Vacuum heat insulation cover plate for granulation template

A technology of vacuum heat insulation and cover plates, which is applied in the field of vacuum heat insulation cover plates for granulation templates, and can solve the problems that the effect of solid metal cover plates is not very obvious and cannot block heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

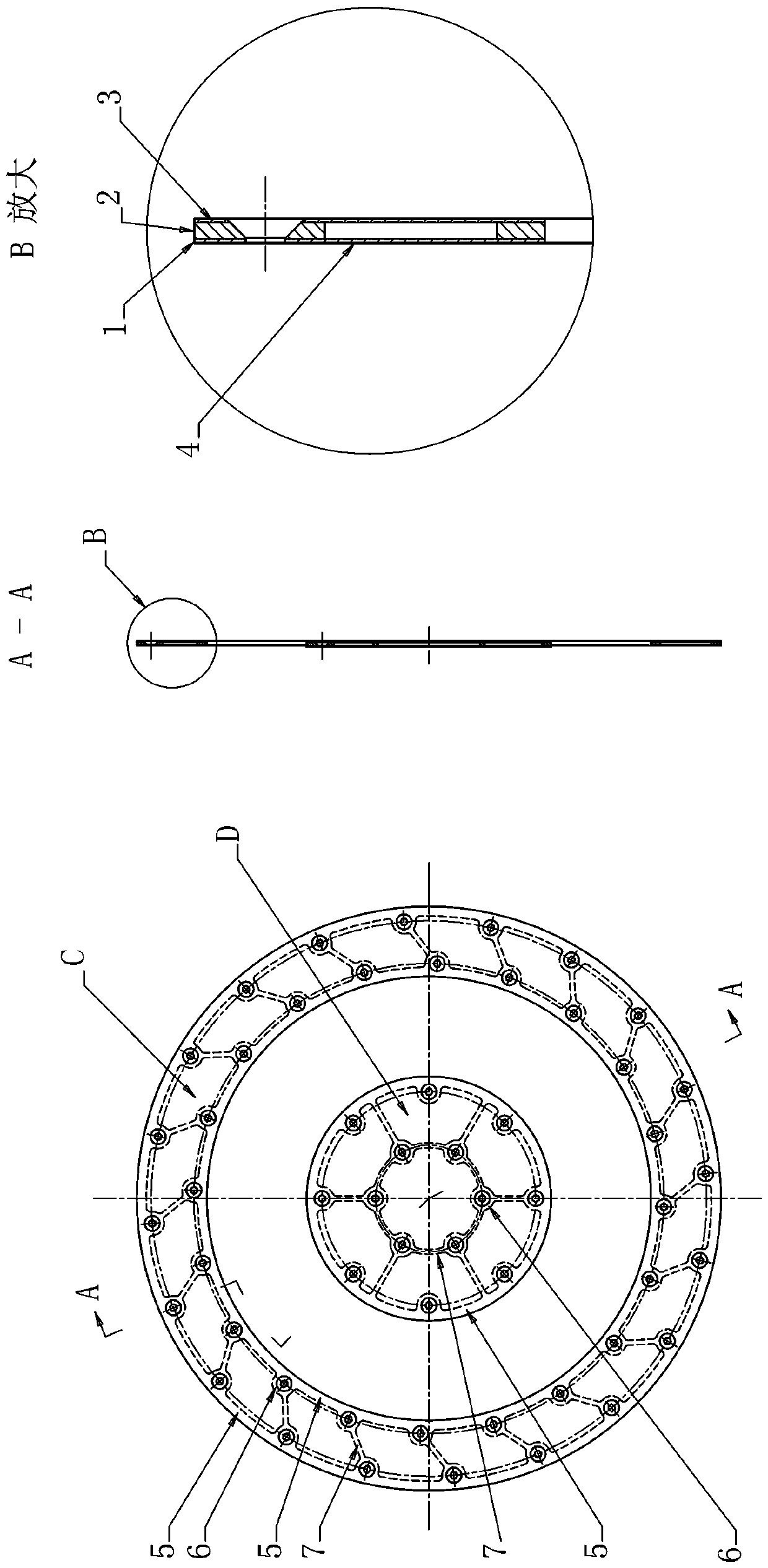

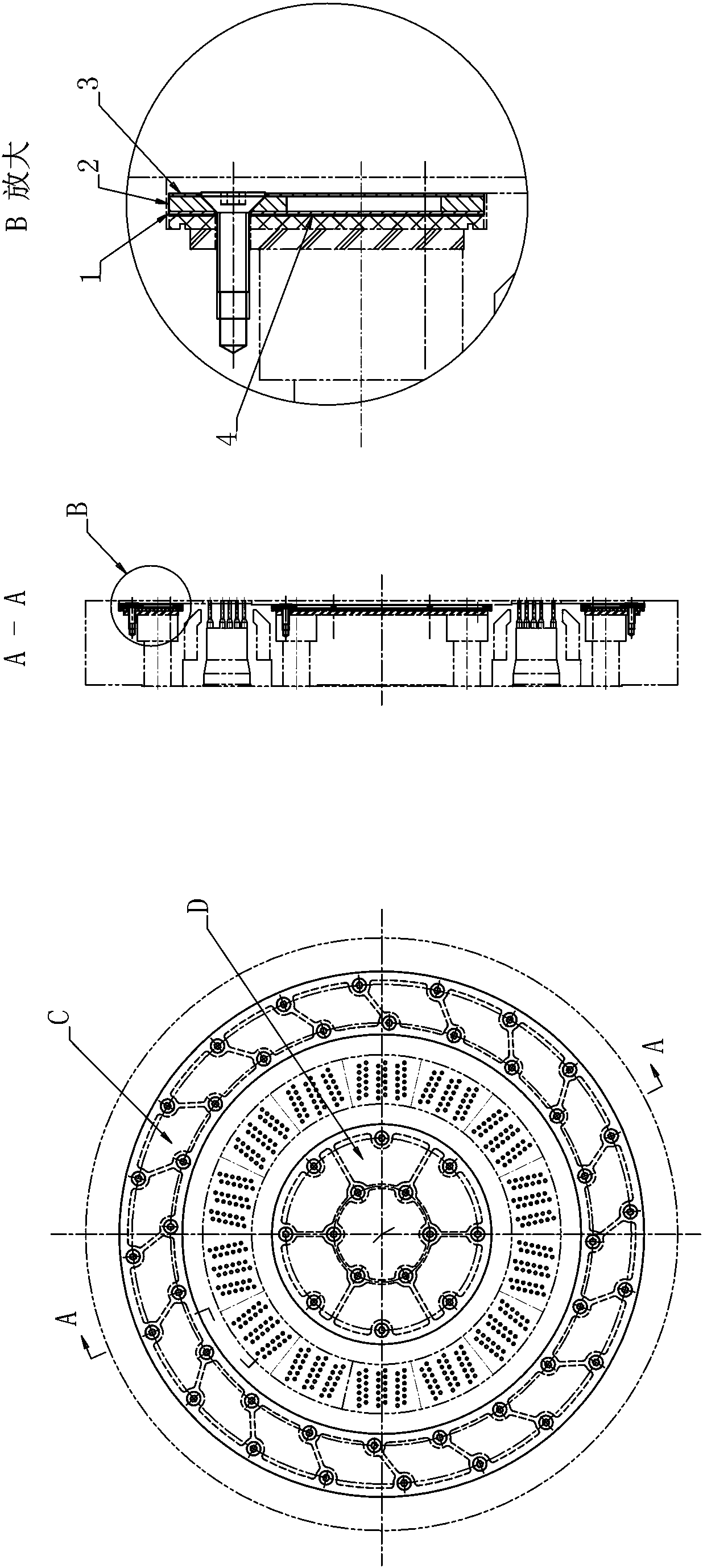

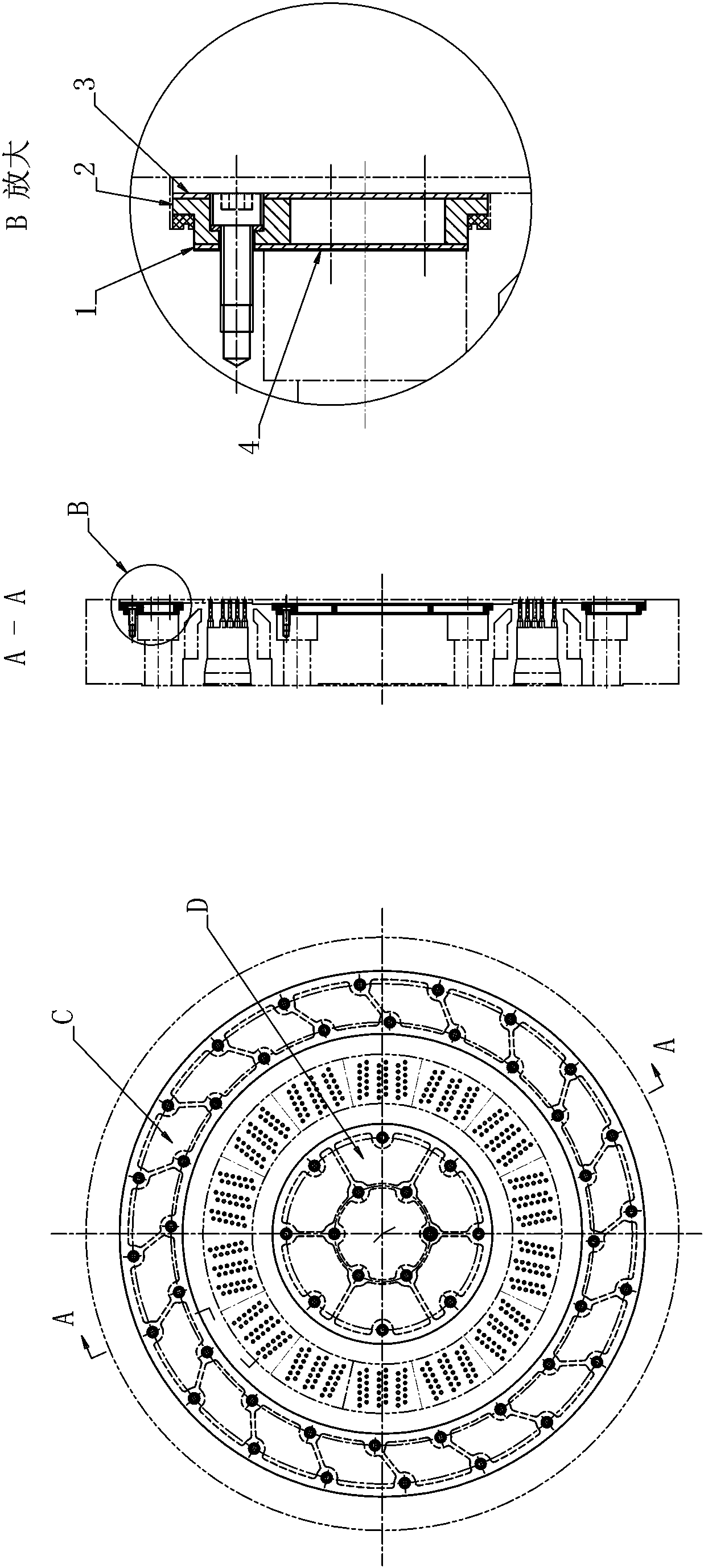

[0025] Specific implementation combined with figure 1 , figure 2 , image 3 , Figure 4 The first embodiment of the present invention is further described:

[0026] The lower cover plate 1, the middle support grid plate 2, and the upper cover plate 3 are formed by laser cutting.

[0027] Align the lower cover plate 1 with the outer circle of the middle support grid plate 2 and the upper cover plate 3, and align all the screw mounting holes, sandwich metal brazing solder between each layer, and connect the lower cover plate 1 with the middle The support grid plate 2 and the upper cover plate 3 are fixed, brazed and welded in a vacuum brazing furnace. After brazing, the inner and outer edge support rings 5 and the support connecting ribs 7 and The cavities surrounded by the upper cover plate 3 form several independent vacuum chambers.

[0028] Clean up the solder flowing out after brazing, reshape, ream the screw mounting holes, sandblast and clean the surface of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com