Method and device for sanding and descaling mining explosion-proof type shell

An explosion-proof and explosion-proof technology for mines, which is applied in the field of sand blasting and cleaning, can solve the problems of unsatisfactory rust removal effect, low production efficiency, and high time cost, and achieve the effects of reducing paint peeling off, improving production efficiency, and reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

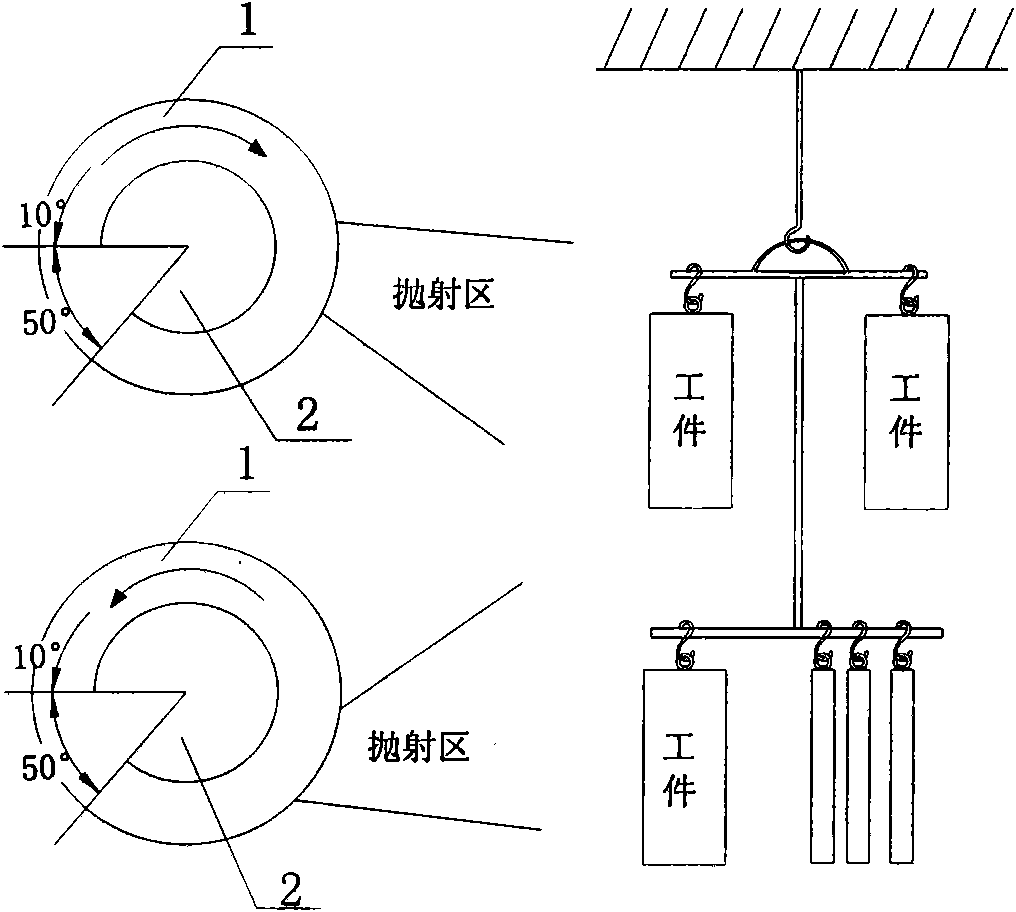

[0040] The invention discloses a sand blasting and derusting method for an explosion-proof shell of a mine. The explosion-proof shell adopts a shot blasting machine to throw steel shots, and the shell is subjected to steel shot blasting and derusting treatment. The explosion-proof casing is hooked on the track, and the casing is subjected to steel shot sanding and derusting treatment in the cleaning room. Two shot blasting machines are used to perform steel shot sanding and derusting treatment on the shell at the upper and lower positions respectively.

