Unpowered rolling brush cleaning device

A technology of cleaning device and rolling brush, which is applied in the direction of cleaning device, transportation and packaging, and conveyor objects, etc., which can solve the problem of poor working environment of belt conveyor, damage of belt and cleaning device scraper, increased daily maintenance work of equipment, etc. problems, achieve energy saving, simple structure, and reduce maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

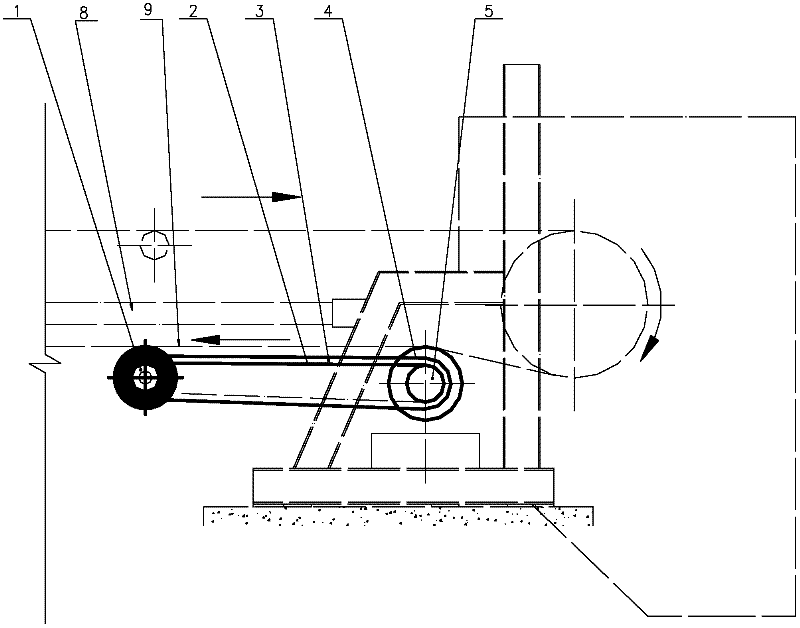

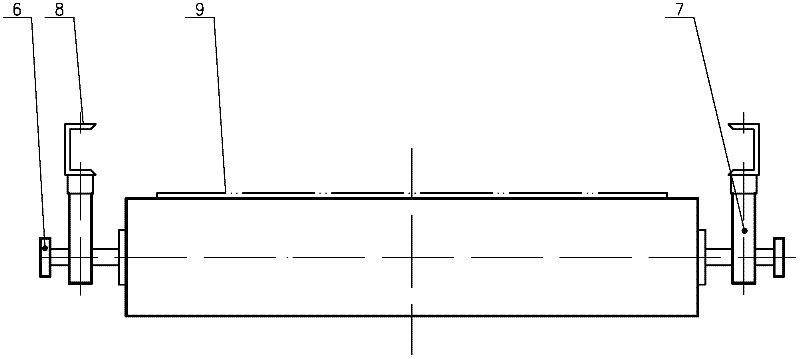

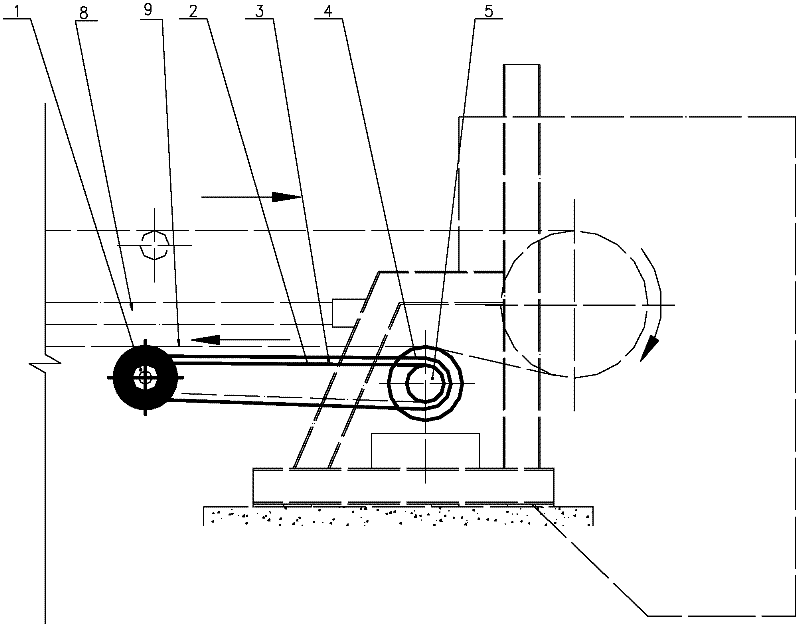

[0021] Attached below Figure 1-2 The present invention is further described.

[0022] The unpowered roller brush cleaning device provided by the present invention includes a roller brush 1 and a transmission mechanism, and is characterized in that: the roller brush 1 is parallel to the reversing roller 4 of the belt conveyor, and the extension shaft of the roller brush 1 is parallel to the reversing roller. 4. A transmission mechanism is arranged between the extension shafts, and the reversing roller 4 drives the roller brush 1 to rotate through the transmission mechanism.

[0023] The transmission mechanism is a chain drive or a belt drive. Correspondingly, sprockets or pulleys are arranged on both ends of the extension shaft of the roller brush and the extension shaft of the reversing roller. The sprockets are connected by chains, and the pulleys are Attached by belt.

[0024] The main beam 8 lower end surface of the reversing drum 4 top hangs and installs the roller brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com