Dust collection system of air jet loom and method

A technology of air-jet loom and dust collection system, which is applied in the direction of looms, textiles, papermaking, and weaving auxiliary equipment. It can solve problems such as hindering the normal operation of machinery and equipment, operator errors, and cord fabric drop, and achieve self-collection. Dust removal function, ensure the grip force, and ensure the effect of the layout structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

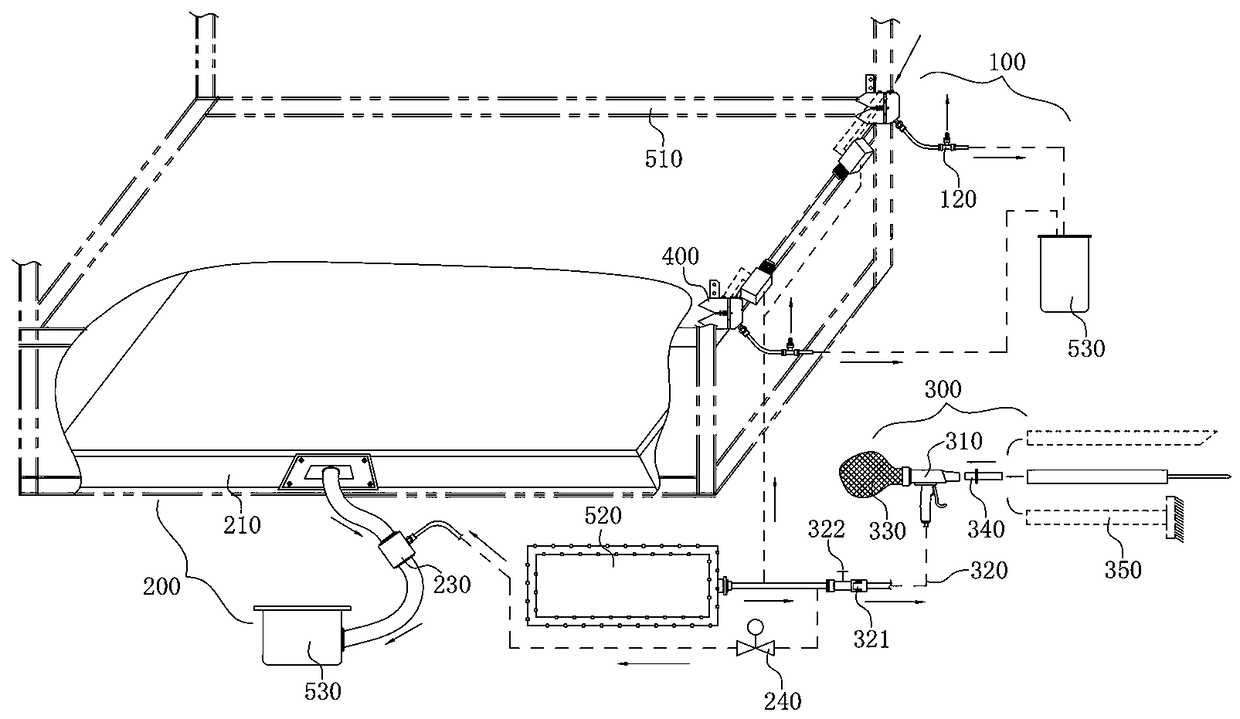

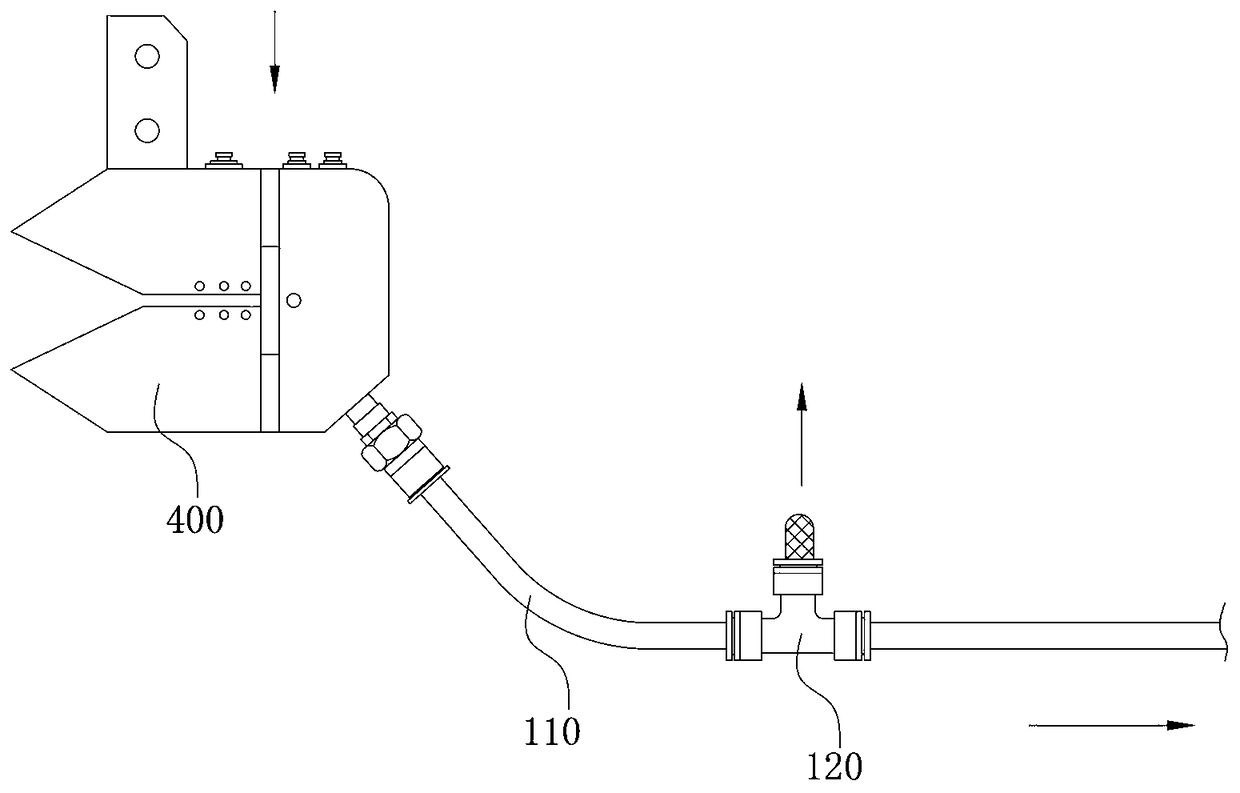

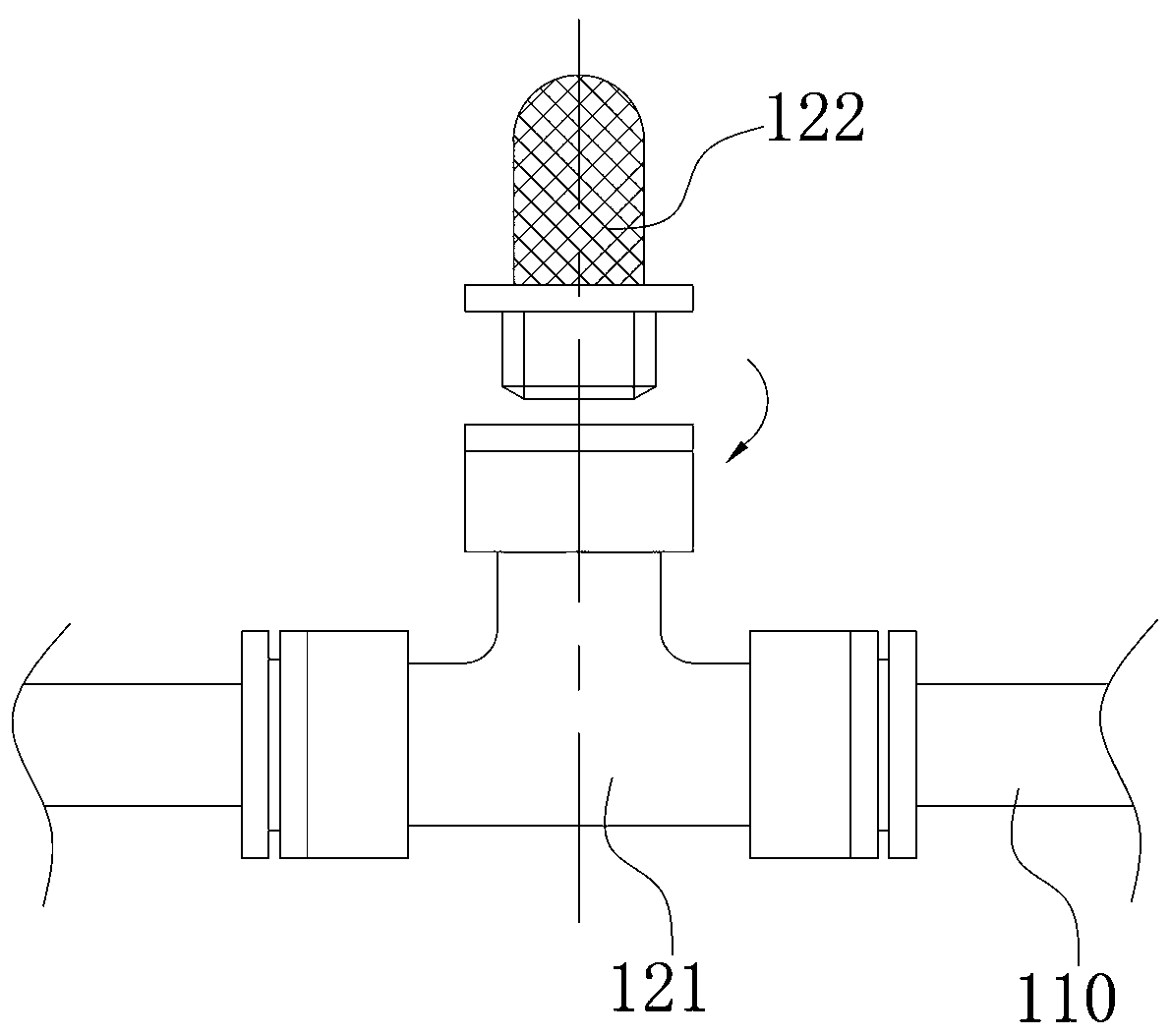

[0047] see Figure 1-Figure 18 , a dust collection system of an air-jet loom according to the present invention, comprising an upper dust collection assembly 100, a lower dust collection assembly 200, and a dust collection box 530, through which the upper dust collection assembly collects the cotton dust appearing at the hemming device at a fixed point, that is, the weft thread After cutting, the cotton dust generated during the holding process of the weft end is collected by the holding air pressure; through the lower dust collection component, the entire air-jet loom realizes the micro-dynamic field of air flow, so that the direction of the cotton dust scattered in the air follows The airflow is continuously collected, not floating randomly in the air or scattered on the workshop floor.

[0048] Wherein, the upper dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com