Ship rust removing equipment

A hull and equipment technology, which is applied in the field of hull derusting equipment, can solve the problems of not being able to achieve good derusting effect, easily affecting the derusting effect of the hull, and affecting the stability of equipment support, etc., to achieve expanded derusting area, smooth running, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

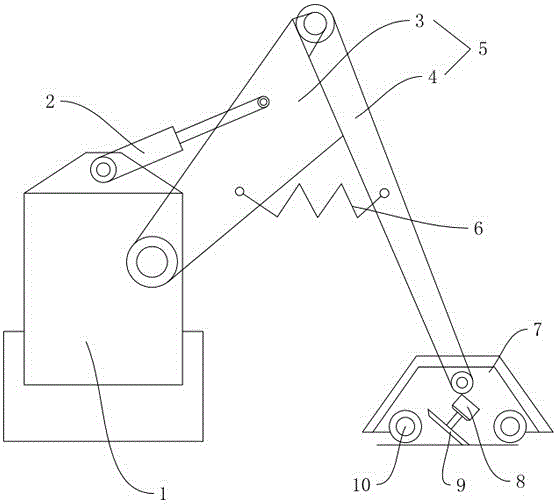

[0023] Example 1: A hull derusting equipment (see figure 1 ), including a magnetic crawler adsorption device 1 that can move on the surface of the hull, a swing arm 5 that can be deployed on the magnetic crawler adsorption device, and a rust removal device installed at the end of the swing arm. The rust removal device adopts a grinding wheel grinding device. The unfolding direction of the swing arm is perpendicular to the moving direction of the magnetic crawler adsorption device.

[0024] A telescopic component that drives the swing arm to swing to move the rust removal device is connected between the swing arm and the magnetic crawler adsorption device. The telescopic component in this embodiment adopts a telescopic cylinder 2 . The swing arm includes a rotating rod 3 and an unfolding rod 4, the rotating rod is hinged with the unfolding rod, the rotating rod is hinged with the magnetic crawler adsorption device, and the rust removal device is connected to the end of the unfo...

Embodiment 2

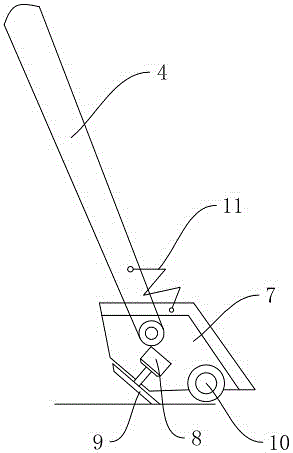

[0027] Example 2: A rust removal device for a hull, which is different from Example 1 in that: a rotating wheel 10 is provided on the balance trolley, the rotating wheel is cylindrical, the grinding wheel is on the side of the rotating wheel, and the axis of rotation of the grinding wheel is the same as the rotating wheel. The rotation axis of the wheel is vertical, and an angle adjustment part 11 is connected between the balance trolley and the swing arm (see figure 2 ), in this embodiment, the angle adjustment component adopts a tension spring. The balance trolley is hinged with the end of the unfolding rod, and the hinged position is just between the upper part between the grinding wheel and the rotating wheel. The rest of the structure refers to Example 1.

Embodiment 3

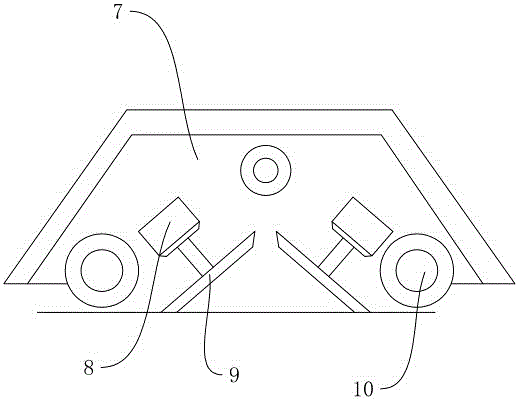

[0028] Example 3: A rust removal device for a ship hull, which is different from Example 1 in that there are two motors, the two motors are inclined to each other, the grinding wheels on the two motors are inclined to each other, and the adjacent sides of the two grinding wheels are opposite to each other and retracted to balance inside the car (see image 3 ). The balance trolley is provided with two cylindrical rotating wheels, the two rotating wheels are parallel to each other, the two motors are fixed inside the balance trolley, and the two rotating wheels are located outside the two motors. The rest of the structure refers to Example 1.

[0029] There are two grinding wheels inside the balance trolley. When the unfolding rod is unfolded, the leading grinding wheel is ground for rust removal. When the unfolding rod is retracted, the rear grinding wheel is ground for rust removal, so that the balance trolley is also in working condition when it returns. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com