High-speed filter backwashing energy-saving device and use method thereof

An energy-saving device and filter technology, which is applied to chemical instruments and methods, filtration treatment, water treatment parameter control, etc., can solve the problems of backwashing mains long water flow, poor sealing performance, small flow leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

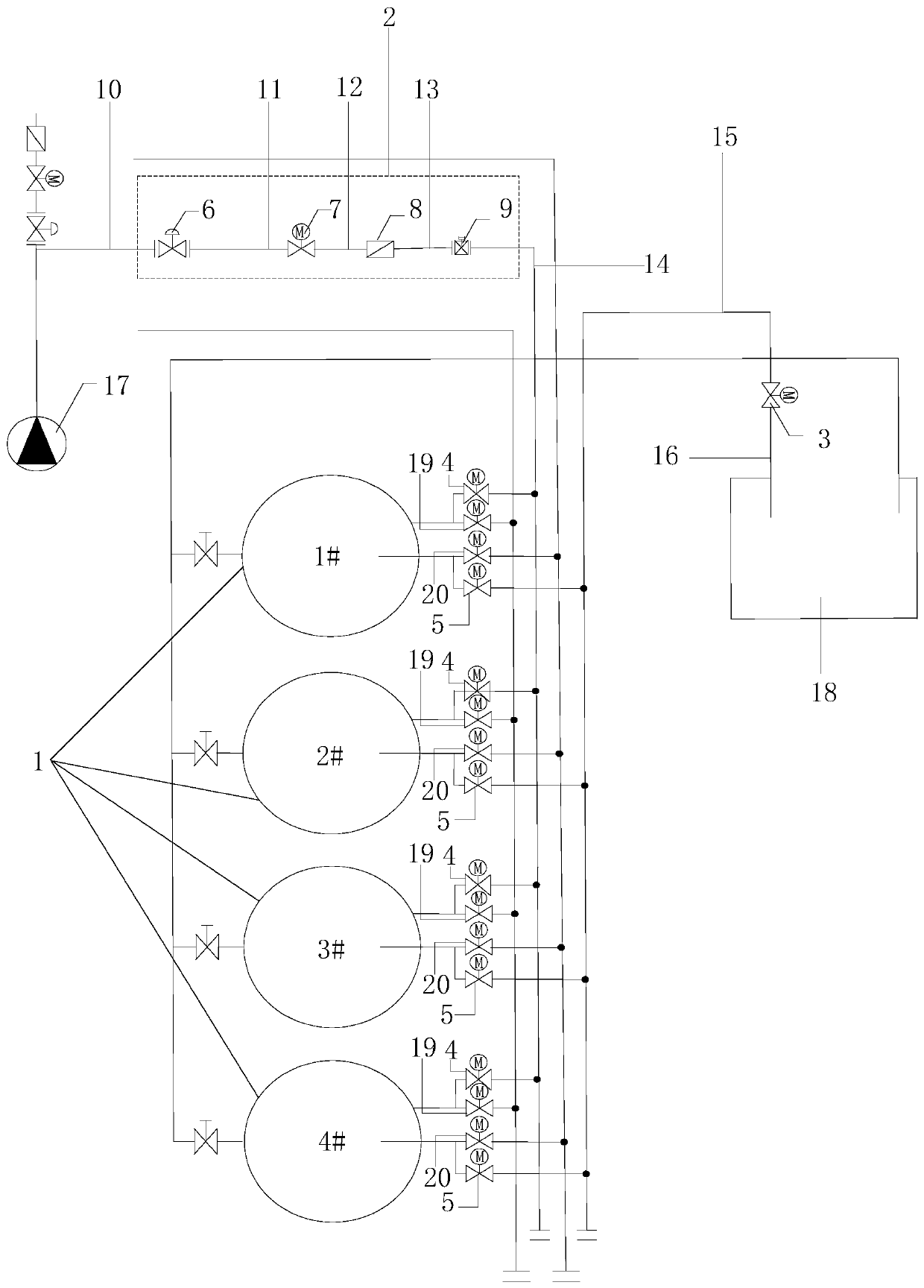

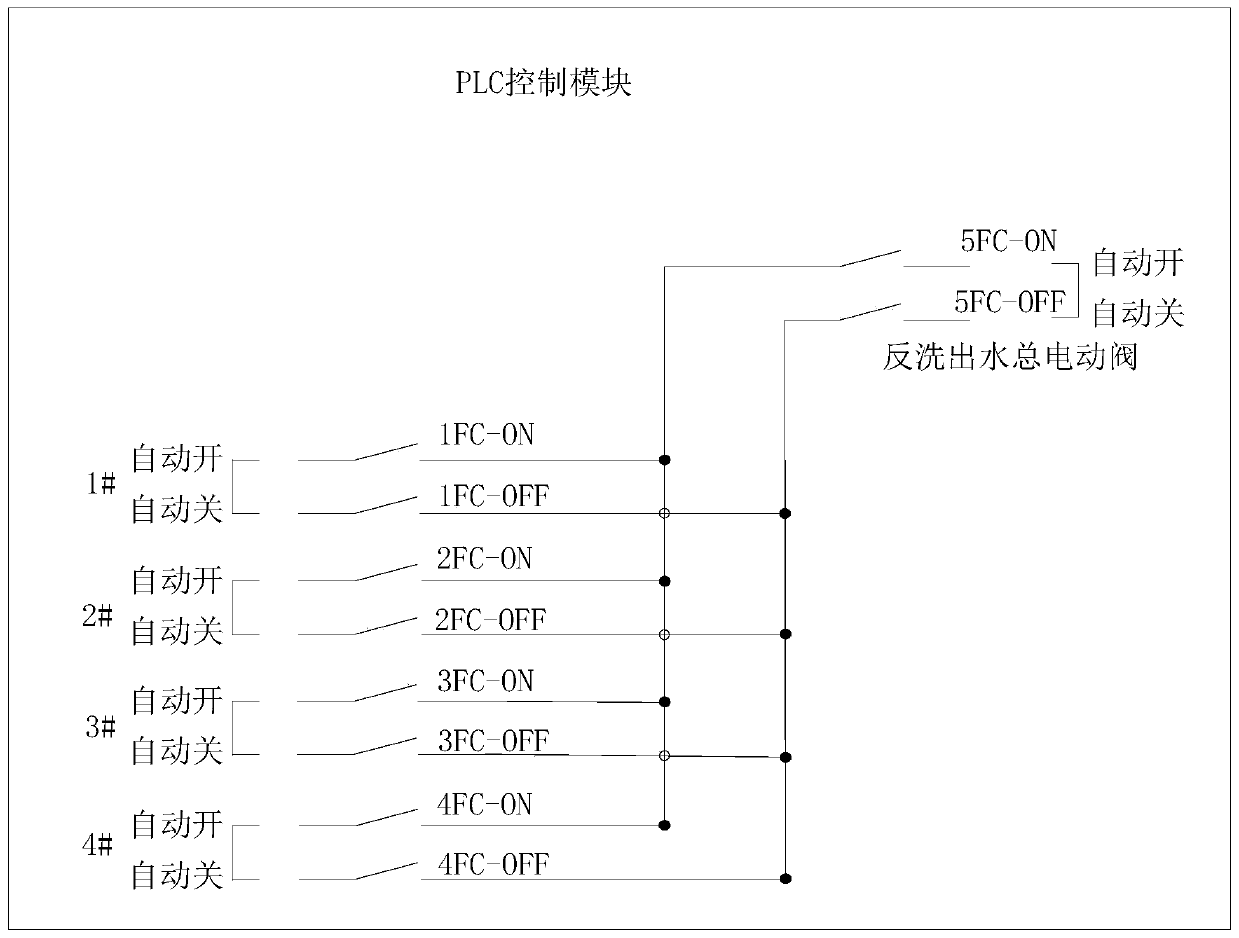

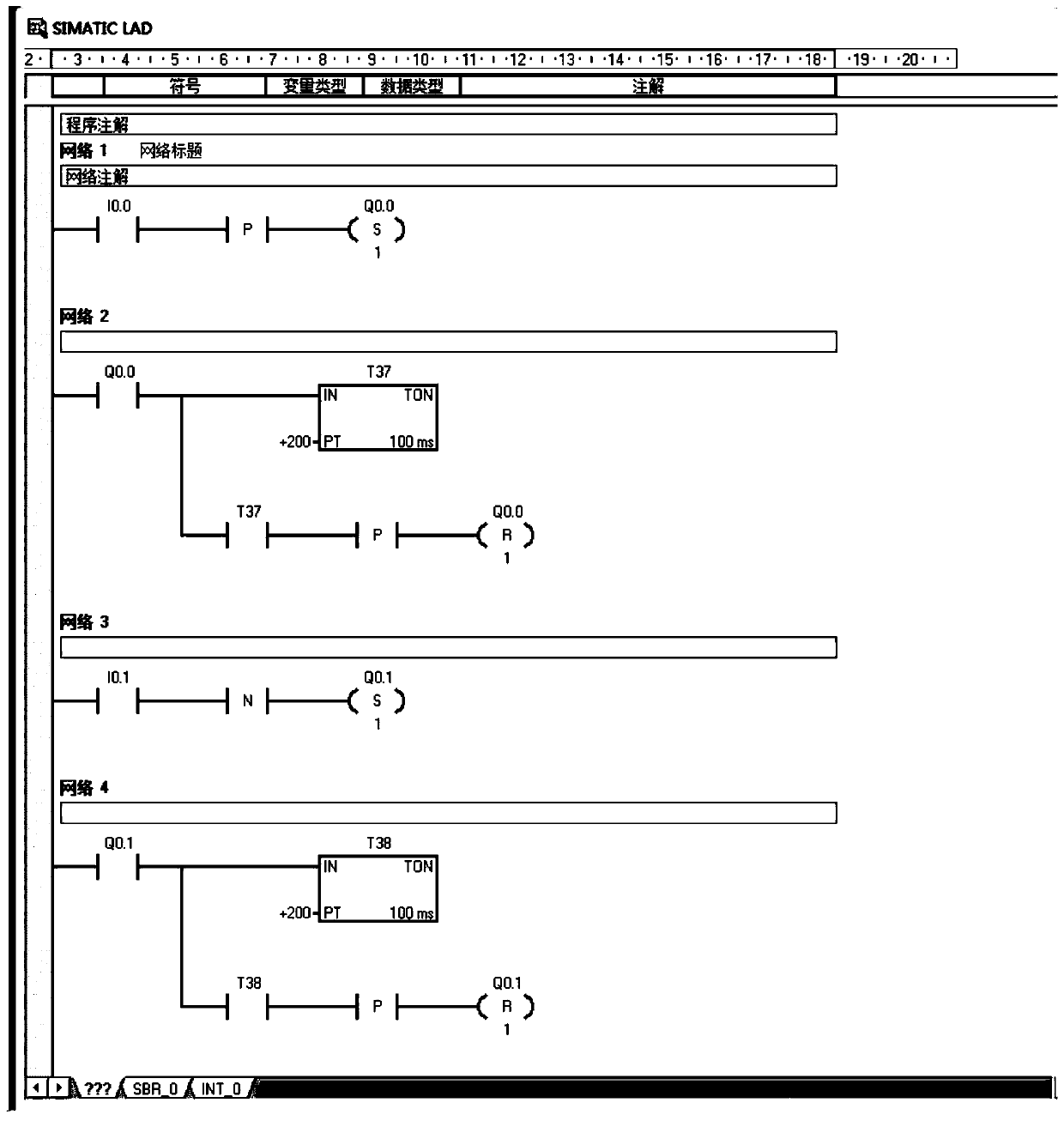

[0032] The scheme will be described below in conjunction with the accompanying drawings and specific implementation methods.

[0033] figure 1 A high-speed filter backwash energy-saving device provided for the embodiment of the present application, including 1#, 2#, 3#, 4#, a total of 4 high-speed filters with a flow rate of 400 cubic meters per hour for backwashing 1, The backwash water inlet start-stop control system 2 and the backwash water outlet main electric valve 3, and the four high-speed filters 1 are all equipped with a filter water inlet electric valve 19 and a filter water outlet electric valve 20 for normal filtration, which are used for the normal filtration process. For water inlet and outlet, the four high-speed filters 1 are also equipped with backwash water inlet electric valve 4 and backwash water outlet electric valve 5 for backwashing, wherein:

[0034] The start-stop control system 2 of the backwash water inlet comprises a multifunctional water pump cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com