A Control Method of Pumping Unit Based on Motor Power Torque

A technology of motor power and control method, applied in the direction of AC motor control, control system, software algorithm control, etc., can solve problems such as failure of a single pumping unit, poor quality of the feedback unit feedback grid waveform, and great influence on the grid, so as to reduce The effect of labor intensity and spare parts, reducing wear and tear of ineffective equipment, and reducing motor energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

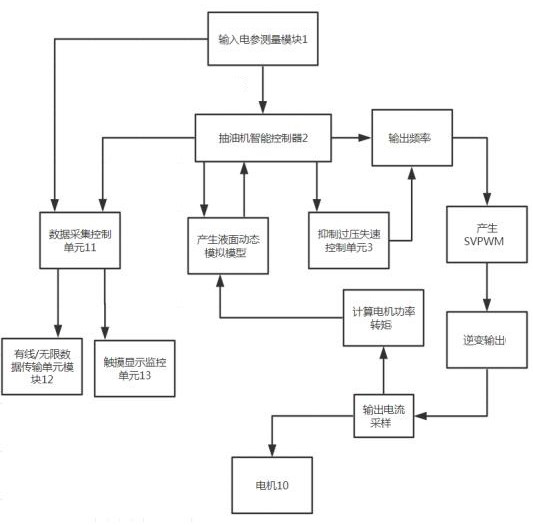

[0035] Such as figure 1 As shown, a pumping unit control method based on motor power torque includes the following steps:

[0036] The first step is to establish a liquid level dynamic simulation model.

[0037] In the second step, the intelligent controller of the pumping unit controls the operation of the motor;

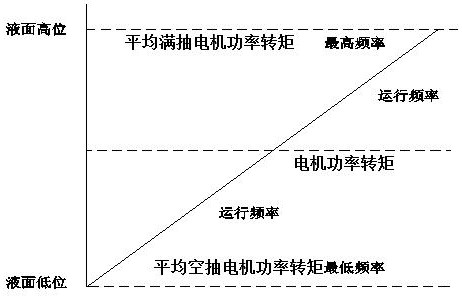

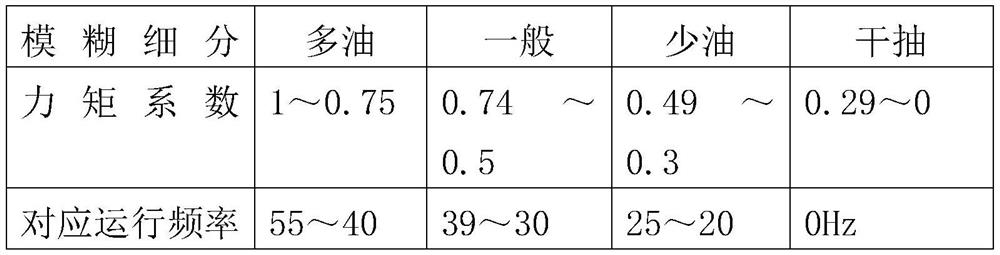

[0038] In the third step, the pumping speed of the pumping unit is changed to obtain the motor power torque of the motor 10, and the intelligent controller 2 of the pumping unit adjusts the operating frequency of the motor 10 according to the relevant parameters of the dynamic simulation model of the liquid level and the power torque of the motor. Thereby changing the pumping speed of the pumping machine;

[0039] The fourth step is to stop working in intermittent pumping mode.

[0040] When the power torque of the motor conforms to the empty pumping state in the liquid level dynamic simulation model, the intelligent controller 2 of the pumping unit controls the...

Embodiment 2

[0050] On the basis of Example 1, such as figure 1 As shown, the method for establishing the liquid level dynamic simulation model is that the intelligent controller 2 of the pumping unit self-learns the average full pumping motor power torque, the average empty pumping motor power torque and the theoretical interval time between pumping pumps, and according to the self-learning average full pumping The power torque of the pumping motor and the average power torque of the empty pumping motor are used to establish a dynamic simulation model of the liquid level.

[0051] Let the intelligent controller 2 of the pumping unit perform self-study first to obtain the average full pumping motor power torque, average full pumping motor power torque and theoretical pumping interval time, and establish a liquid level dynamic simulation model to prepare for subsequent comparisons .

[0052] The self-learning method of pumping unit intelligent controller 2 is as follows: 1) Full pumping to...

Embodiment 3

[0061] On the basis of Example 2, such as figure 1 As shown, in the second step, the method for the intelligent controller 2 of the pumping unit to control the operation of the motor 10 is that the intelligent controller 2 of the pumping unit gives the motor 10 a current with an initial output frequency, and the current is delivered to the motor 10 and then dragged. The motor 10 operates. The pumping unit can only provide a current to the motor 10 by the controller 2, and the operating frequency of the motor 10 is also different according to the output frequency of the current.

[0062] The specific current at the initial output frequency is modulated to generate SVPWM, and the SVPWM is output by inverter and then sent to the motor 10 to drive the motor 10 to work.

[0063] The output frequency of the output current of the pumping unit intelligent controller 2 is adjusted every 5 minutes. The output current is sampled every 5 minutes, and the result is fed back to the intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com