Anticorrosive coating for chemical storage tank and construction method thereof

A technology of anti-corrosion coating and construction method, which is applied in anti-corrosion coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of high anti-corrosion failure rate and many joints in the inner layer of chemical storage tanks, and achieve the realization of Automatic operation, ensuring continuity, and improving the effect of micro-smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of anticorrosion coating for chemical storage tank according to embodiment 1 of the present invention comprises at least 2 anticorrosion coating units successively connected on the inner wall of chemical storage tank, and each anticorrosion coating unit comprises primer layer and spray coating Polyurea layer; Among them, in the basic anti-corrosion coating unit directly connected to the inner wall of the chemical storage tank, the thickness of the primer layer is controlled to be 10-100 μm, and the thickness of the sprayed polyurea layer is 0.5-1mm; the chemical industry connected to the primer layer The inner wall of the storage tank is obtained after sand blasting and pickling in sequence.

[0038] In the present invention, the number of anti-corrosion coating units other than the basic anti-corrosion coating unit can be determined according to the thickness of the polyurea coating actually required. In each anticorrosion coating unit except the basic anticorro...

Embodiment 2

[0044] Embodiment 2 of the present invention is the construction method for the anticorrosion coating on the inner wall of the chemical storage tank of the above embodiment 1, comprising the following steps:

[0045] Step 1. Pretreating the inner wall of the chemical storage tank: performing sandblasting and pickling treatment on the inner wall of the chemical storage tank in sequence, and then washing the inner wall of the chemical storage tank with clean water to obtain the pretreated inner wall of the chemical storage tank.

[0046] Wherein, the sand blasting treatment can adopt the existing conventional process. Before sandblasting, grind the welds and solder joints so that the entire substrate can transition smoothly. Then carry out sand blasting to remove rust, completely remove the corrosion layer, old paint, oil stains and other impurities on the surface of the substrate, and blast the substrate to Sa2.5 level.

[0047] The pickling treatment uses a high-pressure spra...

Embodiment 3

[0054] In the construction method of the anti-corrosion coating for the inner wall of chemical storage tanks of the present invention, operations such as pickling, coating spraying, and sandblasting are required. There are many construction steps, and manual operations are completely used, which is not only time-consuming and labor-intensive, but also has operational errors. The quality is not easy to control uniformly, therefore, the present invention also provides an automatic displacement operating device.

