Automatic pressure transmitter batch measurement and verification system and method

A metrological verification and transmitter technology, applied in the measurement of fluid pressure, instruments, measuring devices, etc., can solve the problems of low metrological verification efficiency of pressure transmitters, inability to realize digitization, and high probability of error introduction, and achieve rich content, The effect of improving labor efficiency and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

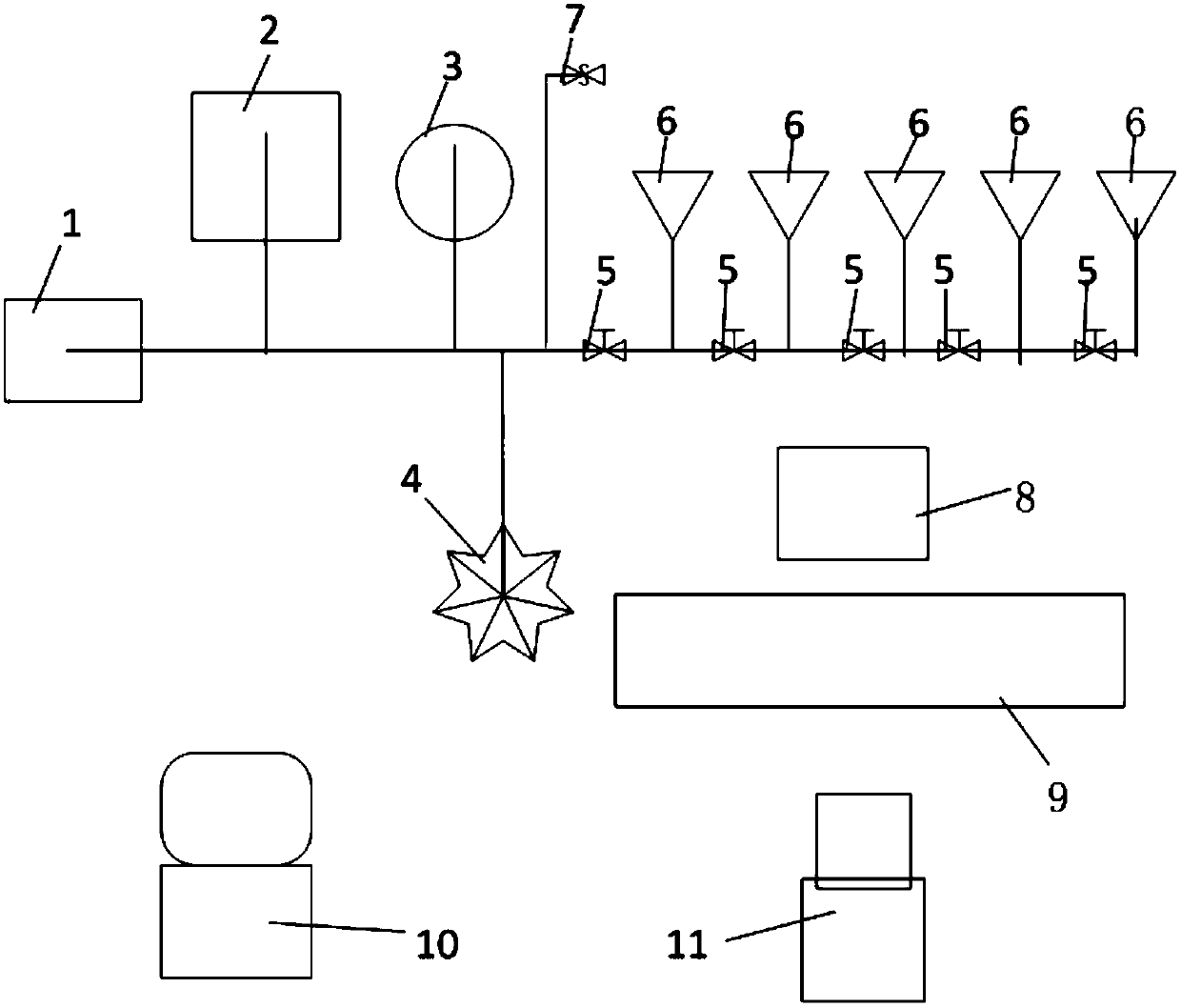

[0043] From figure 1 It can be seen that the system of this embodiment includes a preloading device 1, a medium container 2, a digital precision pressure gauge 3, a manual fine-tuning preloading hand pump 4, a pressure relief protection valve 7, and a stop valve 5 connected in sequence on the pressure pipeline. , quick connector 6, DC standard power supply 8, multi-channel number table 9 and control system 10; the joint 6 of the pressure transmitter to be tested is used to connect the pressure transmitter to be tested; each joint 6 of the pressure transmitter to be tested corresponds to a Group stop valve 5;

[0044] The control system 10 includes a control unit, an information input unit, a data acquisition unit and a data processing unit;

[0045] The control unit is connected to the preloading device 1 to control the preloading device 1 to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com