Inflammable refuse gasification gas making device preventing generation of dioxin and technique

A gasification gas and dioxin technology, applied in the petroleum industry, special carbonization, coking ovens, etc., can solve the problems of no devices and processes, and achieve the effect of avoiding pollution and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

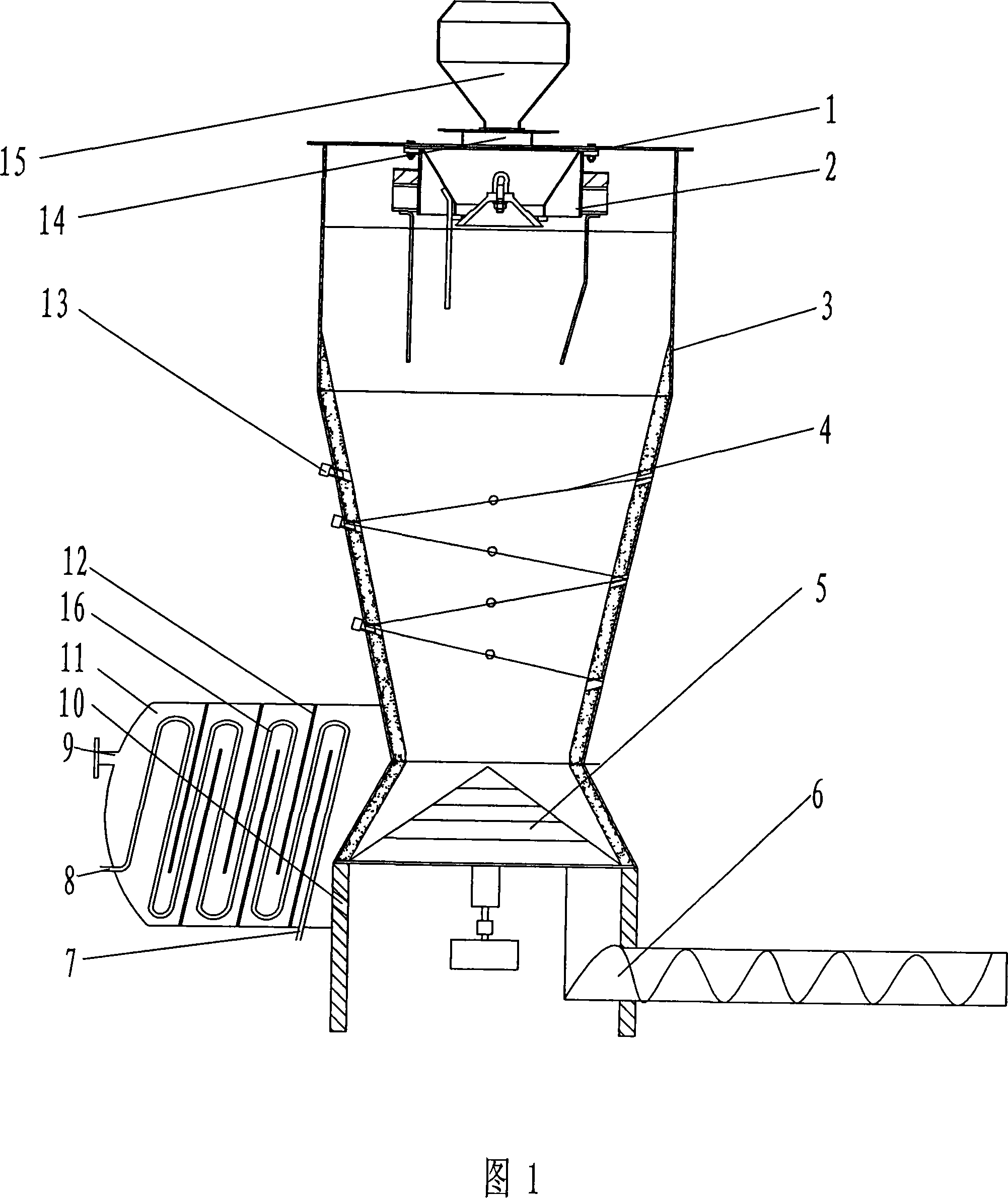

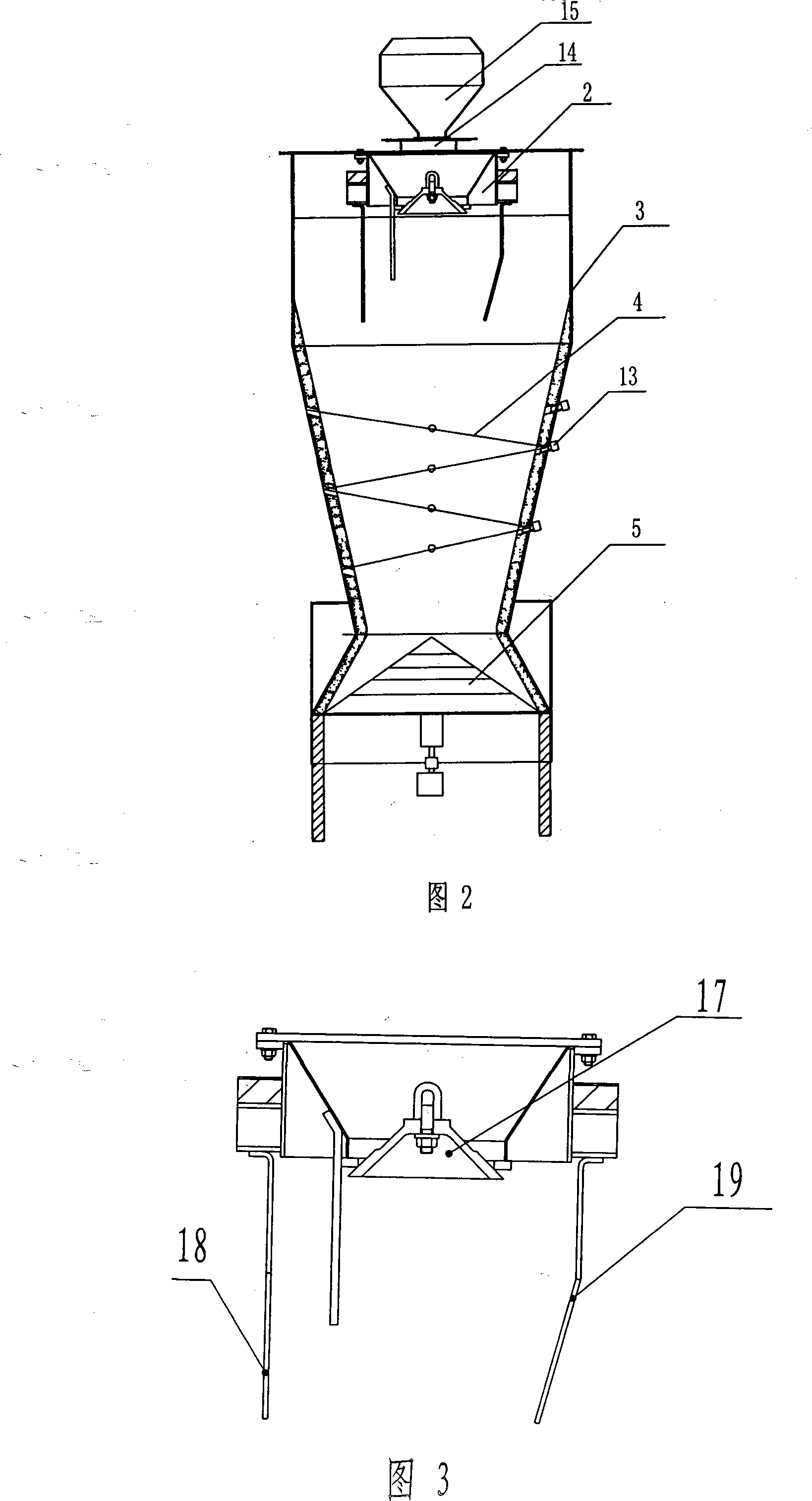

[0042] A. The gas production capacity of this gasifier is 600m 3 / h. The combustible garbage is fed into the distributor 2 from the feed hopper 15 above the gasifier. The distributor 2 is conical and connected to the end cover 1 of the upper furnace body with a flange. 4 cloth straight boards and 4 slanted boards for the cloth, uniformly distribute the cloth 360 degrees into the furnace;

[0043] The furnace body 3 adopts an inverted cone structure to ensure that the garbage and other materials have a sufficiently high gasification reaction intensity when they move downward with the gasification process. The radiation high temperature refractory layer in the furnace ensures the life span and high temperature resistance of the furnace itself.

