Steel bar rust removal device used for power station construction

A technology for steel bars and power stations, applied in the field of steel bar rust removal devices for power station construction, can solve problems such as low work efficiency, cumbersome operations, and poor rust removal effects, and achieve the effect of improving rust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

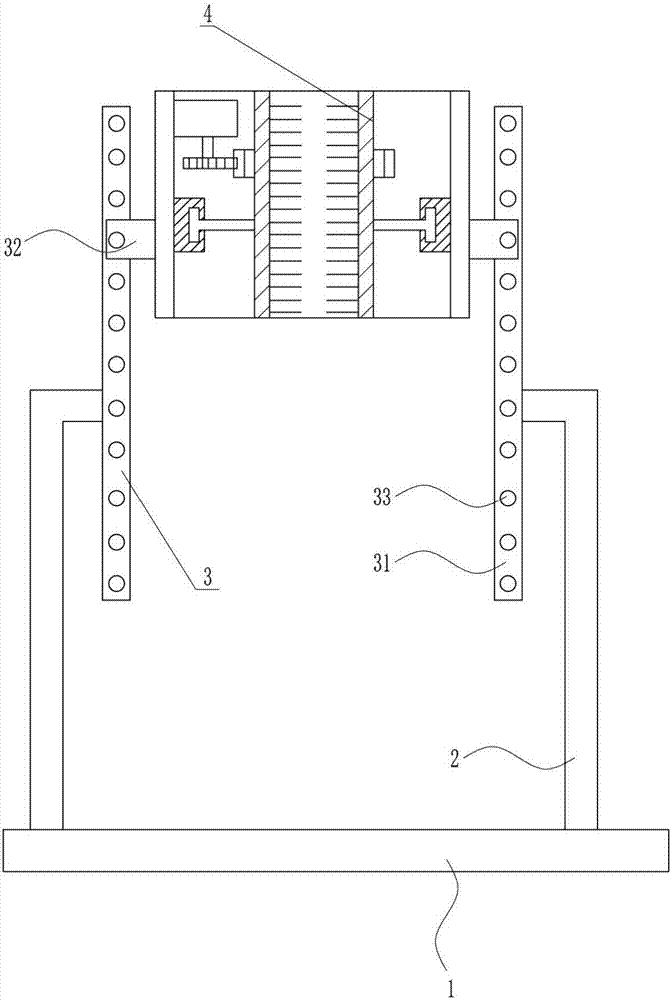

[0027] A steel bar derusting device for power station construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a bracket 2, an adjustment device 3 and a rust removal device 4. The left and right sides of the top of the bottom plate 1 are connected to the bracket 2 by bolts, and the upper part of the inner side of the bracket 2 is equipped with an adjustment device 3. The adjustment device 3 The inner side is provided with a derusting device 4 .

Embodiment 2

[0029] A steel bar derusting device for power station construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a bracket 2, an adjustment device 3 and a rust removal device 4. The left and right sides of the top of the bottom plate 1 are connected to the bracket 2 by bolts, and the upper part of the inner side of the bracket 2 is equipped with an adjustment device 3. The adjustment device 3 The inner side is provided with a derusting device 4 .

[0030] The adjustment device 3 includes a first slide rail 31 and a first slide block 32, and the top of the inner side surface of the bracket 2 on the left and right sides is vertically installed with the first slide rail 31 by means of bolt connection, and the first slide rail 31 is of sliding type. A first sliding block 32 is arranged on the ground, and both the first sliding rail 31 and the first sliding block 32 are provided with latch holes 33 .

Embodiment 3

[0032] A steel bar derusting device for power station construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a bracket 2, an adjustment device 3 and a rust removal device 4. The left and right sides of the top of the bottom plate 1 are connected to the bracket 2 by bolts, and the upper part of the inner side of the bracket 2 is equipped with an adjustment device 3. The adjustment device 3 The inner side is provided with a derusting device 4 .

