System and method of testing high-voltage circuit breaker

A high-voltage circuit breaker and testing system technology, applied in circuit breaker testing, instruments, measuring electricity and other directions, can solve the problems of low test accuracy, low measurement accuracy, difficult high-voltage circuit breakers, etc., to reduce the interference of human factors, The effect of improving the level of operation management and reducing the total maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

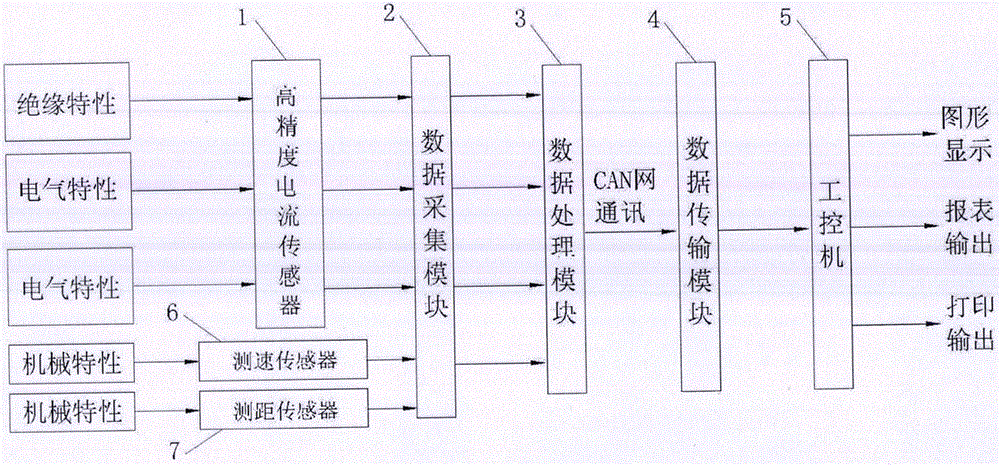

[0036] like figure 1 As shown, a high-voltage circuit breaker testing system related to the present invention includes a speed measuring sensor 6, a distance measuring sensor 7, a group of current sensors 1, a data acquisition and processing system, and an industrial computer 5; the speed measuring sensor 6, measuring The distance sensor 7 and the current sensor 1 transmit the detected insulation characteristics, electrical characteristics and mechanical characteristics of the high-voltage circuit breaker to the industrial computer 5 through the data acquisition and processing system.

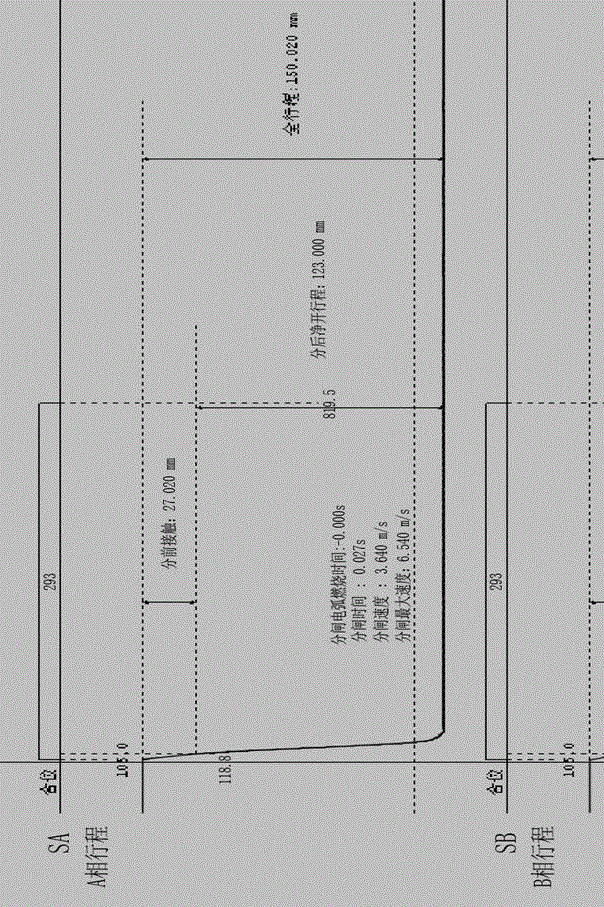

[0037] The speed measuring sensor 6 and the distance measuring sensor 7 are installed on the high-voltage circuit breaker through a mounting bracket, and its output end is connected with the data input end of the data acquisition and processing system for testing the mechanical characteristics of the high-voltage circuit breaker; the mechanical characteristics are High-voltage circuit breaker A...

Embodiment 2

[0042] A test method of a high-voltage circuit breaker test system related to the present invention comprises the following steps:

[0043] 1. Place the distance measuring sensor 7 at the moving contact of the high-voltage circuit breaker, place the speed measuring sensor 6 at the opening and closing coil of the high-voltage circuit breaker, and lead out the data plug of the current sensor 1 from the fracture of the high-voltage circuit breaker plug-in connector;

[0044] 2. Open and close the high-voltage circuit breaker to be tested.

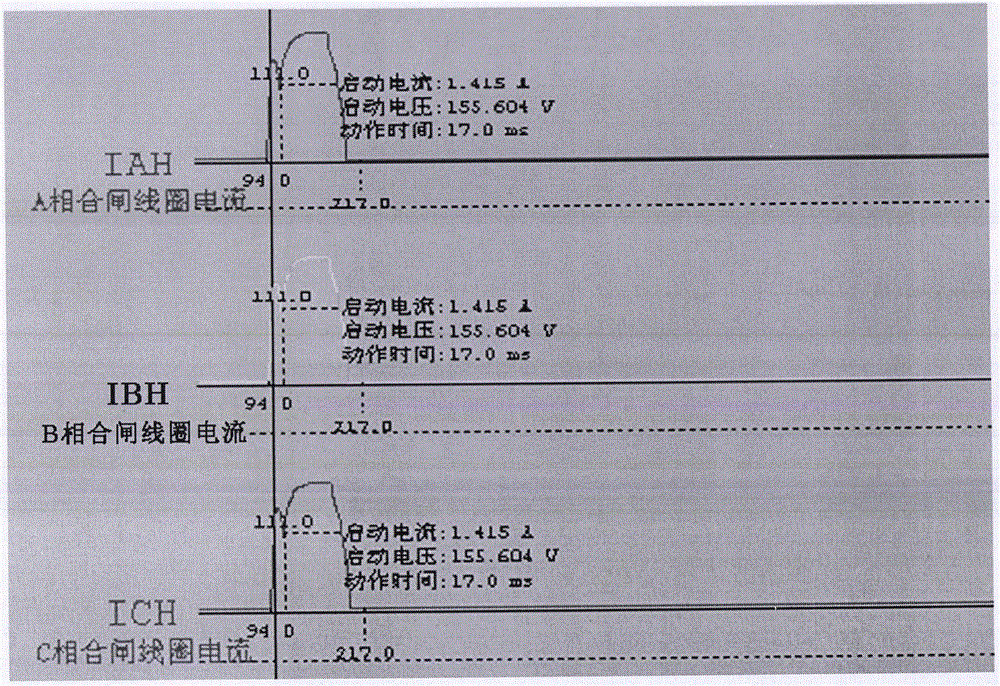

[0045] 3. The distance measuring sensor 7 and the speed measuring sensor 6 transmit the measured mechanical characteristic signals such as the stroke displacement of each phase of the high-voltage circuit breaker A, B, and C to the data acquisition module 2 of the data acquisition and processing system; the current sensor 1 will measure The obtained high-voltage circuit breaker A, B, C fracture measurement loop current, A, B, C phase opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com