Material return device anti-blocking device for CFB boiler, and operation method thereof

A technology of feeder and feeder, which is applied in the field of anti-blocking device of CFB boiler feeder, can solve problems such as time-consuming, affecting equipment and unit safety, and stalling, so as to reduce costs, reduce the number of unplanned outages, reduce The effect of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

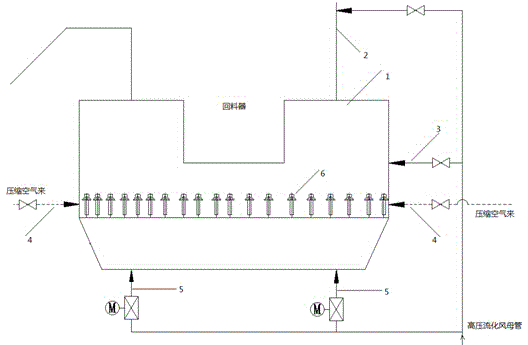

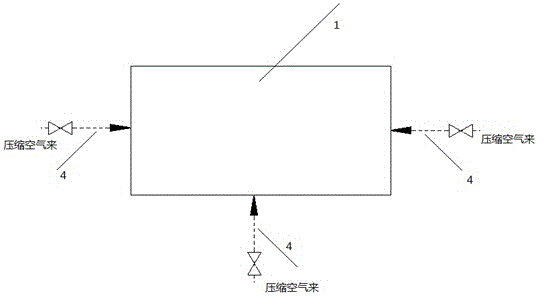

[0015] An anti-blocking device for a CFB boiler feeder, which includes a feeder 1, a feeder box loosening wind 3, a feeder cap 6 and a bottom fluidization wind of the feeder, which is lowered on the feeder 1 box At the position of the wind cap 6 of the feeder, there are at least three loosening winds 4 at the lower part of the feeder box.

[0016] In order to further reliably fluidize the blocked part inside the feeder without shutting down, the loosening wind 4 at the lower part of the feeder box is respectively arranged on the front and rear walls of the feeder and the side of the feeder box, in order to reduce the spare parts rate and To increase the versatility of parts and reduce the cost of use, the pipe size and material of the loosening wind 4 at the lower part of the feeder box are the same as the loosening wind 3 at the bottom of the feeder box.

[0017] The pipeline of the loose air 4 at the bottom of the feeder casing is provided with a cut-off door, and the air so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com