Marinating device and method for marinated products

A technology of stewed products and stewed soup, which is applied in the direction of dairy products, cheese substitutes, food science, etc., can solve the problems of low production efficiency, large amount of stewed soup, large workshop space, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

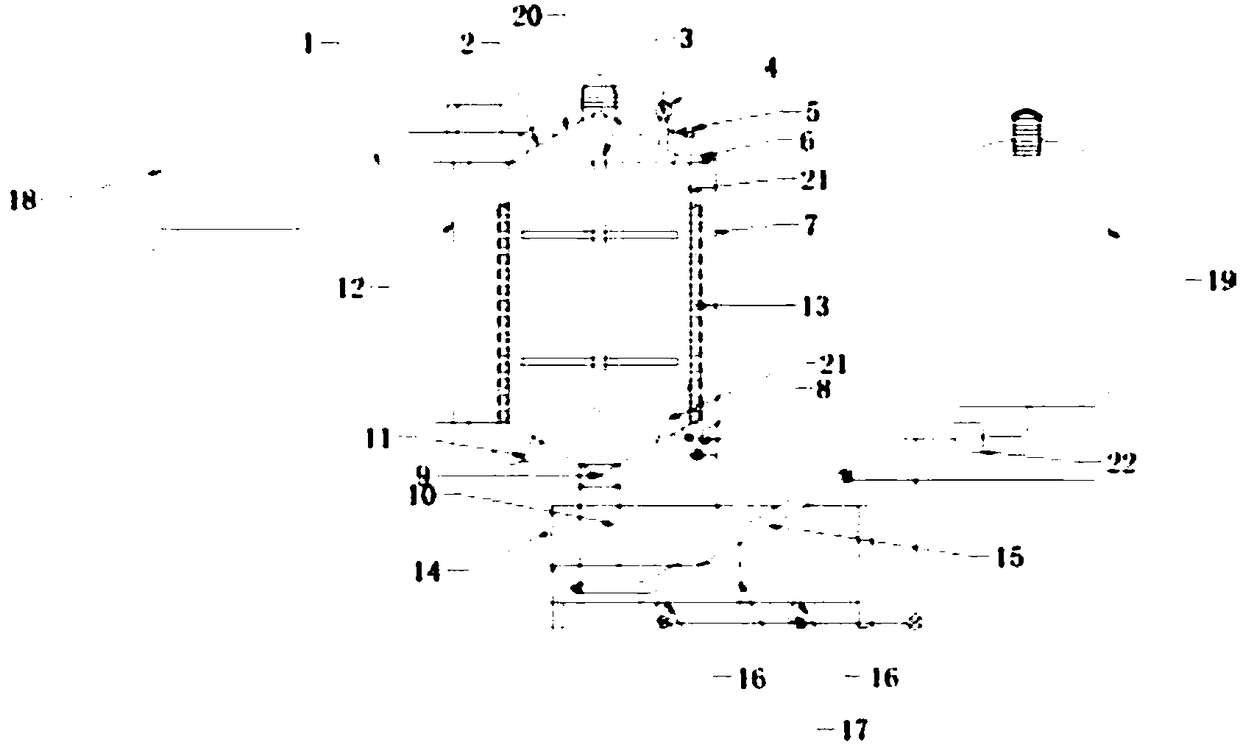

[0029] like figure 1 As shown, the present invention provides a stewed product brine device, which includes a brine tank 20, a discharge tank 14 and a control system. The stewed tank 20 is a pressure-resistant, high-temperature-resistant sealed tank body, the part in contact with the stewed soup is made of 316 stainless steel, and the rest is made of 304 stainless steel. The stewed tank 20 includes a tank body, a feed port 2 , an agitation device 3 , a compressed air connection 4 , an overflow port 6 , a stewed soup inlet 8 and a material outlet 9 . The feeding port 2 is connected with the feeding device 1, and the feeding device 1 includes a conveying lifting device and a counter. When the stewed product is eggs, the feeding device 1 can be connected with the egg shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com