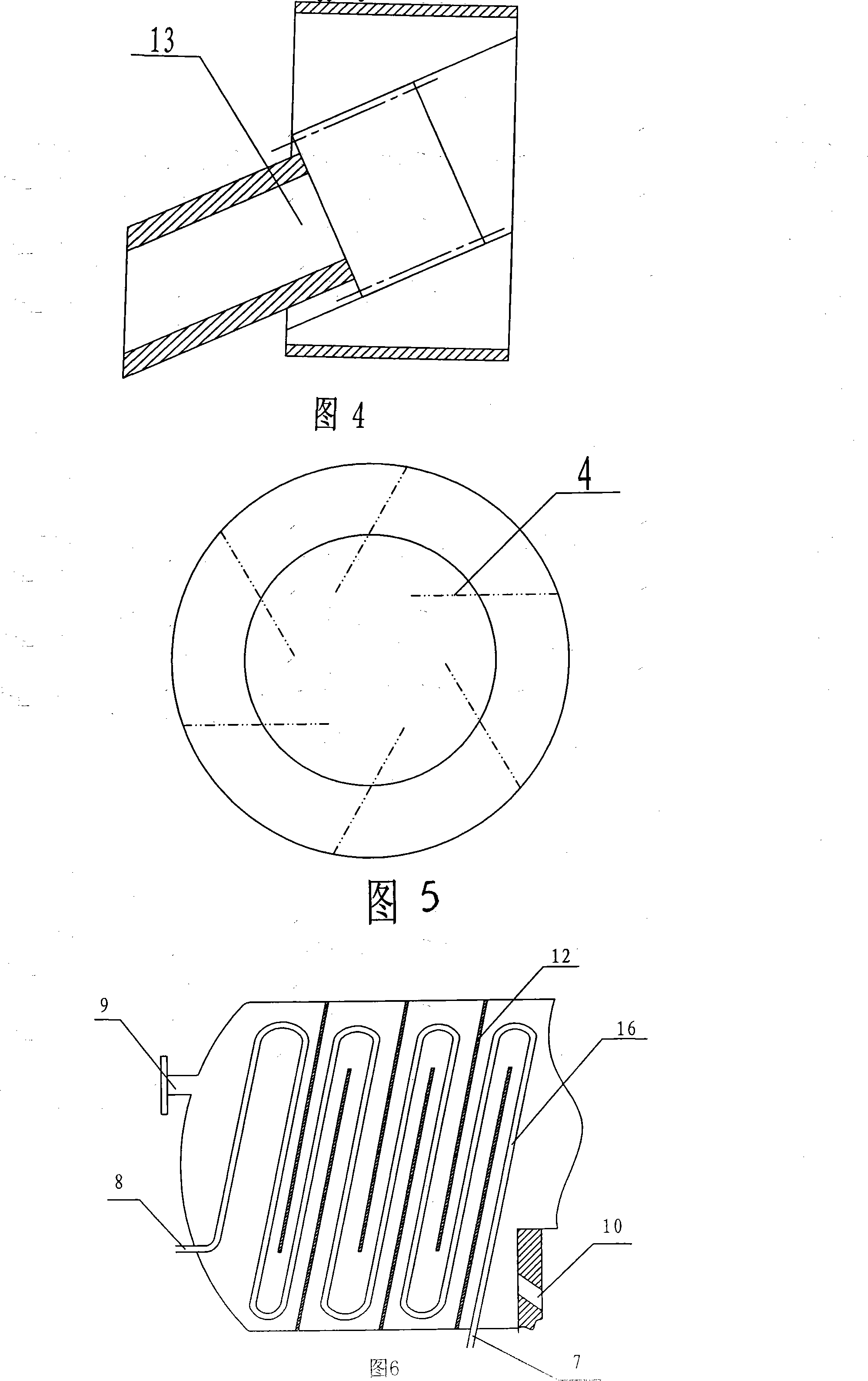

[0044] B. Send high-temperature air at 100°C through nozzles 13 arranged around the redox zone of the furnace to achieve uniform air distribution in the redox zone; the nozzle 13 is at 45 degrees to the inner wall of the furnace, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com