Steam generating iron

A steam and iron technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of increasing steam, high cost of raw materials, and no water spray, etc., to reduce spare parts and assembly processes, simplify operations, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

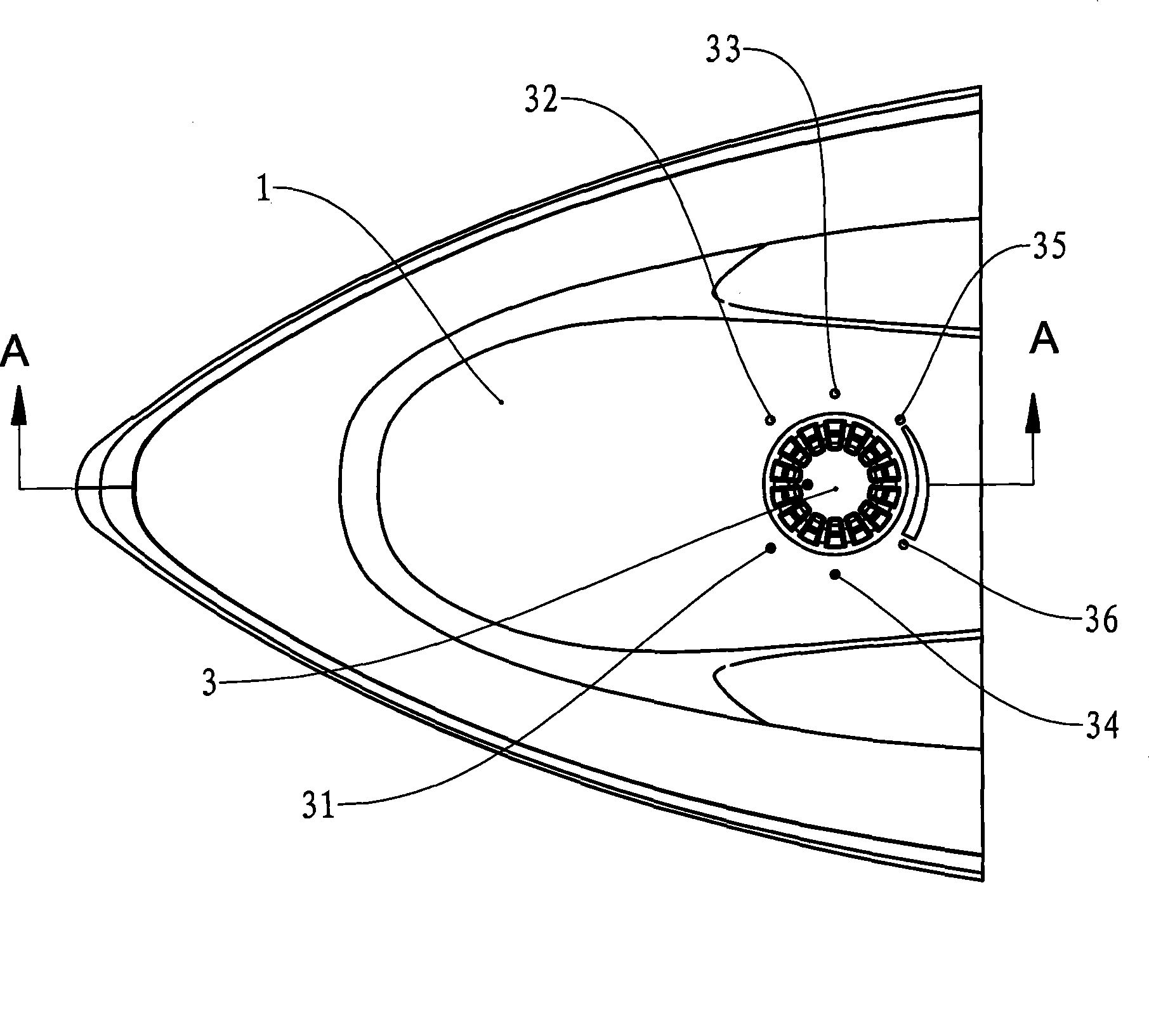

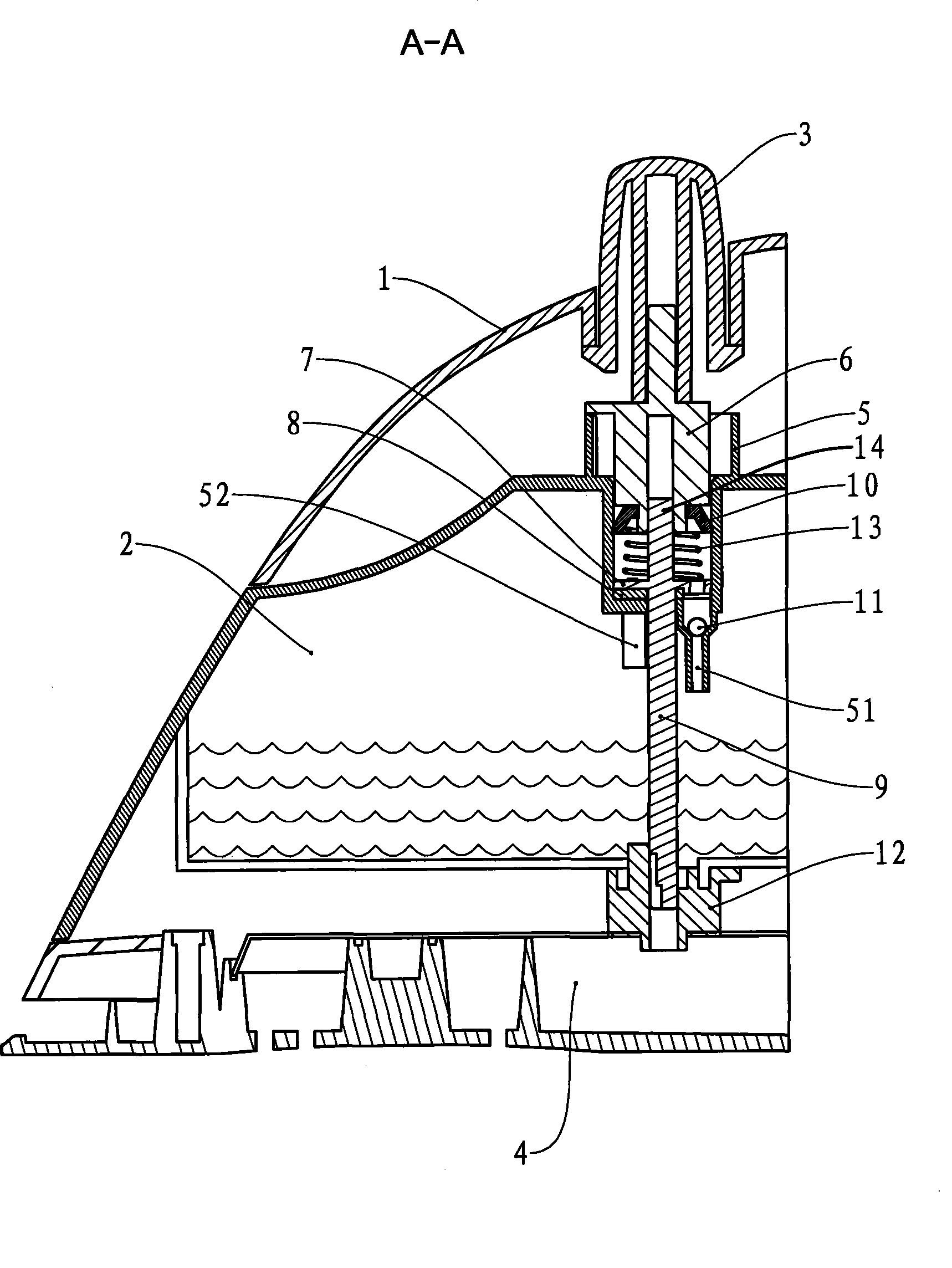

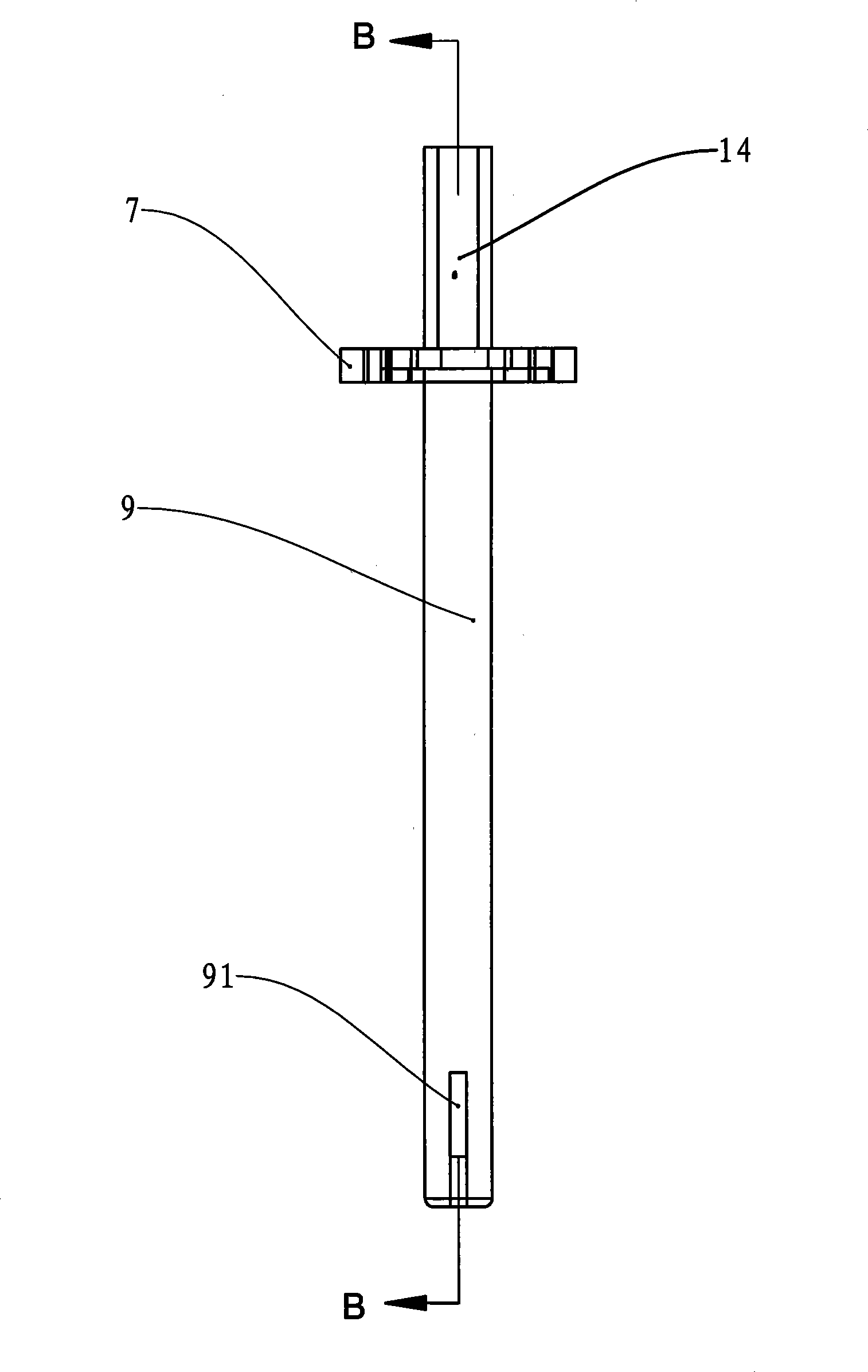

[0036] see figure 1 and figure 2 , are respectively the top view and the cross-sectional view of the embodiment, for the sake of clarity in the drawing, figure 1 , figure 2 And the second half of the steam iron irrelevant to the present invention has been omitted in each corresponding figure of the following. The steam iron mainly includes an iron casing 1 , a water tank 2 , a control knob 3 , a bottom plate vaporization chamber 4 , a pump body 5 , a pump stick 6 , a selection gasket 8 , an adjustment rod and a steam nozzle 12 . The adjusting rod includes a guide rod 14, a selection sealing part 7 and a steam shaft 9 from top to bottom; the guide rod 14 is rigidly connected with the selection sealing part 7 and the steam shaft 9, and of course it can also be an integral structure. The three are integrated structure. The control knob 3 is arranged between the iron casing 1 and the water tank 2, and there is a buckle on the control knob 3 to prevent it from falling out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com