Column formwork clamp and using method thereof

A column mold and fixture technology, which is applied in the field of column mold fixtures, can solve the problems of inability to adjust the length, inconvenient installation and disassembly, complicated operation, etc., and achieve the effect of reducing manpower input, less spare parts of the device, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

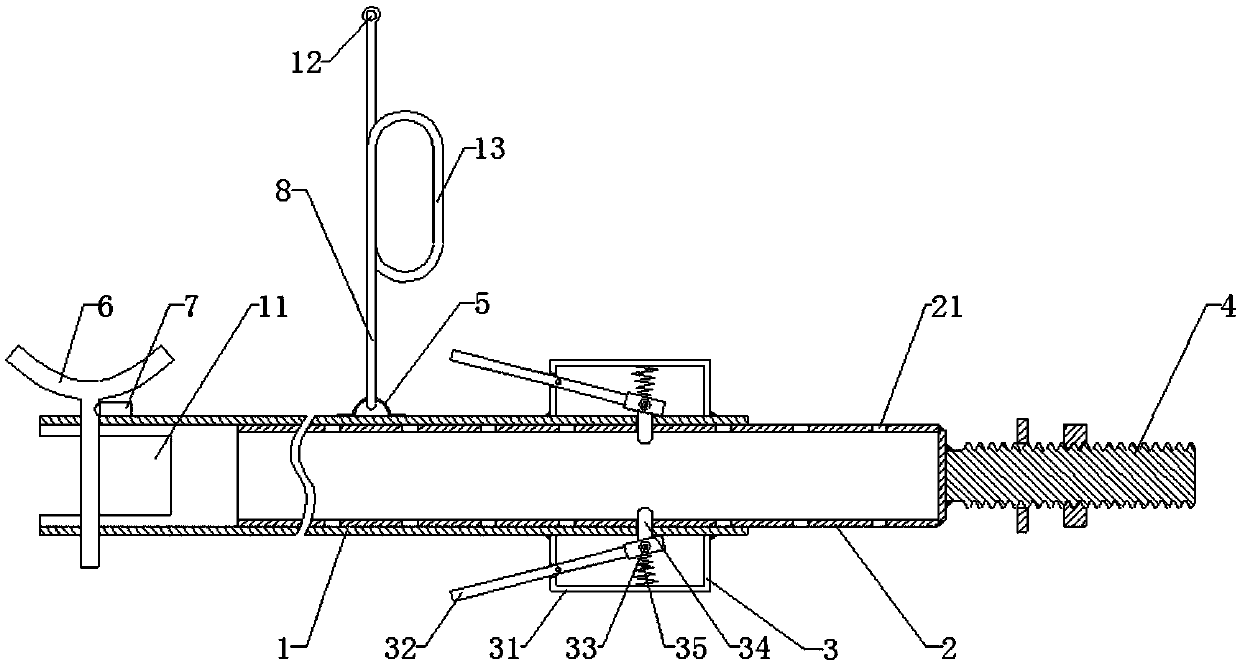

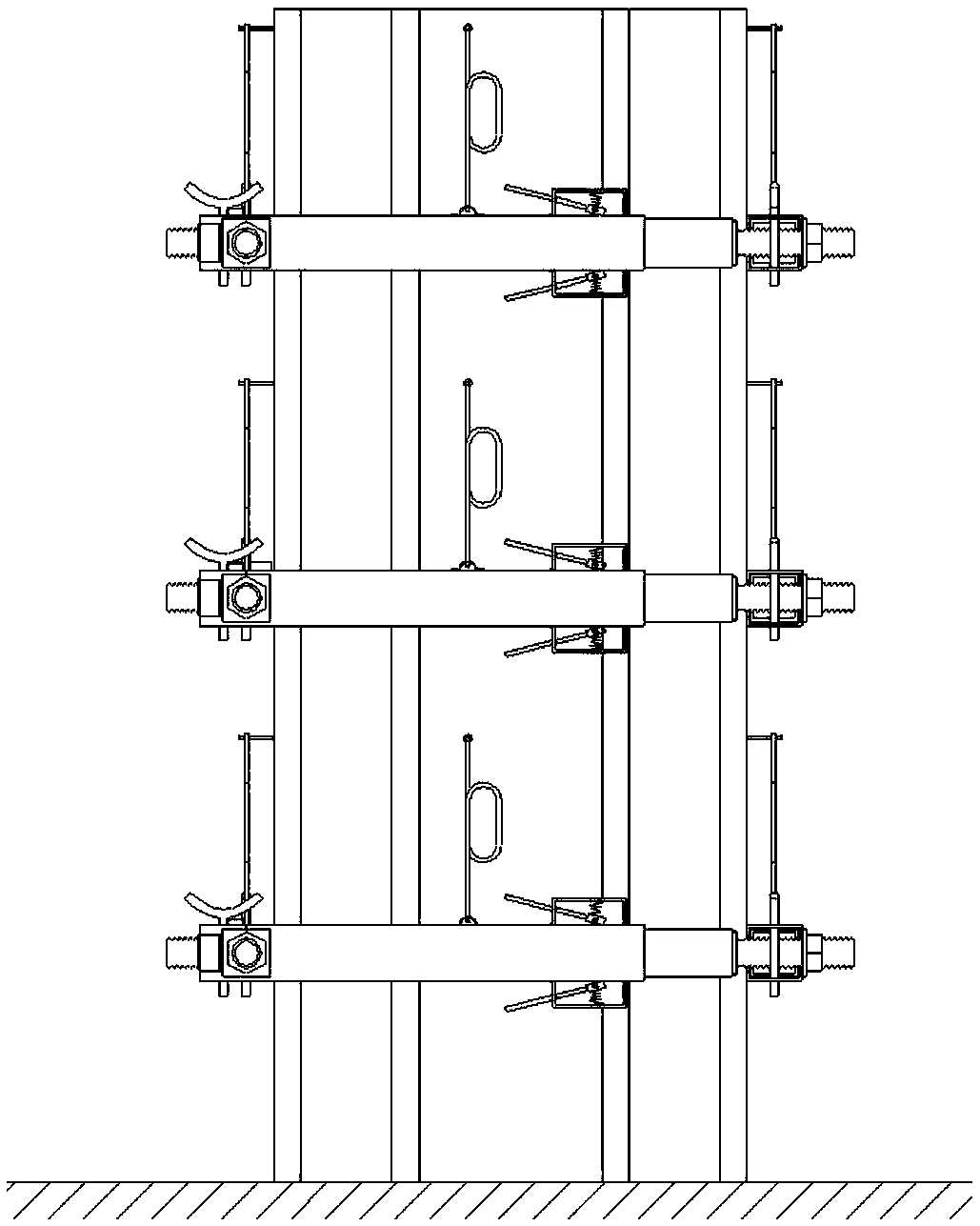

[0028] Such as figure 1 As shown, a column mold fixture includes an outer tube 1, an inner tube 2, a locking mechanism 3, a screw rod 4, a lifting ring 5, and a pin shaft 6, and the outer tube 1 is a square tube with a specification of 60mm×60mm×3mm. The length is 450mm to 500mm, and the inner tube 2 is a square tube with a specification of 50mm×50mm×4mm, and the length is 450mm to 500mm. One end of the inner tube 2 is inserted into the outer tube 1, and the other end is connected to the screw rod 4. The locking mechanism 3 is fixed on one end of the outer tube 1, the inner tube 2 is connected with the outer tube 1 through the locking mechanism 3, the suspension ring 5 is fixed in the middle of the outer tube 1, the pin shaft 6 is vertically inserted into one end of the outer tube 1, and passed through the inner tube After the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com