Open hole well packer

A packer, open hole technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of permanently plugging the bottom of the well and limited time for unsealing, etc.

Inactive Publication Date: 2011-06-15

东营市兆鑫工贸有限责任公司

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current expandable packer will be unsealed when there is no pressure inside, which is not suitable for oilfields to permanently seal the bottom of the well. Some expandable packers have a one-way mechanism inside, which can guarantee It will not be unblocked when there is no pressure difference, but the time for remaining unblocked is limited, and it is not suitable for the requirements of permanent plugging of the bottom of the well in the oil field

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

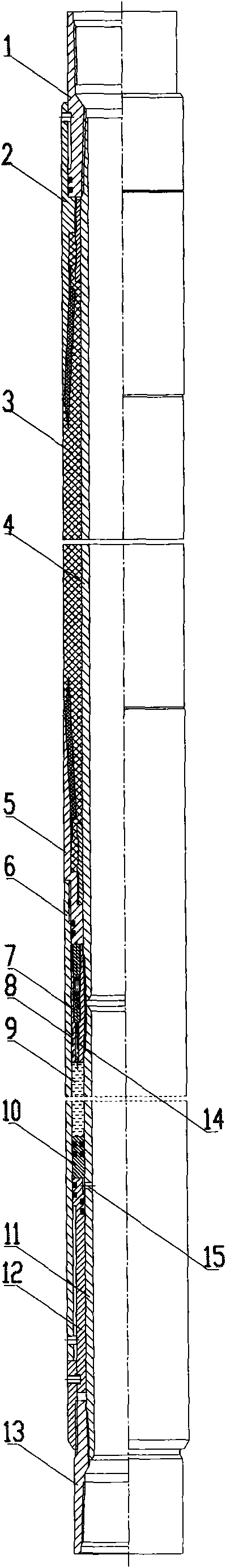

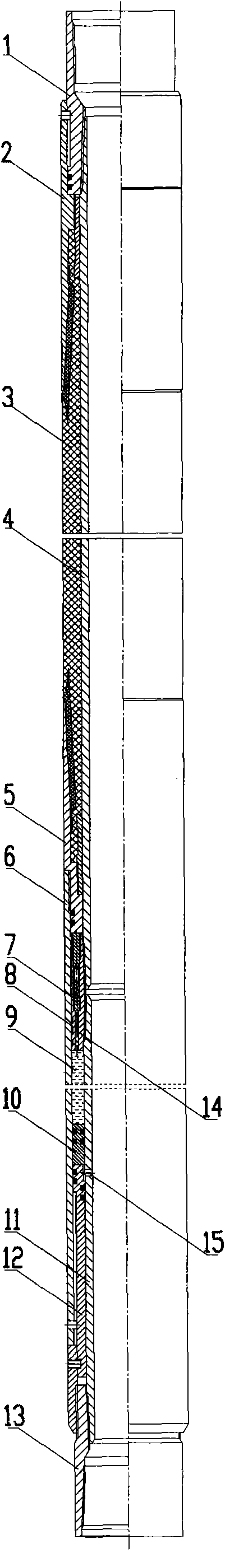

The invention relates to an open hole well packer, a rubber tube is sheathed outside an upper inner tube, an upper joint, the upper inner tube, a combined valve body, a lower inner tube and a lower joint are sequentially connected, the lower part of an upper rubber tube sheath covers the upper part of the rubber tube, the upper part of the upper rubber tube sheath is sheathed outside the upper joint, the upper part of a lower rubber tube sheath covers the lower part of the rubber tube, the upper part of a sealing sleeve is connected with the lower part of the lower rubber tube sheath, the lower part of the sealing sleeve is sheathed outside the combined valve body, an upper piston and a lower piston are mounted between the sealing sleeve and the lower inner tube, preset solution is perfused above the upper piston, the lower piston is arranged below the upper piston, a communicating hole is arranged on the upper piston, the communicating hole is positioned between the upper piston and the lower piston, a vertical pore canal is arranged on the combined valve body, a one-way valve is mounted at the upper part of the vertical pore canal, the one-way valve is designed for enabling the rubber tube to be in expansion state permanently, the rubber tube is expanded by the preset solution, and the one-way valve can not be corroded and damaged, so that the rubber tube can work effectively for a long time and meet the requirement on permanent blocking of the well bottom of an open hole well in an oilfield.

Description

Open hole packer technical field The invention is a device for permanently sealing the bottom of a well in an oil field, and is an open hole packer. Background technique The expansion packer used for oilfield water injection is to expand the rubber sleeve outward when the pressure inside the rubber sleeve is higher than the external pressure of the rubber sleeve, so as to realize the sealing of the annular space of the oil casing. The current expandable packer will be unsealed when there is no pressure inside, which is not suitable for the requirements of oil fields to permanently seal the bottom of the well. Some expandable packers have a one-way mechanism inside, which can guarantee It will not be unblocked when there is no pressure difference, but the time for keeping it unblocked is limited, and it is not suitable for the requirements of oilfields to permanently seal the bottom of the well. Contents of the invention The purpose of the present invention is to provid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B33/126

Inventor 曲绍琨马宝龙曲哲王中华杨永刚

Owner 东营市兆鑫工贸有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com