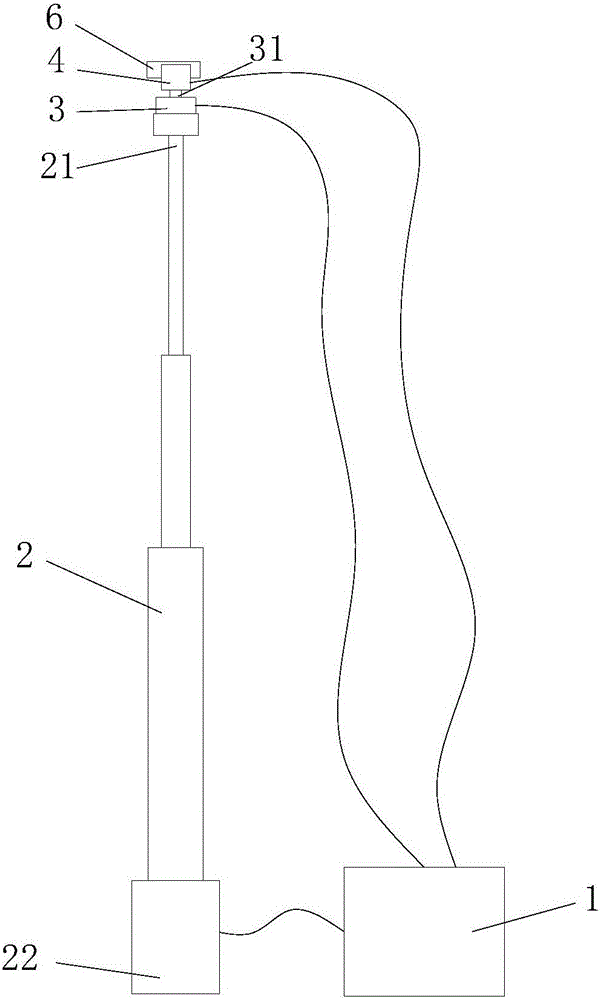

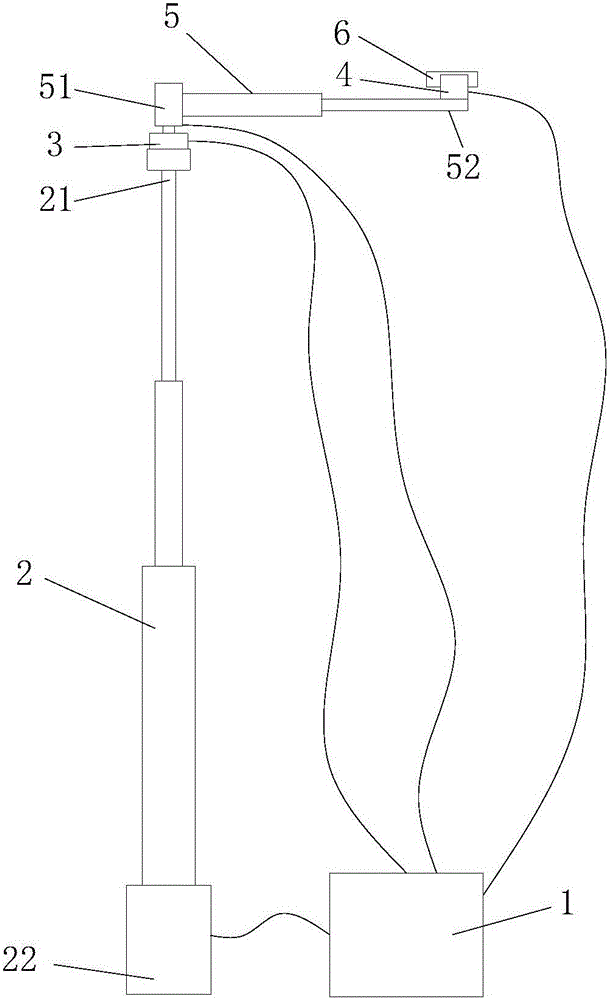

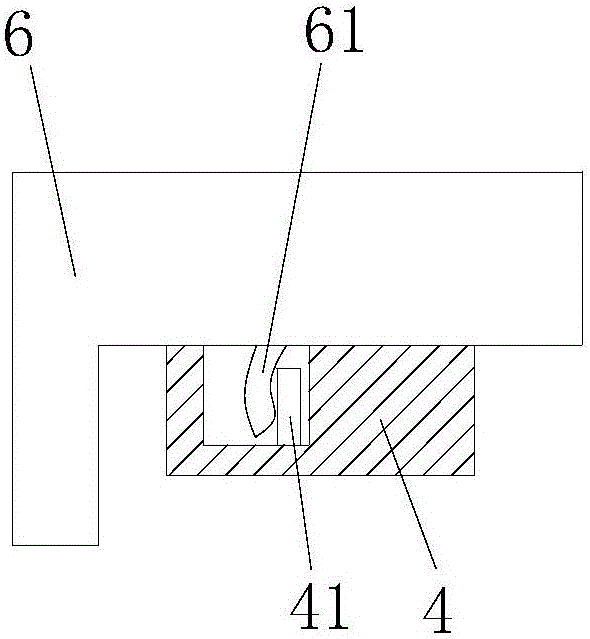

[0055] Such as Figure 1 to Figure 3 As shown, the automatic displacement operating device includes a controller 1, a telescopic unit 2, a rotating unit 3 and a spray gun control base 4, and the controller 1 is respectively connected to the control end of the telescopic unit 2 and the control end of the rotating unit 3 The telescopic end 21 of the telescopic unit 2 is connected to the fixed end 32 of the rotating unit 3; the fixed end 22 of the telescopic unit 2 is fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com