Water jet hull rust remover and operating method thereof

A rust remover and water jet technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. rust and other problems, to achieve the effect of good rust removal, simple structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

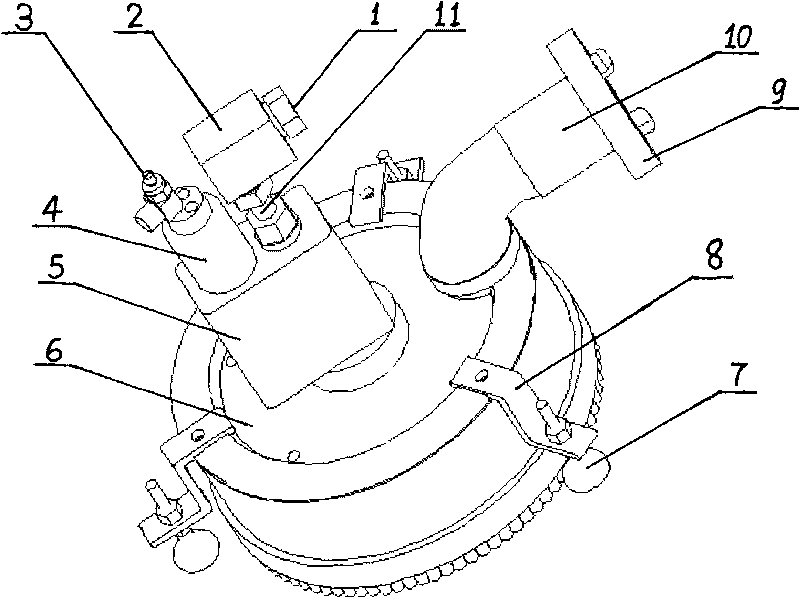

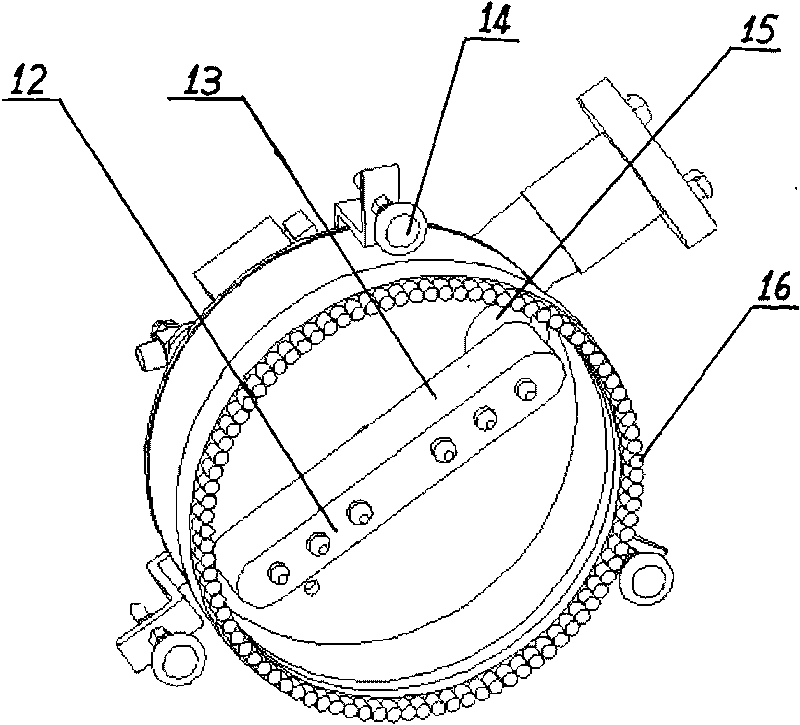

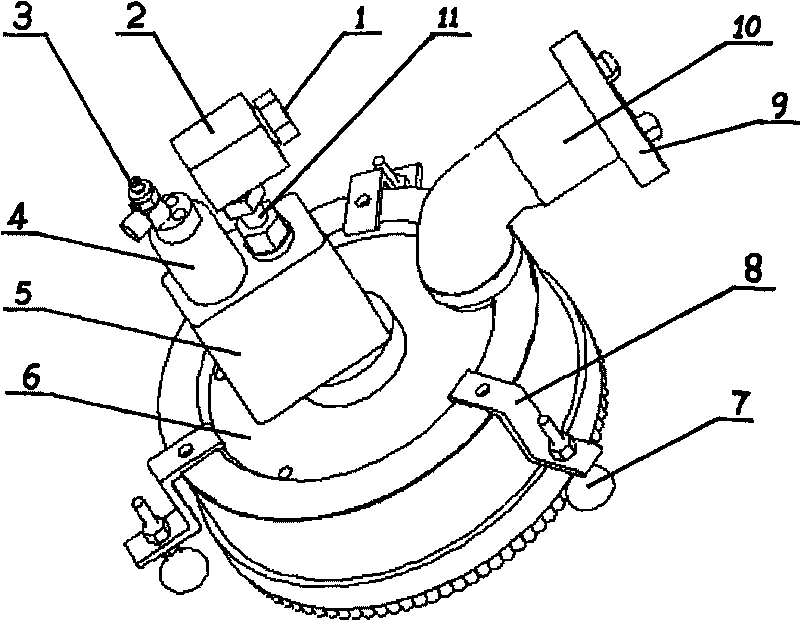

[0020] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 As shown, a water jet hull rust remover includes a high-pressure water pipe interface 1, a high-pressure water pipe interface seat 2, a rust removal plate 6, a high-pressure water interface seat bracket 11, a nozzle 12, a nozzle swivel frame 13, and also includes an air pipe interface 3, Air pipe interface seat 4, air motor body 5, vacuum recovery flange 9, vacuum recovery pipe 10, vacuum recovery port 15, high-pressure water sealing ring 16, the high-pressure water pipe interface 1 is connected to the high-pressure water pipe interface seat 2, and passes the high-pressure The water interface seat bracket 11 is installed on the air motor body 5, the air pipe interface 3 is installed on the air motor body 5 through the air pipe interface seat 4, and the air motor body 5 and the vacuum recovery pipe 10 are respectively installed on the rust removal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com