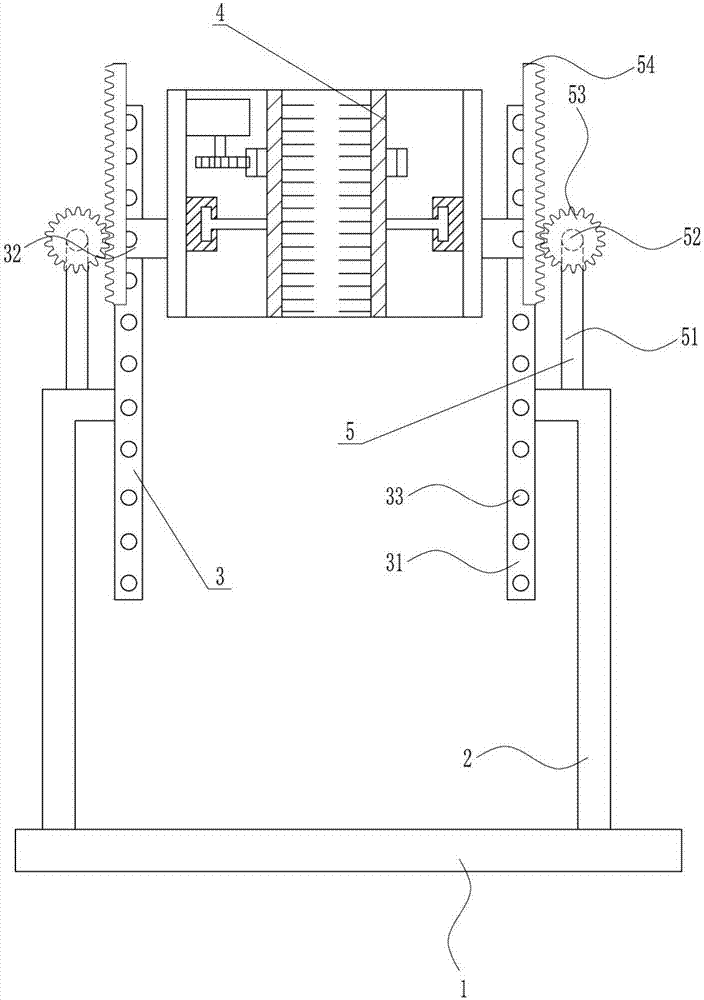

[0033] The adjustment device 3 includes a first slide rail 31 and a first slide block 32, and the top of the inner side surface of the bracket 2 on the left and right sides is vertically installed with the first slide rail 31 by means of bolt connection, and the first slide rail 31 is of sliding type. A first sliding block 32 is arranged on the ground, and both the first sliding rail 31 and the first sliding block 32 are provided with latch holes 33 .

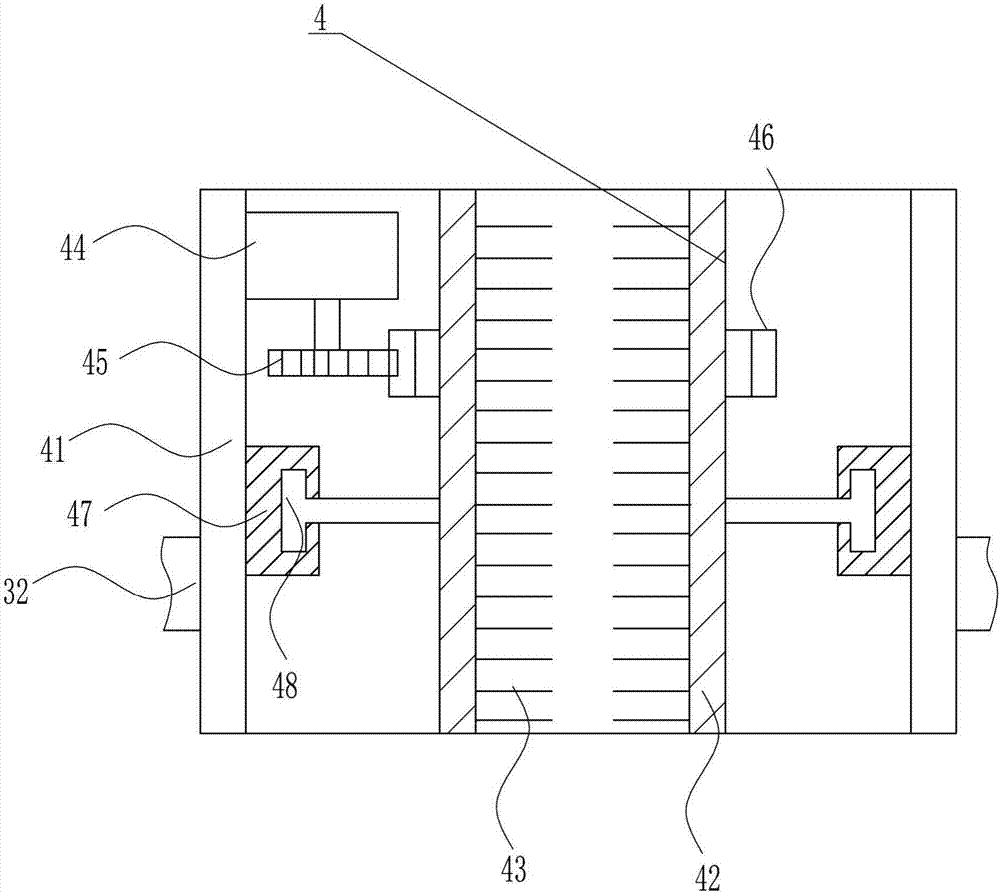

[0034] The derusting device 4 includes a frame body 41, a sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com