An AC high-power MW level constant temperature and voltage regulation automatic control plasma power supply

An automatic control, plasma technology, applied in the direction of plasma, output power conversion devices, electrical components, etc., can solve problems such as temperature rise, achieve the effect of average power supply, stable voltage, and avoid voltage decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

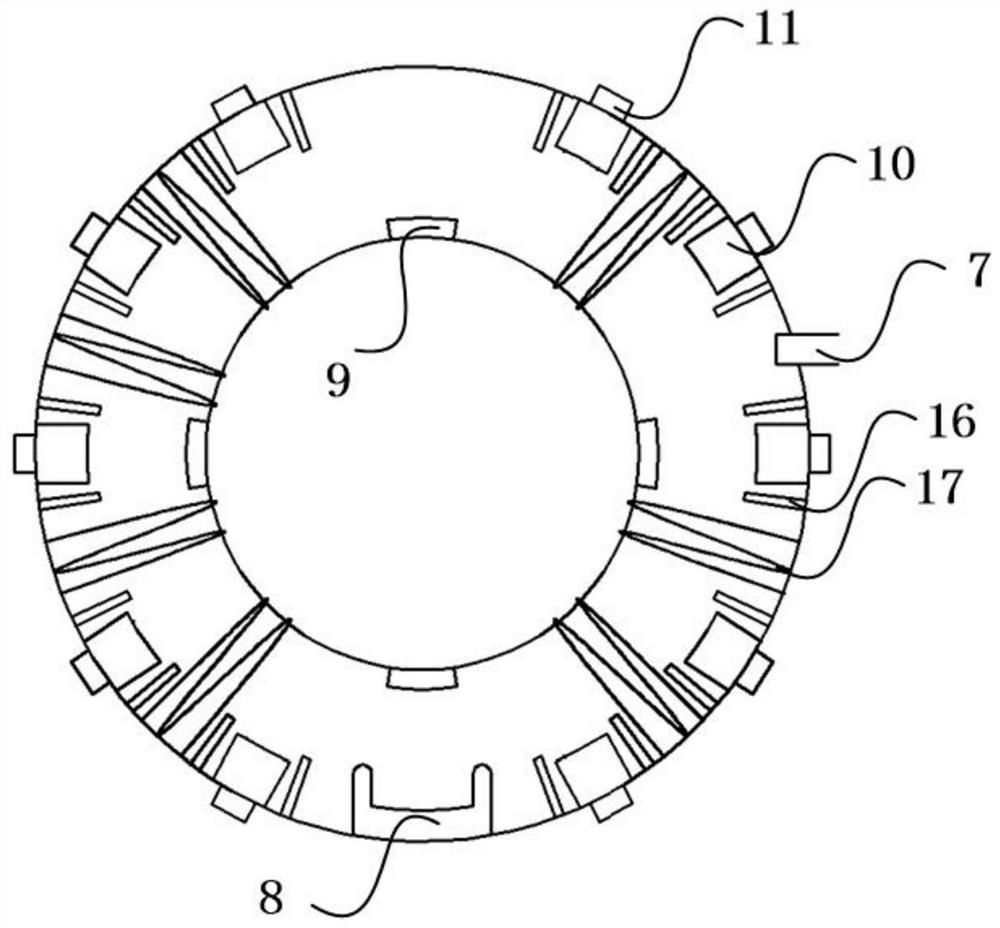

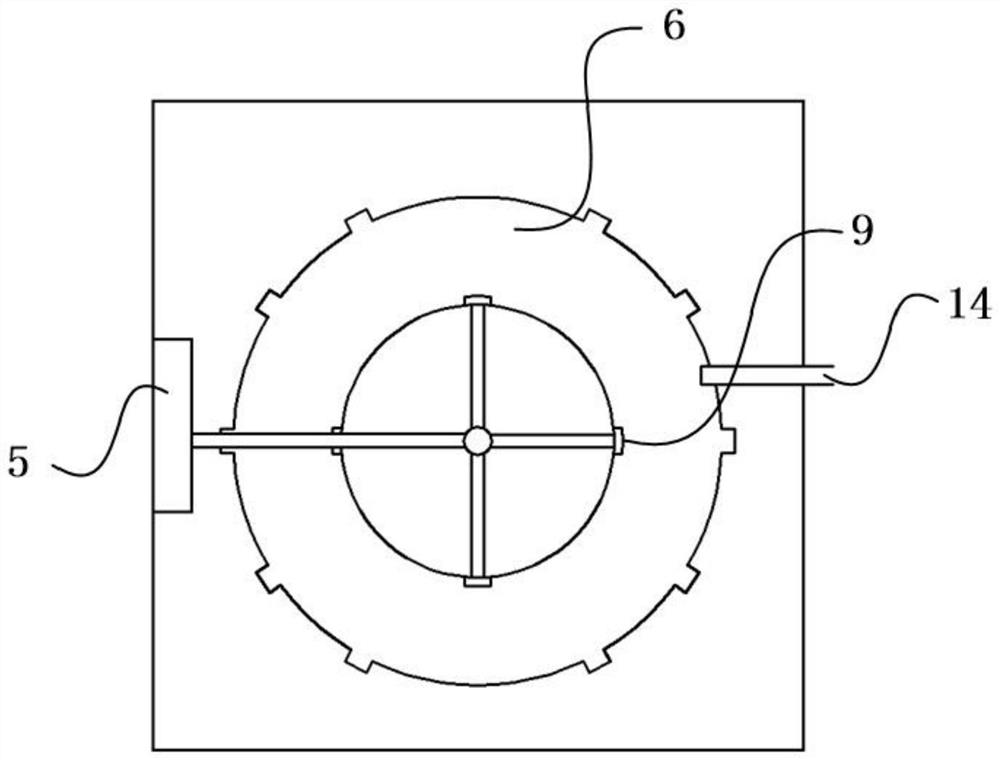

[0032] refer to Figure 1-4 . An AC high-power MW level constant temperature and voltage regulation automatic control plasma power supply, comprising: a three-phase power input device 1, a transformer box 2, a reaction box 3 and a gas control box 4, the three-phase power input device 1 is connected to the transformer A pressure box 2, the transformer box 2 is connected to the reaction box 3, and the reaction box 3 is connected to the gas control box 4.

[0033] The reaction box 3 includes a high-temperature heating device 5, several plasma reaction cabinets 6 and a first channel opening, the high-temperature heating device 5 is arranged on the inner side wall of the reaction box 3, and the first channel opening is arranged on the reaction box 3. On one side wall of the box 