Embodiment 2

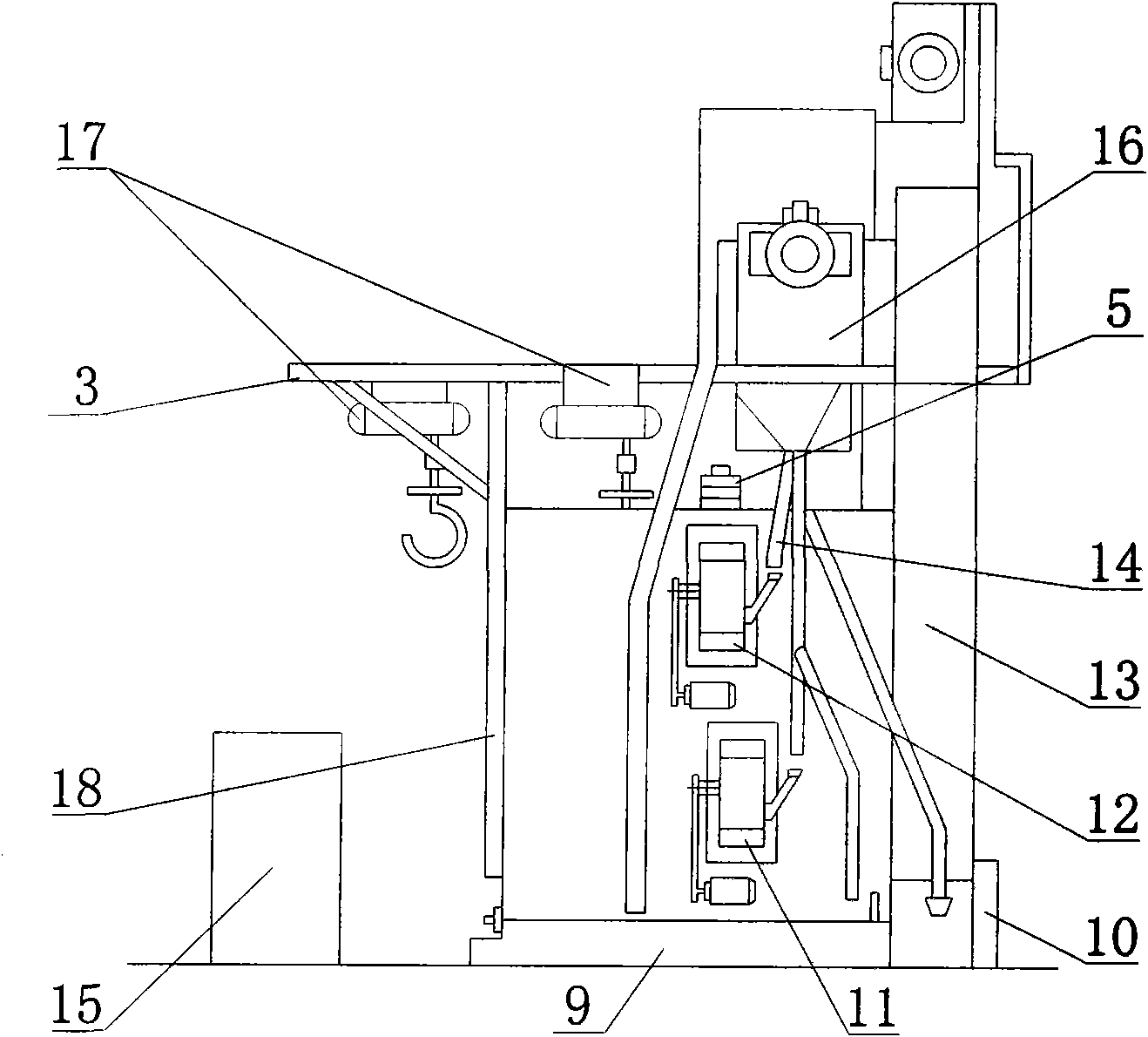

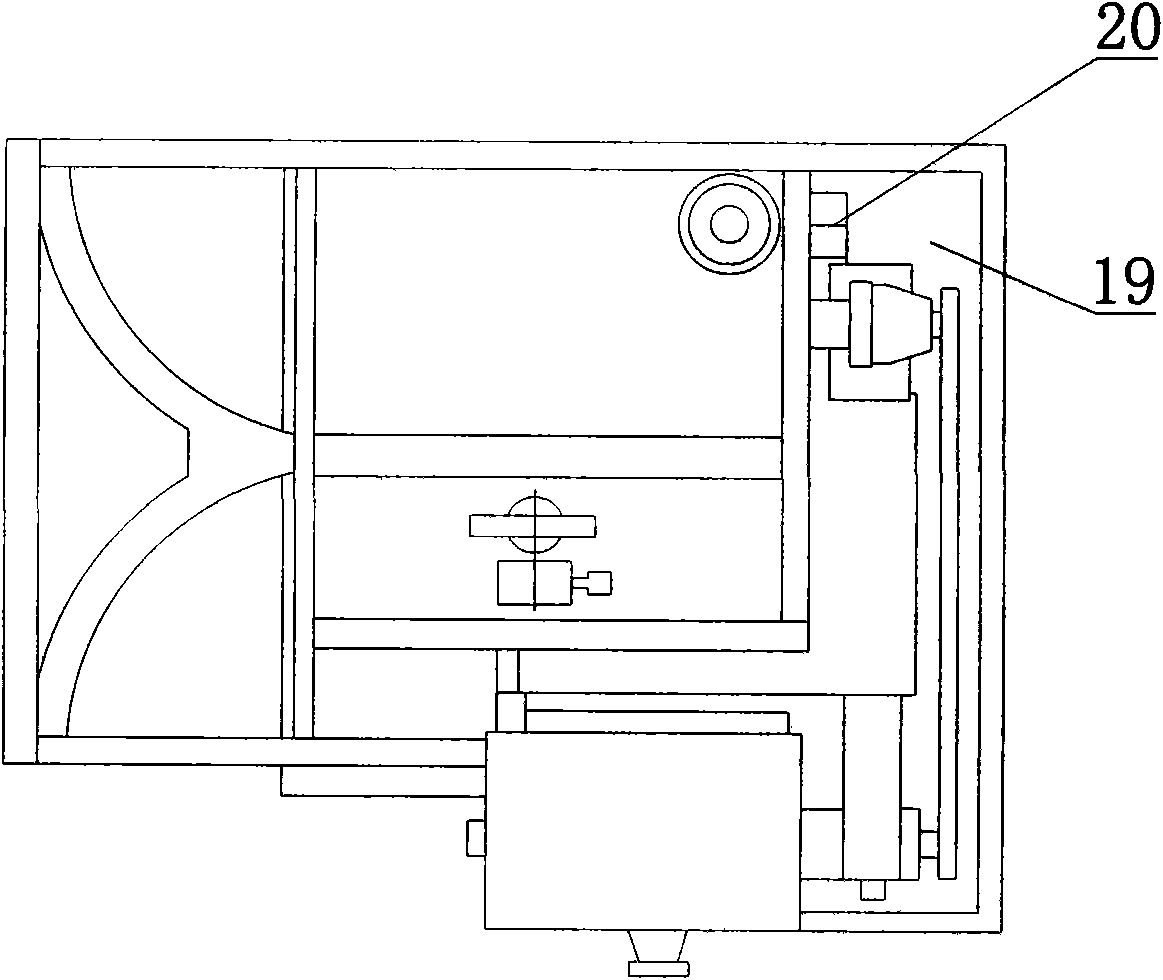

[0042] An explosion-proof casing sand blasting and derusting device for mining, including a shot blasting machine, a track 3 and a cleaning room 9, with a screw conveyor 10, a shot blasting device 11, a shot blasting device 12, a hoist 13, a shot feeding system 14, Electrical box 15, separator 16, hook 17, gate 18, ladder 19, platform 20. Shot blasting machine is housed in cleaning room 9, and track 3 is established on the top of cleaning room 9, and electric hoist 4 hangs hook explosion-proof shell on track 3. The shot blasting machine includes a shot blasting machine, a screw conveyor, an elevator and a separator. The shot blasting machine is equipped with blades and an adjustable orientation sleeve in the center of the blade. The window position of the orientation sleeve forms an angle with the blade. The hook on the track 3 is equipped with a rotary drive mechanism, the drive mechanism includes a motor 7, a reducer 6, a friction wheel 8 and an autorotation wheel 5, the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com