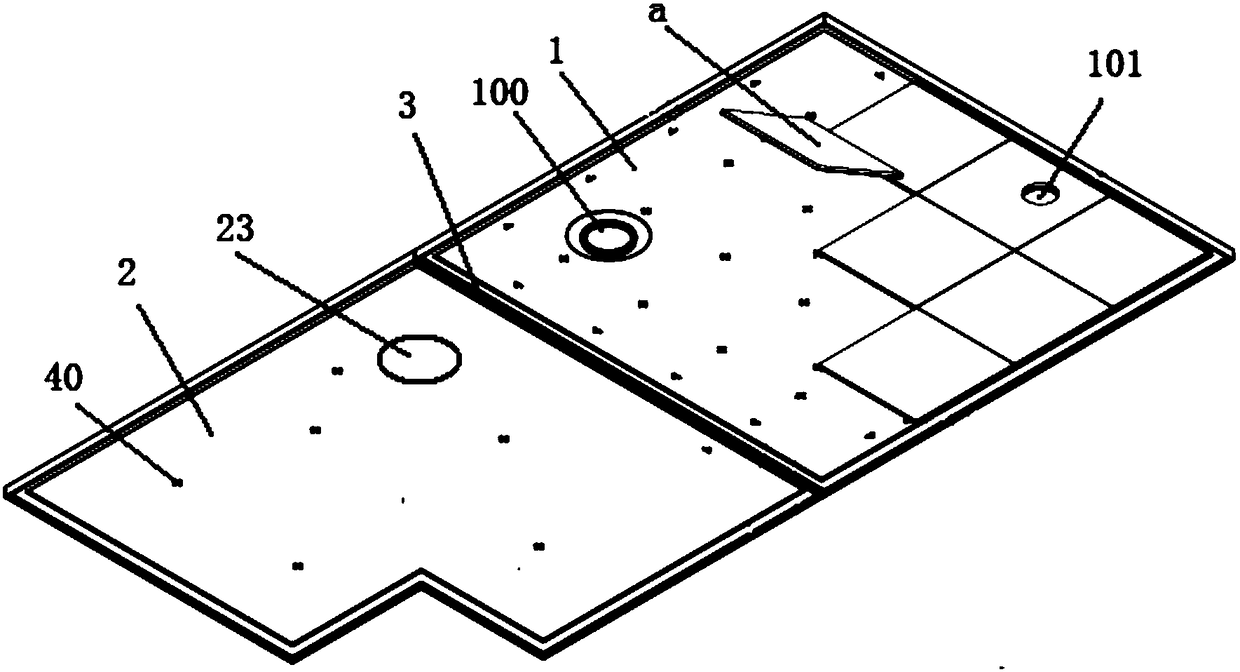

[0034] The bathroom floor provided in this embodiment includes at least one positioning component, wherein the backside of the floor tiles laid in the waterproof bottom box is compounded with an adhesive layer.

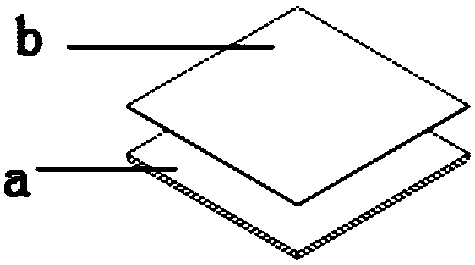

[0035] like Figure 2a to Figure 2e As shown, the bathroom floor includes a waterproof bottom box, floor tile a, toilet flange, basin flange, floor drain, and positioning components. like Figure 2b As shown, the back of the floor tile a laid in the waterproof bottom box is compounded with an adhesive layer b, wherein the back of the floor tile a is the side in contact with the waterproof bottom box. The waterproof bottom box includes a dry section 1, a wet section 2, and a water retaining strip 3, and the dry section 1 and the wet section 2 are respectively located on both sides of the water retaining strip 3. Wherein, the dry section 1, the wet section 2 and the water retaining strip 3 are integrally formed. The dry area 1 is formed with a toilet hole 100 and the...

Embodiment 3

[0039] The method for laying the bathroom floor provided by this embodiment sets a waterproof bottom box on the original building floor of the bathroom.

[0040] The steps of the method for laying the bathroom floor provided by the present embodiment are as follows:

[0041] 301. The step of installing the bottom box.

[0042]The waterproof bottom box is divided into wet area and dry area. After cleaning the original building floor, weld the waterproof bottom box to the original building floor of the bathroom, so that the shape of the waterproof bottom box matches the original building floor of the bathroom, and glue waterproof tape at the welding place.

[0043] 302. The step of laying bricks.

[0044] Floor tiles are laid in the wet area of the waterproof bottom box, and the floor tiles are pasted in the wet area; water retaining strips are installed at the junction of the wet area and the dry area of the waterproof bottom box; floor tiles are laid in the dry area, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com