3, the plasma reaction cabinet 6 includes a closed ring pipe structure, the plasma reaction cabinet 6 is vertically arranged, and the plasma reaction cabinet 6 is vertically and evenly divided into a first ...

Embodiment 2

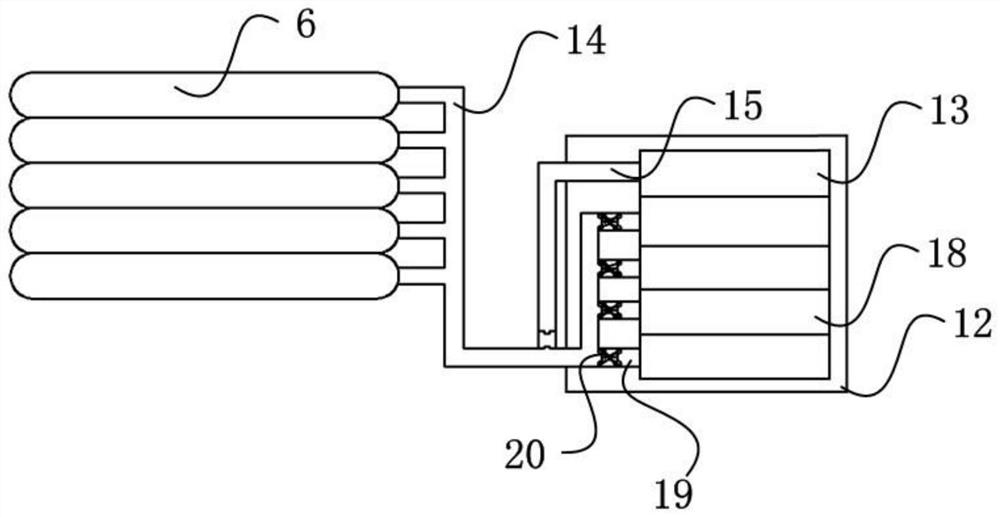

[0047] refer to Figure 1-4 . As a preferred mode of the present invention, the working gas box 12 is divided into several sub-working gas boxes 18, and the sub-working gas boxes 18 respectively store different working gases, and the sub-working gas boxes 18 pass through the sub-first A gas channel 19 is connected to said main first gas channel 14 .

[0048] As a preferred mode of the present invention, each sub-first gas channel 19 is provided with a proportional valve 20 , and the sub-first gas channel 19 is connected to the main first gas channel 14 through the proportional valve 20 .

[0049] As a preferred mode of the present invention, it also includes a load detector and a controller, the load detector is connected to the plasma power supply and the power supply output line of the plasma power supply, and the load detector detects the total amount of work load connected to the plasma power supply;

[0050] The controller is connected to the proportional valve 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com